Chemical composition

To ensure a long service life, the chemical composition is kept balanced. In addition, the composition does not contain a large number of alloying elements, which ensures ease of production. The composition of steel 20 is characterized as follows:

- The main part of the metal is iron. Its concentration indicator is 98%.

- As previously noted, the main performance characteristics depend on the amount of carbon and the uniformity of its distribution. When labeling, this particular element is indicated; in the case under consideration, its concentration is 0.2%. It is worth considering that the regulatory documentation indicates the limit that the brand must meet: from 0.17 to 0.24%.

- The composition also contains a high concentration of magnesium and silicon: the first element is in the range of 0.35-0.65%, the second is 0.17-0.37%. These elements also largely determine the performance characteristics of the metal.

- The composition also contains other chemical elements, including harmful ones. Their concentration is maintained within a strict limit, since their presence causes a decrease in strength and reliability, durability and deterioration of other qualities.

St. 20

Despite the fact that the alloying process significantly increases the cost of the metal, this process can significantly increase the characteristics of the material. An example is the addition of chromium to the composition, due to which the structure becomes more resistant to moisture. All stainless steels have a high concentration of chromium in their composition.

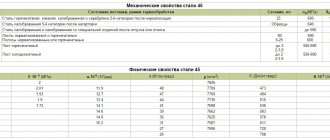

Heat treatment of steel 45

Heat treatment of steel 45 - structural carbon. After preliminary heat treatment of steel 45 - normalization, it can be machined quite easily. Turning, milling, etc. Parts are obtained, for example, such as pinion shafts, crankshafts and camshafts, gears, spindles, bandages, cylinders, cams. After the final heat treatment of steel 45 (hardening), the parts acquire high strength and wear resistance. Often sanded. The high carbon content (0.45%) ensures good hardenability and, accordingly, high surface hardness and strength of the product. 45 steel is hardened “on water”. That is, after calcination, the part is cooled in water. After cooling, the part is subjected to low-temperature tempering at a temperature of 200-300 degrees Celsius. With this heat treatment of steel 45, a hardness of about 50 HRC is obtained.

Heat treatment of steel 45 and use of products: The jaws of machine chucks, according to GOST instructions, are made from steels 45 and 40X. Hardness Rc = 45 -50. In the jaws of four-jaw chucks, the thread hardness should be in the range Rc = 35-42. Tempering of cams from steel 45 is carried out at a temperature of 220-280°, from steel 40X at 380-450° for 30-40 minutes.

Interpretation of steel grade 45: grade 45 means that the steel contains 0.45% carbon, C 0.42 - 0.5; Si 0.17 - 0.37; Mn 0.5 - 0.8; Ni up to 0.25; S up to 0.04; P up to 0.035; Cr up to 0.25; Cu up to 0.25; As up to 0.08.

Main characteristics and properties

When choosing a metal, much attention is paid to the main characteristics. We include:

- Hardness index. It can vary over a wide range and depend on whether heat treatment has been carried out. The hardness of steel 20 is maintained at 163 MPa. This is quite enough for the manufacture of various products that have high wear resistance.

- Density is also taken into account. Less dense materials are used to make products that will be lightweight. In the case under consideration, the indicator is 7.85 k/cm3.

- When considering the main characteristics, the yield strength and tensile strength are taken into account. They are considered when creating various projects. Metal St 20 can be improved in order to increase the characteristics of the material.

- The structure is characterized by the fact that it is not prone to temper brittleness and the formation of flakes.

- The heat treatment of steel 20 can significantly increase the service life of the product. It is carried out under certain conditions. For example, for forging, the structure is heated to a temperature of 1,280 degrees Celsius.

- If necessary, it is possible to weld parts.

- The impact strength of steel 20 determines that the metal is often used in the manufacture of shafts and other similar products that can be used to create elements used in the creation of various mechanisms. The elastic modulus is also taken into account when considering the basic properties of the metal.

