Today, pumping wells is a necessary procedure at any summer cottage. It prevents the appearance of microbes harmful to the body in the well and helps fill the well with clean water. Pumping water from a well can be done either by professionals who will quickly pump out stagnant water and dispose of it without harming the environment, or independently using an electric drainage pump.

Using an ordinary well or borehole on a country or farm plot is a necessary source of clean water. It can be safely used for household needs and watering the garden, bathing in the shower or bathhouse.

Drainage pumps and their capabilities

Pumping equipment works with clean and dirty liquid. If the particles in it do not exceed 5 mm in size, it is clean water; larger ones (up to 35 mm) are dirty. This is taken into account when selecting equipment. Depending on what kind of water the pumps are intended for, they have different technical characteristics.

They differ:

- diameter of the outlet pipe;

- cross-section of the receiving hole;

- the material from which the parts are made.

If the equipment corresponds to the level of water contamination, then it can be used to solve many problems related to pumping or supplying liquid.

Drainage pumps are used:

- in case of flooding of basements, cellars and other objects;

- when eliminating accidents on water supply and sewer lines;

- for cleaning wells after drilling;

- for cleaning septic tanks from sludge;

- in fountains, swimming pools, artificial reservoirs;

- for drip irrigation of berry fields and vegetables on farms.

The ability of the equipment to operate automatically is used when it is necessary to constantly monitor the water level during construction. The device is installed in the drainage pit and connected to the network. Then it works, turning on and off depending on the liquid level.

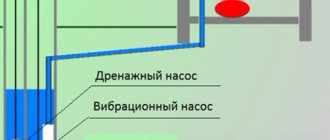

Schematic representation of the installed drainage system

Off-label use is also possible. Temporarily replace the deep pump for clean water. True, the performance of the drainage device is less than that of special equipment.

Owners of private houses who have a shaft well use drainage pumps to pump out water and clear the bottom of silt and sand. This equipment eliminated the need to carry out such work manually; no one has to go to the bottom of the well.

Surface pumps for wells

The surface pump is installed on a flat area, on the surface; installation in a farm building is possible. Two hoses extend from the unit: one is connected to the suction pipe and the other end is lowered into the well. The second hose connects the pump to the drain point. The length of the hoses, as a rule, does not exceed 7 meters; this is not always enough if the pump is purchased for watering a garden or for a deep well. Advantages:

- On the one hand, such pumps are quite reliable and practical, but on the other hand, they are sensitive to moisture in the atmosphere (rain, fog), for the reason that the housing is not well sealed.

- High pressure and high performance.

- There is no need to lay a waterproofed electrical main to the well;

- Long-term uninterrupted operation;

- Ability to pump out both clean and dirty water. The number and sizes of permissible inclusions are indicated in the technical data sheet of the device

Surface pump for a well

Disadvantages:

- The suction height of such units usually does not exceed 9 meters, that is, they can be used for wells no more than 6-7 meters deep.

- Pump operation is accompanied by a high noise level;

- The suction line must be filled with water before starting.

Selecting a pump based on performance and pressure

Performance is a characteristic that indicates how much water a pump can pump per unit of time.

The larger the value of this parameter, the faster the unit will cope with the work.

The pressure indicator characterizes the ability of the equipment to raise water to a height. When choosing a pump, take into account that 10 m in the horizontal plane equals 1 m vertically . If, for example, it is necessary to clean a well 6 m deep and drain the liquid 10 m outside the site through a hose laid on the ground, the lifting height must be at least 7 m.

Pumping equipment is supplied with instructions that indicate the maximum performance and pressure indicators. The last parameter for drainage pumps is small - they are designed for pumping water from shallow depths.

When choosing, take into account that increasing the lifting height leads to a decrease in productivity. The interdependence of the parameters is shown on the graph, which is in the instructions for the equipment.

How to choose

Before you start choosing a drainage pump model, you need to determine the parameters of the underground tank for which you plan to use such a device:

- the depth of the well (it can be determined using a cord with a weight attached to its end);

- parameters of the cross-section of the well shaft - the diameter or size of the sides of the shaft if it has a square shape.

Knowing these parameters, you can calculate the maximum volume of water that needs to be pumped out. To make such calculations more accurate, it is necessary to take into account at what level in the well shaft the water surface is located.

Design features of pumps for clean and dirty water

The quality characteristics of the water in the well are another important parameter that should be taken into account when choosing a drainage pump. In this case, this parameter refers to both the number of insoluble inclusions in the water composition and their linear dimensions. The instructions for each model of drainage pump must contain information about the size of solid particles in the pumped water with which such a device can work. Naturally, in order for the pump you have chosen to work correctly and not fail after short-term use, the size of the inclusions contained in the pumped water should not exceed the standard values for a specific model.

The choice of drainage pump is also influenced by the mode in which such equipment will be used - year-round, seasonal or periodic.

Higher demands are placed on the selection and use of drainage pumps that are operated year-round. Installation of such pumps is carried out in a heated room to avoid freezing of the liquid in the pipeline system during the cold season.

