Due to systematic changes in temperature conditions in the heating system, the volume of coolant takes on different values. Which often leads to emergency situations. To avoid such problems, it is necessary to establish stable operation of the installation, maintaining the required characteristics within normal limits. To do this, you need to study in detail the structure and operating principle of a membrane expansion tank for heating.

Why is it needed?

Practically, all coolants for heating systems are weakly compressible liquids.

Accordingly, there is a need to use stabilizing devices - membrane expansion tanks for the heating system (operating principle), capable of accepting part of the liquid when volume and pressure increase, and returning it to the circulation circuit when these indicators decrease.

To compensate for the volume of coolant in the system when the temperature changes, expansion tanks are used.

Among them there are 2 types of devices:

- open;

- closed (sealed);

Open expansion tanks have become widespread, but are gradually giving way to sealed heating systems, since they have a number of disadvantages:

- additional installation costs, since they are installed at the top point of the system to create the required level of excess pressure;

- loss of coolant due to natural evaporation, and, as a result, the need to constantly monitor the liquid level and top it up;

- the danger of the development of corrosion processes in the system due to constant contact of the heated coolant with oxygen in the air.

Do you know which pond pump to buy? Read this useful article about the best equipment for artificial ponds.

What kind of air compressor is needed for a pond is written on this page.

Sealed expansion tanks do not have such disadvantages.

Let's compare closed and open heating systems

The operation of an open heating system is based on the laws of thermodynamics, due to which the coolant moves. From an area of high pressure and corresponding temperature at the boiler outlet, water moves through pipes to an area of lower pressure, and its temperature decreases. The cooled coolant is sent back to the boiler and the process is repeated. Thus, natural circulation of liquid occurs, according to the laws of physics.

Since when water is heated, its volume increases, an expansion tank is provided in the design of an open heating system. For efficient movement of open-type coolant, the expansion tank is installed at the highest point of the system, and the heating boiler at the lowest. Installing an expansion tank in the attic seems to be the best option. Its device is not complicated.

Over time, water evaporates, so its level must be replenished in a timely manner. During breaks in the use of heating and at negative ambient temperatures, the water must be drained, otherwise it will freeze in the pipes and burst them. An open heating system has the following advantages:

- independence from electrical energy sources;

- no noise;

- ease of maintenance;

- quick start and stop.

You can select radiators for any type of heating system based on the recommendations of the article “Which radiators are best to choose for heating a private home: photos, dimensions and technical characteristics.”

In a closed heating system, water does not evaporate because it is sealed. The movement of the coolant is carried out using a pressure or circulation pump, which can be found in the article “Which circulation pump to choose for a water heating system for a private house, technical characteristics.” At the same time, for effective operation, an expansion tank made of durable metal is also required. A closed heating system consists of a heating boiler, a circulation pump, a pipeline network, radiators and an expansion tank. A closed heating system has the following advantages:

- no need to constantly monitor the coolant level;

- possibility of using antifreeze;

- internal pressure adjustment;

- possibility of connecting additional devices.

Closed heating system

With proper installation of heating equipment, both options will work perfectly. The choice between them is determined by operating conditions and placement features. The differences between the two systems are as follows:

In an open heating system, the expansion tank is located at the highest point. In a closed heating system it can be located almost anywhere. The likelihood of air locks forming in a closed heating system is much lower. This is due to increased internal pressure and lack of direct contact with the atmosphere. To operate an open heating system, large diameter pipes are required. Installation work is complicated by the need to take into account hydraulic rules when distributing flows, making turns, slopes, and so on. Small diameter pipes used in a closed heating system reduce its cost

Here it is important to correctly install the circulation pump so that during its operation it creates as little noise as possible.

Design and principle of operation

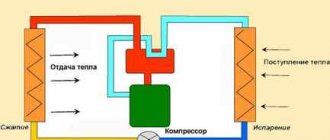

The design and principle of operation of the device become clear from the name “membrane tank”.

It represents a hermetically sealed metal container, which is divided into 2 chambers by an elastic membrane.

One of them, the pneumatic chamber, contains air or gas under pressure. Coolant enters another hydraulic chamber (about plastic water tanks written here).

The device works as follows:

- in a state of equilibrium, the air pressure in the pneumatic chamber compensates for the liquid pressure in the heating system, the volume of the hydraulic chamber and the coolant in it is minimal;

- when the fluid pressure in the system increases (including during heating), the pressure in the hydraulic chamber increases, where excess coolant begins to flow;

- due to the elasticity of the membrane, the volume of the pneumatic chamber decreases, accompanied by an increase in gas pressure in it;

- as soon as the increase in pressure in the pneumatic chamber compensates for the increase in pressure in the hydraulic chamber, the system returns to equilibrium.

