What is a polymer sewer manhole: dimensions and diameter? How much does a well cover weigh? Cast iron hatch. Let's look at it in detail with tables and examples.

Sewer hatches are special devices designed to protect the sewer system from dirt and debris, as well as from possible damage. One of the popular materials used for the production of hatches is polymer. Structures made using polymers can withstand loads of up to 20 tons. Also, the popularity of the material is ensured by the fact that the manufacturer can produce any size of sewer hatch.

Main functions of a sewer hatch

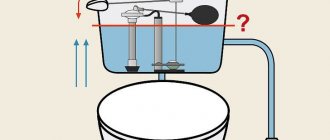

The main purpose of the products is to provide access to utilities laid underground, since sometimes there is a need for their preventive maintenance or repair. Shafts for various purposes, the shafts of which are closed with a lid, provide this opportunity.

In addition, sewer hatches:

- Provide security. A person or a car wheel will not accidentally fall into a closed well.

- They protect against debris and storm water infiltration, thereby increasing the service life of the equipment.

- Prevents the spread of bad odors from wastewater.

- Prevent possible damage and theft of valuable equipment. For this purpose, some types of products are equipped with locks.

It is prohibited to operate wells without hatches . During construction, mines must be closed.

Which shape is suitable?

Not so long ago, only round hatches were in demand, as they were considered universal. They are suitable for septic tanks and other pits that have a hole above the ground of a certain shape. During operation, they show themselves on the positive side. But today there are other models that are actively purchased and used.

Rectangular models are a little less common. Another type is square hatches for wells. You need to initially make just such a neck. They look quite acceptable, and the well itself does not lose its purpose. These are all conditional divisions; experts believe that it is important to rely on where it will be used, since reliability depends on many factors.

Overview of manhole design

The design of the hatch is simple, functional and has not changed for decades. Recent innovations concern the development and installation of different types of locks.

Main details

The hatch has only 2 parts: a mounting rim is installed on the neck, and a cover is installed on top. It has protrusions that coincide with the grooves on the body.

Lids are made mainly:

- round: even incorrectly installed ones will not fall into the inspection shaft;

- with a ribbed surface: improved traction with pedestrian shoes and car wheels;

- flat or convex to prevent water from collecting.

To make opening easier, many modern lids are equipped with a hole through which they can be pryed with a hook. Holes are made only in the covers for sewer, water supply, drainage, and storm wells - water gets inside through them.

With or without lock

Locks are needed on cast iron hatches for several reasons:

- To protect against third-party penetration into wells that provide access to valuable equipment.

- If there is a lock on the cover, it cannot be installed incorrectly. Distortions with a loose fit can cause an accident on the road.

- Protects against theft for the purpose of selling for scrap metal.

Cast iron sewer hatch with a lock.

Locking devices come in several options:

- Flag connection installed between the cover and the rim. Lock with a secret.

- Threaded. The cover is screwed into the body and can get stuck, so this option is unreliable.

- A security bolt connecting both parts.

- A spacer mechanism on the lid that locks the product when closing.

- A crab with 2-6 beams on the hatch to block the entrance.

Access to the manhole with communications and electricity is blocked by 2 covers: protective and locking. The latter is located in the shaft of the shaft, made of steel, equipped with a lock to prevent unauthorized persons from gaining access to the cables.

Heavy products are equipped with simple locks in the form of protrusions that fit into the grooves of the neck. They open with special hooks. Flag, bolt or spacer locks are expensive and are installed on wells of communication and power supply networks that require increased protection.

Sewer hatch with a locking device.

Installation of a polymer-sand hatch on a well

Installing a polymer-sand hatch is quite simple and does not require special skills in the construction field; to carry out the work you will need a hammer drill with a Pobedit and a regular metal drill with a diameter of 10 mm, a small construction level, and a hammer and a wrench from household tools. It is more reliable and easier to attach the rim to nut anchors with a diameter of 10 mm in the amount of 4 - 6 pieces and a length of 80 - 100 mm. Before installation, prepare the base - to do this, level the top of the well with a cement-sand screed, then work is carried out in the following sequence:

1) Using a hammer drill with a metal drill, make 4 - 6 equidistant holes with a diameter of 10 mm in the ring shell.

2) Apply the circle to the well opening, mark with a pencil at the points of the drilled holes; if the hatch ring is heavy, it is easier to lay it, and without removing it, drill the concrete in place.

3) Make holes in the concrete of the well in the perforation mode of the required depth, after which the anchors are driven into them with a hammer.

4) Take a wrench and tighten the anchor nuts tightly.

Rice. 10 Installation of PPL

Plastic hatches for wells, in contrast to their cast iron counterparts, not only have advantages in decorativeness, many physical parameters and chemical characteristics, but also significantly benefit in price - their cost is 5 times lower. Thanks to this, composite products have completely replaced cast iron products from the sphere of domestic use; they are increasingly being used by government organizations.

