- Do-it-yourself grinding grinder: drawings with dimensions of components and assembly algorithm

- Do-it-yourself belt sanding machine: operating principle

- Grinder design features

- How to make a grinder with your own hands: assembly rules

- Do-it-yourself grinding grinder: drawings with dimensions of structural elements

- Do-it-yourself homemade grinder grinder: choosing a suitable drive

- Features of making a grinder from a washing machine with your own hands

- Making grinder rollers with your own hands: drawings

- Characteristics that a sanding machine belt must meet

- How to glue sanding grinder tape yourself

- Homemade grinder: drawings with turntable dimensions and assembly tips

- Do-it-yourself grinding grinder at home from a drill: assembly features

- Do-it-yourself grinder at home: video and instructions for assembling from an angle grinder

- Video: how to make a grinder with your own hands

Do-it-yourself grinding grinder: drawings with dimensions of components and assembly algorithm

A grinder is a grinding machine that has an electric drive and an abrasive coated belt. This machine is used for finishing metal, wood, and polymer surfaces. The main thing you need to pay attention to when assembling a grinding grinder with your own hands is the choice of suitable materials.

The grinder allows you to grind products made of wood, plastic, metal, as well as process any surface.

What is a grinder and what is it intended for?

The word "Grinder" is of English origin and literally reads as crusher. In technical terms, this term is used to refer to a grinding device. So one could simply call this unit a sander, but then there would be confusion with manual sanders, which have a slightly different design. A grinder is a stationary unit with an electric drive.

Otherwise, its design is very similar to a manual sander and is based on a rotating pulley with a strip of abrasive paper

What is a grinder used for? First of all, it is a mechanism for sharpening home cutting tools. With a certain skill, you can perfectly sharpen kitchen knives or scissors, wood cutters. In addition, craftsmen grind wooden parts, stone and metal parts using a stationary machine. The grinder will help you level the edge of glass, fiberboard or MDF.

With the help of a blade, it is easy to clean metal from paint and rust.

Professional machines are not cheap - from 30,000 rubles, so the question of how to make a homemade grinder with your own hands is hotly discussed on many forums.

Do-it-yourself belt sanding machine: operating principle

A distinctive feature of this device is that it has a simple design that anyone can replicate at home. This grinding unit includes an electric motor, rollers and the working tool itself – a belt with an abrasive coating. The strip may have different grain sizes. This indicator is selected in accordance with the purpose of the instrument.

The grinder, unlike the usual stationary machine, is a more versatile tool.

When assembling a grinder with your own hands at home, you should prepare and study the principle of its operation. When the unit is turned on, the engine starts. It has a shaft that connects to the main (drive) roller. The roller begins to rotate around its axis, acting through the abrasive belt on the secondary (driven) rollers.

Sanding is quite simple when the device is turned on. To do this, you need to attach the workpiece to a moving abrasive belt. During work, you need to focus on the position of the working strip.

A self-made grinding machine will allow you to process workpieces made of different materials. Such a unit has the ability to eliminate defects on the surface of metal, wood, and glass. Using grinders, rollers are often adjusted, which makes it possible to process defects of different depths.

It is worth remembering that with prolonged use, the sanding strip wears out, which leads to its stretching. In such units this problem is solved very simply. One of the device's rollers contains a special mechanism that allows you to tension the tape. Most often, such a device is installed on a roller located between the main and secondary roller of the device.

A grinder can easily remove rust from the surface and sharpen a knife.

Consumables and parts

The only consumable material for a belt grinder is a tape (not counting grease for bearings and hinges. The tape can be ordered to the desired length (see at the end), but you can also make it yourself from textile-based emery cloth. It is highly desirable - flexible, unimpregnated. In general The procedure for making a grinder belt with your own hands is as follows:

- We cut the workpiece - a strip of the required length and width.

- We prepare a mandrel (not necessarily round) with a length along the generatrix slightly less than the length of the tape.

- We outline the mandrel with the workpiece inside out.

- We bring the ends of the workpiece exactly end to end and securely fasten them.

- Place a piece of glue stick for a hot glue gun on the joint.

- Heat with a construction hairdryer until the glue melts.

- We apply a patch of thin fabric to the joint.

- Press with something hard through the Teflon film until the glue hardens.

Read also: Repair of microwave ovens

There are three significant points here. The first is to use a rough PET film with a thickness of 25-50 microns (sold) instead of fabric for the patch. It is very durable, but just try running your finger across a PET bottle. Not very slippery? Rough PET film cannot be stretched under tension even over polished metal. And instead of a patch, it is better to seal the back of the tape with a continuous strip of PET film with an overlap of 2-3 cm. The runout of the tape will be no more than 0.05-0.1 mm. This is less than from the thinnest calico and even less than the error in the thickness of the blank skin.

Second, insert the finished tape into the machine and grind something indecent with it without strong pressure. The scar on the seam will be sealed, and the tape will become no worse than the branded one.

But the most important thing is that in terms of elasticity, the best adhesive for gluing grinder tape is not expensive and difficult to use, thermal or assembly, but ordinary PVA. If the tape is covered with a lining along the entire length of the back, then its PVA strength will be more than enough. How to glue PVA grinder tape, see video

Video: gluing grinder tape with PVA glue

The generatrix (side surface in cross-section) of the grinder drive pulley must be straight. If you use a barrel pulley, the belt will bend like a trough along its entire length. The rollers prevent it from slipping, see below, but the generatrix of the pulley must be straight.

