What is wastewater?

Wastewater is formed as a result of the removal of melt water, rainfall, sewage from residential premises, industrial complexes, which enter natural bodies of water through sewer pipes and can pollute them. Cities have a central sewer system that collects, drains, and then treats it before disposal. All types of wastewater are polluted and require treatment measures. Wastewater generated after the use of liquid for household purposes usually consists of organic particles. Wastewater accumulated during industrial activities is contaminated in the form of radioactive and chemical elements and requires different processing methods than household waste.

General information about storm drainage

Dirty puddles on roads and sites, washed out slopes, flooded basements, all this is a consequence of improperly constructed storm drainage or its complete absence. The severity of the problem is directly proportional to the size of the catchment area and the amount of precipitation that needs to be drained. For a country house or cottage, the question is usually limited to the area of the roofs of buildings and small areas of the yard with hard surfaces. For industrial and commercial enterprises occupying an area of thousands of square meters, installing a surface water removal system can be complex and costly, and the price of a storm drain with a sand trap can be too high. The situation worsens if surface runoff, passing through the site, is saturated with technological pollution. It is not always permissible to discharge them directly into ditches, reservoirs or village storm sewer systems without preliminary treatment.

Based on their legislative standards, before discharging melt and storm water into city sewers and reservoirs, it is necessary to carry out a number of measures aimed at improving the quality of purified water and bringing it to the required levels. There are different requirements for the quality of stormwater treatment depending on the nature of the water: industrial or urban sewerage. Petroleum products and suspended substances act as limiting indicators of wastewater pollution.

Building protection and decoration

The purpose of storm drainage is to prevent flooding of basements and wetting of the foundation. In addition, storm drainage should prevent waterlogging of the soil under and around the building in order to avoid waterlogging or soil erosion.

Also, the purpose of storm drainage is to protect the sidewalks and blind areas of the building from the negative effects of rain flows that fall from the roof. And at the same time, it is necessary that the entire structure looks very presentable and certainly does not deteriorate such an important appearance of the selected building. If you approach the stormwater system correctly, you can easily achieve these goals.

Drainage of water from a personal plot

Individual development plots include a significant proportion of areas allocated for lawns and green spaces. They easily absorb surface water and, with proper care, are not washed away even by high-intensity rains. Typically, rainwater and meltwater are drained from collection points on roofs or paved courtyards and driveways.

The relatively small volume and velocity of the flow make it possible to limit the organization of wastewater along the slopes of hard surfaces with release into a ditch and discharge into the settlement system or onto the terrain. Sometimes a storm sewer is used in conjunction with a drainage system, removing sediment and underground runoff. Laying a storm drain is justified if it is impossible to organize drainage from the surface.

Despite the apparent attractiveness of underground drainage, it is more expensive, more complex to design and operate, and therefore less reliable. It should be taken into account that the depth of soil freezing in central Russia is about one and a half meters. The cost of a storm drainage system that can operate year-round seems significant. A smaller pipe may be useless during the spring melting of snow due to negative temperatures in it, since the soil at depth thaws much later.

Storm drainage on the territory of enterprises

Production areas are distinguished by their significant size and large areas with hard surfaces that prevent the natural filtration of water into the soil. Unlike individual developments, it is rarely possible to limit oneself to cheap methods of installing surface drainage, and production sites are usually equipped with a full-scale storm sewer system, including, in addition to a sand trap, large-scale storm water treatment facilities. Drainage from the roof of rain and melt runoff is concentrated at several points; with a large roof area, the flow can reach tens of liters per second. This can lead to erosion of asphalt and concrete surfaces and penetration of water into the underground part of the premises.

The installation of a storm sewer with receiving elements for removing precipitation from roofs is quite justified. Sites and access roads also collect significant volumes of wastewater; drainage along the surface causes degradation of coatings or is simply impossible due to terrain conditions. In this case, an underground system of stormwater inlets and sewer wells is created, through which water is collected at several points and transported to the discharge point.

Rainwater drainage design

To understand what a drainage system is and how to install it on a site, it is necessary to understand the purpose of the main elements of the system and the operating principle of storm sewer treatment facilities. The sewerage system for melt and rainwater consists of receivers, filters, channels and reservoirs:

- Gutters: Water receptacles installed along the bottom edge of the roof. Through them, the liquid enters vertical pipes with a curved tip to drain stormwater from the foundation.

