Having decided to purchase a country house, you first need to find out whether electricity is supplied to it and whether there is water in the garden area. And if the first problem can be solved today, then the second may become an obstacle to the purchase of this particular plot. After all, without water it is just a piece of land, and talking about people living on it makes no sense. The way out of this situation is to extract water by digging a well. And plastic pipes will help to equip it.

Corrugated pipes of large diameters can be used to equip a drinking well shaft

Advantages and disadvantages

Wells made from polymer pipe products have many advantages, which have led to the fact that owners of suburban areas began to give preference to water sources created not from reinforced concrete rings, but equipped with plastic. The advantages of such structures include:

- a well made of a polymer pipe is a seamless structure with a maximum level of tightness. But the density of the connecting seams of reinforced concrete rings is lost over time under the influence of soil;

- moderate cost of materials;

- the plastic pipe for the well is lightweight, which greatly facilitates the construction of a water source;

- resistance to rotting and corrosion. This property ensures the absence of dangerous contaminants in drinking water;

- minimal thermal conductivity. Thanks to this characteristic, the probability of water freezing during the cold season is close to zero;

- the presence of stiffening ribs gives the walls of the plastic pipe additional strength;

- on the plastic walls of the well, the reproduction and vital activity of microorganisms is difficult;

- a wide selection of sizes and shapes of polymer pipe products;

- ease of installation and maintenance;

- long service life.

You can use any type of pipe, the main thing is that it is two-layer and seamless

Plastic wells do not have serious disadvantages that can outweigh the existing advantages. The same factors that are listed below can rather be interpreted as features of the use of the design, but not at all as significant disadvantages.

- To prevent deterioration in the quality of drinking water due to atmospheric precipitation and mechanical impurities entering the well, its neck must be covered with a plastic lid.

- It is important to subject plastic wells to periodic maintenance - clean the bottom, perform maintenance on the filter and pump (if equipped).

Service life, operation and proper care

The period of operation of the well after installing the liner depends on the material of the plastic insert. Most manufacturers estimate the service life of their products at 50 years. Maintenance requirements are limited to ensuring that no objects enter the well that could damage the plastic insert.

Before restoring a drinking well or septic tank, in addition to familiarizing yourself with the instructions for installing plastic liners, it is important to watch training videos that indicate errors during the work.

Construction of a plastic well

The main problem of all drinking water sources is their contamination by surface waters. But at present, means of protection against this phenomenon have been developed. One of them is to install a plastic pipe in the well instead of traditional well concrete rings. It must be seamless so that the perched water does not leak into the mine, and the presence of a layer of geotextile will prevent the source from becoming sandy. But here one nuance is of great importance - to ensure a sufficient flow rate of the well, it is necessary to get as accurately as possible to the aquifer closest to the surface.

Good to know! In fact, a well created using a plastic seamless pipe is a capture well that accumulates groundwater.

The creation of such a hydraulic structure includes the following stages:

- purchase of plastic double-layer pipes. Their diameter should be 400 millimeters. Only such products can be installed in soil;

- determination of the place on the site where the underground spring hits with maximum force. To do this, you need to call a hydrogeologist. However, you can use a method based on the use of a vine branch shaped like a slingshot. Even in the 21st century, many owners of country houses, in order to save money, use this method, which came to us from ancient times;

- open-pit excavation of a place for a source;

- Having penetrated to a depth of two meters, begin to give the hole a round shape until you reach the aquifer;

- After the key is filled in the shaft, a seamless plastic pipe is prepared for the well.

- lower the pipe into the well. Make sure it reaches the bottom of the shaft;

- pour sand into the space between the pipe and the walls of the hole.

