cutting

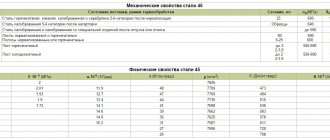

| Initial data | Machinability Ku |

| State | HB, MPa | sB, MPa | hard alloy | high speed steel |

| hot rolled | ≤207 | 590 | 1,3 | 1,0 |

physical characteristics

| Temperature | E, GPa | G, GPa | r, kg/m3 | l, W/(m °С) | R, NOM m | C, J/(kg °C) | a, 10-6 1/°С |

| 0 | 212 | 82 | 7850 | — | — | — | — |

| 20 | 213 | — | 7850 | 515 | 160 | 483 | — |

| 100 | 206 | 80 | — | 51 | 221 | — | 119 |

| 200 | 201 | 78 | — | 48 | 296 | — | 128 |

| 300 | 192 | 75 | — | 46 | 387 | — | 135 |

| 400 | 176 | 68 | — | 42 | 493 | — | 141 |

| 500 | 163 | 63 | — | 38 | 619 | — | 146 |

| 600 | 151 | 58 | — | 34 | 766 | — | 149 |

| 700 | 131 | 50 | — | 30 | 932 | — | 152 |

| 800 | 118 | 45 | — | 25 | 1110 | — | 125 |

| 900 | — | — | — | 26 | 1150 | — | 135 |

| 1000 | — | — | — | 269 | 1180 | — | 135 |

| 1100 | — | — | — | 28 | 1207 | — | 152 |

| 1200 | — | — | — | 295 | 1230 | — | 145 |

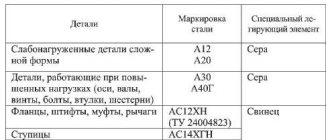

Material A40G – mechanical properties

| Assortment | GOST | Dimensions – thickness, diameter | Heat treatment mode | t | KCU | y | d5 | sT | sв |

| mm | 0C | kJ/m2 | % | % | MPa | MPa |

| Rolled hot rolled products. | 1414–75 | 20 | 14 | 590 |

| Caldibrovan | Annealing | 17 | 590 |

Description

Steel 40 is used : for the production of rolled sheets 4−14 mm of category 1−2, intended for cold stamping; crankshafts, connecting rods, ring gears, flywheels, gears, bolts, axles and other parts after improvement; shafts and extensions of hydraulic generator shafts; medium-sized parts that require high surface hardness and increased wear resistance with low deformation (long shafts, rollers, gears) after surface hardening with high-frequency heating; parts of pipeline fittings after hardening and tempering; hot-rolled strip profile with slope for agricultural machines; forged blanks of shafts of compressor machines and gas turbines (made of steel 40A); wire used for making spokes for motorcycles and bicycles.

Note

Degree of deoxidation - sp.

Brand A40G - exact and closest foreign analogues

| England | Bulgaria | Hungary | Germany | European Union | Spain | Italy |

| B.S. | BDS | MSZ | DIN, WNR | EN | UNE | UNI |

| 216M36 |

| 226M44 |

| 44SMn28 |

44SMn28

ANS2

44SMn28

1.0762

45MnS6

CF44SMn28

| China | Poland | Romania | USA | France | Czech |

| G.B. | PN | STAS | — | AFNOR | CSN |

| Y40Mn |

A35G2

AUT40Mn

1141

|

| 1144 |

| C1144 |

| G11410 |

| G11440 |

| G11444 |

| G11460 |

45MF6

11140

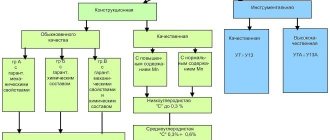

What is steel alloy made of?

In addition to the iron and carbon we already know, steel can contain quite a few important components from the periodic table, which to one degree or another affect its properties, directly affecting the characteristics of knife steel. Those elements that are introduced into the alloy to improve its certain properties are called alloying, and steel is called alloyed. Let's start with the required component, and then according to the degree of prevalence in steel.

- Carbon. Thanks to its presence, steel can be subjected to a hardening process. The alloy contains no more than 2.14%. If there is more of it, then this alloy is called cast iron, if less, then tin. Its task is to provide the alloy with the required strength and hardness, reducing viscosity and flexibility to the required levels. If it contains more than 0.6%, then the alloy is said to be high-carbon. Mid-priced knives, kitchen options often contain carbon from 0.4% to 0.6%.