Marking of hatches: water supply and sewer

To make it easier to select products, the lids are marked. On the outside there are letters with numbers.

The first letters indicate the permissible load on the hatch:

- L - lungs;

- C - average;

- T - heavy.

Further in brackets there is a marking according to GOST, which indicates the maximum load:

- A15 -1.5 t;

- B125 - 12.5 t;

- S250 - 2.5 t.

The letters after the brackets indicate the purpose of the hatches. Water pipes are marked with the letter “B”, sewer pipes – “K”, drainage pipes – “D”.

The following numbers indicate the design features:

- 1 - for general purposes;

- 2 - with locking lock;

- 7 — with a hinge;

- 8 - square shape.

The last numbers indicate the diameter or size of the sides in centimeters.

Example of marking: C (B125) K-2.60. Explanation: medium hatch, withstands 12.5 tons, sewer with a lock, diameter 60 cm.

An example of marking a sewer hatch.

Polymer hatches have appeared recently; there is no GOST for them. Manufacturers produce products with their own dimensions, thickness, and weight. Marking is practically not applied.

Disadvantages of sewer covers

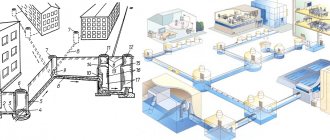

Construction of a sewer well

Cast iron hatches are heavy and expensive - these are the main disadvantages of the products. Several workers must be involved in their installation. In addition, they often become prey for scrap metal collectors - placing them in an unguarded area is extremely unprofitable.

The main disadvantage of polymer hatches is the impossibility of installation on highways and other areas with increased load.

A properly selected and installed sewer hatch is a guarantee of reliable protection of the entire communications system and the prevention of accidents. Modern technologies have made it possible to replace traditional cast iron products with cheaper polymer analogues, which can be used in most cases when arranging urban areas and private households.

Related video: Installation of sewer manholes

Publications on the topic

Characteristics and installation technique of cast iron sewer pipes (according to GOST 6942-98)

Features of insulation of sewer pipes

Purpose and installation of sewer wells

Classification of hatches by shape

The shape of the products corresponds to the type of manhole, so they are round and rectangular.

Most inspection shafts have cylindrical necks, so their hatches are round.

Advantages of this form:

- Smallest area. If we compare a round lid with a diameter of 60 cm and a square one with the same sides, then the area of the first is almost three times smaller. This reduces the consumption of raw materials for manufacturing products.

- A circle, especially a convex one, can withstand heavy loads. It has increased resistance to deformation under the influence of temperature changes.

- The cover fits tightly to the hatch, there is no play. The round shape prevents it from swinging, turning over, or falling into the well.

A hatch of the same shape is mounted on a rectangular neck. Products are installed mainly where they will not be subject to loads. Square plastic covers are used in private septic tanks and home plumbing.

Types of sewer manholes by shape.

What materials are used to create the lid?

Not only the cost of the cover, but also the duration of operation and reliability will depend on the selected material. There are the most common and well-known:

- Cast iron is one of the most reliable and frequently used materials; its service life reaches 100 years. Relevant in places where the load on the well is large - roads, highways. It is neither rational nor cost-effective to install a well hatch made of such material on your site.

- Plastic is another material that is increasingly in demand. Because the cost is several times less than the first model. In addition, different shapes and colors are available for sale. They are light in weight, which means that a person can install them without additional help. In addition, such an element is easy to open. This model is most suitable for a private home.

- Concrete – occurs, but not often. Because the level of tightness is not the highest, but the weight is significant. But they can be found on non-standard wells with a large inlet hole.

Material of manufacture

Today, cast iron hatches are most often found, since for a long time there was almost no alternative to the material. Concrete and steel products were occasionally used. Plastic lids have appeared recently, but they are expensive. Polymer ones are cheaper and superior in quality to plastic.

Cast iron

When the hatch is subjected to increased mechanical and weight loads, cast iron is the optimal solution. The service life of a product made from it is more than a century; it does not deform from frost or heat. Significant disadvantages of cast iron hatches are their large mass and high price.

At the enterprises, the lid and neck are cast, which can be with a cast iron rim and a concrete base. Some modern models are equipped with rubber gaskets. The metal of the body is less durable, the lid is stronger. The design can withstand heavy loads.

In home sewers, hatches are located where they are not subject to intense loads. Therefore, it is more rational to use models made of lighter and cheaper materials. Cast iron products are heavy, making them difficult to open.

Cast iron sewer hatch.

Polymer

In parks, garden paths, and cottages, polymer and plastic covers are more common. Plastic is an expensive material and is inferior in strength and durability to polymers. Large plastic covers are rarely found; small inspection hatches are mostly used.