A pulley for a grinder that is not intended for particularly precise work, firstly, does not have to be turned. In a scheme with 3 rocker arms, the beating of the belt from its misalignment will go out on the rollers before it reaches the working branch. In a simple vertical grinder, the beating of the belt will be sufficiently damped by the tension spring. Therefore, it is quite possible to make a pulley for a grinder without a machine, see video:

Video: drive wheel on a grinder without a lathe

Secondly, the pulley, rollers and, in general, all the parts of a home grinder can be made from plywood. In production, this is certainly not an option, even if a plywood grinder is offered for free with an additional payment: the grinder needs a salary, and the wooden grinder in the workshop will completely wear out before it pays for it and itself. But you won’t be running a grinder at home every day in 3 shifts. And no tape slips along the plywood pulley. Incl. homemade. So you can safely make a grinder pulley from plywood:

Video: pulley for grinder made of plywood

Table for calculating the speed of the grinder belt based on the diameter of the pulley and motor speed

Fortunately, for most abrasive-material pairs, the permissible belt speed limits are quite wide, so choosing a pulley for the grinder can be easier:

Video: what wheel is needed for a belt grinder

Rollers

The rollers of the grinder, oddly enough at first glance, are its most important parts. It is the rollers that keep the tape from slipping and ensure its uniform tension across the width. Moreover, there can be only one video in kinematics, see, for example, the video above about the grinder for incisors. Only barrel rollers can cope with this task, see below. But the “trough” of the belt after any roller must straighten before it reaches the working area.

Rollers with flanges (sides, edges) will not hold the tape. The issue here is not only and not so much with the misalignment of the roller axes: the grinder belt, unlike the drive belt, must withstand the loads from the parts being processed without slipping. If you make videos with flanges, then if you barely touch the tape with something, it will creep onto the flange. In the grinder you need to use Type 3 barrel rollers (highlighted in red on the left in the figure).

What should the grinder videos be like?

The dimensions of Type 3 rollers are also given there. It is advisable to take the diameter of the rollers no more than 0.5 of the width of the tape (so that the “trough” does not go far), but not less than 20 mm for turned steel and not less than 35-40 mm for plywood. The tension roller (the probability of the tape slipping from it is greatest), if the working branch of the tape does not come off it, can have a diameter of 0.7-1.2 its width. Plywood rollers are made in the form of a thick shell into which the bearing is pressed; then the roller is mounted on the axle (in the center in the figure) and processed cleanly, see e.g. track. video:

Video: barrel roller for grinder

Not every turner can turn a profile roller barrel exactly according to GOST even on a machine. Meanwhile, there is a way to make videos for the grinder without significant difficulties. The same PVC-reinforced garden hose will help out, on the right in Fig. previously. A section of it is pulled tightly onto a roller blank with a straight generatrix and cut off with a margin along the edges to the thickness of the hose wall. The result is a roller with a complex profile of the generatrix, which holds the tape even better and gives it a smaller “trough”. Don't believe me? Try to get to an airplane or missile graveyard and dig around in them. You will find rollers with exactly the same generatrix profile. It’s just that mass production of complex profile rollers is much more expensive than Type 3 barrels.

Grinder design features

It is recommended to take into account all the design nuances of factory devices. This will allow us to produce the most efficient tabletop grinding machine. The standard equipment of this type of device includes a support table. In addition to its main purpose, this surface performs another auxiliary function: it is used to fix the workpiece being processed.

In factory devices, such a table can be rotated about one axis. The rotation angle is usually 90°. This makes it possible to grind two planes of the workpiece (located perpendicularly) without changing the position of the part fixed on the rotating surface. When assembling a simple grinder with your own hands, you can make a static table. This will greatly simplify assembly, but the finished unit will have less functionality.

There are other, equally important parts that are included in the design of such machines. Let's consider what other structural elements any grinder used for grinding workpieces made of different materials must have:

- skating rinks;

- base;

The main task in making a grinder is to find a powerful motor that will need to be equipped with a drive.

- ribbon;

- tension mechanism;

- protective wall.

All these parts are quite easy to make with your own hands. The belt sander may produce dust or sparks during operation. This depends on the material of the part processed on such a machine. Because of this, experienced professionals strongly recommend using special glasses. In addition, it is recommended to organize a protective wall, for the manufacture of which acrylic glass is used.

Portable units are equipped with a housing made of steel. The grinder stand must have holes that are necessary to fix the machine on a wooden surface (using bolts). When choosing a tape, it is worth considering that its length depends on the power of the unit (and vice versa). The higher this indicator, the correspondingly more powerful the drive should be.

Schematic diagram of the grinder design and the principle of its operation

As we have already said, the design of the grinder resembles a simple device of a manual grinder. The movement of the sanding belt is carried out using rollers, and they are rotated by an electric motor. To ensure that the tape is tensioned without sagging, there is a tension mechanism that moves one of the rollers. The difference from a manual unit is only in the presence of a device that fixes the workpiece. It is a table with a rotating mechanism and reliable latches. The table can be rotated to process parts from different angles.

To ensure safety measures when working with a rotating mechanism, the grinder is equipped with an acrylic screen.