- The average thermal conductivity coefficient determines that the structure can heat up quickly enough, but at the same time heat is removed with high efficiency.

Properties St 20

The mechanical properties of steel 20 determine the fairly wide distribution of this grade in mechanical engineering and other industries. As previously noted, technical characteristics can be improved by heat treatment or alloying. Restructuring the structure of the metal makes it possible to increase the hardness of the surface layer; by adding other chemicals, special qualities can be imparted, for example, corrosion resistance.

Download GOST 1050-2013

Heat treatment involves changing the structure due to exposure to a certain temperature. Critical points are selected depending on the characteristics of the chemical composition. The features of such a procedure include the following points:

- To provide the required impact, special equipment is used. Examples include blast furnaces and induction furnaces. For a long period, blast furnaces were used, but they are inferior to induction furnaces. The second version is suitable for installation in small workshops.

- Critical points are taken into account when carrying out the procedure under consideration. It is worth considering that they have already been identified for all metals, so there is no need to conduct the research again.

- The workpiece is heated to the required temperature, after which the initial restructuring of the structure occurs. The holding time is also an important indicator that must be taken into account, as is the heating rate.

- Attention is also paid to the cooling process. Workpieces that are too large are cooled in air, as problems arise in creating the required environment. For a long period of time, cooling was carried out in water, but this led to the appearance of scale. It is possible to ensure a higher quality of heat treatment by using oil as a cooling medium. However, when cooling in oil, one should take into account the high probability of toxic smoke formation and surface ignition due to high temperature.

Steel hardening colors

In many cases, surface defects are formed after heat treatment. That is why the procedure is used for workpieces or products that are created taking into account the allowance. After hardening, tempering is often carried out, which allows you to relieve internal stresses and reduce the likelihood of damage to the product when dropped or subjected to an impact load.

Heat treatment (heat treatment) of steel, alloys, metals.

Heat treatment (heat treatment) is a technological process of changing the structure of steels, alloys and non-ferrous metals through a wide range of temperatures: gradual heating and cooling at a certain speed. Such processing greatly changes the properties of steels, alloys, and metals in the direction of improving performance, but without changing their chemical composition. We can say that the main purpose of heat treatment is to improve the properties and characteristics of products made from it.

Types (stages) of heat treatment of steel

Annealing is a thermal treatment (heat treatment) of a metal, which is a process of heating to a given temperature, and then a process of slow cooling. There are different types of annealing depending on the temperature level and the speed of the process.

Normalization is a heat treatment that is fundamentally similar to annealing. The main difference is that the annealing process involves a furnace, and during normalization the steel is cooled in air.

Hardening is a stage of heat treatment based on heating the raw material to a temperature level that is above the critical level (recrystallization of steel). After holding at this temperature for a given time interval, cooling occurs, quickly, at a given speed. Hardened steel (alloys) are characterized by a nonequilibrium structure and therefore a type of heat treatment such as tempering is used.

Tempering is a heat treatment stage necessary to remove residual stress in steel and alloys or to reduce it to its maximum. Reduces the fragility and hardness of the metal, increases viscosity. It is carried out after the hardening stage.

Aging is also called dispersion hardening. After the annealing stage, the metal is heated again, but to a lower temperature level and cooled at a slow rate. The purpose of such heat treatment is to obtain special particles of the strengthening phase.

Depending on the degree of required depth of processing, a distinction is made between surface heat treatment, which affects only the surface of the product, and volumetric heat treatment, when the entire volume of raw materials is subjected to heat treatment.

In industry, in particular in mechanical engineering, the following grades of steel most often undergo heat treatment:

— steel 45 (substitutability 40Х, 50, 50Г2)

— steel 40Х (substitutability 38ХА, 40ХР, 45Х, 40ХС, 40ХФ, 40ХН)

— steel 20 (substitutability 15, 25)

— steel 30KhGSA (substitutability 40KhFA, 35KhM, 40KhN, 25KhGSA, 35KhGSA)

— steel 65G

— steel 40ХН

— steel 35

— steel 20Х13

Heat treatment of steel 45

Structural carbon. The pre-heat treatment stage is called normalization and takes place in air and not in an oven. It is quite easy to machine. Turning, milling, etc. Parts are obtained, for example, such as pinion shafts, crankshafts and camshafts, gears, spindles, bandages, cylinders, cams.