Polymer sand products have become widespread. This is a synthetic material for the manufacture of which a special technology is used: 30% polymers, 69% fine sand and 1% iron oxide are mixed. The production uses recycled materials from plastic bottles, etc., so the products are cheap. After adding sand and heat treatment, the mass is pressed and cooled. Strength is increased by incorporating reinforcement into rings and caps.

Manufacturers pay great attention to the decorative design of lids. They are colored by adding pigments. Color camouflages the product or, conversely, attracts attention, signaling danger. The lids are often made in relief, with patterns and ornaments.

Polymer hatches are easy to use: they open and close easily and do not freeze to the neck in winter.

They have much less weight than cast iron lids, but they are much inferior in their ability to withstand loads. Therefore, polymer and plastic products are not installed on roads with heavy traffic.

Polymer hatch.

Structures made from other materials

Concrete hatches are most often used in the construction or renovation process . They are a reinforced concrete slab with protruding brackets with which it is moved.

If the product is of non-standard size or shape, it is covered with a reinforced concrete cover. In home sewers, these hatches are used to ensure the tightness of a well made of concrete rings or a rectangular monolith. Such products are made to individual orders.

Steel hatches are almost never used, because they are heavy, inconvenient, and rarely provide tightness. These products are used primarily as a second inner cover in shafts containing electrical and telephone cables. They are equipped with locks.

Installation Features

Installation of a polymer sewer cover is identical to the list of works that are performed when installing a cast iron product. The main difference lies in how much the manhole cover weighs. Naturally, metal is much heavier than plastic. This means that you won’t have to hire help to install the polymer structure.

When the required hatch option has been selected, you can begin to work:

- First of all, the ring is installed on the cover of the sewer shaft. This part is very often called the shell. Here it is important to check in advance that a support ring is installed between the shaft cover and the hatch. This element allows you to reduce the load directly on the slab by three times. Instead of a factory part, you can use a masonry installation. However, the brick crumbles over time and the lid may fail. Here it is important to remember how much a sewer hatch weighs in order to choose the right method for arranging the support.

- To achieve the ideal installation of the ring, which serves to distribute the load, it is worth resorting to the help of a building level. It is strictly forbidden to mount the structure at an angle, because such actions will lead to subsidence and deformation.

- Next, the ring is filled with concrete mortar around the entire perimeter of the outer side.

- For the last stage of work, it is necessary to wait until the concrete mixture has completely hardened.

- The installation is carried out directly into the ring. In this case, it is quite important to treat the working surface with grease or lithol. These substances are capable of ensuring 100% opening of the well even at negative temperatures outside the window.

Dimensions of sewer manholes

For round products, the external and internal dimensions of the mounting rim are important. They must match the neck opening and the diameter of the lid.

Size table depending on load class

| Name | Class according to GOST | Rated load, t | Weight, kg | Dimensions (diameter/height), mm | Installation location |

| garden small-sized lightweight | A15 | 1,5 | 11 — 25 | 540×80; 750×80; 730×60 | gardening areas, sidewalks, private properties |

| easy | A15 | 5,0 | 52 | 750×90 | parks, parking lots, sidewalks |

| average | B125 | 12,5 | 57 | 750×100 | streets with light traffic |

| heavy | C250 | 25 | 60 | 800×110 | busy roads |

| heavy trunk | D400 | 40 | 140 | 810×120 | motorways |

| super heavy | E600 | 60 | 155 | 810×150 | industrial, transport enterprises |

| super heavy | F900 | 90 | 174 | 785×160 | air and sea ports |

Table of hatch sizes depending on weight

| Name | Maximum weight, t | Case dimensions, mm | Cover dimensions, mm |

| easy | 1 | 720×60 | 600×25 |

| easy | 2 | 750×90 | 690×55 |

| square hatch | 2 | 640×640 | 600×600 |

| easy | 5 | 750×90 | 690×55 |

| average | 5 | 750×100 | 690×50 |

| heavy | 25 | 800×110 | 700×70 |

Dimensions are established by GOST. Cast iron hatches are available in diameters from 380 mm to 810 mm, plastic hatches - 315-1000 mm.

The dimensions of rectangular hatches are also established by GOST. Side dimensions - from 300 mm to 800 mm. The increase occurs in increments of 50 mm.

Specifications

When choosing a polymer lid, you should definitely pay attention to each technical characteristic of such a product. The main features are considered to be:

- Weight (this parameter is especially important);

- Type;

- Rated load.

It is important to have an idea of the permissible load class of the product, because the maximum value of the load that the product can withstand without damage depends on this parameter. Also, this value influences the choice of installation location. For example, a cover belonging to type “L” is a lightweight product that can withstand a maximum load of one and a half tons. Accordingly, such covers are not allowed for installation on the roadway. To close the drainage system shafts in courtyard driveways or parking lots, medium and heavy structures are used. Such products can easily withstand loads ranging from 15 to 25 tons.

You may also like: Sewer well - types and design