To more accurately select a drainage pump, it is necessary to determine and take into account the following parameters:

- minimum and maximum water level in the well;

- average water level in the well being served;

- the intensity with which water flows into the well (source debit).

Main characteristics and rules for their calculation

In addition to the parameters of the well, before choosing a drainage pump, it is necessary to determine the characteristics of the device itself. This includes the performance of the pump and the pressure force of the liquid that such equipment pumps.

The performance of the pump, which characterizes the volume of liquid pumped by it per unit of time, is determined based on the total volume of water in the well and the length of time during which all the liquid contained in the underground reservoir must be pumped out.

To determine the amount of liquid pressure, the depth of water intake and the distance over which the pumped water must be transported along the horizontal section of the system are summed up.

Calculation of pressure for a drainage pump

Design features

The suction hole of a submersible drainage pump is located at the bottom of the device, which ensures the most complete pumping of water from the well shaft. For the manufacture of the hydraulic machine body, cast iron, polymer material or steel alloy can be used. More preferable are devices with a steel body, which is not too heavy and is highly durable. Cast iron cases, although reliable, have a significant weight, and plastic ones are not strong enough.

The size of inclusions in the pumped water that a pump can handle without compromising its technical condition is mainly influenced by the size of its working chamber.

Types of submersible pumps

Among submersible pumps that pump out water, centrifugal and vibration ones are in demand among owners of country houses. Their main difference is in the method of collecting liquid. When choosing the type of pumping equipment, you should take into account the quality of water: what can be pumped out by centrifugal pumps and what by vibration pumps.

With centrifugal mechanism

The main component of a centrifugal apparatus is an electric motor. An impeller is attached to its shaft, which, when rotated, draws water through the inlet in the housing. The impeller blades are designed to push fluid away from the center. Water is collected in a snail-shaped chamber and, under the pressure of a new incoming portion, is thrown into the outlet pipe.

Design of a drainage pump with a centrifugal mechanism

The centrifugal design principle increases productivity and prevents abrasives that may be present in the liquid from entering the apparatus. The volute and impeller, depending on the manufacturer and model of the unit, are made of steel or polymer.

Submersible drainage devices are equipped with automation that controls their operation. It turns off the equipment when the water level drops so much that there is a risk of dry running. Automation can be electronic, but most devices have a mechanical one, which is simpler and more reliable.

The mechanical switch is called a float. This is a sealed housing with contacts that open when the float and liquid drop to a critical level. The motor in a submersible pump is cooled by water. If it continued to operate in airspace, it would fail due to overheating.

The internal structure of the drainage pump float and its operating positions are indicated in the installation diagram.

Installing a drainage pump - step-by-step instructions

Installation of drainage equipment is carried out on a flat surface so that the pump is in its vertical operating position.

Then perform the following steps step by step:

- Connect the pressure hose to the nozzle.

- If the model is equipped with a float switch, a check valve is mounted on the line.

- Attach a rope through a carabiner to the eye of the pump and begin to slowly lower it. At the same time, monitor the vertical position of the pressure hose.

If the pump consumes 380 V, before running, check in which direction the impeller rotates. To do this, turn the pump on and off quickly, noting the direction of rotation. If it does not correspond to the arrow on the body, swap the 2 phases.

Vibrating Submersible Pumps

There is a coil in the sealed housing of the vibration pump. When current passes through it, a magnetic field is created, causing the diaphragm to vibrate. The alternate rapid movement of parts creates a difference in pressure inside the housing. Conditions arise under which liquid enters the receiving chamber and is supplied upward.

Structure and appearance of vibrating drainage pump

Water intake can be carried out through the upper inlet. Such models are well cooled under any conditions because they are always completely immersed in water. When they work, sand and silt do not rise from the bottom. The water remains the same degree of purity as it was. Therefore, they are not suitable for cleaning wells. They are best used for lifting clean water.

If the intake is carried out through the lower suction hole, then the vibrations of the liquid lift sand and silt from the bottom. If debris gets into the working chamber, all rubber parts quickly fail. A filter is installed for protection.

The design does not provide any automation or thermal protection.

The craftsmen found another way out. If there is little water in the well, the suction hole of the vibration pump is located at the very bottom, and the device is placed in an iron bucket. It pumps water without lifting sediment from the bottom.

The advantage of vibration pumps is their durability. When used correctly, they do not break. The device is such that no part rotates, there are no bearings. If there is no friction, nothing breaks.

To clean the well, vibration pumps can be used as auxiliary units. They use them to pump out water, even if it’s a little muddy, but they scoop out sand and silt by hand.

Selecting a hose for pumping water

The main requirement for the hose is that its cross-section must correspond to the diameter of the pressure pipe so that it can withstand the pressure created by the pump. If you adhere to it, it not only creates convenience in work, but also extends the service life of the device.

Set of drainage pump and hose for pumping water

A good hose is quite rigid. Strength is imparted by reinforcement, corrugation, and walls with increased thickness.

