The demand for water supply in a country house is no lower than in city apartments. Here it is necessary to provide not only tap water, but also the functioning of equipment, as well as irrigation. Pump performance should be maximum. Electricity often goes out in rural areas, and as a result, it is better to have an alternative to a constant water supply. You can make a water supply system at your dacha using HDPE pipes with your own hands according to the diagram.

Organization of water supply at the dacha

Water supply at the dacha can only be carried out using a pump. It can be connected in two ways: from a storage tank or from a battery.

When using the first option, water enters the tank, but the pressure in the system is low. This is due to the difference in height: the tank is cleaned at an elevated location - in the attic of the house or on the roof. The main condition is that its bottom must be higher than any water supply point.

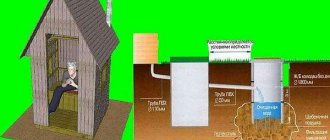

Water supply scheme

The second method is more convenient - with a hydraulic accumulator. Here the pressure in the system itself is formed and maintained mechanically. If the battery is complemented by a pump and automatic equipment (pressure switch), the entire assembly is called a pumping station. This is a cylindrical tank divided into 2 parts by an elastic membrane. When water enters, it actually creates pressure in the system (approximately 2 atm).

When the tap opens (household appliances are turned on or watering occurs), water pours out of the system. This gradually reduces the pressure. Its value is controlled by a special relay. As soon as the lower threshold is reached, the pump turns on, restoring its set value. The highest threshold is monitored by a second sensor, which turns off the pump. This water supply system can operate both in winter and summer.

Advantages of HDPE casing pipes

Structures made from this material have a number of advantages:

- environmental friendliness (plastic does not affect soil or water);

- high strength of the product;

- resistance to low temperatures;

- smooth internal surface, which prevents the formation of deposits and increases the throughput of the pipeline;

- no corrosion;

- light weight, which facilitates transportation and installation;

- low cost;

- the presence of threaded connections - thanks to this, assembly is carried out without the use of special tools.

The length of the assembled system can be adjusted by adding new modules.

Threaded connections ensure reliable tightness of the system due to minimal load on the joints.

If a section of the pipeline is damaged, the failed segment can be easily replaced with a new one.

Pipe selection

Just a decade and a half ago there were no questions about the use of pipes, since there was only metal. Nowadays, metal is practically not used for suburban water supply. We use modern pipes that do not rust - plastic. They are one of the best options for country water supply.

HDPE pipes are products with a complex structure that are considered the best among others. Having been known for many years, polyethylene materials fully justify their implementation and price. HDPE is considered when organizing water supply for domestic or technical needs in household, suburban and private dwellings.

Thanks to HDPE pipes, DIY water supply installation is possible. Users receive water from a well at the dacha, which is then used for irrigation, filling the summer shower tank and other purposes. In most cases, customers buy PE 100 and PE 80 manifolds for the system. Since operation, the temperature range of the products varies from + 40 to + 15. They are ideal for cold water.

These materials have advantages such as:

- Reliability.

- Long service life.

- Quick installation.

To lay water pipes, you can use HDPE pipes of different diameters. Do-it-yourself installation of plumbing in a residential building using plastic manifolds is simplified thanks to special fasteners (fittings, couplings). Sometimes brass bushings are used as connecting components. Polyethylene pipes can be installed using compression fittings.

HDPE pipes for water supply in the country, which are easy to install yourself, have excellent physical, mechanical and performance properties. In terms of cost, products made from HDPE are more profitable than polypropylene.

Pros of HDPE:

- long service life - up to 40 years;

- corrosion resistance;

- inaccessibility of scale on internal walls, including during long-term use;

- low thermal conductivity and lack of condensation effect;

- 6 times lighter than iron products;

- low toxicity;

- Easy installation using welded technology.

When choosing a material for the construction of the main water supply system at a dacha, HDPE shows its best side in year-round operation. It is not inferior in reliability and durability to polypropylene analogues.

Disadvantages of pipes:

- narrow operating temperature range;

- vulnerability to ultraviolet radiation.

DIY installation

Installation of a capital water supply system at a summer cottage is carried out according to the selected scheme. Water is taken from a well, well, river, village or city central highway. To ensure constant pressure in the system, a pumping station is installed . Kit includes:

- pump;

- locking equipment;

- relay and pressure indicator.

Required Tools

To install a capital water supply system with your own hands you will need:

- bayonet shovel for digging trenches;

- adjustable or gas wrench;

- cutter and scissors;

- building level;

- pegs, cord, tape measure.

When connecting directly with compression fittings, no additional tools are required. For the hot joining method, it is necessary to prepare a special welding iron that heats the ends of the pipes.

Fitting connections

To connect HDPE pipes, 2 types of couplings are used:

- Compression couplings are screwed onto the threads of the two sections being connected. The elements are sealed through rubber seals.

- Diffusion (electric welded) couplings . Used for temperature sealing using a special apparatus.

Compression couplings are screwed exclusively by hand. Adjustable wrenches can damage the connecting elements.

You will need these fittings:

- connecting for docking;

- transitional for connecting pipes of different diameters;

- plug to disconnect part of the water supply from the circuit.

Additionally, sprinkler heads, drip irrigation systems, and watering guns are purchased.