- Trays and pallets: designed to collect water from the surface of the site. They are installed in front of the entrance to the building, along the sides of roads, in front of pedestrian crossings, and in places most susceptible to the formation of puddles.

- Pipes and gutters: elements used to drain accumulated sediment from receivers. Install with a slight slope towards the collection point.

- Distribution well: the product has the shape of a square, rectangle or cylinder. The side walls have holes for connecting sewer pipes. It can be a collection point for runoff from the vertical parts of a storm drainage system from the roof of a building, or a node element for the transition of several channels into a single larger main.

- Grille: A cover with perforations or slots designed to protect storm drains. The main function of the barrier is primary filtration from large debris: stones, chips, leaves.

- Pipeline: sealed drainage systems are laid in the ground. They are designed to transport stormwater to its final destination (septic tank or ditch).

At the dacha, a storm drainage well is installed as the final point of the storm drainage system. Water from the well is used to water the garden.

Reception elements

Based on the type of receiver, rainwater drainage is divided into 2 types:

- Point: represented by a group of storm water inlets, which are interconnected by pipes into a single network. This storm drain is designed for installation around the house.

- Linear design: Assembled from surface laying gutters. The purpose of this type of system is to collect rainwater from both the building and the surrounding area.

Based on the type of transmission channels, storm sewers are divided into open, closed and mixed.

Rainfall receivers

A storm water inlet is a container with liquid drainage connected to the sewer system. The materials used are polypropylene, polyethylene and polymer concrete.

Advantages of polymer concrete:

- ease of installation;

- reliable waterproofing;

- light weight;

- protection against clogging due to smooth inner surface;

- do not require repair for a long time;

- ease of transportation.

This material is considered the most expensive option for arranging a tray, but lasts longer than others.

The rainwater inlet is equipped with basket-type filters to protect the system from the ingress of large contaminants, such as stones, plants and other debris of mineral, organic and inorganic origin. Modern versions of receivers are equipped with siphons to protect against the appearance of odors in the area. At any time, the filter can be removed and cleaned of accumulated sediment.

Pallets

Unlike storm water inlets, pallets (trays) are placed directly in front of the entrance to the building. They are equipped with drain pipes at the bottom and covered with a metal grill at the top. This design allows you to remove excess water from the area and clean your shoes from dirt. Door pallets often also play a decorative role thanks to the variety of grilles and fences.

Conveyors

These include pipes and gutters that redirect melt and rainwater from trays and receivers to the collector for further processing, as well as the entire storm drainage system from the roof of the building. Conveyors are made from the following materials:

- PVC. The best option for do-it-yourself storm drainage in a private home. They are easy to install; special seals are used to seal the joints. Affordable.

- Corrugated polymer. Multilayer material is used for closed systems, as it can withstand constant soil load. Polyethylene and polypropylene are lighter in weight compared to PVC, and their flexibility allows installation of conveyors without installing swivel fittings.

- Steel. Steel pipes are practically not used in modern storm drains due to their high cost, heavy weight and complexity of storm drain installation. But they can withstand loads better than plastic.

Important! When choosing a material, the depth of the pipes, soil pressure per 1 cm2, the average ambient temperature for the year, the features of the facility and the landscape of the area, as well as the experience of the people who will perform the installation, and the overall budget are taken into account.

Wells

Reinforced concrete drainage wells are now rarely used due to the difficulties of transportation and heavy weight. Preference is given to polymers. They ensure complete sealing of the element, reliability, and the ribbed surface of the body protects it from floating under the influence of groundwater (concreting the pit is not required).

Protective elements of storm drainage

Sand traps

Mandatory dirt protection element for all systems. It removes sand and soil particles from the water, protecting pipes from clogging. Due to the difference in the diameter of the pipes, the water flow loses its speed, while suspended particles sink to the bottom under the influence of gravitational forces.

Impurities are collected in a special basket and must be removed periodically. After initial coarse purification, the water is sent through transmission collectors for further filtration.

Gasoline separators

Sponge polymer filters moistened with water, which collect drops of oil and gasoline. Most often they are installed on industrial storm drains, but if the machine is regularly washed and serviced on the site, the presence of this unit is necessary, because fine gasoline particles clog the system and disrupt its operation.