LSM design

The entire mechanism is connected to the universal machine using reliable fasteners. Factory-produced models are, without a doubt, quite powerful and give the impression of ease of control. But home craftsmen complain about the unreliability of standard fasteners and the excessive length of the tape, which requires a high-power motor. So, not only because of the high cost, but also for purely practical reasons, many decide to make a belt grinder with their own hands. This work is not as difficult as it seems at first glance, and you can also use used spare parts from other mechanisms.

How to make a grinder with your own hands: assembly rules

Before you start independently constructing a grinding unit of this type, you must carefully study the sequence of actions and also take into account some rules. The first and most important step is preparing to assemble the grinder. Let's consider what actions this item includes.

A drawing with the dimensions of the grinder is an important document on which the performance and technical characteristics of the unit will depend.

The first step is to draw up a suitable drawing. It should be remembered that the circuit must correspond to specific operating conditions. You can draw up the drawing yourself. The second option is to download the finished circuit from the Internet. On specialized websites and forums you can find many modifications of such devices, the design of which is most suitable for home assembly.

The more detailed the drawing, the better. The diagram must contain a detailed description of all individual structural elements with their dimensions. A drawing with dimensions is a very important document on which the performance and technical characteristics of the future machine will depend. Therefore, it is worth approaching its preparation with all seriousness.

You can make different versions of grinding grinders yourself. In addition to stationary devices, there are also simpler types (for example, a do-it-yourself grinder made from an angle grinder). A drawing and video for assembling such a device can also be easily found on the World Wide Web.

The next point worth considering is preparing all the necessary parts and tools for assembling the unit.

To construct a grinder at home, you will need the following equipment:

- jigsaw;

In order to make a grinder, you need to understand the principle of operation of the machine.

- drill;

- Bulgarian.

On a note! When selecting tools, it is necessary to take into account that the design of the grinder involves the use of metal parts, as well as their processing.

Many parts of this grinding equipment are difficult to make for a beginner. Therefore, it is recommended to study in detail the various structural elements and their features. It also wouldn’t hurt to look at the drawings and videos. Making a grinder with your own hands is much easier if you have the opportunity to consult with a qualified craftsman who can give valuable recommendations on this issue.

Some structural elements cannot be created with your own hands without the use of turning equipment. You don't have to do this kind of work yourself. To perform complex parts, you can use the services of a professional turner.

When making a grinder with your own hands, it is advisable to take into account one more important point. The most effective are devices that can be used to process not only horizontal, but also vertical surfaces. Experts recommend choosing a drawing that allows you to grind workpieces at different angles.

You can make different versions of grinding grinders with your own hands.

Assembly of the finished structure

Further operation of the structure depends entirely on the quality of the assembly of the machine (mini-grinder) with your own hands. In his work, the master must take into account absolutely all the details, the smallest details and subtleties of assembly. Instructions on how to make a grinder with your own hands at home:

The first to install is the frame on which the belt for sanding parts and surfaces will be located. Most often, this is a metal plate that can withstand significant loads (vibration, mechanical stability).

Two rollers are attached to the side surface of the frame: a guide roller and a drive roller. One of them should be significantly larger in diameter, which makes the rotation of the belt more efficient.

Along the side contour of the frame, it is necessary to make a bed for the drive: this is a small platform that reliably holds the motor while the sanding belt moves. Most often, the platform is made of metal, complemented by sides and internal rubber gaskets, which reduce the degree of vibration.

Connect the drive to the drive roller, check the speed and quality of rotation of both rollers (if there are gross defects, they can be eliminated at this stage).

Working with sanding most materials involves the risk of damaging the eyes and skin of the hands, so be sure to install a protective screen (most often made of acrylic). The master will be helped by ready-made drawings with the dimensions of the grinder for doing it yourself.

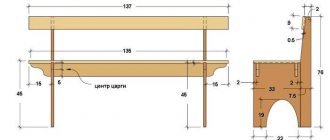

Do-it-yourself grinding grinder: drawings with dimensions of structural elements

The development of an appropriate scheme is the most important preparatory stage. The drawing can be ordered from a qualified craftsman. In this case, it will be as accurate as possible and will allow us to produce equipment that will last for many years.

How to make a grinder with your own hands? Drawings, videos, as well as photos of grinders at various stages of assembly - all this makes it possible to independently produce a high-quality unit.

The second option is to download the diagram from the World Wide Web. In this case, it is worth knowing that some drawings located on the Internet are not effective. Therefore, before downloading this or that diagram, it is recommended to read the reviews of real people who have already used it to assemble belt grinding equipment.

It is also recommended to compare the diagram drawn up yourself with other drawings with the dimensions of the grinder yourself. Videos with relevant topics allow you to quickly understand all the nuances of manufacturing such a unit. There are a huge number of them on the Internet.

In order for the machine to serve for a long time, you need to order a drawing of the grinder from a qualified craftsman.

The diagram must be accurate and contain sketches of all structural elements of the structure. The dimensions of individual parts must be indicated. And finally, you can post the finished diagram on a specialized forum and ask what inaccuracies it contains. It is possible that in this case it will be possible to obtain valuable advice on its improvement.

Do-it-yourself homemade grinder grinder: choosing a suitable drive

Before you begin assembling such a grinding unit, you need to prepare a suitable motor. Most often, a drive with a power of at least 1 kW is used for these purposes. There are several factors to consider when choosing an engine. Let's look at them in more detail.