- Chromium. Responsible for resisting aggressive air-liquid environments. In other words, it provides knife steel with corrosion resistance. Its content in the alloy must be at least 11.5%. A high chromium content affects hardness. If it is 14% or higher in the alloy, then this steel is classified as “stainless”.

- Molybdenum. Prevents the appearance of brittleness and fragility of the knife, allows steel for making knives to be resistant to high temperatures. Affects the uniformity of steel composition, increasing the properties of Chromium and improving all properties of the alloy. If its content is more than 1% in steel, then the alloy can be subjected to “air hardening”.

- Vanadium. Increases wear resistance and strengthens the strength of steel. Its increased hardness is used to create fine-grained alloys, making it possible to obtain a blade with a blade of a high degree of sharpness. However, sharpening such a knife will not be easy.

- Tungsten. Increases wear resistance and increases the hardness of steel. This chemical element has a melting point higher than other metals. If the alloy contains chromium or molybdenum, then in tandem with any of them, tungsten improves the cutting ability of the knife.

- Cobalt. It is added in small quantities to alloys, increasing their hardness and cutting properties. Contained in steel in an amount of approximately 1.6%.

- Nitrogen. Often acts as a substitute for nickel and carbon. If there is not enough carbon in the alloy, adding even 0.1% nitrogen allows the blade to be hardened. It enhances anti-corrosion properties and increases wear resistance.

- Nickel. Significantly increases the degree of strength, hardness, toughness and anti-corrosion.

- Silicon. Affects the hardness of the alloy, increases the anti-corrosion properties and degree of strength of the knife, removing oxygen from the metal. It is introduced into steel at the forging and rolling stage.

- Sulfur. Its content has a good effect on the ability of the knife to be processed. However, it reduces the knife's strength and corrosion resistance.

- Manganese. Gives steel a grain structure, increasing strength, hardness and wear. Introduced into steel during rolling and forging.

- Niobium. Titanium. Rare components. Increases corrosion resistance, enhances wear resistance and strength of steel.

- Phosphorus. It’s better not to be proud of the steel for knives where it exists. Very harmful to knife metals. Increases fragility and brittleness, reduces the mechanical qualities of the alloy. It shouldn't exist at all.

Now, knowing the content of necessary and harmful components, you can easily understand the composition of the alloy. But these are not all “metal” secrets. Now let's get to the fun part - types or brands of steel for knives.

Legend

Mechanical properties

| HRСе | HB | KCU | y | d5 | sT | sв |

| MPa | kJ/m2 | % | % | MPa | MPa |

| Rockwell hardness | Brinell hardness | Impact strength | Relative narrowing | Elongation at break | Yield strength | Short-term strength limit |

| Ku | s0.2 | t-1 | s-1 |

| Relative machinability factor | Proof of yield strength with 0.2% tolerance when loaded to plastic strain value | Torsional endurance limit (symmetrical cycle) | Endurance limit under compression-tension (symmetrical cycle) |

| N | number of deformation/stress cycles sustained by an object under load before fatigue failure/crack appears |

Steel 40 structural carbon quality

Substitutes

steel, 40G.

Foreign analogues

| Germany DIN(EN) | C40 (1.1186) |

| USA (AISI, ASTM) | 104 |

| France (AFNOR) | XC42H1 |

| UK BS | 080M40 |

| Japan JIS | S40C, S43C |

| Czech Republic (CSN) | 12041 |

| Poland (PN/H) | 40 |

Decoding steel 40X

The number 40 means that the average carbon content in steel is 0.4%.

Type of delivery

- Long products, including shaped steel: GOST 1050-88, GOST 2590-88, GOST 2591-88, GOST 2879-88, GOST 8509-93, GOST 8510-86, GOST 8239-89, GOST 8240-89, GOST 10702 -78.

- Calibrated rod GOST 10702-78, GOST 7417-75, GOST 8559-75, GOST 8560-78.

- Polished rod and silver steel GOST 10702-78, GOST 14955-77.

- Thick sheet GOST 1577-93, GOST 19903-74, GOST 4041-71.