The durability of the hose is affected by the material from which it is made. Polyvinyl chloride and rubber are in demand. PVC is cheap, but that’s where its advantages end. Rubber ones are more expensive, but will last longer. They can be used at any temperature, while PVC does not like sudden changes.

If there is a fire hose, it can replace the hose.

The bend at the point of transition from the vertical to the horizontal position is eliminated using a plastic corner. It is inserted into both ends of the cut sleeve and secured with clamps.

Features of connecting submersible pumps

Before lowering the pump to pump water into the well shaft, measure the depth. The equipment should be within 0.5 m from the bottom if the water intake is from above, and 1 m for devices with a bottom suction hole.

If it is necessary to lower a pump into a well for flushing after drilling, the depth in practice is determined as follows:

- the device on the cable is lowered to the bottom;

- raised by 2 m;

- check the work;

- If everything is fine, they fix it.

The method is used at a trunk depth of up to 15 meters.

The housing is protected from possible damage when it touches the walls of the well with a rubber ring. A piece of thick elastic rubber is tied between the upper end of the rope on which the apparatus is attached and the crossbar on the upper well ring. It will dampen vibration.

Single-phase units have a plug at the end of the cable. To connect to electricity, just plug it into an outlet.

Three-phase devices often do not have plugs. The connection is made according to the diagram in the instructions. It shows the colors of the wires. Particular attention is paid to the grounding conductor so as not to confuse it with the phase conductor. Be sure to install a circuit breaker whose power is specified in the instructions.

Connection diagram for a drainage pump with three-phase power supply to the network

The standard cable length is 10 m. If it is not enough, connect an additional cord and carefully insulate it. The connection point must be outside the shaft.

Installation procedure

Installation of the drainage pump, the correct implementation of which determines the correctness of its operation, is carried out according to the following algorithm:

- The suction pipe is connected to a pressure hose or pipe.

- A float sensor is installed in the well, which will automatically turn on the pump when the water level rises and turn it off when all excess water has been pumped out.

- If the pump is connected to a three-phase power supply, it is necessary to check that the drive motor shaft rotates clockwise.

Installation diagram of a submersible drainage pump

Cleaning a heavily silted well

It is difficult to clean such wells with a household drainage pump: it quickly becomes clogged with sand and cannot cope with the job. Professional equipment would have been more useful here, but the craftsmen found a way out.

First, preliminary work is carried out. Need to find:

- barrel with a volume of 200-300 l;

- surface pump or budget vibration pump;

- sand filter.

The container is installed near the well.

First, clean water is pumped out so that as little of it as possible remains, about 1 m. It is sent through a hose beyond the boundaries of the site or found another use. Now you can start cleaning the source from sludge.

The technology is as follows:

- A drainage pump pumps muddy water into a barrel.

- From there it is fed under pressure back into the well. But it is already clean - the filter does not allow sand to pass through.

- The sand is washed away by a strong jet, the drainage pump captures the muddy liquid and delivers it upward.

The process goes on almost continuously. They stop only to lift the device and rinse with clean water any deposits in the water channel, which can lead to equipment failure.

Application area

For country houses and dachas, drainage pumps are indispensable. Using such a device, you can pump out well water from an underground reservoir before cleaning it, organize the supply of water for irrigation from natural reservoirs or storage tanks, and also solve many other problems.

Before installing such a pump, it is necessary to make sure that the liquid for which it is planned to be used for pumping meets the requirements for the size of insoluble inclusions contained in its composition.

The need to use drainage pumps arises in the following situations:

- an increase in groundwater levels, which leads to excessive filling of wells and waste tanks, the appearance of water in the basements and cellars of houses;

- liquidation of the consequences of the past flood;

- liquidation of the consequences of a pipeline break;

- tidying up the local area after heavy rainfall;

- supplying water to fountains, maintaining artificial reservoirs and swimming pools;

- supplying water to drip irrigation systems for plants growing over large areas.

Rules for operating the pump when cleaning a well

It is important not to make a mistake when choosing a pump for pumping water from a well. Units with different characteristics are hidden under the name drainage. Some are intended only for clean water; if you try to remove silt from the well with them, breakage cannot be avoided. The apparatus used must be able to handle pumping water containing mechanical inclusions and fibers. Data on the purpose and capabilities of the pump are specified in the instructions for it.

The power of the unit is selected depending on the frequency of flushing the well. If this is done frequently, for prevention, a low-power device is suitable. To clean a silted well, it is advisable to use a high-power unit.

Heavily contaminated mines are cleaned manually before pumping out water . To do this, a person goes down a ladder into the shaft and scrapes sediment from the walls. This will help to clean the well with the pump faster, its working parts will become less clogged.

The cleaning procedure is simple:

- the apparatus is lowered into the well to a depth at which its intake hole does not reach the bottom 0.5-1.0 m;

- turn on the device and begin cleaning;

- regularly turn off, lift up, clean the filter of the unit;

- after 2 hours of work, take a break for 15 minutes.

Make sure that there is no constant switching on and off. This happens when water flow is low. Then the pump overheats and stops.