Why do you need a grinding machine?

The purpose of the grinding machine is clear from the name itself - it is designed for grinding. That is, this mechanism is designed to process material (be it wood or metal). The goal is to achieve the lowest possible degree of roughness of the product. In some cases, grinding machines are also used to adjust any objects to the required dimensions (for example, you need to reduce the radius of a part).

Grinding machines are actively used in construction work. They are used when you need to polish boards and give them the smoothest surface possible. Most often, such “operations” are carried out before varnishing - in order to coat wood with any impregnation, you first need to clean it of wooden burrs.

Grinding machines are also used in factories. If a product or part turns out to be too large during production, it can be sanded. This will remove the excess layer of material and the product will acquire the desired appearance.

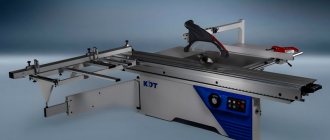

Grinding machine

Where is it most often used?

As a rule, a grinding machine is used only in large-scale production. However, some manufacturers produce smaller models that can be placed in a garage and used for repair and construction work. In addition, with the help of such a tool a person can create unique things and set up his own business, albeit a small one.

This device offers the ability to process an object over a long period. Products made of wood, metal, stone or granite are suitable for work. The main thing is to choose the right nozzle. Therefore, this device can be found in almost any industry. Consumables are sold in all construction stores at an affordable price.

But the main purpose of a grinding machine is large-scale processing of wood, so the unit is indispensable in this area.

Types of grinding machines

Depending on their purpose, grinding machines are divided into several types. Each of them is different in structure and internal characteristics. Let's look at the main types of grinding machines:

- Cylindrical grinders. Used to process cylindrical products. They themselves are also universal and non-universal. In universal models, it is possible to rotate both the work table and the workpiece itself, and in some cases, the grinding wheel. Non-universal models do not have this function.

- Surface grinding. Designed for grinding flat surfaces that have a minimum angle of curvature.

- Centerless grinding. This type of machine is intended for mass processing and grinding of surfaces.

- Honing. Used for “delicate” grinding. During operation, the machine removes small layers of material from the surface of the product (their thickness can be only a few hundredths of a millimeter).

Main types of grinding machines

Video - Review of tabletop belt-disc sanding machines for wood

Rating of the best cylindrical grinding machines

MD1320B

A professional device in the mid-price segment that will allow you to carry out work faster and better. The minimum diameter of the workpiece is 8 mm, the maximum value is 20 cm. The control buttons are located above the worker’s head, which simplifies control and increases ergonomics. In addition, there is an adjustable light on top, which will not allow you to miss important details.

Length of the workpiece: from 500 to 750 mm, weight should not exceed 50 kg. Thanks to a reliable electric motor, processing parts will take a minimum of time, while the quality will remain at the best level. The design of the device is strict, made in a classic style, so it will not stand out from the general background. The control levers are located in an accessible place. The mass of the assembled equipment is 4 tons.

Sold at a price of 2,135,000 rubles.

MD1320B

Advantages:

- Quality at an affordable price;

- Controls are at hand;

- Efficiency;

- Durability;

- Maintainability.

Flaws:

- Not found.

ME1350

A device in a more expensive price segment, which is designed for operation in large-scale production. The power of the electric motor reaches 20,000 W, which is a balanced solution. The maximum diameter of the processed part is 50 cm. In this case, the maximum mass of the part should not exceed one ton.

In appearance, the equipment does not differ from standard representatives that can be found on the secondary market. The main advantage is located inside the grinding machine. Each element is made of reliable material. The service life of the product is tens of years, and the chance of breakdown is minimal. And if this happens, the manufacturer provides a guarantee for free elimination of the resulting defect.

The average price is 8,015,000 rubles.

ME1350

Advantages:

- Withstands high loads;

- The maximum weight of the workpiece is 1 t;

- Good technical equipment;

- Convenient control;

- Engine power – 20,000 W.

Flaws:

- Not found.

Centerless semi-automatic 3E183VM

An excellent machine that can handle any metal surface. And also with products made of wood or stone, you just need to choose the right tape. Main features of the machine:

- Excellent performance, which will allow you to cope with dozens of workpieces per working day;

- The processing accuracy is at a high level, which will eliminate the formation of defects and reduce the percentage of defects;

- The machine is made of durable materials so that mechanical damage or frequent overloads do not cause breakdowns;

- The equipment is controlled by an electronic controller;

- The control system is also supplied by Mitsubishi.