- Thin sheet GOST 16523-70. Tape GOST 10234-77, GOST 2284-79.

- Strip GOST 103-76, GOST 82-70, GOST 1577-93.

- Wire 17305-91, GOST 5663-79.

- Forgings and forged blanks GOST 8479-70, GOST 1133-71.

Characteristics and description

Steel 40 refers to structural carbon unalloyed special quality steels. Grade 40 steel is recommended for fasteners.

Chemical composition, % (GOST 1050-88)

| WITH | Si | Mn | Cr | S | P | Cu | Ni | As |

| no more |

| 0,37-0,45 | 0,17-0,37 | 0,50-0,80 | 0,25 | 0,04 | 0,035 | 0,25 | 0,25 | 0,08 |

Chemical composition, % (GOST 1050-2013)

| steel grade | Mass fraction of elements, % |

| C | Si | Mn | P | S | Cr | Ni | Cu |

| no more |

| 40 | 0,37-0,45 | 0,17-0,37 | 0,50-0,80 | 0,030 | 0,035 | 0,25 | 0,30 | 0,30 |

Application

After surface hardening with high-frequency heating, grade 40 steel is used for the manufacture of medium-sized parts that require high surface hardness and increased wear resistance with low deformation, for example:

- long shafts,

- running rollers,

- gear wheels.

After improvement, steel 40 is used to manufacture the following parts:

- crankshafts,

- connecting rods,

- ring gears,

- flywheels,

- gear wheels,

- bolts,

- axes.

In the oil, petrochemical and gas industries, grade 40 steel is used for the manufacture of:

- sucker rod couplings,

- centrifugal pump shafts,

- compressors,

- rotors,

- mud pump rods,

- barrels and swivel subs,

- subs for working and drill pipes,

- core bit bodies,

- fingers of crossheads of mud pumps,

- preventer rollers,

- bevel gears,

- clamps and keys of drilling rigs,

- sprocket wheels of drilling drawworks,

- pins,

- thrust screws,

- rolling pin pumps,

- trunnions, etc.

The use of steel 40 for the manufacture of spindles and rods (GOST 33260-2015)

| steel grade | ND for supply | Working environment temperature, °C | Additional instructions for use |

| 40 GOST 1050 | Long products GOST 1050 | -40 to 425 | It is used after heat treatment (hardening and high tempering) at temperatures below minus 31°C to minus 40°C |

Use of steel 40 for the manufacture of fasteners (GOST 32569-2013)

| steel grade | Technical requirements | Acceptable operating parameters | Purpose |

| Wall temperature, °C | Medium pressure, MPa (kgf/cm2), no more |

| Steel 40 GOST 1050, GOST 10702 | STP 26.260.2043 | -40 to 425 | 10 (100) | Studs, bolts |

| 16 (160) | Nuts |

| -40 to 450 | 16 (160) | Washers |

Limits of application, types of mandatory testing and control of steel 40 for flanges for pressures above 10 MPa (100 kgf/cm2) (GOST 32569-2013)

| Steel grade, standard or specification | 40 GOST 1050 |

| Technical requirements | GOST 9399 |

| the name of detail | Flanges |

| Limit parameters | Wall temperature, °C, no more | -40 to +200 |

| Nominal pressure, MPa (kgf/cm2) no more | 32 (320) |

| Mandatory tests | σ0.2 | + |

| σв | + |

| σ | + |

| f | + |

| KCU | + |

| HB | + |

| Control | Flaw detection | + |

| Non-metallic inclusions | — |

Resistance of steel 40 against crevice erosion

| Durability group | Point | Erosion resistance against steel 12X18H10T |

| Unstable | 6 | 0,005-0,05 |

NOTE The coefficient of erosion resistance of a material is the ratio of the rate of erosive wear of the material to the rate of erosive wear of steel 12Х18Н10Т (taken as 1).

Temperature of critical points, °C

| Ac1 | Ac3 | Ar3 | Ar1 | Mn |

| 730 | 790 | 780 | 690 | 340 |

Heat treatment

Parts made of steel grade 40 are subjected to normalization at a temperature of 860-880 ° C or quenching in water from a temperature of 840-860 ° C followed by tempering; The tempering temperature is set depending on the required mechanical properties. For example, parts of drilling rigs (gears, retainer, keys), preventer (main support plate, rollers) are tempered at a temperature of 550°C, and sprockets of a drill drawworks are tempered at a temperature of 500°C.