When the coolant pressure decreases in the heating system lines, reverse processes occur.

The air (gas) compressed in the pneumatic chamber expands, displacing liquid from the hydraulic chamber into the system until the pressure difference is compensated.

This hermetic design eliminates contact of the coolant with air, which significantly reduces the likelihood of the development of corrosion processes not only in the tank itself, but also in other elements of the heating system - boilers, pipelines, etc.

In addition, expansion tanks (sealed expansion tanks) in accordance with SP 41-101-95 “Design of Heating Points” are equipped with safety valves (safety valves), which allow limiting the maximum pressure in the system to a level acceptable under operating conditions.

Due to this, the expansion tank acts as a protection device for the elements of the heating system.

general information

What is an expansion tank and what is it for?

Its very name gives a hint: for expansion. With a fixed mass of coolant in the heating circuit and pipes, the elasticity of which tends to zero, with a change in coolant temperature the pressure in the system will inevitably change. Thermal expansion, remember? Water or any other coolant expands when heated.

As soon as the force exceeds the tensile strength of the pipe or radiator... Boom!

The reason for a possible accident is that water, changing its volume when heated, remains practically incompressible. Hence the concept of water hammer: elastic interactions in a liquid medium, to put it simply, are absent.

The obvious solution is to create a reservoir in the system with an easily compressible substance - air. As the volume of water increases in the presence of such a reservoir, the pressure will increase slightly.

Useful: to prevent oxygen from the air tank from contributing to pipe corrosion by dissolving in water, in tanks for closed systems it is separated from the water by a rubber membrane.

This is what this simple device looks like in cross-section.

However, we have described only one of the functions of the expansion tank.

In addition to closed heating systems of private houses with fixed volumes of both the circuit and the coolant in it, an expansion tank can be found:

- In open systems in contact with atmospheric air;

- In central heating systems with top filling. There, the expansion tank is located in the attic and connects directly to the supply pipe of the house heating system.

In both described cases, installation of a heating expansion tank is necessary in order to get rid of air pockets. The difference between the two threads in the case of central heating is only about two meters. In heating systems of private houses with natural circulation - even less.

Clarification: the author can almost hear the exclamations of more or less knowledgeable people who, at the height of the heating season, saw a 10 times greater difference in the elevator unit. Typically 6 kgf/cm2 on the supply pipeline and 4 on the return pipeline (1 atmosphere of excess pressure corresponds to a water column of 10 meters). Do not confuse warm with soft: it is not supply water that enters the heating system, but a mixture. The elevator draws return water into a repeated cycle through the heating system, injecting a stream of hotter water with higher pressure into it through a nozzle from the supply pipeline. As a result, as stated, the difference between the mixture and the return does not exceed 2 meters, or 0.2 kgf/cm2.

With such a difference, the water pressure will not be able to squeeze the air plug out of the upper part of the heating system. Hence the simple solution: put some kind of container to collect air where it will accumulate, and bleed it out when the system starts. In the case of an open system, of course, no active actions are needed.

All air in the system will be forced up and into the expansion tank. In an open system, it will immediately reunite with the atmosphere. When closed, it will wait until the owner of the house opens the air valve.

Differences from a hydraulic accumulator

The design of sealed expansion tanks is similar to the design of hydraulic accumulators, however, the purposes of these devices are different. The expansion tank compensates for the expansion of water that occurs due to heating in the heating system. The hydraulic accumulator accumulates the volume of water under pressure in a water supply system that has a pressure pump in order to reduce the frequency of activation of this pump and smooth out water hammer. In addition, more often than not, inside the accumulator there is a bulb made of food-grade rubber. It is this that is pumped with water; as a result, the water does not come into contact with the tank body. The expansion tank for heating systems is made with a membrane made of technical rubber. It divides the housing into two compartments, and the coolant has contact with the housing.

Types of hydraulic accumulators

For heating systems, manufacturers produce tanks that differ in membrane design.

Membranes for expansion tanks are divided into:

- balloon;

- diaphragm.

The diaphragm membrane is a permanent partition made, most often, of thin metal or elastic polymer.

The main difference between this option is its small internal capacity and the ability to compensate for minor pressure drops in the system.