First of all, you need to understand that devices that operate on a standard network are suitable for use at home. The voltage in such a network is traditionally 220 V. Higher voltage is necessary for the use of professional equipment, which is found in small enterprises, but not for a home-made device. The grinder grinder must be created in accordance with a pre-prepared drawing.

Another important point is the number of drive revolutions. The accuracy of workpiece processing depends on this parameter. A certain pattern can be traced here. The higher the engine power, the more revolutions it can produce.

For a grinder, a drive with a power of at least 1 kW is most often used.

The most suitable drive option includes special blades in its design. Their function is to neutralize overheating that occurs during engine operation. It is easy to make such a device yourself in a home workshop.

Most often, a simple motor from a washing machine is used to assemble such grinding equipment. A do-it-yourself grinder of this type fully meets all operational requirements and is used for processing small workpieces made of metal, wood, and plastic.

An example of a well-thought-out mechanism is the grinder from Chapai

The brand “from Chapay” is a universal tool due to its competent and practically thought-out device and design

Chapaev machines are capable of processing wood, metal, plastic, and stone. They are ordered by people who need constant use of this tool and its special settings. Such grinders are an example of homemade devices with high productivity. Here is a short overview of one such model:

view grinder Chapay

Features of making a grinder from a washing machine with your own hands

The engine power is selected depending on the size of other structural elements. First of all, this concerns the dimensions of the main (drive) pulley. If the size of this element is the standard 150 mm, then you need an engine with power that can produce up to 3000 rpm.

Of course, you can purchase a ready-made engine, but this will cost extra money. The best option for assembly at home is to use an unnecessary motor from a washing machine. The grinder, which is based on such a device, is certainly not able to compare with the factory one, but it is quite suitable for simple everyday work.

To make a grinder, you can use a regular commutator motor from an old washing machine.

The motor, removed from an old automatic washing machine, has low power (below 300 W). It is distinguished by good reliability and is unpretentious in operation. The popularity of using just such a drive is due to its wide distribution.

The drive from the washing machine must be included in the preliminary drawing. A do-it-yourself grinder at home requires a motor with an output shaft. In this case, the shaft has a threaded connection, the design of which allows it to be connected to the pulley without much difficulty.

On a note! For assembling grinding units, engines not only from old automatic machines are suitable, but also new generation drives. When using devices of the second type, you must remember that they need a device that will regulate the speed. This is due to the fact that the maximum rotation speed of such drives can reach up to 18 thousand rpm.

New generation drives have one significant drawback. With the active use of grinding equipment, quite rapid wear of the motor brushes occurs.

The grinder, which is based on a motor from a washing machine, cannot compare with the factory unit.

When constructing a grinder with your own hands from a washing machine engine, you must also take into account that such a drive is best suited for a small unit. Therefore, it is worth choosing in advance the optimal dimensions of the leading and secondary rollers.

Making grinder rollers with your own hands: drawings

Designing rollers for a grinding unit of this type is a serious step that requires care and precision. One of the most important elements of a grinder is the main skating rink. It must be remembered that its dimensions must be larger than the dimensions of the remaining rollers.

It is no coincidence that the leading roller has similar geometric parameters. Such dimensions allow you to avoid unwanted jerk that occurs during the starting moment. It is also important to understand that for the manufacture of this structural element, in no case should you use materials that have a large mass. Such materials include:

- steel;

- cast iron.

Before you start creating the rollers, you need to prepare the appropriate drawings with dimensions. A do-it-yourself belt grinder should have light and convenient rollers of small dimensions. As a rule, this is quite enough to carry out simple sanding work.

When assembling the grinder yourself, it is important to place the rollers perpendicular to each other to avoid belt distortions.

To reduce the weight of the drive roller, a steel part with a cavity can be designed. There are special reference books that allow you to carry out the calculations necessary for this procedure.

The second option, which is most often used by home craftsmen, is the use of duralumin. This material is lightweight and ideal for this purpose. It contains impurities of copper and magnesium, which provide increased strength to the alloy. To assemble the grinder, it is customary to use duralumin grade D16 and higher.

How to make grinder rollers with your own hands? Experts recommend making a groove on the pulley located at the end. Its dimensions are selected taking into account the size of the abrasive belt that will be used in the machine. This measure is aimed at preventing the tape from falling off during equipment operation. It is advisable to do the same manipulation with the remaining rollers.

The degree of roughness of the rollers is very important. The surface of the rollers may have different levels of roughness. When assembling a grinder, it is recommended to use rollers in which this indicator ranges from 1.25 to 2.5. A table containing information on the degree of roughness of parts can be easily found on the Internet. The pulley for the grinder is mounted on the equipment with your own hands using bearing units.

Duralumin is often used to make grinder rollers.

In this case, closed type bearings are used, which have a static outer ring and are classified as self-aligning. Installing such elements eliminates the possibility of abrasive or any other foreign particles getting onto the roller shaft.

When choosing bearings, it is necessary to take into account their load-bearing parameters. These indicators determine how much load the part can withstand. The higher the unit speed, the more reliable the bearings should be. During work, it is not recommended to deviate from the dimensional drawings. A belt grinder made in accordance with the scheme will be characterized by higher efficiency, as well as a long service life.

How to fix the video in the device? The easiest way to secure the roller at home is to use standard cotter pins. Another fastening option is to use a collar (at one end of the axle).