Filters for storm drains

Devices with different operating principles and designs remove mechanical, organic and other impurities from wastewater in accordance with the requirements of sanitary standards. Large suspensions are removed by mechanical filters, which include lattice surfaces for retaining large household waste, baskets for small debris, and flotators. Sorption installations are based on the principle of absorption of chemicals by activated carbon, shungite and other sorbents.

Important ! After collecting water in a drainage tunnel and purifying it, impurities and contaminants still remain in the drainage. Therefore, to dispose of sediment, septic tanks must be installed, where they are collected, stored and filtered. Even if there is a central sewer system, drainage of wastewater is not allowed if it does not meet sanitary standards.

Storm drainage system

Stormwater treatment facilities consist of the following components:

- Distribution well.

- Sand separator.

- Oil and petrol separator.

- Sorption filter.

- Control well.

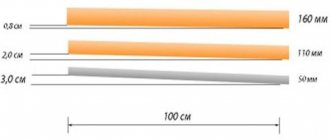

For laying storm drains, plastic pipes made of polyethylene or polyvinyl chloride with sockets and sealing collars are used. The diameter is selected taking into account the maximum per second volume of wastewater, but for individual development and small production areas, 150 - 250 millimeters is usually sufficient. The pipes are laid in a trench at a given depth over an underlying layer of medium-sized sand, and the laid lash is sprinkled with it to avoid the risk of damage from solid soil inclusions.

To change the direction of the route, rotary wells are installed. In extended areas, over 30-50 meters, intermediate inspection wells are installed. The slope of the pipelines depends on the diameter, but less than 10 ppm is not recommended. If there is a significant difference in height between the ends of the route, bypass wells with a pressure damping system are installed. Local network is displayed:

- on the relief;

- into the village sewer system;

- local wastewater accumulation and treatment system.

Materials and components of drainage systems

The choice of material for organizing a drainage system depends on personal preferences and the affordable cost of the products. Different suppliers offer a certain color range and standard sizes of products, each of which has a certain service life. It is necessary to coordinate the color of the roofing, finishing of the eaves and components of the drainage system. Ease of installation for the conditions of a particular home is also important.

Let's consider the types of materials for drainage systems that modern manufacturers offer.

- Products made of galvanized metal are characterized by low cost, average availability and low corrosion resistance.

- Materials with multi-layer, polymer painting, have a variety of colors, have corrosion resistance and a large set of components.

- Drainage systems with zinc-titanium or copper coating are highly durable and impeccable in appearance, but their cost is very high.

- Polyvinyl chloride parts, highly resistant to ultraviolet radiation, corrosion, with sealed connections and a good set of components.

For efficient installation of the entire system, manufacturers offer sets of fasteners, connectors and other elements, which should be considered separately, taking into account the complex configuration of the water drainage system from different roofs.

It should be remembered that the color scheme from different suppliers, as well as the standard size, may differ slightly, therefore, in order to avoid inconsistencies and discrepancies, you need to purchase materials from the same batch.

The drainage system consists of the following list of products:

- brackets of different sizes for attaching gutters and pipes, both to the rafters and to the wall of the building;

- gutters equipped with connectors, with the ability to adjust the direction of fasteners;

- internal and external corner gutters, for 90° turns;

- plugs with seals;

- adapter from gutter to funnel;

- funnel;

- universal rings with an angle of 72° or elbows;

- drainpipes;

- protective net against debris;

- taps with an angle of 60°.

All these components are light in weight, but when assembled they load the walls and rafters, so they need to be fastened at a recommended pitch of about 60 cm. Suitable ones are selected from the standard section of gutters and pipes, depending on the area of the slopes and the angle of inclination of the roof.

In the case of roofs with a complex configuration, in addition to calculating the area, consultation with a specialist is required.

Advantages of stormwater treatment facilities

Among the advantages of stormwater treatment facilities, the following are worth highlighting:

- there is no need to install an additional structure for sewerage;

- convenient dimensions of the sewer system, which makes it possible to place it in any territory;

- it is possible to install a bypass line, which will optimize construction costs;

- Treatment facilities may be placed at the required depth of the route with subsequent regulation of the height of the wells.