If such a tank malfunctions, it must be completely replaced.

The advantages of such devices include simplicity of design, reliability in operation and low price.

The balloon-type membrane is a container installed inside the tank made of high-quality rubber that is resistant to significant temperature changes.

A flange fastening of the membrane is used, which allows for its simple and quick replacement (how to install pipeline shut-off valves with your own hands is written here).

The advantages of balloon membranes include:

- wide range of operating pressures at which the use of a sealed expansion tank is allowed;

- the ability to replace the membrane , thanks to which repairing the device (about a manual pipe cutter for plastic pipes is written here) becomes faster and cheaper;

- ease of setting the minimum (set) pressure for any system.

The model ranges of tanks with replaceable membranes produced by manufacturers cover a wide range of not only pressures, but also volumes.

At the same time, devices are available in various designs, for horizontal and vertical installation, with mounting on building structures or installation on legs, which significantly increases the flexibility of designing heating systems.

Design features

In residential and industrial premises, heating networks are installed according to open and closed schemes. The first option is more suitable for centralized systems, which allows the liquid to be collected directly for hot supply. In this case, the tank is installed in the upper zone of the circuit. The container makes it possible to control the process of pressure surges by removing air pockets from the pipes.

The second type of installation involves the use of tanks with a membrane. They are distinguished by their comparative simplicity of design. They consist of an expansion tank and a membrane-plate, which, in turn, can be:

- Balloon. This means that the heat carrier is placed inside a rubber cylinder, and on the outside there is nitrogen or air. If this element breaks down, it’s easy to replace; you don’t have to buy a whole new device.

- Diaphragm. Made in the form of a permanent partition made of metal or polymer material. This part has a compact capacity and can neutralize only small pressure surges in the network. If it fails, it is impossible to replace it, as a result of which you will have to purchase another tank. Of course, the cost of this membrane is slightly lower than the above option.

Device nuances

The functions performed by the membrane for the expansion tank determine the features of its design. It is a metal body in the form of a cylinder, the internal space of which is divided into two parts. One of them contains gas or air. They are compressed to a certain level, the value of which is indicated in the technical data sheet. The other cavity, which is formed by the replaceable membrane of the expansion tank, is filled with water. Thanks to this, the gas pressure will coincide with the same parameter in the pipes.

The raw material for the manufacture of the tank body is steel, onto which a protective red paint coating is applied. This finish prevents rust and helps provide visual separation from blue epoxy painted accumulators. The rubber membrane of the tank is made from synthetic rubber using the casting method, which allows the production of products with a spherical or pear-shaped configuration. The basis for the production of elastomer is ethylene and propylene, subjected to polymerization. The finished material is characterized by the following:

- resistance to high temperatures;

- the ability to deform under load and restore its original shape in its absence;

- inertness to chemicals;

- good elasticity.

Typically, the heating expansion tank membrane is suitable for installation in products from different manufacturers (for all manufacturers they are the same size and interchangeable).

The exception is the Wester brand (their membranes are suitable only for tanks of the same name and cannot be replaced by any others).

Installation location

An expansion tank for closed-type heating is installed in a straight section in front of the circulation pump. Before, in the sense that the pump drives water from the expansion tank, and not into it. In this case, the expander works more correctly.

Place for installing a membrane expansion tank

To install a membrane tank, install a tee, from which comes a pipe to which the container is connected. The installation height does not matter. But it is better to install shut-off valves in front of and behind the tank. The membrane fails every few years. Even more often you have to check it and pump it up. To avoid having to stop and drain the system for maintenance, a shut-off valve is installed. It is blocked off and the tank can be removed, checked, and repaired.

At the highest point

In open-type systems, the installation location of the expansion tank is selected based on other considerations. It is placed at the highest point of the system. In this case, it also works as an air collector. Air bubbles tend to rise, and if there is an expansion tank at the highest point, they rise to the surface, escaping into the atmosphere. So such a tank is deliberately made leaky so that the air from the heating system can escape naturally.

Air pressure in the tank

The water or coolant in the heating system is always under pressure. In private houses it is 1.6-2 atm., in multi-storey houses - many times more. To ensure that the coolant does not lose pressure during normal operation, the upper part of the expansion membrane tank must be filled with air.

The air pressure in the upper chamber should be 0.2 atm. lower than the coolant pressure in the system. A regular bicycle or car pump is suitable for pumping air. The only thing you may need is an adapter.