Manufacturing process

For the manufacture of power parts of the machine, it is necessary to use sheet metal 10 mm thick. To draw the contours of such parts for their further cutting, you can refer to the drawing. There is no need to follow the dimensions exactly, since only the dimensions of the parts that you are going to process on the belt grinder will depend on them. You can draw the outlines of the parts on a sheet of metal with a marker, and use a grinder and a jigsaw to cut them out. It is much easier to cut out such parts using a plasma cutter, but not everyone has such equipment at home.

Read also: DIY branch chopper for heating drawings

Base, machine body parts and engine before assembly

To make the base of your homemade grinder more reliable, it is better to use a 12 mm thick sheet of metal for its manufacture. You can use screw connections to assemble the grinder base, but then you will have to drill a lot of holes, which will significantly weaken the entire structure. It will be much easier and more reliable to assemble the base of your machine using electric welding.

The semicircular grooves on the parts of the belt grinder, which ensure the rotation of the platform on which the rollers are placed, will require a lot of time. To make such grooves yourself, you will need to tinker with a drill, cutters and a file, and also use a drill. You can make your task much easier if you entrust the making of such grooves to a qualified milling machine operator.

Model of the machine made of plastic: thanks to the rotating unit, the grinder can be in a vertical position...

To make the rollers of your homemade mini-machine, it is best to use titanium or duralumin (D16). If it is not possible to find blanks made from these materials, then steel can also be used, but then the rollers must be made as light as possible by choosing metal from their inner part. To make rollers for a homemade machine, you will need the help of a qualified turner, just make sure to prepare a drawing for it.

In any case, the largest roller of the belt grinder, which will be fixed on the electric motor shaft, will need to be made of steel, since a titanium blank of this diameter is very difficult to find, and duralumin may not withstand significant loads. For the entire homemade machine, you will need to make 4 rollers, the dimensions (diameter) of which are: drive roller - 150 mm, tension roller - 100 mm, two small ones - 70 mm. If you are going to make a mini-machine, then the diameters of the rollers may be smaller.

...as well as horizontally

When you assemble your homemade machine with ready-made rollers, it is very important that they are positioned strictly in one line. Otherwise, you will constantly experience tape jumping off.

The width of the rollers depends on what size sanding belt you intend to use on your equipment. When you make a drawing for the manufacture of rollers, be sure to keep in mind that they must be barrel-shaped, this will ensure that the sanding belt is securely held on them during operation. In order to give the rollers this shape, a small bevel is made from each edge: 1–2 mm.

The finished rollers of your homemade belt grinder should have a smooth surface; you need to tell the turner who will make them about this. The bearings on which they will rotate must only be of the closed type, otherwise they will quickly become clogged with dust generated during the operation of the grinding machine. In order for your homemade equipment to work for a long time and without failures, you must choose bearings for it that have a class of at least 6. The rollers of the grinding machine rotate at high speed, so the bearings for them must be of very high quality.

Ready-made grinder in a horizontal position with an additional table

Characteristics that a sanding machine belt must meet

Selecting an abrasive strip is an important step when assembling a mini-grinder with your own hands. First of all, you need to decide on the length of the tape and its width. The geometric parameters of the strip are influenced by two main factors:

- grinder dimensions;

- purpose of the unit.

The fabric base better withstands surface tension.

Endless abrasive strips are also classified into grit types. The length of the sanding strips can be different (from 610 to 1830 mm). Such tapes have a width of 50 or 100 mm. The first option is most often found in units assembled by hand at home.

A high-quality abrasive strip must have an elastic fabric base. When choosing the right tool, you also need to pay attention to how many revolutions the strip can withstand. It is recommended to purchase products that can operate at 1500 rpm. This option is best suited for making a belt grinder with your own hands. The drawing drawn up earlier must contain information about the dimensions of the abrasive strip and its other characteristics.

A good tape must have high abrasive resistance. The wear resistance of the tape depends on this indicator. For homemade machines, it is recommended to use belts whose length is no more than 123 cm. The abrasive strip must not only be resistant to wear, but also have good resistance to high temperatures generated during friction against the workpiece during operation.

It is worth noting that short length tapes are much more susceptible to wear than longer length products. Experts advise paying attention to pictures depicting finished products. Photos of the machines allow us to answer the question of how to make a grinder with your own hands. The design of the device can be significantly simplified if ready-made elements purchased separately are used in its assembly.

The speed and quality of product processing depends on the choice of tape.

And finally, special attention must be paid to the place where the abrasive tape is glued. The junction of the two ends of the strip should be as neat as possible, without any defects or protrusions.

Tape is still better

A belt grinder allows you to do everything a disk grinder can do, and much more. Therefore, next we will focus on how to make a belt sanding machine with your own hands. Amateurs, focusing on industrial designs, sometimes make very intricate grinders, see figure:

Homemade belt sanders

And this is justified: the design and kinematics of the belt grinder are very flexible, which makes it possible to successfully use scrap materials and old scrap metal. You just need to follow 3 principles:

- Do not do as in the second photo from the left: the abrasive side of the tape should only touch the workpiece. Otherwise, the abrasive will eat both the guide rollers and itself. The accuracy and cleanliness of processing during one work operation will be unpredictable;

- The design of the machine must ensure uniform tension of the belt, regardless of the nature of the operation performed;

- The speed of the belt must correspond to the nature of the operation being performed.