You need to dig a shaft for a well in an open way, giving the hole a round shape

Pipe preparation includes the following steps:

- in the cavities of the fins to a height of 500 millimeters, drill numerous holes with a drill with a diameter of 7 millimeters;

- wrap the opening of the hole and pipe with two layers of geotextile;

- secure the well filter with wire in a plastic sheath. It will prevent the passage of sand and, at the same time, allow water to pass through well;

- do not forget to insulate the pipe section protruding 1 meter above the soil surface with foam plastic;

- To start pumping the well, lower the submersible pump into it. To improve the quality of water after pumping, load a layer of quartz sand and shungite into the lumen of the pipe.

Installing an insert in an old well

Plastic inserts can be installed directly into the well, or into an existing concrete well. Both installation options will be considered. First, the process of restoring an existing well.

This requires a minimal amount of time, since most of the work has already been done. Drilling a tube well from scratch requires a lot of effort. It is important to choose the right place. The service life of the well largely depends on this.

Before starting work, it is necessary to pump out the water and clean the walls of the old well. This can be done with a regular spatula, going down to the bottom of the excavation. This must be done if the distance between the insert and the concrete rings will be filled with concrete mortar.

Filling with mortar completely solves the problem with the strength of the structure, but makes it immobile. With this method, the insert cannot be reused.

Fixing with crushed stone or sand allows for simple dismantling, which will make it easy to fill up the old well. In this case, no concrete structures remain on the site. Everything is dismantled and can be moved.

If the well is not overgrown with moss, then it is not necessary to clean its walls. After cleaning the walls, it is necessary to completely remove the old drainage. As a rule, crushed stone of different fractions is used for filtration.

After removing the crushed stone, you can proceed to installing the insert. First, you need to assemble it correctly. The individual segments are connected to each other using sealing rubber parts. The connection method is similar to sewer pipe assembly, but on a larger scale.

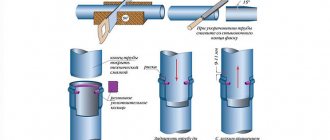

Pipes are also screwed onto threads. The assembly of the insert segments must be carried out on the surface. After the structure is assembled, it is lowered into the well

Depending on the length of the structure, it can be installed manually or using machinery. You need to lower it carefully. It is necessary to ensure that there is no sharp impact on the bottom of the excavation, since a single mechanical impact may cause the plastic to crack. At the next stage, the insert is fixed in the well.

If distance allows, the space between the walls of the well and the assembled structure is filled with crushed stone. For this, in addition to small fractions of crushed stone, you will also need large ones to ensure optimal adhesion

If the diameter of the well is slightly larger than the insert, then the distance is filled with a solution with a cement or gypsum base. To mix the binder composition you will need a sand-gravel mixture, the binder itself and water. For the solution, you need to mix three parts of ASG and one part of cement.

Water is added gradually, its amount directly depends on the humidity of the ASG. The finished solution is poured between the insert and the well along a special chute, which is a sheet of bent tin. After pouring, it is necessary to leave the well for 2 - 3 weeks until the solution completely hardens.

Construction of the Abyssinian well

The term “Abyssinian well” or “Abyssinian well” means a thin channel in the ground, which is performed by piercing the soil to a depth not exceeding 10 meters. Plastic pipe products with a diameter of no more than 1.5 inches are inserted into it. Marble chips are poured into the bottom of the well,

Of course, the density of plastic does not allow it to penetrate the soil to the aquifer, but it will be able to fulfill its assigned role later. To create a hole of the required length, you can use a garden drill equipped with collapsible rods. This will allow the aquifer to be reached.

Cut the pipe into 1-2 meter sections and build them on top of each other as you move deeper into the hole. In this case, it is necessary to achieve maximum reliability of the connection, otherwise the structure may be damaged. To facilitate the process of passing the pipe through a hole in the ground, install a filter needle at its end.

The Abyssinian well is a well of small diameter, so plastic pipes are often used for its construction

Important! Among other things, this element will purify water from various mechanical particles and prevent siltation of the source.

When liquid appears in the well, the deepening process can be stopped and flushing can begin. If this procedure is carried out efficiently, all that remains is to wait no more than a day until the water purifies itself and becomes suitable for consumption.