Hardness HB for metal products made from steel 40 (GOST 1050-2013)

| steel grade | Hardness HB, no more, for metal products |

| hot rolled and forged | calibrated and with special surface finishing |

| without heat treatment | after annealing or high tempering | hard-worked | after annealing or high tempering |

| 40 | 217 | 187 | 241 | 197 |

Mechanical properties of metal products (GOST 1050-2013)

| steel grade | no less |

| Yield strength σt, N/mm2 | Tensile strength σв, N/mm2 | Relative elongation δ5, % | Relative narrowing Ψ, % |

| 40 | 335 | 570 | 19 | 45 |

Mechanical properties of rolled products

| GOST | Delivery status | Section, mm | σ0.2, MPa | δ5(δ4), % | Ψ, % | KCU, J/cm2 | Hardness HB, no more |

| no less |

| GOST 1050-88 | Hot-rolled steel, forged calibrated steel and silver steel of the 2nd category after normalization | 25 | 570 | 19 | 45 | 59 | — |

| Calibrated steel, category 5: |

| after cold hardening | — | 610 | 6 | 35 | — | — |

| after annealing or high tempering | — | 510 | 14 | 40 | — | — |

| GOST 10702-78 | Steel calibrated and calibrated with special finishing after tempering and annealing | — | Up to 590 | — | 40 | — | 197 |

| GOST 4041-71 (transverse samples) | Heat-treated sheet of categories 1 and 2 | 4-14 | 510-650 | 21 | — | — | 167 |

| GOST 1577-93 | Normalized or hot rolled sheet | 80 | 560 | 20 | — | — | — |

| Annealed or high tempered sheet | 80 | 520 | 21 | — | — | — |

| Normalized or hot rolled strip | 6-25 | 570 | 19 | 45 | — | — |

| GOST 16523-89 (transverse samples) | Hot rolled sheet | Up to 2 | 510-660 | (16) | — | — | — |

| 2-3,9 | (17) | — | — | — |

| Cold rolled sheet | Up to 2 | 510-600 | (17) | — | — | — |

| 2-3,9 | (18) | — | — | — |

| GOST 2284-79 | Cold rolled annealed strip | 0,1-4 | 450-700 | (14) | — | — | — |

| Cold-worked tape, strength class H2 | 0,1-4 | 850-1050 | — | — | — | — |

| GOST 10234-77 | Annealed flattened strip | 0,1-4 | Up to 700 | 10 | — | — | — |

Mechanical properties of forgings (GOST 8479-70)

| Heat treatment | Section, mm | KP | σ0.2, MPa | σв, MPa | δ5, % | Ψ, % | KCU, J/cm2 | Hardness NV, no more |

| no less |

| Normalization | 300-500 | 215 | 215 | 430 | 18 | 40 | 44 | 123-167 |

| 500-800 | 16 | 35 | 39 |

| 100-300 | 245 | 245 | 470 | 19 | 42 | 39 | 143-179 |

| 300-500 | 17 | 35 | 34 |

| Up to 100 | 275 | 275 | 530 | 20 | 40 | 44 | 156-197 |

| 100-300 | 17 | 38 | 34 |

| Quenching+tempering | 300-500 | 275 | 275 | 530 | 15 | 32 | 29 | 156-197 |

| 500-800 | 13 | 30 | 29 |

| 100-300 | 315 | 315 | 570 | 14 | 35 | 34 | 167-207 |

| Up to 100 | 345 | 345 | 590 | 18 | 45 | 59 | 174-217 |

Mechanical properties after quenching at 850 °C in oil

| ttp, °С | σ0.2, MPa | σв, MPa | δ5, % | Ψ, % | KCU, J/cm2 | Hardness NV, no more |

| 200 | 750 | 930 | 7 | 45 | 29 | 267 |

| 300 | 710 | 860 | 8 | 51 | 69 | 247 |

| 400 | 640 | 790 | 10 | 57 | 88 | 225 |

| 500 | 550 | 730 | 12 | 62 | 127 | 208 |

| 600 | 450 | 660 | 16 | 66 | 167 | 188 |

| 700 | 380 | 620 | 17 | 71 | 206 | 170 |

Mechanical properties at elevated temperatures [81]

