Types of nozzles

Wood and other surfaces are processed using various types of tools. Grinder attachments are divided according to processing class, degree of hardness and roughness. For example, cutting discs are divided into several categories:

- To work with metal, tools of different diameters and thicknesses are used. Common sizes in diameter range from 110 to 230 mm, and thickness reaches up to 3 mm. The parameters depend on the goals and the strength of the applied load.

- Cutting and grinding of stone materials is carried out with disks of identical sizes, differing in the formation parameters.

- Wood discs are used with extreme caution; if safety precautions are not followed, there is a risk of injury. The best, safest option is to use a fine-toothed tool. The casing of the rotating element of the angle grinder must not be removed. When working on wood, the best option is to use a stationary tool for an angle grinder.

- The diamond blade has gained the most popularity because... used when working with various materials. It is mainly used when working with granite, tiles, stone or concrete. The materials imply the use of different discs for each composition; they differ in the structure of the edges and the presence of slots.

When choosing a cutting disc in a store, it is difficult to determine its intended purpose by its appearance and the location of the edges. In order to choose the right disc, you need to read the purpose on the packaging.

Cost and most common companies

The cost of the instrument varies widely. It depends on the following indicators:

- Brand.

- Size.

- Functionality.

- Processing quality.

- Purpose.

By purchasing a professional diamond blade from a reputable brand, you will be sure that the equipment will not overheat throughout the entire shift. The most common brands are:

- Intertool.

- Matrix.

- Distal.

- Bosch.

The middle class wheel, which was released by Hilti, allows you to process reinforced concrete and concrete. The products of this company have high strength and wear resistance is quite reliable. The domestic brands Sparta, Tsentroinstrument, and ZUBR are of decent quality.

Cost of nozzles

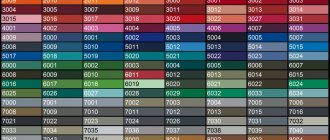

| Name, manufacturer | Type, purpose | Cutting method | Maximum rotation speed | Thickness, mm | Landing diameter, mm | Disc diameter, mm | Price, rubles |

| Special, China | Segmented diamond cutting disc | dry | 6600 | 2,4 | 22,23 | 230 | 825 |

| Hilti DC-D | 12250 | 2 | 125 | 630 | |||

| Jet Norton Granite, Poland | Solid with a wavy turbine edge, cutting reinforced concrete is allowed | 13300 | 2,2 | 115 | 430 | ||

| Metabo, Germany | Solid diamond disc with welded diamond edge | wet | 12200 | 2,15 | 125 | 425 | |

| Keos Professional, South Korea | Segmented, high tooth frequency | Both ways | — | 3,2 | 25,4 | 230 | 9560 |

| Anchor Expert, Russia | Turbocharged, for cutting reinforced concrete | dry | 12900 | 2,2 | 22,23 | 125 | 710 |

| Iterskolar Era, China | With a turbo edge with a diamond concentration of more than 30% | 6600 | 2,5 | 230 | 1140 | ||

| Bosch Best for Concrete, Germany | Diamond wheel for grinding thick layers of concrete | — | — | 4,5 | 125 | 11200 |

Sources

- https://tokar.guru/instrumenty/ushm-bolgarki/almaznyy-disk-dlya-bolgarki-po-betonu-i-zhelezobetonu.html

- https://laminatepol.ru/19524-nasadok-dlya-shlifovki-betona-na-bolgarku.html

- https://obetone.com/oborudovanie-i-instrument/vidy-diskov-po-betonu.html

- https://armatool.ru/vybiraem-almaznyj-disk-dla-bolgarki-po-betonu/

Rough processing

During rough processing, work is carried out with two main attachments - a roughing attachment and a disk plane. Grinder work with this type of disc is carried out with a protective casing, because pieces of wood may fly in different directions. The plane disk is used in cases where roughing is required, preparing fence supports, constructing a log house, etc.

Planer attachment

Peeling attachment for grinder

Requires protection from flying wood chips, glasses, thick clothing, and tough gloves. The use of a protective casing is not necessary, because The disk is all-metal, its destruction is almost impossible. When sanding wood, a grinder is used only with a second handle; work must be done with both hands.