The advantages of an Abyssinian well made of plastic pipes include:

- long service life;

- high quality water. The presence of a self-priming pump on top and the small diameter of the well prevent chemical contaminants, dust and microorganisms from entering the water;

- cheap creation procedure.

Approximate prices for plastic inserts in wells

The price depends on the pipe diameter, height and availability of additional parts. The indicated dimensions are directly related to the depth and diameter of the well. Our website presents options for inserts ordered for reinforced concrete wells for collecting fecal waste.

| Insertion height (mm) | Insert diameter, mm | Wall thickness, mm | Price, rub | |

| 1500 | 950 | 5 | 15500 | — |

| 2000 | 950 | 5 | 21900 | — |

| 2500 | 950 | 5 | 23800 | — |

| 3000 | 950 | 5 | 225800 | — |

| 3500 | 950 | 5 | 32100 | — |

| 4000 | 950 | 5 | 34100 | — |

| 4500 | 950 | 5 | 36100 | — |

| 5000 | 950 | 5 | 42400 | — |

| 5500 | 950 | 5 | 44300 | — |

| 6000 | 950 | 5 | 46300 | — |

| 1500 | 1450 | 6 | 29500 | — |

| 2000 | 1450 | 6 | 40600 | — |

| 2500 | 1450 | 6 | 44400 | — |

| 3000 | 1450 | 6 | 48100 | — |

| 3500 | 1450 | 6 | 59200 | — |

| 4000 | 1450 | 6 | 63000 | — |

| 4500 | 1450 | 6 | 66700 | — |

| 5000 | 1450 | 6 | 77800 | — |

| 5500 | 1450 | 6 | 81600 | — |

| 6000 | 1450 | 6 | 85300 | — |

| 1500 | 1950 | 8 | 50100 | — |

| 2000 | 1950 | 8 | 67700 | — |

| 2500 | 1950 | 8 | 74400 | — |

| 3000 | 1950 | 8 | 81100 | — |

| 3500 | 1950 | 8 | 98600 | — |

| 4000 | 1950 | 8 | 105300 | — |

| 4500 | 1950 | 8 | 112000 | — |

| 5000 | 1950 | 8 | 129600 | — |

| 5500 | 1950 | 8 | 136300 | — |

| 6000 | 1950 | 8 | 143000 | — |

Other uses

Reanimation of a reinforced concrete well. Using polymer materials, you can not only build a new well, but also breathe a second life into an old concrete one. If there is a source on the site with water quality that is unsatisfactory to its owner, the simplest solution to this problem seems to be installing a plastic pipe inside the well. For this purpose, polymer pipe products are used, the diameter of which is 10-20 percent smaller than the cross-section of reinforced concrete rings. Cement mortar is poured into the resulting free space. Plastic prevents the penetration of soil contaminants that appear due to the destruction of the reinforced concrete column, and also prevents plaque from entering the water, which settles on the walls of the reinforced concrete rings.

Plastic does not release harmful substances into the water, so concrete and metal pipes of old wells are replaced with polymer ones

Plastic sewer wells. Polymer pipe products have also found application in the construction of domestic wastewater disposal systems. This is due to the requirements of SNiPs, according to which each sewer system must be provided with special wells. Their number is determined in regulatory documents. They allow you to maintain the system in working condition and timely service it.

Sewage wells are of the following types:

- rotary. Installed in places where the flow of transported liquid changes direction;

- overflow. They allow you to control the functioning and maintain the drainage system in places where pipeline diameters change;

- viewing rooms Designed for servicing straight sections of sewerage, the length of which exceeds 12 meters.

When installing plastic wells of any of the above types, you need to understand that if their bottom is below the ground aquifer, the structure may float.

Advice! This phenomenon can be prevented by installing a concrete anchor or thoroughly compacting the bulk soil.