After hardening, which is the final stage of heat treatment, the parts achieve a high level of strength and excellent wear resistance. Subject to grinding. The high carbon content (0.45%) ensures good hardenability and, accordingly, high surface hardness and strength of the product. Steel 45 is calcined “on water” when, after calcination, the part is cooled in water. After cooling, the part is subjected to low-temperature tempering at a temperature of 200-300 degrees Celsius. With this heat treatment, steel 45 reaches a hardness of about 50 HRC.

Products: The jaws of machine chucks, according to GOST instructions, are made of steel 45 and 40Х. Hardness Rc = 45 -50. In the jaws of four-jaw chucks, the thread hardness should be in the range Rc = 35-42. Tempering of cams from steel 45 is carried out at a temperature of 220-280°, from steel 40X at 380-450° for 30-40 minutes.

Interpretation of steel grade 45: grade 45 means that the steel contains 0.45% carbon, C 0.42 - 0.5; Si 0.17 - 0.37; Mn 0.5 - 0.8; Ni up to 0.25; S up to 0.04; P up to 0.035; Cr up to 0.25; Cu up to 0.25; As up to 0.08.

Heat treatment of steel 40Х

Alloy structural steel. For high-strength parts such as axles, shafts, pinion shafts, plungers, rods, crank and cam shafts, rings, spindles, mandrels, racks, ring gears, bolts, axle shafts, bushings and other high-strength parts. 40X steel is also often used to produce forgings, stampings and pipe fittings. However, the last listed parts require additional heat treatment, which consists of quenching through water in oil or simply in oil, followed by tempering in oil or air.

Decoding steel grade 40X. The number 40 indicates that the steel contains 0.4% carbon. Chromium content is less than 1.5%. In addition to the usual impurities, it contains specially introduced elements in certain quantities, which are designed to provide specially specified properties. In this case, chromium is used as an alloying element, as indicated by the corresponding marking.

Heat treatment of steel 20

Heat treatment of steel 20 - high-quality structural carbon steel. Widely used in boiler making, for pipes and heating pipelines for various purposes; in addition, the industry produces rods and sheets. Steels 15 and 25 are used as a substitute for steel 20.

According to the requirements for mechanical properties, five categories are distinguished.

— Category I: steel of all types of processing without testing for impact strength and tensile strength.

— Category II: samples made of normalized steel of all types of processing with a size of 25 mm are tested for impact strength and tensile strength.

— Category III: tensile tests are carried out on samples made of normalized steel, 26-100 mm in size.

— Category IV: samples for tensile and impact strength tests are made from heat-treated blanks with a size of no more than 100 mm. The requirements of the third and fourth categories apply to calibrated, hot-rolled and forged quality steel.

- V category. Tensile tests of mechanical properties are carried out on samples made of calibrated heat-treated (high-tempered or annealed) or cold-worked steels.

Chemical composition of steel 20: carbon (C) - 0.17-0.24%, silicon (Si) - 0.17-0.37%, manganese (Mn) - 0.35-0.65%; copper (Cu) and nickel content (Ni) allowed no more than 0.25%, arsenic (As) - no more than 0.08%, sulfur (S) - no more than 0.4%, phosphorus (P) - 0.035%. The structure of steel 20 is a mixture of pearlite and ferrite. Heat treatment of steel 20 allows one to obtain the structure of lath (packet) martensite. With such structural transformations, strength increases and ductility decreases. After thermal hardening, rolled steel 20 can be used for the manufacture of hardware products (strength class 8.8).