The process of trimming a workpiece, removing the hard top layer of wood, is carried out with a peeling disk. A qualified specialist is able to perform wood sampling using this type of attachment for an angle grinder. An angle grinder can replace a carpenter's ax if a log house is being built.

Safety Recommendations

You need to follow the rule: the larger the rasp disk, the lower the speed. In addition, manufacturers protect the user as much as possible by releasing discs with high (sometimes double) strength. But if the disk is used more than necessary, all these measures become meaningless.

Important tips on what to do:

- working with a protective casing;

- protect your face and head;

- check lumber for nails and screws;

- hold the device firmly by hand;

- use an additional handle (many people hold the device with one hand);

- Do not allow the instrument to heat up, avoiding the risk of smoke.

In addition, if there are no plans for large-scale work with an angle grinder, there is no need to buy a lot of disks “as a reserve” - since the humidity in the air begins to affect the bakelite. The bond strength is noticeably reduced. It is better to get the necessary wood discs for an angle grinder (grinder) immediately before work.

Originally posted 2018-03-28 15:09:01.

Milling

Milling attachments are produced in various designs; a distinctive feature is the size of the abrasive grains. According to their intended purpose during work, such attachments are similar to rasps; the use of an angle grinder allows you to increase the speed of processing the material. Craftsmen use these devices for final processing of wood.

Milling cutter for grinder

Special cutters are produced, there is an abundance of assortment on the market, each tool differs in purpose and features. Main areas of application:

- preliminary alignment of edges;

- sawing or cutting out a bowl from small-section blanks;

- groove sampling.

When working with milling and grinding attachments with a grinder, it is prohibited to remove the protective device - the tool casing. Each tool has a technical purpose and instructions, which clearly describe the materials suitable for use and the operating modes of the tool.

Grinding

The main purpose of the grinder is grinding. For materials processing work, there are grinding wheels, cord brushes, end and flap devices. Cord brushes are used for sanding rough wood, removing irregularities, and giving the workpiece the required dimensions. Processing of the ends of lumber is carried out by using end discs.

Sanding attachment

Polishing

Giving a perfectly smooth surface and shine to wooden workpieces is done by the polishing process. When polishing or grinding with an angle grinder, a varying number of attachments are used, such as felt, fine-grit sandpaper or a sponge. Such designs are widely used in the form of Velcro, on which the base for the grinder is attached. During the process, the used part can be easily changed without using a special key to replace the disk.

Polishing attachment

Sandpaper

The most universal tools for working with wood are sandpaper or a sanding wheel. Main areas of application:

- parquet cycling;

- processing of ends and edges of wood;

- grinding;

- cleaning the wooden surface before painting.

Sandpaper attachment for an angle grinder

The design of the attachment for the grinder is a support that is attached to the grinder; the sandpaper is attached with Velcro on top of the tool. This fastening method allows you to easily replace the used element and select the grain size.

Velcro attachment

The main repurpose of easy-to-remove kits is to polish various materials. The tool can be used when working with stone, metal, wood and other materials. Main parameters, characteristics of the Velcro attachment:

- The basis is taken on a platform, the diameter of which is generally 125 mm, fastening occurs using special Velcro;

- fastening occurs on the mounting platform, which is fixed to the angle grinder;

- The grain size of sandpaper for an angle grinder varies, from coarse, marked p40, to fine, p220.

Velcro attachment

There are varieties with holes, they are adapted for vibratory grinding devices. Before purchasing, you need to pay attention to the diameter and grain size.

Types of discs for grinders

Today the entire range is divided into three main areas:

- Saw blades. They resemble a regular saw, but are made from completely different materials. Until recently, such specimens could not be found, but now they are sold completely freely. The most preferred option is tungsten carbide.

- Diamond coated disc. The most popular variety. In turn, it is divided into solid and segmented. Their scope of application is different, but they have a common feature - high-quality and accurate results of work on concrete, metal or stone.

- Abrasive. Universal consumable, suitable for any type of surface. It cuts, grinds and polishes well.

Of the listed disks, the first and second are not suitable for wood. Natural wood has a very dense structure, and if you use a diamond disc, the grinder will overheat to the point of breaking.

The products also vary in diameter. The most practical ones have a diameter of 125 mm; in rare cases, a compact disk is needed - 115 mm. There are specimens up to 230 mm, but they are not suitable for wood. Their use may cause injury.