Purpose

It is often profitable not to do expensive repairs of concrete inspection chambers of sewer structures, local septic tanks, and water supply collectors, but to replace the products with new ones.

They solve the problem of repairs at minimal cost, extending the operation of concrete structures for decades.

To prevent sewerage sewage from entering the ground through cracks and cracks in the chambers or from surface water seeping into drinking wells, PVC liners are used. Such products must provide:

- protection of drinking facilities from crumbling soil and seepage of surface water into the mine;

- sealing the sewer system to prevent sewage from entering the aquifer;

- strengthen the structures, impart rigidity to the structure, preventing the rings in the chamber from moving relative to each other;

- protection against the formation of fungus and moss on the walls of the structure;

- efficiency and ease of installation work, without the use of lifting equipment;

- protection of the earth's ecosystem from aggressive acidity and decomposing sewage waste;

- trouble-free operation of the facility for five decades.

Plastic inserts are installed in the concrete rings of the well if repairs are necessary. Constantly being in an aqueous and aggressive environment with changing temperatures and seasonal cycles, polymer structures do not rot or corrode and retain their shape.

Restoring a concrete device using a liner will not cost more than repairing or replacing monolithic chamber rings. And reducing the time for restoration and guaranteeing long-term operation of the structure when using polymer will provide cost savings.

Types of plastic pipes for wells and boreholes

Modern industry produces similar pipes from the following materials:

- low density polyethylene;

- polypropylene;

- polyvinyl chloride;

- unplasticized polyvinyl chloride (UPVC).

A plastic pipe for a well or well can be:

1. Triangular profile with threads of various lengths - short and long. The dimensions of the first type of pipe are:

- wall thickness 6 ≤ Sst. ≤ 15 mm;

- diameter 114 ≤ D ≤ 508 mm.

A coupling of a certain size is used to connect these pipes. The thread itself has the shape of a cone.

The meaning of the above parameters for pipes with long threads is as follows:

- wall thickness is the same: 6 ≤ Sst. ≤ 15 mm

- diameter 114 ≤ D ≤ 245 mm.

The diameter and wall thickness of the pipe required for the well depend on the size of the well opening and the type of soil in which it is located

The threads on them are cut or rolled using special equipment, and the end has a cone-shaped shape:

2. Trapezoidal profile with tapered thread. This plastic pipe for wells and wells has the following dimensions:

- wall thickness: 0.6 ≤ Sst. ≤ 1.5 mm

- diameter 114 ≤ D ≤ 340 mm.

3. Pipe with connections characterized by a high level of tightness. Such products are recommended for use in super-wet soil.

Types of plastic rings

Manufacturing materials, dimensional parameters

As mentioned above, wells can have different purposes, and accordingly, operating conditions will vary. Therefore, for the manufacture of rings for assembling a well, polymers with different physical and operational characteristics can be used.

Both in terms of material of manufacture, and in size, and in the principle of installation, rings can vary quite seriously

The table below will help you figure out which wells are best suited for rings made of one material or another:

| Illustration | Brief description of products and their properties |

| Polymer-sand components are the most popular of all plastic rings, as they are used for arranging almost any kind - sewer storage, rotary, inspection, drop-off and filter wells. They are made from a sand mixture, which makes up 75% of the total volume of material, as well as polymer and dye, which make up 25%. The light weight of the rings allows you to transport and install them yourself. The rings are joined together using the tongue-and-groove principle; before installation, a special sealant is applied to their joints. The material is resistant to high loads, low temperatures and high humidity, and is inert to chemical influences, so rings made from it can be used for the installation of drinking and sewer wells. | |

| Polyethylene rings are highly resistant to low temperatures and are also inert to the aggressive chemical effects of ground moisture. However, this material does not have the most outstanding strength, so rings made from it are most often used as liners in already old wells made of concrete rings. They increase the durability and tightness of the structure. Polyethylene elements are installed both in newly constructed wells and for repairing those that have been in use for a long time. Repairs using such tabs will cost much less. However, you can also purchase high-quality PE rings with thick walls and pronounced rings of rigidity, which are perfect for creating shallow inspection or storage sewer wells, or for caisson equipment. Stiffening ribs will help such a well cope with external soil pressure. | |