Kinematics and design

As mentioned above, there are many designs of grinders. When considering what and how to build a grinder for yourself, it is better to focus on industrial designs designed to be fully mechanized for precise and clean grinding of large-sized profiled parts: once it “sands” the blade of an airplane propeller or wind turbine properly, it can handle any other work.

Read also: Tables of metric threads external and internal

Kinematic diagrams of grinders for the specified purpose are shown in Fig.:

Basic kinematic diagrams of belt grinding machines (grinders)

Pos. A is the most complex and perfect, with three rocker arms. If the length of the tension roller rocker arm is approx. 2 times less than the working one, then by adjusting the tension of the springs, it is possible to achieve uniform tension of the tape when the working rocker moves 20-30 degrees up and down. By tilting the bypass rocker, firstly, the machine is reconfigured for belts of different lengths. Secondly, in the same way you can quickly change the belt tension for different operations. The working branch of the belt can be any, except for the one running from the drive pulley to the tension roller, i.e. A grinder with 3 rocker arms is both horizontal and vertical.

The scheme with one misaligned rocker arm is used quite rarely in industry, because in principle, it does not allow achieving uniform tape tension. However, it gives accuracy that is quite sufficient at home and allows you to build a very good simple grinder.

What's good for what?

Now let's see what is possible to “squeeze” out of this or that circuit from the point of view of an amateur master. And then we’ll try to figure out how to make a grinder belt ourselves and do without custom-made turned parts.

3 rocker arms

Competent amateurs build their grinders exactly according to the scheme with 3 rocker arms, on the left in Fig. below. Not all propeller blades can be ground, but in this case another advantage of this scheme applies: if the grinder is used as a vertical grinder, then the working branch of the belt is elastic. This allows a skilled craftsman, for example, to guide cutting edges and blades with literally micron precision.

Homemade and industrial-made tape grinders

In industrial grinders for home use, the 3-rocker design is also widely used (in the center) for the same reasons. Repeating them yourself in most cases is quite possible. For example, the drawings of the KMG grinder, popular abroad, can be downloaded from the link.

The dimensions are, however, inch - the machine is American. For the drive, in any case, it is possible to use an angle drill-grinder (on the right in the figure, quite suitable in terms of power) with a homemade pulley and rollers, see below.

Note: if you are making a stationary drive, try to get an asynchronous motor at 2-3 speeds from an unusable washing machine with a horizontal tank. Its advantage is low speed. This makes it possible to make a large-diameter drive pulley and thereby eliminate belt slippage. A belt slip during operation is almost certainly a damaged part. Most washing machines with 2-3 speed asynchronous motors for 220 V are Spanish. Shaft power – 600-1000 W. If you come across one, don't forget about the standard phase-shifting capacitor bank.

Coaxial rocker

Amateurs do not make pure grinders with a coaxial rocker arm. A coaxial hinge is a complicated thing; you can’t make an elastic band yourself, and store-bought ones are expensive. Grinders with a coaxial rocker are most often used at home in the version for small precision work from a table, i.e. with a rigidly fixed horizontal rocker arm. But then the need for a rocker arm as such disappears.

An example is a mini grinder, the drawings of which are given in the figure:

Drawings of a mini-grinder for small precision work

Its features are, firstly, an overhead bed for the tape (item 7), which significantly expands the possibilities of use. For example, the plane iron is straightened on this grinder with an angular stop literally by itself. In this case, the grinder works, so to speak, like a self-propelled whetstone (emery block). Having removed the bed, we get a grinder with an elastic band for precise grinding/polishing of rounded small parts. Secondly, the tension shaft (item 12). By clamping it to the groove with nuts, we get a relatively fixed tension of the tape for working with the bed. And after releasing the nuts, we switch the grinder to the gravitational belt tension mode for fine work. Drive - not necessarily through a pulley (pos. 11). You can screw it directly onto the drive shaft shank (item 16) from the drill through the adapter coupling, see above.

A specialized tool grinder (for example, for guiding and straightening turning tools) generally loses any semblance of the original design. A high-speed motor is used for it (200-300 W is enough power). The drive pulley is, accordingly, of small diameter. The bypass pulley, on the contrary, is made larger and heavier for inertia. All this together helps reduce tape runout. The tension roller for the same purpose, plus for greater uniformity of belt tension, is moved further away and spring-loaded with a long, not very strong spring. How to make a grinder for processing incisors, see the video below.

Video: grinder for making cutters

One rocker

In amateur practice, grinders with a misaligned rocker arm are good because they do not require precise parts at all. For example, hinges can be made from card loops. At the same time, the processing accuracy remains sufficient for ordinary amateur requests.

In this case, the original scheme is also modified: the rocker arm is turned 90 degrees, moved up and spring-loaded, on the left in Fig. It turns out to be a simple vertical grinder. And, importantly, it works without problems with homemade non-stretchable tape. A tension spring (in the center) or a compression spring can provide tension to the tape. Its strength is not so important, as long as the tape does not bend excessively during operation. No adjustments are required during use.

How a simple vertical grinder works

How to glue sanding grinder tape yourself

Belt grinders contain a spring, which performs a very important function: it tensions the belt that has sagged due to wear. The belt is changed several times even when processing a small workpiece. This should be remembered.

When assembling a grinder with your own hands from plywood or metal, you can make an abrasive strip yourself. Gluing such tape is a complex undertaking that does not tolerate mistakes. There is a lot of advice on the Internet on how to properly glue tape, but many of them are incorrect.