At the top of the expansion tank there is a nipple with a spool. The operating principle is the same as in car or bicycle wheels. To deflate the air, just press the small tongue inside it.

Some manufacturers fill the tank not with air, but with nitrogen. In fact, this will not change the effectiveness of its work at all. This is an advertising ploy - they are trying to force you to buy more expensive equipment.

Use as a hydraulic accumulator

Thus, the expander is used in water supply systems. Thanks to the unit, it is possible to accumulate a certain amount of liquid and then use it for its intended purpose. It is noteworthy that to organize the supply, the accumulated liquid medium under pressure is used without taking into account the operation of the pumping station. The pump does not have to be turned on too often, which significantly extends its service life.

In addition, the membrane cistern replenishes the expansion of H2O in the hot water supply.

Calculation of the expansion tank using the formula

If you do not want to go into details, you can install a tank with a capacity of 10% of the total coolant volume. But sometimes it’s better to calculate everything exactly. By equipping a large heating system, you can save a lot.

To calculate the required volume of the expansion tank, you need to know the following:

- Minimum coolant temperature;

- Maximum coolant temperature;

- Heating system volume;

- The percentage of ethylene glycol or propylene glycol in the coolant.

Important! If you are going to heat a house or cottage where you do not live permanently, be careful when selecting the type of coolant. They have different freezing temperatures and expansion coefficients.

To calculate the volume of the expansion tank you need to use the formula:

V = V1 x ( Q – Q1)

In this formula:

- Q1 – expansion coefficient at minimum temperature (see tables below);

- Q – expansion coefficient at minimum temperature (see tables below);

- V1 – volume of coolant in the heating system in liters;

- V – volume of the expansion tank in liters.

If an expansion tank is already installed in the heat source, then it must be taken into account. To do this, subtract the built-in capacity from the obtained “V” value. The resulting number is the required volume of your expansion tank.

Important! If you have a heating system with forced circulation, the minimum total capacity of the expansion tank is 15 liters.

Thermal expansion coefficient of ethylene glycol solution

| t, °С | 10% | 20% | 30% | 40% | 50% | 60% | 70% | 80% | 90% | 100% |

| 0.00013 | 0.0032 | 0.0064 | 0.0096 | 0.0128 | 0.016 | 0.0192 | 0.0224 | 0.0256 | 0.0288 | |

| 10 | 0.00027 | 0.0034 | 0.0066 | 0.0098 | 0.013 | 0.0162 | 0.0194 | 0.0226 | 0.0258 | 0.029 |

| 20 | 0.00177 | 0.0048 | 0.008 | 0.0112 | 0.0144 | 0.0176 | 0.0208 | 0.024 | 0.0272 | 0.0304 |

| 30 | 0.00435 | 0.0074 | 0.0106 | 0.0138 | 0.017 | 0.0202 | 0.0234 | 0.0266 | 0.0298 | 0.033 |

| 40 | 0.0078 | 0.0109 | 0.0141 | 0.0173 | 0.0205 | 0.0237 | 0.0269 | 0.0301 | 0.0333 | 0.0365 |

| 50 | 0.0121 | 0.0151 | 0.0183 | 0.0215 | 0.0247 | 0.0279 | 0.0311 | 0.0343 | 0.0375 | 0.0407 |

| 60 | 0.0171 | 0.0201 | 0.0232 | 0.0263 | 0.0294 | 0.0325 | 0.0356 | 0.0387 | 0.0418 | 0.0449 |

| 70 | 0.0227 | 0.0258 | 0.0288 | 0.0318 | 0.0348 | 0.0378 | 0.0408 | 0.0438 | 0.0468 | 0.0498 |

| 80 | 0.029 | 0.032 | 0.0349 | 0.0378 | 0.0407 | 0.0436 | 0.0465 | 0.0494 | 0.0533 | 0.0552 |

| 90 | 0.0359 | 0.0389 | 0.0417 | 0.0445 | 0.0473 | 0.0501 | 0.053 | 0.0557 | 0.0584 | 0.0613 |

| 100 | 0.0434 | 0.0465 | 0.0491 | 0.0517 | 0.0543 | 0.0569 | 0.0595 | 0.0621 | 0.0647 | 0.0673 |

How to determine the required expander volume

The volume of the expander must exceed the value of the required volume, which represents the maximum amount of coolant entering the tank as a result of its heating.