| Products made from low-density polyethylene (HDPE) very often have a two-layer structure - an outer dense corrugated casing of a dark color and an inner light layer that smoothes the relief of the corrugation. These products often cannot justifiably be called rings, since they are full-fledged pipes of various lengths. The convenience of using solid pipes for a well lies in the absence of joints, which guarantees complete tightness of the walls. Products made from HDPE are highly durable and designed for a long service life, but the cost of such rings or pipes is quite considerable. Such pipes can be used as an insert in a concrete well during its overhaul, renovation, or used independently, without the use of concrete rings, when constructing a new well. If you need to equip a well for water, you should choose products that have a blue longitudinal stripe along the inner surface. | |

| Polypropylene rings for wells are designed for operation at temperatures from 0 to +95 degrees, and have very poor resistance to ultraviolet rays. And these negative features of the material limit its outdoor use. In principle, there is nowhere for direct sunlight to come from in a well, but the “weakness” to negative temperatures should alert the consumer. However, there are exceptions among polypropylene products. For example, it produces rings from this material that are quite resistant to low temperatures. Polypropylene has good heat resistance (at the upper limit) and wear resistance. Moreover, it is a thermoplastic material, that is, it is possible to ensure the tightness of the created structure by welding the seams between the rings. Rings made of this material can be used to construct caissons, wells for drinking water, drainage or storage chambers. | |

| PVC rings are resistant to ultraviolet radiation, designed for operation at temperatures from -60 to +45 degrees, the material hardness coefficient is SN8, which indicates their increased strength. The durability of the products is estimated at 50 years or more. PVC rings are well suited for arranging sewer wells. A clear disadvantage of PVC products is their low resistance to high temperatures. |

In addition to the material of manufacture, plastic rings can vary significantly in both configuration and dimensional parameters:

- The internal diameter of the rings varies in the range of 400÷1500 mm.

- The outer diameter depends on the wall thickness and the height of the corrugation relief (stiffeners). For products used at the private construction level, it can reach up to 1600 mm. In this case, the pit for installing a plastic well shaft must be dug 150÷200 mm larger than its diameter.

- The height of the rings can range from 200 to 1500 mm (anything larger can most likely be mistaken for a pipe, although there is still no clear “transition boundary” between these concepts). The height of the individual sections and their number are selected depending on the planned structure and the overall depth of the well.

- The wall thickness of products can also vary significantly. Thus, on the thinnest models, a thickness of only 6 mm is found. and for others it even reaches 55 mm. It is clear that this parameter directly affects the mechanical strength of the product. And the deeper the well, the greater the loads it will experience from the outside and inside, the thicker the walls should be chosen.

Expert opinion: Afanasyev E.V.

Chief editor of the Stroyday.ru project. Engineer.

It is clear that the dimensions must be specified upon purchase, including the markings and accompanying documents. There is no single standard in labeling, so it makes no sense to dwell on this. We can only note that diameter and height usually appear.

Practice shows that an internal diameter of 900÷1000 mm is the best option for most wells, both water-bearing and technological, those that have to be descended into quite often. A smaller diameter will be inconvenient when operating the mine. For inspection purposes, for example, in storm sewers, smaller diameters may well be used. True, a lot depends on the performance of the system in this particular area.

How are storm drains planned and calculated?

Stormwater is a rather complex “organism”. And in order for it to work as its owners expect, it is necessary to carefully calculate each of its sections: from areas and points of rainwater collection, to storage collectors or discharge to filtration fields. An approximate diagram, main elements and bridles and methods for calculating storm sewers are in a special publication on our portal.