Petal nozzle

Wooden surfaces can be easily sanded using flap attachments. The component part has sandpaper superimposed on each other over the entire area of the tool. Due to the dense design and proper use, it is possible to use the kit for a long time, unlike its analogues.

Petal nozzle

The petal attachment on the grinder is used in an increasing manner. At the first stage of processing, a set of coarse abrasive is used, then medium and fine sections.

Metal brushes

Many craftsmen believe that metal brushes are used to remove rust and oxides only from steel products. In refutation of this fact, products made from brass wire are popular in wood processing. The relatively low price and increased service life make the brush a direct competitor to abrasive attachments.

Attachment for an angle grinder in the form of metal brushes

Removing rust using a brush attachment

The main purpose is to remove paint and varnish from the surface of the material. It should be understood that the top layer of paint can be removed by exposure to temperature; a brush is used when working in hard-to-reach places. It is also possible to brush wood using a grinder with a brush. The process involves artificial aging of surfaces in the production of unique interior products. The surface is processed with soft particles of wood, irregularities and temporary rings stand out against the general background.

Rough processing of wood using an angle grinder

However, it is possible to process wooden workpieces using an angle grinder. You just need to use special factory-made attachments and strictly follow safety precautions when working with an angle grinder.

Using an angle grinder as a plane

When roughing logs, for example for building a log house, special plane disks are used. This is a relatively safe way to process wood, subject to operating rules. It is a mechanized replacement for the carpenter's axe.

The nozzle is used without a protective casing, since it cannot be destroyed during operation. It is prohibited to use such a disc with it facing up. When working on a grinder, be sure to install a handle to hold the tool with both hands.

Since during stripping of wood, large chips fly out from the working area, it is necessary to have tight overalls and protect not only your eyes, but also your face. A positive side effect of this tool is that you can easily chop shavings and large sawdust for a home smokehouse.

Roughing discs

To remove bark from logs and give them the shape of a primary workpiece, there are special peeling attachments for angle grinders.

Using such a chain wheel, you can not only strip the trunk of bark and branches, but also give the workpiece the required shape for subsequent processing with a more precise tool. Such a device can easily replace an ax for cutting out a bowl in a log when building wooden log houses.

You can use this disk as a cutting wheel, but the cut will be torn and the loss of wood is too high; the thickness of the cut is several centimeters.

Attachments for processing stone surfaces

Polishing of marble and granite is done with professional-type attachments, which are used only by professionals. The main application is in processing, finishing polishing of marble monuments, the appearance is like a turtle.

Polishing marble with a grinder

It is necessary to carry out work at low speeds, so a grinder with adjustable shaft rotation speed is used. Polishing and processing of stone surfaces is carried out with different grain parameters, from 30 to 2000-3000. There is a special attachment marked BUFF, which allows you to polish products to a perfect shine and get a mirror effect.

What you need to know when working with an angle grinder

Grinder

Grinder is a traumatic hand tool. In order to prevent injury, it is necessary to follow safety rules both before starting work and during the process.

Before starting work

Before you start working with a hand-held electric tool, including an angle grinder, you must:

- A person working with a potentially dangerous tool must be healthy, sober and adequate.

- The employee must be provided with personal protective equipment (overall clothing, gloves, goggles, etc.).

- Check the serviceability of the angle grinder and the attachments used.

During work

A person working with an angle grinder must know the rules for working with this tool, namely:

- The grinder must be held firmly with both hands, while using the special handles that this type of tool is equipped with.

- The electric wire of the angle grinder should be located as far as possible from the rotating part of the angle grinder (from the attachment).

- The person working with the angle grinder should not be in the plane of operation of the attachment.

- It is forbidden to put the tool down until the rotation of the grinder shaft has completely stopped.

- If it is necessary to move the angle grinder, it must be disconnected from the electrical network.

- The attachments may become hot during operation, so do not touch them before they have cooled down.

- When working with an angle grinder, you must be extremely careful in order to prevent a backlash, which can lead to negative consequences.

Backlash

Reverse impact is the most dangerous mode, which is characterized by a sharp throw of the angle grinder towards the working person. The reasons for this situation may be the use of faulty attachments or their jamming in the material being processed.

To avoid kickback, you must:

- Use serviceable attachments designed specifically for this tool.

