Structure and types of equipment for EEE

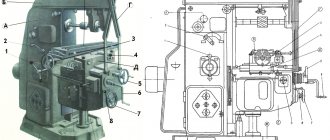

A typical EDM machine includes:

- several electric motors operating autonomously from each other;

- electrode-tool supply unit;

- bath with working environment;

- table for placing the workpiece being processed;

- control scheme.

The equipment in question is classified according to the following criteria:

- According to technological purpose. It is possible to distinguish universal, specialized and special machines for EEE;

- Based on the principle of arrangement of the main components. It can be made horizontal and inclined, but a vertical layout is more often used;

- By type of table: fixed or coordinate;

- By type of bath – removable or rising;

- According to the degree of accuracy - equipment for work of ordinary precision and precision;

- Based on the principle of excitation and subsequent regulation of electrical discharge parameters.

The size range of types of electrical erosion equipment of domestic production is determined by the requirements of GOST 15954.

Methods for producing an electrical discharge in the working circuits of machine tools

Dimensional processing can be carried out by spark, pulse and arc discharges. In the first case, a spark discharge of low duty cycle is formed between the cathode and anode, but with precisely specified characteristics of the interelectrode gap. Such machines are compact, distinguished by high accuracy of operation and surface quality after electroerosion, ease of regulation by technological parameters, but at the same time they have low power, and, therefore, productivity. Areas of expedient use of such machines are precise cutting of difficult-to-cut materials (in particular, hard alloys), and production of parts with complex contours. They can also be used to remove broken tools, etc.

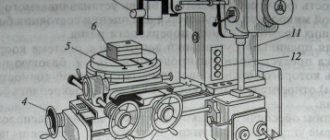

Diagram of a wire-cut electrical discharge machine

An increase in the energy of the electric discharge is achieved by introducing a pulse generator into the circuit, which increases the interval between adjacent discharges and at the same time increases the thermal power during a single electrical erosion event. As a result, work productivity increases, but accuracy decreases, and the surface of the machined part may have a fairly extended heat-affected zone, which is not always acceptable. Electric pulse machines are used where more significant metal removal per unit of time is required.

If it is necessary to ensure even higher metal removal (and not only to change the shape of the original workpiece, but also to strengthen it), electric arc machines are used. The productivity of such equipment increases several tens of times, since the arc, unlike other types of electrical discharge, burns continuously. To control the technological parameters of the arc discharge, it is compressed by the transverse flow of the dielectric medium, which is constantly and under high pressure pumped through the arc combustion zone by a pumping unit provided in the machine circuit. Electric arc machines can be used to produce large blanks for rolls, hot hammer dies, etc.

Electroerosive machine - operating principle, design and purpose

Processing materials with a dense structure manually is ineffective, as it requires a lot of labor and does not provide high accuracy. Among the installations that allow to some extent or completely (depending on the type and model) to automate the process, electrical discharge machines are less known, although they have unique capabilities, which sets them apart from the majority of their “brothers” in the machine park.

The features, operating principle and specific application of electrical discharge machines will be discussed in the material offered to the reader.

general information

- Regardless of the model, EDM machines have limitations in processing parts. They can be used to perform various operations only if the sample is made of materials of the “conductive” category (metals, alloys).

- There are several methods of electroerosive impact on a product, differing both in the method of delivering electrical discharges and in the parameters of the pulses. In accordance with this, all such machines allow the production of parts in different ways, depending on the expected result.

- An undoubted advantage of electroerosive installations is the ability to process a sample simultaneously in different directions.

What can happen as a result is shown in the diagrams (the most common options for using electrical discharge machines).

Methods for processing workpieces

- electric/pulse;

- electric/spark;

- anode-mechanical;

- email/contact.

Types of technological operations

- Strengthening the structure.

- Grinding.

- Marking.

- Cutting out.

- Finishing.

- "Firmware".

- Segment.

- Volume copying.

- Treatment:

- electroerosive abrasive;

- anodic-mechanical;

- electrochemical;

- combined.

Capabilities of electrical discharge equipment

The range of use of electrical erosive machines is truly enormous. The main technological operations include:

- obtaining holes (blind openings, recesses) of the most complex configuration, if necessary, with threads;

- sampling of material to any depth from the internal surfaces of samples;

- performing operations that are impossible or economically impractical to carry out on other types of machines (milling, turning);

- production of parts from materials that are difficult to process with traditional tools (for example, titanium and alloys based on it).

The operating principle of electroerosive type machines

Despite the difference in the design of the equipment and the implemented methods of electrical discharge machining, the operating principle remains the same.

Conventionally, the process can be divided into two technological stages.

First. Under the influence of pulse discharges arriving “through the plasma channel” (10), the structure of the sample (2) in this area is destroyed. They appear at a certain moment when the electrode (4), which is the working tool of the machine, approaches the workpiece. Electrical energy is converted into heat, and as a result, the metal (alloy) melts in the area required by the specifications.