Technological properties of steel 20: The start temperature of forging steel 20 is 1280° C, the end temperature is 750° C, the forging is cooled by air. Steel 20 is non-floczen sensitive and not prone to tempering. The weldability of steel 20 is not limited, excluding parts subjected to chemical-thermal treatment. Recommended methods for welding ADS, KTS, RDS, under gas protection and flux.

Steel 20 is used for the production of lightly loaded parts (pins, axles, copiers, stops, gears), cemented parts for long and very long service (operation at temperatures not exceeding 350 ° C), thin parts exposed to abrasion. Steel 20 without heat treatment or after normalization is used for the production of crane hooks, bearing shells and other parts for operation under pressure in the temperature range from -40 to 450°C. Steel 20 after chemical-thermal treatment is used for the production of parts that require high surface strength (worms, worm pairs, gears). Steel 20 is widely used for the production of pipeline fittings, pipes intended for steam pipelines with critical and supercritical steam parameters, seamless high-pressure pipes, welded profiles of rectangular and square sections, etc.

Heat treatment of steel 30KhGSA

Refers to medium alloy structural steel. Steel 30KhGSA undergoes improvement - hardening followed by high tempering at 550-600 ° C, therefore it is used in the creation of improved parts (except for aircraft parts, these can be various casings, axles and shafts, blades of compressor machines that operate at 400 ° C, and much more), levers, pushers, critical welded structures operating under alternating loads, fasteners operating at low temperatures.

Steel 30KhGSA has good endurance, excellent impact strength, and high strength. It also has excellent weldability.

Welding steel 30KhGSA also has its own characteristics. It is carried out with preheating of the material to 250-300 ° C, followed by slow cooling. This procedure is very important because cracks may appear due to the sensitivity of the steel to sudden temperature changes after welding. Therefore, upon completion of welding work, the torch should be withdrawn slowly, while heating the material at a distance of 20-40 mm from the welding site. Also, no more than 8 hours after completion of welding, welded joints of 30KhGSA steel require quenching with heating to 880 °C, followed by high tempering. Next, the product is cooled in oil at 20-50 °C. Tempering is carried out by heating to 400 - 600 ° C and cooling in hot water. Welding must be performed as quickly as possible in order to avoid burnout of alloying elements.

After undergoing thermomechanical low-temperature treatment, 30KhGSA steel acquires a tensile strength of up to 2800 MPa, impact strength doubles (in contrast to conventional heat treatment of 30KhGSA steel), and ductility increases.

Heat treatment of steel 65G

Structural spring steel. Springs, leaf springs, thrust washers, brake bands, friction discs, gears, flanges, bearing housings, clamping and feed collets and other parts that require increased wear resistance and parts that operate without shock loads are used in industry. (substitutes: 70, U8A, 70G, 60S2A, 9HS, 50HFA, 60S2, 55S2).

Heat treatment of steel 40

High quality carbon structural steel. Industrial use: pipes, forgings, fasteners, shafts, discs, rotors, flanges, gears, bushings for long and very long service at temperatures up to 425 degrees.

Heat treatment of steel 40ХН

Structural alloy steel Used in industry: axles, shafts, connecting rods, gear wheels, excavator shafts, couplings, gear shafts, spindles, bolts, levers, rods, cylinders and other critical loaded parts subjected to vibration and dynamic loads, with the required requirements for increased strength and toughness. Rolls of rail and beam and large-section mills for hot rolling of metal.

Heat treatment steel 35

High quality carbon structural steel. Used in industrial applications. These are parts of low strength that are subject to a low level of stress: axles, cylinders, crankshafts, connecting rods, spindles, sprockets, rods, rims, traverses, shafts, tires, discs and other parts.