The maximum grinding diameter is 40 mm. Electric motor power – 11,000 W. Accuracy class – B. Product weight is 4.5 tons.

The average price is 3,417,000 rubles.

Centerless semi-automatic 3E183VM

Advantages:

- Effective work;

- Durability;

- High-quality components;

- Value for money.

Flaws:

- Not found.

SHU-321 750mm

The equipment is designed for grinding work on the inside and outside. For processing, the part is mounted in the center or placed in a chuck, it all depends on the chosen method.

The machine is equipped with a hydraulic feed control system, which makes it possible to carry out cyclic processing of the external part, spending a minimum of time. Maximum processing diameter – 320 mm, length – 710 mm. The power of the main engine is 5.5 kW.

The product is ideal for placement in a large manufacturing plant with a changeover system. The machine can be operated for a long period without stopping. And if you carry out timely maintenance, the chance of a breakdown will be reduced by half and the device will not cause additional repair costs. Weight – 4.5 t.

Sold at a price of 3,660,000 rubles.

SHU-321 750mm

Advantages:

- High-quality assembly;

- Convenient adjustment of parts;

- Efficiency;

- Ergonomics;

- Good engine;

- Maintainability.

Flaws:

- Not found.

3E183NC21

An expensive device made in Belarus, which is designed for working with smooth, conical or stepped surfaces. Works with almost all types of metal structures, showing excellent results.

The controls are simple and even an inexperienced user can handle it, the main thing is to show the basics of control. The product has virtually no differences from Russian and foreign analogues; it is still the same high-quality product that can work for a long period and will not break after a couple of years of active use. Weight – 4580 kg.

The average price is 7,375,200 rubles.

3E183NC21

Advantages:

- Convenient control panel;

- Reliability;

- Excellent grinding;

- Long service life;

- Reliable supplier.

Flaws:

- High price.

Which is the best grinding machine to choose in 2021?

Buying a machine is an individual decision for everyone. Therefore, it is impossible to single out any best grinding machine. So, for budget buyers, the best option would be the Einhell TC-US 400 or Zubr ZShS-330. For frequent use, it is worth purchasing a Holzstar ZSM 405 or JET 31A 2685033 machine. For those who have not yet decided on their choice, we have specially collected all the models discussed in the article in one comparative table:

| Name | Weight, kg.) | Belt rotation speed (rpm) | Cost, rub.) |

| 7,6 | 2950 | 6.500–7.000 |

| 7 | 2850 | 8.000–8.500 |

| 12,9 | 1450 | 9.000–9.500 |

| 18 | 1420 | 9.500–10.000 |

| 17 | 1450 | 11.000–11.500 |

| 20 | 1450 | 14.000–14.500 |

| 19 | 2850 | 15.000–16.500 |

| 34 | 1430 | 18.000–19.000 |

| 13 | 2000 | 25.000–28.000 |

| 145 | 2950 | 65.000–70.000 |

| 44 | 1400 | 70.000–75.000 |

| 80 | 1440 | 80.000–85.000 |

| 115 | 2400 | 90.000–96.000 |

Features of equipment use

The devices help make wooden blanks look presentable. With their help, primer, paint sagging, “washboard effect”, roughness, protruding glue and other imperfections of the untreated workpiece are removed. To optimize the operation of the machine, it is necessary to set the pressure correctly. Some features:

- flat elements, frames and large workpieces are processed by cantilever units;

- to prepare the wood surface for painting, use a monolithic or sectional iron.

To simplify and speed up the implementation of calibration or grinding work, electronic and pneumatic monitoring systems are used. Surface grinding is performed by almost any machine, even with minimal functionality. Circular or figured grinding is more demanding, so specialized equipment is used.

Different calibrating grinding machines are used for grinding different surfaces. To remove a thick layer of wood without strict requirements for the roughness of the part, it is enough for the machine to have one shaft. If a higher surface quality is required, then a rubberized shaft of the required hardness is installed behind the steel shaft. An iron is additionally used to process the product for final painting. The first category of machines calibrates to size, the second carries out standard grinding, and the third completes the processing of the workpiece, giving it the desired appearance.