- Work on complex elements of the structures being processed should be carried out carefully, carefully monitoring the processing process (rough processing, milling, grinding).

- If the attachment is jammed, you need to turn off the grinder and then remove the cutting element.

The main rule, in order to prevent a kickback, will be the first point from the list of safety rules when performing work, this is - you must firmly hold the tool you are using and stand firmly with your feet on a hard and level surface.

What kind of circles are there for cutting wood?

Processing wood with a grinder is a safe process, unlike cutting. The process is very dangerous; the tool is not intended for cutting wood. Soft woods are processed with an angle grinder attachment with extreme caution, because the tool may jam and be torn out of your hands. The cutting process at high speeds implies a high temperature effect on the disc material, as a result of which it can simply shatter into small pieces.

Despite the fact that the grinder is not suitable for cutting wood products, manufacturers offer various cutting discs for use. It is recommended to use the grinder as a stationary station when sawing wood.

Circular saws

Circular saw attachments are dangerous when using an angle grinder. The diameter of the circle must be selected based on the parameters and dimensions of the tool in order to be able to use a protective casing.

Circular saw attachment

There are more expensive modifications of circular nozzles; they have anti-jamming protection. The design has teeth set in different directions, smaller in size, the price of such a device is different, but you should not save on your health.

Chainsaws

The chain type of nozzles has a safer design. The sawing disc, which uses a chain from a chainsaw, eliminates jamming of the tool and reduces the risk of injury during work. The design has a system that allows the main element, which is attached to the angle grinder, to continue rotating, and the chain can remain stationary.

Chain disks come in many different modifications, with the help of which it is possible to carry out gardening work or use it for collecting small firewood. A disk of a chain design can be used instead of a peeling disk for cutting out cups in a log or removing a layer of bark.

Saws with few teeth

Increased safety when working with wood is achieved by using discs with a small number of teeth. Small discs usually have 3 teeth, those with a diameter of more than 180 mm - 4 teeth. This type of cutting disc is used for cutting both along and across the grain of wood. The saw wheel makes it possible to cut grooves and make tenons of various shapes.

Four tooth disc

It should be understood that when working with an angle grinder, you must adhere to technical regulations. There is no need to install larger diameter discs bypassing the protective casing; smaller discs can be used without loss of cutting properties.

Tungsten carbide discs

Tungsten carbide cutting discs have been produced relatively recently and are popular when working with an angle grinder. The universal tool is not equipped with teeth; instead of cutting elements, there are cutouts in the disk. The operation of the tool is most safe when cutting wood; it eliminates jamming when nails or thick rods of wood hit. The appearance is similar to a diamond blade for cutting concrete, the purpose is indicated on the packaging or instructions.

Tungsten Carbide Disc

The price of such a disk is high, but it is justified. It is worth overpaying for a modified tool rather than going broke on the sad consequences of using a regular saw blade.

Disc care and storage

The discs do not require any specific care procedures. The only condition is to remove them from the grinder at the end of the work. It is believed that the quality of the tool is affected by atmospheric humidity - the higher it is, the worse the performance of the attachments will become. This is true, but we must take into account that for a noticeable deterioration in the condition of the disks, they must be stored in poor conditions for a long time.

Typically, nozzles are kept on special stands, where they are not protected from atmospheric air in any way. Organizing high-quality ventilation of the room, or at least regular ventilation of the workshop, will help here. However, most often the nozzles are completely worn off and simply thrown away. If there are several unused disks, it is easier to place them in a plastic bag and thereby cut off the access of airborne moisture to the instrument.

Did the article help you understand discs for angle grinders?

Of course! Not really

The number of varieties of attachments for angle grinders is very large. They differ in certain characteristics:

- Purpose

- Design

- Size

- Manufacturer

When choosing a disk, you should take into account the type of material to be processed, the specifics and volume of the work to be done. More expensive professional attachments are designed for long-term processing of large quantities of parts. For small occasional jobs, inexpensive attachments are usually chosen, which are quite enough to solve small problems.

The purpose and other parameters can be found out from the markings applied to the surface of the disk or supplied as a separate label. When working, you should follow all operating and safety rules, which will increase the service life of the disks and avoid injuries and damage.

