What is a riveter and how does it work?

Riveters or riveters are devices for installing rivets. There are special tools for different types of fasteners. There are separate ones for blind rivets. There are also universal models, but they belong to the group of professional tools, and accordingly, they cost a lot.

One use case

To choose the right riveter, it is advisable to understand how it works. Regardless of the type of rivets with which the unit works, the principle of riveting is always the same: the device flares the second (distant) part of the rivet, forming the closing head. Only the flaring method may differ:

- When installing blind rivets, the jaws grasp and pull the rod. At the end of the rod there is a ball that rests against the edge of the rivet body and crushes it. When a certain force is reached, the rod breaks off.

The work of a riveter when installing blind rivets - The installation of screw rivets is different. There is a thread inside the hollow body. A screw of suitable diameter is screwed into this hardware. When twisted, it begins to tighten the edge of the rivet, due to which the ductile metal is flared (see video below).

- When installing hollow rivets (piston rivets), simply flaring occurs with a cone-shaped nozzle. Piston rivets are used in unloaded places, but more often not in construction, but for finishing or when joining parts made of leather, fabric, etc.

Piston rivets are the easiest to install, but they also have the lowest reliability. They are rarely used in construction, except in crafts.

In general, the process is clear. As you can see, the only differences are that in one case you need to pull the rod, in another you need to turn the screw, in the third you press the conical nozzle. When choosing the type of rivets, please note that the tool for rivets is inexpensive, but for screw rivets it usually costs a lot. This basically limits the use of screw rivets. Well, and because they are hollow, they are not airtight.

Kinds

The range of works that require the installation of riveted seams is very wide. And each process has its own specifics. The correct choice of tool determines with what quality, in what time frame and how much cost it will take to complete the required task.

By type of fastener use

Since the method of joining all types of rivet joints remains banally simple, riveters repeat this entire process, only by “automating” it.

The method remained the same - filling a through hole in the two parts being connected with metal. Only technologically this task is performed in different ways.

The drawing tool, to fill the entire space of the through hole, deforms the metal by pulling it out. And the threaded one fills a through hole using the method of twisting and then tightening. This also causes the connecting metal to flatten.

For these actions, in both cases, special fastening materials are used for drawing and cutting tools, respectively. Let us dwell in more detail on the mechanism of their operation.

Exhaust

The device of the tool is a simple mechanism. A hole is first drilled in the materials to be fastened. The body of the rivet is inserted into this hole. This body is the material with which the through hole will be filled. The rivet maker's jaws grip the rivet rod up to the working part (shoulder).

In fact, the rivet shank is designed to deform the body of the rivet to fill the entire through hole. This is accomplished by the tool's pulling mechanism, which pulls the head of the shank through the body of the rivet toward the base. In this case, the body of the rivet (a cylinder made of soft metal) is easily flared. A tight connection of materials is established between the head of the rod and the shoulder of the rivet body. When the rivet joint is ready, the rivet shank breaks off.

Example of operation of an exhaust device

Threaded

The operating principle of such a tool is also not difficult. A threaded rivet is installed in a hole prepared in advance in the connected parts. The rivet has an internal thread. The riveter screws the holder onto the threads of the rivet body. Then, using a traction load, we lift the holder. In other words, we use a riveter to pull the holder together with the body of the rivet towards the base (shoulder). This also causes the body of the threaded rivet to flatten. In some cases, the body of the threaded rivet (sleeve).

By food type

The need for combining materials is high - from the domestic sphere to the industrial sphere. At the same time, the requirements for the riveting tool are different. Hand tools can handle light-duty tasks quite well. For more complex tasks, enhanced versions of hand tools or battery-powered tools are available. The requirements for a professional device are higher - since it is necessary to perform a large number of operations.

Summarizing the above, we can distinguish three types of tools based on the type of power supply:

Selecting the drive type

Before choosing a riveter, you need to understand what they are. Let's start with the drive.

- Manual (power). To install the rivet, you need to squeeze the handles. Sometimes significant efforts have to be made - for hardware with a diameter of 5 mm or more. The most reliable and inexpensive. This is a justified choice if the tool is purchased for a one-time use - installing roofing material, putting up a fence, sewing up slopes.

When using hand tools, you will have to exert physical effort - Electrical. There is almost no effort - hold the tool and pull the trigger. More expensive, but also more productive models. From the network. Not too expensive, so you can buy them for home use. But not every construction site has a source of electricity, and cords/extension cords are a real hassle.

- Rechargeable. With the same performance, they are more mobile, but they weigh more (the battery itself also weighs), and they are more expensive.

Riveters can be manual, battery-powered, electric, hydraulic

Video review of the MILWAUKEE 2550-20 M12 RIVET TOOL cordless riveter.

For household use, manual riveters are purchased. But even this “simple” tool is not easy to choose. First of all, the range of prices is surprising - from $5 to several hundred dollars. How to navigate here? Let’s say right away that it’s definitely not worth taking something too expensive for a one-time use, just like one that’s too cheap. The rest needs to be figured out.

How riveting occurs

In ancient times, riveted joints were made using large and complex mechanisms. This technology was not popular because it required a lot of human effort and was labor-intensive work. It is because of this that manual riveters were invented, which are well suited for home work. Such a tool does not need additional support. In addition, there is no need for open access to both sides of the product. You just need to drill a hole in advance and press a special button. That's why the whole work process becomes quick and easy.