Treatment facilities intended for storm sewers are made of reinforced plastic and high-quality components, so the device is not exposed to the external environment and aggressive components. This allows you to operate the device for a long time without worrying about malfunctions. The presence of a well in the sewerage system intended for sampling allows you to control the quality of cleaning.

Local surface water treatment facilities

The use of local treatment facilities for surface runoff is becoming widespread due to the tightening of environmental legislation and the active work of supervisory authorities. The discharge of water from the territory of an enterprise that contains traces of petrochemical products or other harmful substances results in large fines. A modern solution is complete stormwater treatment facilities, arranged in fiberglass or polypropylene containers with a cascade of filters specially selected for operating conditions, including coalescent elements of coarse purification and fiberglass elements of subsequent stages.

The wastewater coming from one end, after separating solid fractions, goes through a filtration system that removes remaining mechanical and chemical contaminants, entering the outlet pipeline. The treatment station is equipped with a pump, allowing filtered wastewater to be discharged to the surface. Depending on the customer’s needs, cleaning units with a capacity of 1.8 to 720 cubic meters per hour are supplied.

You need to choose stormwater structures based on the main indicators:

- productivity;

- depth of pipelines;

- concentrations of polluting components at the entrance to the structure;

- prices;

- required degree of purification and discharge standards.

Servo-Yug employees will help you choose the necessary equipment for installing storm sewer treatment facilities and will perform high-quality installation of EKORA, as well as perform routine maintenance, including diagnosing the condition of filter elements and replacing them if necessary. It is better to entrust the work to professionals. Call us!

Industrial wastewater

This category includes the entire range of waste that is discharged from the territory of enterprises: atmospheric waste, water from irrigation or washing, liquid chemical waste and much more. Industrial wastewater cannot be discharged into the sewerage system: it must be disposed of using biological treatment or by pouring into cesspools, since the chemical composition of this water is very dangerous.

see also

- Sewage for home in Crimea

- Fiberglass grease traps

- Septic tank Topas. Principle of operation

- Sewer pipe cleaning

- Local sewerage

- Choosing a cesspool cleaner

- Methods for cleaning cesspools

- Replacing a sewer riser

- Sewage check valve

- Manholes

- Sewer drains

- Heating pipes with a heating cable and other insulation methods

- Septic tank maintenance

- Wastewater settling tanks

- Filtering fields: operating principle and design

- Peat dry closet is an excellent solution for a summer residence

- Methods of wastewater treatment and types of sewage treatment plants

- Why does odor appear from the sewer system and how to eliminate it?

- Domestic sewage pumps: types and advantages

- Why are oil and gasoline traps needed?

- How to choose bacteria to improve the performance of septic tanks?

- Drainage systems - protecting the foundation of the house

- Deep biological treatment stations – bioseptics

- Stages of construction of a septic tank from concrete rings

- Autonomous sewage system for a country house: installation features

- The simplest option for local sewerage is a cesspool

- Caisson cellar from

- Well drainage pump

- Sewage tanks and their installation

- Forced sewerage

- How to choose a grease trap

- Fecal pumps: overview

- Sewage plastic wells

- How to properly position a septic tank

- Tips for choosing a septic tank

- How to insulate a well for the winter

- What is a grease trap?

- How to remove odor from a septic tank

- What to do if there is condensation in the caisson?

- Unilos Astra autonomous sewage system

- Topas

- Do-it-yourself septic tank maintenance

- Sewage system

- Drilling an artesian well is the best solution for water supply at home

- cesspool

- Pumping equipment for pumping stations

- Dacha sewerage

- Aeration wastewater treatment

- Installation of sewerage for home

- Sewerage Unilos Astra instead of cesspools

- Unibak-UNIBAC bacteria for septic tanks

- Septic tank. What do anaerobic bacteria do in septic tanks?

- Interesting facts about the evolution of the toilet

- Comparison of a conventional septic tank and a biological treatment station

- Operating principle of an aeration sewage station

- Sewerage Topas-M for the whole village

- Plastic and fiberglass septic tanks

- Sewerage of a country house

- Water supply and sewerage for a country house

- Septic tank

- Why is there a fire in the Unilos Astra or Topas sewer?

- Methods for sewage treatment