Work order

Immediately before installing the pipes, the length of the future highway on the site is checked . To do this, the plan diagram is transferred to the ground, the highway is marked with pegs and a marking cord, and trenches are dug. The length of the line is re-measured and the required number of pipes and fittings are purchased.

The algorithm for performing the work is extremely simple:

- They dig trenches with a slope at the connection point at a slight angle and gradually bring the ditches into a horizontal plane.

- The bottom of the trench is compacted with a sand cushion and waterproofing is laid.

- Cut the pipes into pieces of the required length. They connect to the water intake point and distribute it throughout the area. The sections are insulated.

- After installing the pipeline, it is connected to the water supply devices.

Compression fitting

The compression fitting is installed in the following order:

- The coupling is disassembled, the clamping part and gasket are pulled out.

- The gasket and clamp are placed back on the locking tabs.

- The elements of the assembly are joined, the fitting is screwed on manually, without effort.

Water supply system

An external water supply system at the dacha, based on a personal well, is considered the best way to obtain water. The main thing is to carefully drill the well, secure it and lay the pipeline.

Most owners like to use turnkey drilling company offerings. Experts must determine the depth of the groundwater and calculate the approximate volume of water available from the source. In some areas there is not enough water for irrigation: often the flow speed does not allow this.

Water supply options:

- Seasonal water extraction. This option is an easy method that is used for watering. It is installed on the basis of a system of plastic pipes and hoses that are connected to each other around the perimeter of the garden. In the fall, at the end of field work, the water is turned off and the water supply system is dismantled.

- Permanent system. Installed for year-round use, often on the same principle as simple water supply to personal housing. Pipes from the well are delivered to the home underground and laid in trenches below the freezing depth of the soil. Permanent piping equipment is considered costly. To install it, you will need several types of equipment: a well pump, measuring equipment, a water filter, and a hydraulic accumulator.

Important! The operation of the main pipeline requires electricity to ensure the operation of the pumping equipment. Before starting design, it is necessary to take into account the power that should be enough for uninterrupted operation of the pump.

Installation of water supply in a country house

Installation of water supply in the house is carried out using a slightly different technology:

Measure out the required section of pipe, mark its edge with a marker. At the mark, stick masking tape around the circumference so that its edges align exactly. Cut the pipe as evenly as possible perpendicular to the axis of the pipe, focusing on the edge of the tape.

The auxiliary material is removed. An even bevel 2-3 mm wide is made on the cut end using a chamfer cutter or a regular file, simply grinding off the edge at 20 degrees. Screw on the union nut with a clamping and locking ring, and put an O-ring on the edge of the chamfer. Release the edge of the pipe, slightly moving the previously installed parts to the side, lubricate it with plumbing grease. Insert the free edge into the fitting until it stops. Pull the union nut with the ring closer and screw it onto the threaded part of the fitting.

The same is done on the opposite side of the fitting. It is important that the pipe does not rest against the gasket, but against the collar, then the connection will be sealed. The pipeline is tested by running water into the system. If there are leaks, tighten the connections.

If all connections are made correctly, then there will be no surprises in the form of leaks.

will. If HDPE pipes are connected to metal, then it is better to play it safe by wrapping the tape.

Water transmission scheme

Below is a sample of how to make a stationary summer water supply at your dacha using HDPE pipes with your own hands, running from the well to the house.

Do-it-yourself diagram for assembling a water supply system in a dacha using HDPE pipes:

Assembly diagram

- The inlet through which water flows from the well into the system.

- Filter, iron purifier, softener - depends on the chemical composition of groundwater.

- Check valve to prevent water from flowing back.

- Pump - diaphragm or centrifugal, submersible or surface.

- Measuring equipment - pressure switch, pressure gauge, water meter.

- Drain valve.

- Hydraulic accumulator.

- A pipe with a triple adapter for switching the pipeline in the house, on the site, depending on your own needs.

- Valves for any branch of water supply, water shutoff.

Care should be taken to ensure high quality pipe fittings and couplings, especially where plastic pipes are embedded in iron threaded parts. System performance depends on their properties.

Important! You need to install a separate channel for the electronic pump cable. The pump outlet must be grounded. It is not allowed to lay the cable near underground pipes.

How to choose

Manufacturers make several types of HDPE pipes to choose from. The first difference is what the water with different color stripes will be used for.

For use in drinking water supply systems from wells and boreholes, HDPE pipes with a blue stripe should be used.

To make gas pipes, additives are used that change the composition of water. Pipes with yellow markings can also be used for country water supply, but their cost is noticeably higher. These pipes are designed for high pressure gas and have increased strength and a higher price.

HDPE pipes without markings cannot be used for drinking water supply. These are technical products made from recycled polyethylene. They can release toxic substances into the water.

For underground installation, two types of polyethylene are used:

- HDPE PE 100 according to GOST 18599-2001. The diameter of the products is 20 to 1200 mm, the appearance is a black pipe with a longitudinal blue stripe along the entire length.

- HDPE PE PROSAFE is produced in accordance with GOST 18599-2001, TU 2248-012-54432486-2013, PAS 1075, they are provided with an additional mineral protective shell up to 2 mm thick.

A pipe with a diameter of 40 mm is suitable for connecting the house. For other consumers, 20 mm or 25 mm is sufficient.