Wood sanding attachments

Special attachments have been developed for the grinder, which allow for brushing, peeling, milling, and other work. It is necessary to select the right tool in accordance with the material and type of work. The grinding attachment on the grinder is used depending on the degree of processing of the material; they differ in shape and size.

Peeling attachments

Peeling type attachments are used in most cases to remove the top layer from a surface or paint coating. Various types help to carry out work in accordance with the required technical parameters.

- The end of the product is ground down using an attachment with crumbs and spikes, and an abrasive grinding emery wheel.

- Thanks to a variety of spiked attachments, it is possible to process surfaces of different heights and grind off the required layer.

- Their twisted wire attachments are used for rough cleaning of wooden products and have various modifications.

Sanding wood with an angle grinder

It is important to understand that using coarse wire or peeling attachments for an angle grinder can be unsafe; during operation, it is possible to catch a nail or a thick rod, which will lead to the tool flying out of your hands.

Grinding and polishing attachments

Various surfaces, including wood, are sanded using a special type of attachment. The kit is secured by using a bolt, which is screwed onto the shaft and tightened with the bolt. It is often equipped with a special device that secures it to the drill.

Felt discs are used instead of a wheel for sanding wood; the structure is attached with Velcro, which allows you to replace the used tool without removing the grinder from the shaft. The petal disc has become widespread in wood processing. The name is taken from the shape and location of the processing surfaces.

The use of a grinder or grinder depends on the specific situation. For applying regular paint, a wood sanding attachment for an angle grinder is suitable; deeper processing with an angle grinder is not allowed, because After painting you may notice scratches. A longitudinal belt sander moves in one direction and uses different grits of sandpaper.

Discs for milling and grinding on an angle grinder, purpose and types

The capabilities of angle grinders do not end with cutting, sanding and polishing wood. To expand the range of tool capabilities, manufacturers produce grinder attachments for milling and peeling wood materials. Stripping attachments are designed to remove bark and remove the paint layer from wooden surfaces. Peeling circles are available in different types, and differ in design, shape and purpose.

- With an edge - their main purpose is to remove the top layer of wood, as well as grind the end part of wooden products.

The applied edge made of carbide materials ensures a long service life of the nozzles. After processing wood with such attachments, you will need to additionally grind and polish the surface. - Studded - and they are divided into products with large and small spikes.

Nozzles with small spikes are designed for removing the paint layer from the surface of wood, and with large spikes - for leveling. If a wooden floor has a defect in the form of a different arrangement of boards in height, then sanding discs with large spikes allow you to quickly and effectively smooth the surface - With a working part made of wire or brushes

- such attachments are used not only for processing metal, but also wood. A cup-shaped disc with an angular wire arrangement is used to remove paint layers from large surfaces. A nozzle with an end wire arrangement is used to remove the paint layer in places with limited access, for example, in the grooves of processed wooden structures. Another type of attachment that craftsmen use to work with wood is a brush with a thin wire. Used for finishing roughing of wooden surfaces - A disc plane is an alternative replacement for a conventional manual or electric plane.

The disadvantage of the first option is that it takes a lot of effort and time to complete the work. It is rational to buy an electric planer only when large volumes of work are being carried out to remove the surface layer. Special discs for grinders, replacing electric planers, came to the aid of the home craftsman. The attachment is a massive circle with three flat knives. It is intended for removing bark from a tree, and the end result is achieved very quickly. Dull knives can be sharpened

A special class of attachments for grinders are milling wheels. Special disks, driven by the spindle of the angle grinder, are used for sawing and cutting grooves of different widths. It is also worth noting that the use of milling attachments on an angle grinder is not safe

Every year the number of options for cutter wheels for grinders increases, but you need to work with such attachments with extreme caution. Let's look at the popular options for milling wheels for angle grinders:

- The wheel rim has the appearance of a thickened circle with cone-shaped spikes located on the end part.

Used for making grooves in wooden workpieces. The nozzle has teeth along the base, the main purpose of which is to obtain clean grooves without chips - Serrated toothed disc - used for making shallow rectangular grooves in woodworking materials

- Toothed disc with additional tenons over the entire surface - allows you to make deep grooves in wood workpieces

The production of various attachments for grinders for the purpose of wood processing can significantly expand the functionality of an indispensable tool in the household. The grinder today replaces most hand and electric tools, so every master must have at least one type of this tool.