Products lined with veneer are processed without a calibrating shaft, since it is glued to the part of the required thickness. The iron should ideally consist of several dozen elements with pneumatic pressure or electronic monitoring of the profile of a wooden blank.

Taishet24 on Odnoklassniki

Tips and tricks when choosing a grinding machine

In order not to make a mistake when choosing a grinding machine, you need to know some nuances. Now we will give tips that will help you when choosing a quality device:

- Before choosing, be sure to inspect the machine for mechanical damage. If they are present, then perhaps the machine is used (not new);

- Also, before purchasing, you should definitely start the device and check its performance. Very often, buyers do not do this when purchasing, and they may be sold low-quality, defective goods;

- When choosing, you should also take into account the characteristics of the machine. You need to pay attention to the maximum engine power, the presence of safety systems, the strength of the body and the resistance on the frame. Also important indicators of the machine are its endurance during long-term operation and resistance to temperature changes.

Video - Choosing a grinding machine for the workshop

What to look for when choosing?

Like any complex equipment, this device must be selected correctly. Experts recommend looking at the technical characteristics of the product, since the performance of the equipment and the amount of work it can handle depends on this.

Power

The higher this indicator, the better and more productive the device. In addition, this parameter affects the ability to withstand heavy loads. But it is also worth considering that the unit is designed for high consumption of electrical energy; the home network may not be enough for it. Therefore, they are recommended for use in large-scale production. If a person is looking for a suitable option for organizing a private workshop, then it is best to buy products from the mid-price segment. They are able to satisfy with performance, build quality and durability.

Rotation frequency

The value of this indicator directly depends on the capabilities of the electric motor. This parameter is also important to take into account, since productivity depends on it, and this is important in mass production. It is better to select models with the highest speed to avoid downtime and delays.

Tape width and length

There are dozens of models on sale, they may differ in the dimensions of the tape. To choose the appropriate size, it is important to focus on the tasks that the product will perform. For working with small parts, grinding machines are quite suitable, not machines.

If you need to work with large elements (for example, a cabinet door), then it is best to buy a wide tape, as it can guarantee the quality and speed of work. In a home workshop, it is recommended to purchase products with an average value.

The length of the tape depends on the equipment itself, on average it reaches 91 cm, but some manufacturers may allow larger or smaller values. It is important to understand that the lower this indicator, the faster the rotation will be, and, consequently, the productivity will increase. But this option also has a drawback, for example, rapid wear and tear, which will require additional expenses.

Weight

This parameter is not important for production facilities, but private craftsmen take it into account. Since the ease of use and possible transportation depends on this. There are compact machines on the market whose weight reaches 17 kg and this is considered the optimal solution for this case.

Customer Reviews

This is one of the main criteria for choosing the right model. Because not all manufacturers indicate the shortcomings of their devices, so when buying “blindly”, a person risks investing money in repairs in the future, especially if a one-week or six-month warranty is given. In addition, it is from reviews that the buyer learns the main nuances of using a particular model.

When a person buys a custom-made grinding machine through an online store, he needs to check not only the technical parameters of the equipment and its functional features, but also the store itself, if he has never visited it before or ordered products from there. Often, under the guise of such sites, scammers can hide and receive not only “easy” money, but also information about a bank card. You should never let your guard down, especially on the Internet.

When buying a grinding machine in stores, you can seek help from independent experts or friends who understand this. They will help you choose a quality product and form the most objective opinion on each model. Such assistance cannot be neglected, since productivity and the time during which the equipment can pay for itself depend on it.

Most experts recommend buying products from well-known brands that have been selling products for decades. They offer not only quality, but also issue an official guarantee that will help repair the equipment free of charge in the event of a breakdown that is not due to the user’s fault. If a person wants to save money, then you can buy a Chinese-made model, only in this case you need to be aware of the risks. Since not all companies provide a guarantee.

Voting for the best grinding machine

Which grinding machine would you choose or recommend?