The gluing process is as follows. First you need to select a fabric-based sanding material. Then you should prepare both ends of the abrasive strip. To do this, they are cleaned. The seam on the strip is made exclusively using the butt method. Experts definitely recommend reinforcing the glued tape from the inside with a thick strip of fabric, which is fixed with a special adhesive composition.

Gluing tape is a complex process that does not tolerate mistakes.

On a note! Under no circumstances should you use Moment glue to glue the tape.

In order to connect the ends of the abrasive strip, you need to purchase a special adhesive composition. The best option is to use elastic glue. There is no point in saving money, since cheap products, as a rule, are not of good quality.

Before gluing, it is necessary to prepare a strip for sanding tape. A do-it-yourself grinder (from scrap materials) needs a reliable abrasive strip, which is difficult to do at home. The process is carried out using a glue stick, which is installed on hot-melt guns. First, the composition is heated. To do this, you can use a regular hairdryer, which is found in every home.

Homemade grinder: drawings with turntable dimensions and assembly tips

At home, you can design both a simple version of the machine and a more functional device. In order to expand the operational capabilities of the unit and ensure ease of operation, a rotary-type support table is manufactured. This surface is installed on the side of the largest pulley.

The drawing of the machine is prepared in accordance with its design features.

The advantages of using a rotary table are obvious. First of all, this will allow you to fix the part in a certain position, which will simplify its processing. When assembling a rotary grinder with your own hands, it is worth considering the possibility of changing the direction of the abrasive strip. The emery must necessarily move in the direction where the working surface was turned.

The table must be equipped with a movable locking element - a bracket. This part must implement the function of rotation relative to a horizontal axis at fixed angles.

Most often, for simple machines created at home, a table made of duralumin is used. A wooden option is also available. The drawing of the machine is prepared in accordance with its design features. The thickness of the surface for the manufacture of which duralumin is used must be at least 15 mm. This is very important as a thinner table may not be able to withstand workloads.

The function of the pressure plane in this case is performed by the frame of the unit. To do this, it is necessary to prepare the frame. It is enough to simply grind one of the surfaces of the frame - the one located near the object stage.

For the manufacture of simple machines created at home, a table made of duralumin is used.

Rotary table device

The rotating attachment for the grinder is rather a luxury, but a nice one. Such a system will greatly expand the functionality of the machine and make it easier to work with complex parts. The purpose of such a rotating mechanism is to change the axis of the working surface, in other words, the plane on which sharpening takes place. Very often you can find a rotary table mechanism like this, not very easy to implement, but understandable.

Rotary beds or grinder tables are not used in many homemade models; this is the prerogative of professional machines designed to solve several problems

As we have already noted, a professional grinding machine is not a cheap pleasure. However, if you professionally want to provide services related to the use of mechanisms, then you will have to consider ready-made options for machines. Such solutions are quite universal and, with proper patience and skill, can pay for themselves. Let's take a brief look at some of the models that are currently popular. Prices for professional and semi-professional units vary from 45,000 rubles to 130,000 rubles.

Grinder "Lefty"

Characteristics: motor – 1.5 kW, belt length – 1250 mm (up to 1600 mm); The model is interesting for its ability to use additional equipment (wheel, contour), which is included in the kit.

Grinder-sharpener “Kraton” BG 14-05

Characteristics: the device is used for sharpening metal tools and wooden parts; power consumption – 2 kW, movement of the sanding cloth – 14 m/s; disc diameter – 150 mm; tape width – 50 mm; Features: rigid cast base, adjustable stops and protective screen.

Grinding machine BISON ZShS-330

Characteristics: machine type - disc-and-belt; circle – 125 mm; speed – 2950 rpm; tape size 762×25 mm; power - 330 W; belt speed – 810 m/min.

Sharpener METABO BS 175

Characteristics: sharpener type - with grinding. tape; circle - 175×25×32 mm; circle diameter - 175 mm; circle thickness - 25 mm; landing diameter -32 mm; speed – 2980 rpm; power - 500 W.

Grinder GRIT GIS 150

Characteristics: rated power consumption - 4 kW; voltage/current type at 50 Hz - 3×400 V(3~); voltage/current type at 60 Hz - 3×440 V(3~); Idle speed at 50 Hz - 3,000 rpm; Idle speed at 60 Hz - 3450 rpm; tape dimensions - 150×2000 mm; weight - 93 kg.

And if you still decide to assemble the grinder yourself, we recommend studying several solutions, including in open Internet sources. The fact is that many ideas were created by their inventors for a specific type of work, which means they may not be suitable for solving your problem. Many grinder parts can be purchased ready-made. For example, rollers can be purchased separately or ordered from professional craftsmen. Don’t forget that the main goal is not so much the ability to save on assembling a particular unit, but to simplify the work and make it as safe as possible.

Do-it-yourself grinding grinder at home from a drill: assembly features

Such a grinding device can be made in a simpler way. Of course, assembling a stationary unit, which is designed to be installed on a table, is the best option, allowing you to grind various parts on an ongoing basis. There are other, less complicated options for creating a do-it-yourself grinding device.

If you wish, you can make your own grinder from a grinder or drill. The drill is an electric tool, so you must follow safety rules when working with such a device.