Second. Since both the part and the electrode are immersed in a container with a special composition (most often it is oil), the metal partially evaporates from the high temperature, and the remaining melt is removed from the working area.

Depending on the implemented processing method and the engineering solution in the design of the machine, the parameters of the pulses, the technology for their generation and a number of other factors in different models of electrical discharge installations may differ. But the principle of operation of the equipment remains the same.

The applied voltage “breaks through” the gap between the electrode and the “blank”, resulting in the formation of a so-called “plasma channel” characterized by a high temperature. At the base of this “pillar” a melt of metal appears, which is removed from the working area.

In principle, such a “miracle machine” as an electrical discharge machine can be made independently. But the apparent ease of assembly is deceptive. Before you get to work, you should evaluate your strengths. The main difficulty that the “home craftsman” will face is the installation (and before that the accurate calculation of the parameters) of the spark generator. In addition, the operation of this machine requires special care, since the container with oil can ignite at any time. The author does not set out to dissuade the reader from making a household EDM machine on his own, but he is simply obliged to pay attention to a number of points.

Application of different types of electrical discharge machines

Among the electric spark type equipment, the MA4720 copying and piercing machine is considered one of the most accurate. It is designed to work with difficult-to-process workpieces of complex configuration, for example, for carbide die equipment, molds, and molds. The productivity of the machine does not exceed 70 mm3/min, but it is possible to achieve an accuracy of 0.03...0.04 mm, with a fairly low roughness of the final surface (not higher than Rz 0.32...0.4 μm in finishing processing modes). The work table is moved by a CNC system. The dimensions of the work table and the permissible range of values of the interelectrode gap between the anode and the cathode do not allow the production of products with overall dimensions of more than 120×180×75 mm on this machine.

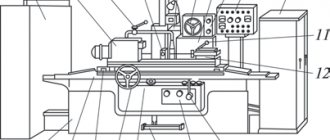

An example of an electric pulse machine is the widespread model 4E723, also equipped with a CNC. Higher specific power values make it possible to achieve EDM productivity of up to 1200 m3/min, with a processing error in finishing modes within 0.25...0.1 mm. Higher accuracy is achieved with EDM of shaped surfaces. The machine is also used primarily in tool production, but the surface roughness increases noticeably - up to Ra 2.5 μm, so grinding will be required after processing in most cases. The machine can perform EDM of parts with overall dimensions of 620×380×380 mm, as well as cutting shaped grooves.

These types belong to universal electroerosive machines. An example of specialized equipment is the model 4531 electrical discharge machine, which produces profile cutting of complex contours using a non-profiled electrode. The 4531 machine uses a brass wire that is continuously rewound across the electrode gap, generating a discharge between the cathode and anode. With a relatively low productivity (no more than 16...18 mm3/min for steel; for hard alloy the productivity is even lower), the 4531 machine, in principle, allows for an error of ±0.01 mm, therefore the equipment in question is effective in the production of die cutting dies matrices of particularly complex configurations and templates The maximum dimensions of the cut contour are 100×60 mm.

Principles of optimal choice of technology and machine size for EDM

The initial data are the accuracy of the contour, the dimensions (depth) of the thermally modified zone, as well as the desired removal rate per unit time. For machines working with non-profiled electrodes, it is important to have devices for automatic threading of wire, and for pulse machines - generators that allow the use of bimetallic wire, which increases the productivity of EDM.

To improve the quality of the process and reduce erosive wear of the electrode-tool, it is better to use oil as a working medium (the most common is a mixture of industrial-20 oil with kerosene). In principle, for products with increased tolerances, it is possible to use water.

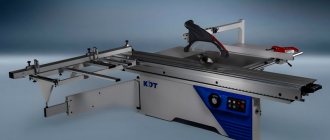

The technological capabilities of electroerosive machines are significantly expanded by the presence of additional devices (for example, for producing conical surfaces).

To remove metal from 20,000 mm3/min and above, only electric arc machines should be used. The smallest operating error of such equipment is achieved with reverse polarity when using graphite electrodes. At the same time, the relatively high surface roughness - not lower than Rz 0.8...1.6 μm - forces, after EDM with an arc discharge, to provide for finishing grinding of the resulting contour. The pumping pressure of the working medium must be at least 50...60 kPa.

Stitching machine

The electroerosive copying and piercing machine in a modern design is equipped with a CNC unit, which has built-in functions of automatic positioning, orbital movement of parts and the ability to burn side surfaces. The machine is also equipped with the functions of automatic edge search and search for the center point of the processing area. Along with this, the CNC block programs include determination of the cavity depth and automatic exit of the tool head to the zero point.

The EDM piercing machine is designed to process both internal and external spherical elements, working along a 3-dimensional linear path. Along with possible surface processing along a 2-dimensional arc, it can perform electrical discharge burning, using the original matrix of the product for processing as an original for copying.

Currently, the price of an electroerosive machine of this type fluctuates around 1 million 800 thousand rubles.