JET 31A 2685033

0.00 % ( 0 )

Holzstar ZSM 405

0.00 % ( 0 )

Jet 10-20 PLUS 628900M

25.00 % ( 2 )

VISPROM BKL-3000

0.00 % ( 0 )

Triton TSPST450 TR894303

12.50 % ( 1 )

JET JDS-12X-M 10000490M

12.50 % ( 1 )

Record Power BDS150-EP

12.50 % ( 1 )

JET JSG-64

0.00 % ( 0 )

Proma BP-100 25702100

12.50 % ( 1 )

Encore Corvette-51 90510

0.00 % ( 0 )

Einhell TC-US 400

12.50 % ( 1 )

JET JDBS-5-M 10000470M

12.50 % ( 1 )

How do the machines work?

Sanding removes some material from the workpiece to shape it to suit your needs. Processing occurs using an abrasive wheel consisting of quartz grains, silicon carbide, and carborundum.

In fact, grinding is an operation that requires certain tolerances, a high class of accuracy, complex measurements (longitudinal or angular), and compliance with geometric dimensions (concentricity, parallelism, perpendicularity). Grinding is also intended for surface finishing, removing roughness and scratches.

Types of devices

There are many types of grinding equipment. Here we will look at what it is, define the criteria necessary when choosing the functionality you need, and list tips that will draw attention to errors that are possible during the purchase, which is not unimportant for the effective implementation of any project you have in mind.

1. Surface grinding

Thanks to the simple design of such a machine, consisting of a longitudinal carriage, it is very easy to operate. Depending on the position of the abrasive element, two types of products are distinguished:

- In devices with a vertical mounting of the grinding wheel on the spindle, the workpiece moves in a straight line and fits tightly to the abrasive. Such machines are usually used for rough processing of planes, although some models can achieve high precision.

- The active element of the tangential apparatus rotates horizontally, works along the edge of the workpiece, and moves in a circular, pendulum motion. Such machines are used, as a rule, for high-tech processing of bell-shaped, inclined, mating surfaces, grooves, and for performing complex profile and intra-face grinding work.

Such equipment can be used in conjunction with other turning and milling equipment. Workpieces are positioned using a magnetic pressure plate and are moved manually or mechanically. The product is equipped with a pump for automatic recirculation and application of coolant to parts.

Scope of use:

- stamps;

- guides;

- plates;

- regular or piston rings;

- Press forms;

- pins;

- profiles for tools.

The dimensions of the workpieces can vary from 40-80 cm to 6 meters. The machine can work with a high degree of reliability on metal and wood; it is possible to install brushing brushes.

2. Cylindrical grinders

These machines can work with workpieces of various shapes, however, the part must have a central axis of rotation: cylinder, cone, ellipse, cam or crankshaft. Let us highlight several subtypes of units:

- On a double-drum machine, the part rotates synchronously with the abrasive.

- The size of the part processed by an internal grinder is always less than the width of the wheel.

- Centerless grinders work with small-sized, cylindrical products; their area of application is bolts or pins. The mechanism consists of two circles that rotate in the same direction; a part is placed between them, without a clamp (that’s why the mechanism is called “centerless”), which rotates in the direction opposite to the abrasive. The drive wheel is inclined at a certain angle, from 1 to 5 degrees, depending on the hardness and size of the material to be processed.

3. Universal

One of the best machines with excellent performance. Using these machines you can grind the outer and inner surfaces of camshafts, crankshafts, cylinders, cones, and liners at home.

The longitudinal carriage included in the design of the unit provides translational movement to the workpiece, and the hydraulic mechanism gives the wheel counter rotation. The characteristics of the workpieces determine the shaft speed using regulators.

4. Special

These machines are used for parts with complex mechanical geometries that cannot rotate on their own. A vertical spindle (sometimes called a planetary spindle) is built into their design; in addition to rotation, it performs circular movement.

The machines are used for processing gears, their profiles, threads, rolling cylinders, guide frames, brake pads, splines, bearings, turbine blades, and aircraft landing gear.

The grinding wheel has many different shapes, grain sizes, and meets international standards.