The need to process metal and wooden workpieces arises quite often in everyday life. Purchasing a factory-made unit for small volumes of work is not the best solution. The easiest way to make a simple grinder is to use a drill.

Most often, improvised materials such as wood, plastic, and plywood are used to assemble such a grinding attachment. Before starting work, it is recommended to prepare a nozzle diagram, which will allow you to make a grinder with your own hands. Videos on this topic are also recommended by experts for viewing, as they cover all the nuances associated with the assembly.

Stationary grinder made from a drill on a wooden base.

It is worth saying that when working with small workpieces made of plastic and wood, this grinding machine performs almost no worse than stationary equipment.

Another advantage of this solution is that modern drill models have a special controller. Its function is to regulate the drive speed. Structural simplicity and high efficiency are reflected in the popularity of this solution.

Do-it-yourself grinder at home: video and instructions for assembling from an angle grinder

In terms of its purpose, a stationary grinder for home use resembles a device made from a drill. Devices based on an angle grinder or, as it is also called, an angle grinder, have their own characteristics. The main distinguishing feature of angle grinders is that their drive has a high rotation speed.

Thus, to make a grinder from an angle grinder, you may need a device that controls drive speed. Angle grinders are often used as electronic files.

For this purpose, there are special belt sanding attachments on sale, namely:

- narrow;

- long.

Grinder constructions are often used for grouting welding seams and sharpening small parts.

Such attachments are quite popular among craftsmen. With their help you can easily process various hard-to-reach places (for example, holes). It’s not difficult to make a grinder from an angle grinder with your own hands. To do this, you need to independently design an abrasive attachment, which is based on a tape of the required size. However, it is much easier to purchase a ready-made tool.

The main design difference between an angle grinder and other equipment operating from the mains is the location of the angle grinder’s output shaft. This element is deployed at right angles to the body. As a result, this design is very convenient and helps ensure easy fixation of the drive roller and abrasive cloth.

Thus, such a nozzle is not difficult to do with your own hands. A drawing of a grinder made from an angle grinder can be found on one of the specialized forums dedicated to this topic. This type of tool is quite comfortable to use. The elongated body of the nozzle facilitates various types of grinding work.

Grinders made from an angle grinder often appear in the everyday life of home craftsmen, because the grinder itself is already a mini-machine for grinding.

Making a simple grinder at home is not a difficult task if you approach the matter competently. Of course, you can design more functional equipment with your own hands, but such work requires more time, materials and effort. The choice of a suitable drawing must be made based on individual needs.

Do-it-yourself vibrating plate: (read more)

How to make a belt sander

Many home craftsmen and professionals are wondering how to make a grinding machine with their own hands. The reason for this question is quite simple: the high cost of serial grinding equipment, which not everyone can pay off if not used regularly. In order to make such equipment, you will need several main components: an electric motor, rollers and a reliable frame. Naturally, drawings of such a device or a photo of it would not be superfluous. Also at the end of the article you can watch videos on assembling a tape machine on your own.

The motor for belt grinding equipment is not difficult to find; it can be removed from an old washing machine. You will have to make the frame yourself; for this you can use a sheet of metal with dimensions 500x180x20 mm. One side of the frame should be cut very evenly, since it will be necessary to attach the platform on which the electric motor will be mounted to it. The platform for the electric motor should also be made of a sheet of metal with dimensions 180x160x10 mm. Such a platform must be secured to the frame very securely using several bolts.

Another version of the bed

The efficiency of a belt sanding machine directly depends on the characteristics of the electric motor that is installed on it. If you are planning to make a grinding machine with your own hands, then an electric motor with a power of 2.5–3 kW, developing about 1500 rpm, is quite suitable for you. In order for the sanding belt to move at a speed of 20 m/s when using such a motor, the drums must have a diameter of about 200 mm. What’s convenient is that if you choose an engine with these characteristics, you won’t need to make a gearbox for your grinding machine.

The drive shaft is connected directly to the electric motor shaft, and the second - driven - must rotate freely on an axis, which is installed in bearing units. In order for the abrasive belt to touch the surface of the workpiece more smoothly, the section of the frame on which the driven shaft is installed should be made with a slight bevel.

You can make shafts for a belt sanding machine from a chipboard with minimal financial costs. Simply cut square blanks of 200x200 mm in size from such a plate, drill central holes in them and place them on the axle with a package with a total thickness of 240 mm. After this, all you have to do is grind the resulting package and make it into a round shaft with a diameter of about 200 mm.

Drawings and detailed analysis of some parts of a machine made of wood.

Wood belt sander (click to enlarge)

In order for the tape to be located strictly in the middle of the shaft, the diameter of its central part should be 2–3 mm larger than at the edges. And to prevent the tape from slipping on the drum, it is necessary to wrap a layer of thin rubber on it, for which you can use an old tire from a bicycle wheel, having previously cut it along its entire length.

The sanding belt for such a machine, the optimal width of which should be 200 mm, is made from ordinary emery cloth. The standard cloth is cut into strips of the required width, and an abrasive tape is already glued from them. It should be borne in mind that the material is glued end-to-end; for this purpose, dense material is placed on the reverse side, which will strengthen the resulting seam. The properties of such a seam are greatly influenced by the glue; it must be of very high quality, then the material will not tear along the seam after a short period of use.

Several more options for manufacturing belt grinding machines can be seen in the video below.

https://youtube.com/watch?v=opM1afRob6o