First of all, the total volume of coolant in the system is determined. By summing the internal volume of pipes and cavities of all system elements (boiler, heating radiators, shut-off valves), we obtain the total volume. The amount of liquid in pipelines can be calculated depending on the size of the pipe, using the data in Table 1. The volume of equipment cavities is indicated in the documentation (passport or manufacturer’s catalog) for the product.

Table 1 - Determination of the volume of coolant in 1 linear meter of pipeline.

Next, knowing the total amount of liquid, determine the required volume of the expander using the data in Table 2. This value is selected depending on the pressure in the system. If the previously calculated value is between two tabular ones, the required tank volume is determined by the larger of the values.

Table 2 - Determination of the required volume of the expansion tank.

The data in Table 2 is valid if water is used as a coolant. For liquids with a coefficient of thermal expansion different from water, the tabulated value of the total volume is multiplied by a correction factor equal to the ratio of the density of water and the liquid used.

Restrictions

Manufacturers impose certain restrictions on the use of membrane expansion tanks, which depend on the design and materials used in the manufacture of the device. Manufacturers have clear requirements for the properties and composition of the liquid in the heating system. The content of, for example, ethylene glycol in an antifreeze solution is limited. The use of a membrane expansion tank at pressures exceeding permissible standards is prohibited. It is mandatory to install a safety group that controls and limits the pressure in the tank. The heating systems of autonomous heating apartments and private houses use equipment with an operating pressure of at least 3 bar.

Design features

The purpose of the membrane expansion tank is that at all operating stages the device must maintain a balance between the pressure of both parts and, if necessary, level off excessive pressure or regulate its differences in the heating structure. Thus, the installation of a membrane expansion tank prevents the occurrence of increased loads in the heating circuit and in emergency situations in the event of malfunctions.

The device comes with a replaceable or non-replaceable membrane. In the first case, the coolant is completely contained in the flexible membrane container and cannot interact with the steel inner surface. All work associated with dismantling and subsequent installation of a new product is carried out through a flange secured with bolts.

If you purchase a device with a fixed diaphragm, it has an internal cavity consisting of two parts. In this case, a non-replaceable diaphragm membrane is used, which is rigidly fixed. A membrane tank for the heating system is selected directly for a specific heating structure, taking into account the amount of coolant. If the volume of the device turns out to be insufficient, the consequences can be very negative - cracks often appear and water can leak through the threads. In addition, the pressure in the system often drops below the permissible norm, as a result of which air gets inside the tank. Therefore, the choice of device must correspond to the necessary design parameters (for more details: “We are making the selection of an expansion tank for heating”).

An expansion membrane tank for heating systems is used to create closed-type coolant circulation in order to compensate for its thermal expansion as a result of an increase or decrease in fluid temperature, thereby preventing water hammer. In constant mode, both chambers of the device - water and gas - have the same pressure, which makes it possible to maintain the tightness of the system. This arrangement of the expansion tank of the heating system has been time-tested and recognized as the most practical.

The water circulating through the circuit does not contain aggressive gases and therefore corrosion will not render the tank unusable, which allows it to be used for a long time. The pressure expansion device is placed in the boiler room, and for this reason there is no need to protect it from freezing.

Despite the fact that the selection of a tank for a heating structure is individual, one should not forget that:

- the initial pressure in the membrane tank for heat supply connected to the cold water supply must exceed the static pressure in the system by 30-50 kPa;

- The device must have a reserve amount of coolant to compensate for possible leaks.

To protect a closed-loop system with an expansion tank from too high pressure, safety valves are installed.

How does an open expansion tank work?

An open expansion tank is simply a container partially filled with coolant. Sometimes there is not even a valve for air to escape, but just a hole.

Open expansion tanks have two big disadvantages. First, they are susceptible to corrosion because they come into contact with open air. Secondly, they can only be installed in systems with natural circulation.

If you have a circulation pump installed that circulates coolant through the system, then it will not go further than the open expansion tank. The coolant will simply fill the tank and overflow.

Volume calculation

The process of calculating the volume of open and closed type expansion tanks is somewhat different. The tank for an open heating system is made of sheet metal. The container has a hole for supplying coolant to the system.

Such devices may have another hole, which is located in the upper part and serves to drain excess liquid into the sewer. In some cases, coolant (water) is supplied to the open expansion tank automatically, as it decreases.