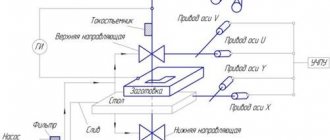

5. With CNC system

Technological progress has led to the appearance on the market of products with numerical control, for example, grinding and calibrating machines. Such machines are used both in large-scale production and in small enterprises; they will help make your project successful and have a number of advantages over conventional ones:

- unification of workpiece processing (top, front, bottom) on one machine;

- full automation, minimal operator intervention;

- the dimensions of the unit allow grinding large parts;

- magnetic clips;

- improved performance, accuracy;

- with the function of turning on servo motors for each axis, which allows you to effectively position the part;

- automatic control of wheel condition;

- possibility of programming Cartesian coordinates;

- air purification system from chips and dust.

After studying this review, you will be able to rank the popularity of the models yourself. Decide which equipment is best to buy for efficient work.

Recommendations and selection criteria

Before choosing a desktop tool, first of all, you need to determine for what purposes it will be used.

It is worth paying attention to the following characteristics:

- RPM power should be maximum. By pressing an object onto the sharpener, the rotation speed is significantly reduced. It is quite difficult to process a large tool on a small machine;

- a manual machine is much easier to maintain than an electric one;

- The heavier the machine, the safer it is. When choosing, you should pay attention to the weight of the installation. Massive and large-sized equipment is more stable, so work on it will be of better quality and less dangerous;

- The rotation shaft must be correctly positioned in relation to the center. Incorrect installation can lead to friction of the sharpener against the protective walls, rapid wear and poor finishing of the tools. This is an important point that you should pay attention to first;

- Safety is the main criterion that should not be forgotten. Before starting work, you need to make sure that the installation is secure and the unit is grounded. The new 2021 models come with protective glass made of transparent plastic. If it is absent, then you should use glasses or a mask.

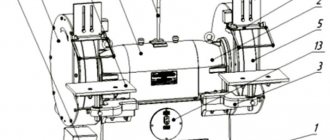

Universal sharpening machine

In 2021, completely new universal sharpening and grinding machines are presented on the market, which are designed for sharpening various tools for home and industrial use.

The machine grinds stone, wood, metal; sharpening of knives, scissors, saw blades. When a tool that can be ground or sharpened is heated, its density is lost. To prevent this problem, universal machines are equipped with a water cooling system.

A tool compartment is built into the machine body, where you can store grinding and leather wheels, holders and installation templates that come with each model.

Which sharpening machine is better to buy for your home?

A sharpening machine is a necessary equipment for a craftsman engaged in carpentry, carpentry, turning or metalworking. Typically it consists of one or two disks of different grain sizes, mounted directly on the motor shaft.

Sometimes a speed reduction gearbox, a wetting system, a sanding belt or a flexible engraving drive are added to the design. Safety and ease of work are ensured by a protective casing, a transparent screen, lighting, and a support platform with an adjustable tilt angle. Let's consider what characteristics an electric emery should have, depending on the intensity of use and the nature of the operations performed.

What power should be depending on the upcoming use

Power determines the maximum load on the electric motor, which will not lead to its overheating and failure. It’s still not worth chasing the limit values for equipment that will be used in a home workshop.

There are inexpensive and compact 150-250 W machines on the market, suitable for sharpening knives, chisels, drills and other small cutting tools. More powerful models may be required for sharpening axes, scythes and other large objects.

How to determine the maximum number of revolutions

With an increase in the rotation speed of the grinding wheel, the productivity of the machine increases, but the risk of overheating of the sharpened part increases with the risk of damaging the internal structure and reducing the hardness of the material.

For grinding high-quality steel, the optimal frequency is 2700-3000 rpm. It is better to process thin edges at low settings. When sharpening particularly hard alloys (for example, hammer drills) with fine-grained diamond discs, 10-15 thousand rpm may be required.

How to choose the diameter of a circle

Grinding wheels of large diameter have an increased service life and are more inertial, which ensures smooth running, uniform load on the engine and high quality processing of large parts.

They are more expensive, and when installed on a machine with a low-power engine, they can cause damage. In a home workshop, medium and small sized disks are usually used.

Wheels for a sharpening machine.

What you need to know about the wheel diameter

For proper installation, the size of the wheel mounting hole must correspond to the shaft diameter. This parameter usually increases in proportion to the power and maximum rotation speed of the machine. Some models are equipped with adapter devices, which gives additional freedom in choosing disks.

All other things being equal, preference should be given to equipment with a large shaft. It better withstands loads associated with disc imbalance, vibrates less and contributes to high processing accuracy.