Heat treatment of steel 20Х13

Corrosion-resistant, heat-resistant steel. Used in power engineering and furnace making; turbine blades, bolts, nuts, fittings for cracking units with a long service life at temperatures up to 500 degrees; martensitic class steel Steel grade 20Х13 and other martensitic class steels: heat-resistant martensitic chromium steels are used in various power plants; they operate at temperatures up to 600° C. Rotors, disks and turbine blades are made from them, and recently they have been used for ring parts large thicknesses. There are a large number of steel grades of this class. Common to all is a reduced chromium content, the presence of molybdenum, vanadium and tungsten. They are effectively strengthened by conventional heat treatment methods, which are based on the y-a transformation and provide for the formation of martensite in the structure with subsequent improvement depending on the technical requirements. (substitutes: 12Х13, 14Х17Н2)

Press service of the Voka group of companies

September 17, 2021

Application area

Low cost determines that steel 20, the use of which is associated with the manufacture of various products, began to be used to create various kinds of workpieces. Considering the features of steel grade 20 and its areas of application, we note the following points:

- Most often used in boiler making. An example is the production of pipes and heating elements for various purposes.

- The industry supplies blanks in the form of rods or sheets.

- Very often steel is improved by carburization. This allows for a hard surface but a ductile core. Examples include various axles, cams and rollers, pins and spindles, pusher valves, spring pins and other elements that are widely used in mechanical engineering.

- Rolled products of various diameters are supplied to production sites. In this case, the workpiece can be processed by cutting using turning, milling, drilling and other equipment.

- Pipes are manufactured using electric welding. For this, sheet steel is used, which is welded at the point of contact. When using the hot deformation method, seamless pipes are obtained that have high performance characteristics.

Sheet steel 20

Such steels have been used for a long period. It is worth considering that the application temperature is quite low. In other words, the structure can heat up quickly, thereby significantly increasing ductility. Also, metal cannot withstand low temperatures, as it makes the structure more fragile. The scope of application of steel 20 could be significantly increased with proper heat treatment, as well as alloying of the structure.

Areas of application

Certain technical characteristics of steel 20 explain its use in different areas of industry:

- Production of pipe fittings (sleeve nuts, fittings, flanges, crosses, nipples).

- Manufacturing of building materials.

- Assembly of various metal structures, machines, ships, industrial equipment.

This metal is used to produce:

- Seamless pipes. Manufactured by cold or hot drawing. Their feature is high strength.

- All-welded cold-rolled pipes.

- Various profiles (wire, I-beams, channels, metal corners, sheets of different thicknesses, rods).

Products from this alloy are manufactured according to certain state standards:

- GOST 17305-91—production of wire of different sections.

- GOST 82-70 - production of metal strips of different widths.

- GOST 16523-97 - production of light sheets of small thickness.

- GOST 10704-9 - pipe manufacturing.

- GOST 8479-70 - production of forged parts, forgings.

- GOST 1577-93 - production of metal sheets of large thickness.

- GOST 14955-77 - production of silver and grinding rods.

- GOST 7417-75 - production of calibrated rods.

- GOST 8240-97, GOST 1050-88 - production of shaped and long products.

GOSTs indicate the basic requirements for finished products and their testing for admission to sale.

Steel sheets

Steel analogues 20

As previously noted, the labeling standards under consideration are applied exclusively in metal production in the CIS countries. Foreign manufacturers produce a large number of analogues that have similar performance characteristics. Steel 20 production is established in the USA, Germany, Japan and many other European countries. Foreign analogues may have a slightly different chemical composition, but the performance qualities are largely similar. If we consider analogues with a different chemical composition, we can pay attention to steel 30, 40X and other alloys. They differ somewhat in their basic qualities, but can still be used in the manufacture of identical products.

In conclusion, we note that a low carbon concentration determines the need for heat treatment. Very often, hardening and tempering are performed, which increase the hardness and wear resistance of the surface, but at the same time reduce brittleness. Cementation and other procedures for introducing chemicals into the surface layer are carried out. For example, carburization can significantly increase the hardness of the product. Many processes involve the use of special equipment. Therefore, it will not be possible to improve metal at home.