When designing a heating system, it is important to calculate the volume of the compensation tank. The main value from which all calculations are based is the total volume of water in the system, for example, 100 liters

Note! When calculating the volume of an open type expansion tank, a value of 10% is taken in relation to the total amount of coolant in the system. In our case, we need a 10 liter tank. Expansion tank with a volume of 10 liters. This calculation system, the so-called folk method, can also be used for closed-type compensation tanks

In addition, there is a more accurate method for calculating the volume of the tank. We will need the following data:

This calculation system, the so-called folk method, can also be used for closed type compensation tanks. In addition, there is a more accurate method for calculating the volume of the tank. We will need the following data:

- RH – the volume of increase in the coolant when heated. For water this value does not exceed 5%, for antifreeze it is within 6%;

- VK is the total volume of coolant in the heating system circuit. The amount of water can be measured using buckets or using a special meter that is installed on the drain pipe;

- DS - maximum pressure in the circuit and boiler (such information is provided in the instructions for the heating device);

- DB – pressure in the expansion tank.

To accurately calculate the volume of a closed compensation tank, the following formula is used:

If we compare the result of the volume of the expansion tank calculated using the traditional method with the value obtained from the formula, then the second result will be smaller. If the size of the tank slightly exceeds the required value, correct adjustment is necessary, which will contribute to the efficient operation of the device.

Operating principle of a closed (membrane) expansion tank

The design of a closed expansion tank differs from a closed one in the presence of a membrane. It is impermeable to air and coolant and divides the container into two parts.

The operating principle of a membrane expansion tank is simple. When the coolant heats up, it increases in volume. Under pressure, the membrane rises. This increases the total volume of the heating system and does not put additional pressure on it.

When cooled below a set temperature, the coolant contracts. The membrane lowers and the volume of the heating system decreases. This compensates for the vacuum created by compression of the coolant.

The main functions of an expansion tank for heating or why it is needed at all

The expansion tank in individual heating systems has the important role of receiving excess coolant water. When heated, water can change its volume, and in heating systems the temperature of the coolant is not a constant value. Thus, when creating a completely closed, sealed hot water circulation system, there is a significant risk of rupture of the connecting elements due to increased pressure. Water is a practically incompressible substance and even the most reliable connection made of soldered plastic, as well as any metal, cannot resist its pressure.

Let's look at how an expansion tank works in an individual heating system, what types of expansion tanks there are, how to choose the right equipment and what subtleties need to be taken into account when installing it in a private home.

Operating principles of the expansion tank

Let's give a simple physical example. Let’s say the temperature of the liquid coolant, water, in our heating system has risen by only 10 degrees. This may be due to more intense operation of the heating device caused by the lower temperature outside. After such a temperature rise, the volume of water circulating in the closed system will increase by 0.3 percent.

It would seem - not a very large value. However, water (or antifreeze used as a coolant) is incompressible, that is, strong excess pressure gradually builds up in the system. To prevent such pressure from destroying the connecting elements of the heating system, the water must be given space to expand. This space will be the expansion tank. When the coolant is cold, it is not completely filled, but when heated, the water level in it increases, which maintains the pressure in the water circulation system at a normal level.

Requirements and recommendations for installing a membrane tank

Small volume tanks are wall mounted

You can install the equipment yourself by following the instructions. When working, adhere to the installation requirements:

- The first stage is choosing a location. It is necessary to ensure free access to the tank for maintenance. A good place is considered to be the section of the return line between the pump and the boiler.

- To ensure the safety of a closed circuit, you will need to install a safety valve, an air vent, a pressure gauge and a thermometer.

- A drain valve is installed in front of the inlet pipe to drain water from the tank.

- Filters must not be installed in the area connecting the tank and the heating system.

- Before connecting the equipment, check the pressure of the gas space. If necessary, pump up air.

- The tank should not be located in a room with sub-zero temperatures.

The tank is securely mounted on the wall, and no additional load should be placed on it. Large volume models are mounted on the floor. A connection diagram with the inlet pipe located at the bottom is recommended. Experts advise making a detachable connection between the pipe and the drain valve in front of it. If necessary, the expansion tank can be easily dismantled.

The manufacturer specifies the requirements for the amount of antifreeze in the coolant. The stated proportions must not be exceeded.

Features of choosing a tank

The main factor in choosing a membrane tank is its volume. When calculating the optimal tank volume, the following nuances should be taken into account:

- number of users of the water supply system;

- number of water intake points: taps, outlets for showers and Jacuzzis, outlets for household appliances and boilers that work with water;

- pump performance;

- the maximum number of pump on/off cycles in one hour.