Additional elements for plastic rings

Almost all companies that produce plastic rings and pipes for constructing or repairing wells also produce additional elements for them. So that you can immediately purchase a complete set with a unified system for pairing and sealing parts.

It is clear that the specification of parts may vary depending on the material of manufacture and model.

Here, for example, is what is included in the main set of parts for a polymer-sand typesetting model:

Polymer-sand kit for arranging a well, which, if necessary, can be supplemented with the required number of rings to achieve the required depth (shaft height).

1 - The sewer manhole (the manhole itself + the ring) for plastic wells can be made of the same polymer. As a rule, the dimensions of the hatch ring are standardized, that is, in fact, even an old cast-iron kit can be used. But there’s no point in loading the well with extra weight - plastic hatches are even more practically and completely safe. It consists of two elements - a ring and a lid.

Plastic sewer manhole - this size standard fits most manhole sets.

2 — The passage under the hatch is often given a conical shape, which is ideal for draining rainwater from the shaft and for constructing a clay castle.

By the way, the transition to the hatch can be of a different type - with an elongated neck, which allows you to place the well (chamber) deeper from the ground surface and narrow the entrance to it. Such measures are often very justified to protect the well from freezing in winter.

The illustration shows a telescopic extension that allows you to precisely adjust the installation height of the hatch.

Such an extension often has a telescopic design, which allows you to set the desired height of the neck, that is, accurately adjust the position of the hatch. It is very convenient during installation - you don’t have to be afraid to make a small error when installing the main structure - you still have the opportunity to position the hatch unnoticeably, flush with the ground surface.

3 — The rings that make up the well shaft. They can have different heights, depending on the material of manufacture. The walls of rings or a solid pipe can be smooth, have stiffening ribs or corrugated relief, sometimes they have ready-made or marked windows for pipe entry that require subsequent cutting. The number and type of rings are selected depending on the required depth and purpose of the well.

4 — The bottom can have different configurations. For example, for sewer wells, various tray options are produced, equipped with several pipe connections. The number, location and diameter of the nozzle may vary. Often, no pipes are used, but only designated areas for cutting out windows, if necessary (by analogy with rings).

Plastic kit for sewer well "Rodlex". The bottom section allows for hermetic insertion of pipes of various diameters.

For some wells, say, for cesspools, for the first (first and second in a three-chamber scheme) chambers of septic tanks, storage tanks, as well as for caissons, solid flat round bottoms are used. And individual hydraulic structures (water-bearing wells or drainage wells, with a filter layer at the bottom) are equipped without any bottom at all.

The diagrams also show O-rings here and there. But these elements are not used in all models, so they may not be included in the kit. And in such cases, other approaches to sealing are used.

Basic methods of connecting polymer well rings

When installing a well shaft from individual polymer rings, several methods are used to connect and seal them

| Illustration | Brief description of the essence of the technology |

| The tongue-and-groove system is the easiest way to connect rings together. But it is successfully used with polymer-sand rings, which still have a certain massiveness, which is necessary for such installation. The scheme is simple - there is a tenon at the lower end of the ring, and a counter groove along the upper edge. That is, everything is elementary - the tenon of the upper next one is inserted into the groove of the installed and aligned lower structural element. If it is necessary to create a guaranteed tightness, for example, in a storage or aquifer well, or in the primary chamber of a septic tank, before installing the next ring, the groove of the lower element is filled with mounting sealant. This, by the way, will add strength to any well, even one that does not require complete sealing. | |

| Threaded connections of parts, from the bottom to the neck and hatch, are provided, for example, in Rodlex systems, as well as in products from other manufacturers. The first lower ring is screwed into the bottom element, then the next ring is mounted into it in the same way, etc. After assembling the shaft, it is closed with a hatch that is screwed into the upper ring. Silicone seals are pre-installed into all connecting nodes. | |

| Bell connection - when a slightly narrowed end of a part is inserted into a slightly widened edge (bell) of the mating element, where the sealing collar is usually located. The principle is the same as that used when installing sewer pipes, only the diameters are larger. The illustration shows a sewer inspection well assembled using the socket principle. | |

| Extruder welding is used to connect rings made of low-density polyethylene or polypropylene. It is carried out from the inside of the structure after completing the installation of parts in the prepared pit. Sometimes welding is also used in a system where the rings are connected with a threaded connection - to give the structure a higher tightness. The work is carried out using a special device - an extruder, which allows you to fill the gaps between parts with a polymer melt. |