| tsp, °С | σ0.2, MPa | σв, MPa | δ5, % | Ψ, % |

| 700 | 99 | 140 | 48 | 85 |

| 800 | 70 | 110 | 53 | 97 |

| 900 | 54 | 71 | 55 | 100 |

| 1000 | 28 | 58 | 69 | 100 |

| 1100 | 24 | 37 | 60 | 100 |

| 1200 | 16 | 26 | 87 | 100 |

| 1300 | 12 | 18 | 56 | 100 |

NOTE. Sample with a diameter of 6 mm and a length of 80 mm, rolled. Deformation speed 16 mm/min; strain rate 0.009 1/s.

Impact strength KCU [28]

| Heat treatment | KCU, J/cm2, at temperature, °C |

| +20 | -40 | -80 |

| Quenching at 850 °C in water; tempering at 400 °C | 78 | 55 | 51 |

Endurance Limit [140]

| Heat treatment | σ-1, MPa |

| Annealing at 850 °C, σ0.2 = 275 MPa, σв = 520 MPa | 231 |

| Quenching at 845 °C in water; tempering at 550 °C, σ0.2 = 600 MPa, σв = 710 MPa, НВ 209 | 393 |

| Quenching from 845 °C into oil; tempering at 430 °C, σ0.2 = 415 MPa, σв = 630 MPa | 230 |

NOTE. σ4001/100000 = 100 MPa; σ4501/100000 = 50 MPa; σ5001/100000 = 30 MPa; σ4001/10000 = 260 MPa; σ5001/10000 = 70 MPa; σ4001/100000 = 190 MPa; σ5001/100000 = 44 MPa.

Technological properties [81]

Forging temperature, °C: start 1250, end 800. Cooling of workpieces with a cross-section of up to 400 mm in air.

Weldability - limited weldability. Welding methods: RDS, ADS under submerged arc and gas shield, ESW. Preheating and subsequent heat treatment are recommended. CTS without restrictions.

Cutting ability - Kv tv.spl = 1.2 and Kv b.st = 1.05 in the hot-rolled state at HB 170 and av = 520 MPa.

Flock sensitivity - not sensitive.

Tendency to temper brittleness - not prone.

Hardenability, mm (GOST 1050-88) [51]

The hardenability band of steel 40 after normalization at 850 °C and quenching from 850 °C is shown in the figure below.

Critical diameter d after quenching from 850 °C

| Amount of martensite, % | d, mm, after hardening |

| in water | In oil |

| 50 | 15-25 | 8-15 |

| 90 | 10-15 | 5-9,5 |

Density ρ kg/cm3 at test temperature, °C

| Steel | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| 40 | 7850 | — | — | — | — | — | — | — | — | — |

Linear expansion coefficient α*106, K-1

| steel grade | α*106, K-1 at test temperature, °C |

| 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 | 20-800 | 20-900 | 20-1000 |

| 40 | 11,9 | 12,8 | 13,5 | 14,1 | 14,6 | 14,9 | 15,2 | 12,5 | 13,5 | 14,5 |

Thermal conductivity coefficient λ W/(m*K)

| Steel grade | λ W/(m*K), at test temperature, °C |

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| 40 | — | 51 | 48 | 46 | 42 | 38 | 34 | 30 | 25 | 26 |

Specific heat capacity c, J/(kg*K)

| steel grade | s, J/(kg*K), at test temperature, °C |

| 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 | 20-800 | 20-900 | 20-1000 |

| 40 | 486 | 497 | 512 | 529 | 550 | 574 | 628 | 674 | 657 | 653 |

Modulus of normal elasticity E, GPa

| Steel grade | At test temperature, °C |

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| 40 | 212 | 206 | 201 | 192 | 176 | 163 | 151 | 131 | 118 | — |

Modulus of elasticity in torsional shear G, GPa

| steel grade | At test temperature, °C |

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| 40 | 82 | 80 | 78 | 75 | 68 | 63 | 58 | 50 | 45 | — |

Find out more

30X structural alloy steel…

Steel 10 structural carbon quality…

Structural alloy steel 30HN2MFA…

Structural alloy steel 50X…