To calculate the approximate volume of the tank, you can use the following guidelines from experts: if the number of users is no more than three, and the pump capacity is no more than 2 cubic meters per hour, then a tank with a volume of 20-24 liters is quite sufficient; if the number of users is from four to eight, and the pump performance ranges from 3-3.5 cubic meters per hour, a tank with a volume of 50-55 liters will be required.

When choosing a tank, remember: the more modest its volume, the more often you will have to turn on the pump and the higher the risk of pressure drops in the water supply system.

Advice. If you assume that over time there will be a need to increase the volume of the membrane tank, buy equipment with the ability to connect additional containers.

How to choose the right membrane expansion tank?

In order for the heating system to operate stably, the tank for it must be selected based on calculations. The correct pressure cannot be generated if the reservoir is larger than necessary; and if it is smaller, it will not accommodate excess liquid, which can lead to an accident.

For the product to work properly, you need not only to correctly select its volume, but also take into account other characteristics. Particular attention should be paid to the following factors:

- the membrane must be resistant to extreme temperatures and pressures or their differences;

- the model must comply with sanitary and hygienic standards;

- tank installation method.

The Russian market offers a large number of expansion tanks of Russian and foreign production, which vary in cost. You should not purchase the cheapest models - such a price may be due to the use of low-quality materials in production. Domestic tanks are cheaper than their foreign counterparts, but are not inferior to them in terms of performance characteristics.

The main characteristic that you should focus on when purchasing an expansion tank is its volume. The standard recommendation is the following: choose a product whose size is 10% of the total volume of coolant in the heating system. Since the coefficient of thermal expansion of the coolant, even with high heating, cannot be higher than 0.08, such a volume of the hydraulic accumulator will be quite sufficient. Calculations before purchasing a product should include the following indicators:

- coolant volume;

- coefficient of thermal expansion;

- maximum permissible pressure of the heating system;

- initial pressure in the tank.

When calculating the total volume of coolant, it is necessary to take into account all components of the heating system. This information is obtained from the building design documentation. In the absence of such documents, you can perform an approximate calculation, taking as a guide that 1 kW is required to heat 15 liters of water.

The coefficient of thermal expansion of the coolant is calculated by its temperature or determined by the composition of the liquid - in apartment buildings it often contains glycols, which improve its characteristics.

The maximum pressure of the heating system is determined using the minimum pressure value allowed for its components. The transfer valve is adjusted to this indicator.

The initial pressure in the heating system with a cooled coolant corresponds to the minimum pressure. To control the initial pressure in the tank, the accumulator is equipped with a pressure gauge. Also, a safety group must be installed on the expansion tank, which limits and controls the pressure.

The use of a membrane tank for heating has a number of limitations depending on the design and material from which it is made. Some models have strict requirements for the composition of the coolant, in particular, they limit the amount of antifreeze and ethylene glycol in its composition.

Please note: expansion tanks cannot be used if pressure limits are exceeded.

Product selection rules

When deciding on a model, you should pay attention not only to the volumetric characteristics. It is equally important that the device meets a number of other requirements:

- the membrane-plate must withstand high temperatures and changes in atmospheric parameters;

- the unit must not deviate from established sanitary and hygienic standards;

- installation features also need to be taken into account when purchasing.

When choosing a device (membrane-type expansion tank), it is easy to notice that today there are many types of tanks on the market, manufactured both in Russia and abroad. The main differences lie in the price range of the products.

Sticking with the cheapest model is definitely not the best decision. After all, a minimum of purchase costs can subsequently result in many problems due to the low quality characteristics of the materials used in production. In this regard, it is worth giving preference to domestic manufacturing companies. The products they produce are in no way inferior in quality to expensive imported products, and are much less affordable. Do not forget that a famous brand does not guarantee the reliability and long service life of the device.

The leading parameter that you should rely on when choosing a tank is its volume. Many experts advise buying an expander with a capacity of 10% of the total amount of coolant in the heating network. The expansion coefficient at maximum temperature conditions must remain within 0.8. Therefore, all required calculations must be carried out with utmost accuracy. And it is necessary to take into account:

- system pressure limit;

- volumetric characteristics of the coolant;

- the initial number of atmospheres in the tank;

- corresponding thermal coefficient.

When deciding on the dimensions of the device, be sure to check the availability of all components. To do this, just carefully review the project documents. If the necessary documentation is missing (lost), the required parameters should be calculated approximately. Just know that 1 kW provides 15 liters of liquid. In high-rise buildings, the coefficient is usually calculated by taking into account the composition of the liquid medium, which often includes glycols, which have a beneficial effect on its quality.