Another approach can be used to diffuse welding of polypropylene rings to form a well shaft - using special equipment that ensures the melting of the edges of the parts and their subsequent precise coaxial compression. But such work is carried out before the installation of the well itself, that is, in fact, the customer receives not the rings, but a finished liner, so this is somewhat beyond the scope of our consideration today.

Polymer liners for concrete wells and chambers are an effective solution to old problems!

Reinforced concrete rings are a very convenient material for the construction of wells or local treatment facilities. But they also have certain vulnerable spots that require special attention - aging and erosion of concrete, leakage at the seams between the rings. how to solve these problems using plastic inserts in concrete wells in a special publication on our portal.

Comparative characteristics of plastic products

Having made a choice in favor of plastic pipe products when building a well or well, it is necessary to take into account that different polymers have specific properties. In particular:

- the density of HDPE pipes is 0.94/0.96, and that of uPVC products is 1.4 g/cm³;

- permissible design stress: for HDPE pipes this figure is 50/63 MPa, for uPVC pipes it is twice as much - 100/125 MPa;

- the elastic modulus for HDPE is 900, PVC-U – 3000;

- tensile yield strength of the polymer: HDPE 20/30 MPa, PVC-U – 50/56.

The uPVC pipe for a well has the following technological advantages:

- due to their higher yield strength, they are more suitable for threaded connections. PVC-U products with a diameter of 125 millimeters have a seven-fold safety margin when installed at a depth of 30 meters. Such a pipe can withstand a load of up to 5 tons.

- PVC-U products are characterized by better hydraulic properties, since their rigidity is as close as possible to the value of this indicator for metal pipe products.

The recommended scope of application for HDPE pipes is the construction of wells up to 3 meters deep. PVC-U products are better suited for wells. When purchasing, pay attention not only to the diameter, but also to the material of manufacture indicated in the passport. There have been cases when HDPE products were issued for PVC-U pipes.

Total: turnkey well

The cost of a new well or its reconstruction is affected by:

- the price of the pipes themselves, depending on the diameter, height and stiffness coefficient;

- delivery of plastic pipes to the site;

- price and quantity of moisture-resistant sealant for connecting ring joints;

- payment for work: 1) for digging a well shaft using the open method; 2) by digging to the depth of one ring with subsequent insertion using the closed lowering method; 3) for cleaning the water intake concrete column before installing a stocking when restoring an old well;

- price of water pump, water hose, filters;

- the cost of dismantling and/or installing pumps and additional filters;

- electrician services and additional materials for connecting the pump to the network;

- bottom filter cost;

- payment for cleaning the shaft and pumping the well upon completion of all work.

Work on digging or restoring a well can be carried out at any time of the year, avoiding the period of snow melting. In wetlands, preference should be given to the autumn-winter period.

How the Abyssinian well works ↑

The construction of an Abyssinian well is not difficult: the soil is drilled with a small diameter pipe (2-2.5 cm) until the first aquifer is reached (about 10 m). To speed up the process, the projectile is equipped with a pointed tip - the so-called needle.

Diagram of the Abyssinian well

Initially, water was pumped out using hand pumps; now special automated pumps are installed in Abyssinian wells.

Important! Is it possible to drink water from an Abyssinian well? The liquid in the well undergoes natural purification with sand and soil, so the likelihood of harmful impurities getting in is minimal. Nevertheless, it is necessary to install bottom filters, protect the well mouth from debris, and be sure to check the chemical composition of the water.