In addition, it is quite possible to determine this value based on the temperature of the coolant. The maximum network pressure is determined using the limit set for the nodes. This is done by setting up special locking elements. The initial number of atmospheres must be minimal. On a number of models it is adjusted by pumping or deflating air. Directly in the tank, control is carried out using a pressure gauge.

The use of an expansion tank with a membrane has its own limitations. The possibility of its use in a given situation is mainly influenced by the production methods used by the manufacturer, as well as the materials. In some situations, special requirements are imposed on the composition of the coolant. Thus, a mandatory reduction in the amount of ethylene glycol or antifreeze may be indicated.

When choosing a suitable product, pay attention to the Russian company -. The products manufactured by the organization meet the highest quality characteristics and are able to serve their owners for a long time. The reliability and high quality of the products are confirmed by the company's many years of experience and many positive reviews from grateful customers.

Possible breakdowns

With prolonged use, the membrane may burst

During operation of the equipment, owners are recommended to inspect the housing for leaks and damage every six months. It is also necessary to measure the pressure in the gas chamber. The condition of the membrane is checked once every 2 years. If there is no use for a long time, the water is drained from the tank.

Common faults:

- Pressure drop in the gas compartment - it is necessary to pump air through the nipple using a pump.

- Damage to the housing - mechanical stress or corrosion can cause a crack to appear. The seal of the container can be restored at a service center.

- Leaking from the air valve - due to high loads and hot water, the rubber may crack. It is better to replace the damaged part in a timely manner.

You can repair the equipment yourself. To replace the membrane, you will need to drain the water, remove the container and relieve the pressure. Then unscrew the flange bolts holding the rubber part. The old membrane is removed and replaced with a new one. All procedures are carried out in reverse order.

The procedure and conditions for installing the tank

The membrane accumulator can be installed independently, without the involvement of a specialist. The list of requirements for installing the device is as follows:

- The device must not be installed in places with sub-zero temperatures;

- the expansion tank can be installed at any point in the heating system before it is branched;

- the fastening must be as reliable as possible, since a filled tank becomes very heavy;

- connections must be sealed, but sealants cannot be used, since they will worsen friction between the tank body and the membrane;

- Do not install the tank on the outlet pipe in the immediate vicinity of the heating boiler.

If the hydraulic accumulator capacity has a volume of 30 liters or more, it is prohibited from attaching it to supporting structures. Most often, such tanks are equipped with special legs, which allow them to be installed directly on the floor. During installation, the following conditions must be observed:

- the pipe must have a three-quarter (inch) circumference; accordingly, a similar threaded channel must be present in the return pipeline;

- any external load on the tank must be excluded;

- paronite gaskets that are resistant to high temperatures or pressure should be used;

- In order to regulate or maintain the required pressure in the gas compartment, the expansion tank must be equipped with an air valve.

When installing the hydraulic accumulator, gross mistakes must not be made, otherwise the equipment will not function normally. The most common mistake is incorrectly calculated maximum pressure (which is about 90% of the critical pressure) in the gas compartment. Such a miscalculation leads to the fact that the membrane does not expand and does not allow excess coolant to pass into the tank. The result will be a pipe break and failure of the heating system. A high-quality pressure gauge installed on the hydraulic accumulator protects against such developments. If after calculations it turns out that the volume of the existing tank is not enough, you will need to purchase an additional small container.

The expansion tank in the heating system is very important, since it determines how correctly the system will work. Installing it is not difficult, but it is necessary to carry out the entire process as carefully as possible, since even a small mistake can provoke an emergency. In a closed heating system, high pressure is constantly applied to the membrane; throughout the entire heating season, this device experiences serious loads. Therefore, at least once every 2 years you should check its condition and, if necessary, replace this part and/or the expansion tank itself.

Installation Requirements

It is quite possible to install the unit even with your own hands. It is absolutely not necessary to call a specialist for this. The main thing is to strictly follow the installation rules and carry out everything according to the design of the expansion membrane tank.

An expander with a volume of 30 liters or more should not be attached to load-bearing walls. As a rule, large tanks are installed directly on the floor on special steps. During installation, you must ensure that:

- the circumference of the adapter was ¾, and the return had a corresponding thread;

- during the installation process, the structural elements did not interfere with the work;

- no excessive load was placed on the tank;

- you had paronite heat-resistant gaskets at your disposal;

- the container was equipped with a special locking mechanism that allowed the gas pressure to be adjusted.