4

Riveting at home - possible difficulties

If you don’t know how to use the tool, there may be certain difficulties during operation:

1. The occurrence of backlash if the rivet is not attached firmly enough. This is a consequence of the drill being too large to make the holes. There is only one way out of the situation - to install a rivet with a large diameter.2. The appearance of sharp edges after riveting - in this case, you used a rivet with a head whose size is larger than the required parameters.3. Waste from the rivets remains in the tool - this happens when the rod is deformed. As a rule, this is typical for low-quality devices that are not capable of performing the job at the proper level.4. To achieve the greatest effect when fixing elements, experts recommend choosing rivets from the same material as the parts being connected. The choice of material is very wide; you can use rivets made of metal, stainless steel, aluminum, and steel. In this case, the fastening will be as strong as possible.

Rivets made of the same material as the parts being fastened will increase the effectiveness of fixation

To avoid such problems, carefully select rivets and drill bits. The holes must match the rivets. After pressing the lever, so-called caps are formed, which basically hold the elements together. If the size is chosen incorrectly, there will be play, which will ultimately lead to the destruction of the fastener.

Types of manual (mechanical) riveters

There are three types of manual rivet setters:

- one-handed;

- two-handed;

- harmonic.

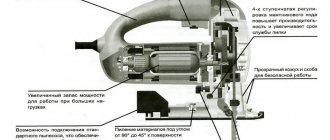

One-handed ones are designed for small fasteners - up to 5 mm. They differ in that their working handles are at an angle of 90° to the installation axis. That is, the handles are pointing down. It is convenient because you can work with one hand. The disadvantage is the small “range” of sizes that the device can work with.

Two-handed ones are large in size; they can also install rivets of large diameters - up to 8 mm. You can distinguish them by their appearance - long handles that are in the same plane as the working jaws. It makes sense to choose a two-handed riveter if you plan to use large diameter rivets.

Types of manual riveters: one-handed, two-handed, accordion

Mechanical accordion riveters are often used with large-sized fasteners. The presence of that very “accordion” allows you to install large-sized fasteners with less effort. Such a device usually has a more expensive tool and is more often used by professionals.

Choosing the type of manual riveter is not too difficult. If you need a reliable machine, choose from two-handed models. Their design is simpler, there is almost nothing to break. At normal quality they are indestructible. If you will only install small fasteners - no more than 2-3 mm, then it is more advisable to use a one-handed one. It's more convenient for them to work.

Advantages and disadvantages of different riveters

The fact that there are several types of riveters on the market is due to the presence of both pros and cons of their use.

Based on them, the tool is selected for work in specific conditions:

- • One-handed models develop a small working force, so they are used for installing rivets made of soft material, such as aluminum. At the same time, they are compact and require only one hand to operate.

- • Two-handed models, due to the presence of two reinforced levers, can easily cope with rivets made of hard material, such as steel. At the same time, the work is performed with two hands, which is somewhat inconvenient.

- • Rocker models support one-handed operation. The force can be increased by leaning on the mechanism with your whole body, which also provides support for the steel rivets.

At the same time, the accordion is not suitable for installing lightweight structures that cannot withstand the high pressure exerted on them required to tighten the fasteners.

Selection criteria for manual rivet installers

So, if you need to choose a manual riveter, pay attention to the following parameters:

- The type of fasteners with which the unit works (screw, pull-out, piston (eyelets), universal - which installs all types of rivets).

- Maximum and minimum rivet sizes.

- Number of nozzles for rivets.

- The fastener material with which the tool works (steel, aluminum or only copper and brass).

- What is the instrument itself made of? Better - stainless steel or aluminum alloys.

Screw-type manual riveter: pay attention to the dimensions of the fasteners that can be installed

Another thing to pay attention to is the handles. The rubber pads on them should be made of good rubber. The handles themselves should be comfortable for you, so you can work faster and longer. Also pay attention to the possibility of fixing the handles when not in use - there is a special wire loop that holds the handles together. This is convenient and important when storing.

How does a manual riveter work?

The riveter consists of the following parts:

- Heads that fit onto the rivet core.

- The body, which is a frame for the stop and a lower handle at the same time.

- Top handle. This part of the tool rests on the body using an axis and serves as a power lever.

- The working sleeve, after compressing the handles, compresses the collet jaws. As a result of their joint work, the rivet rod is firmly fixed.

- Next, using the same collet jaws, the rod is pulled out of the sleeve. A riveted ring is formed.

- While the master opens the handles, the conical bushing opens the collet mechanism and it returns to its original position.

- The spring stop is the cover. If it is necessary to inspect the cams, the riveter is disassembled and removed.

- The case has space for replaceable heads. They are selected depending on the diameter of the rivet.

Considered in general, the riveter is a pistol equipped with two mechanisms:

- spring;

- lever

The first pulls the stave in, where it is flattened using a lever system. As a result, the parts are firmly connected to each other.

Each riveter has several nozzles of different diameters. This allows you to use fasteners of different lengths.

Selecting a blind riveter

Most often you have to work with blind (traction) rivets. They are convenient and inexpensive. The tools to install them don't cost too much either. In addition to the parameters listed above, in order to select a rivet tool for traction rivets, you also need to pay attention to some special characteristics and options.

- Number of clamping jaws (petals) in the collet. The tool grips the rod and pulls it to form the closing head. So, there can be two or three petals. Double-lobed ones are cheaper, but when grabbed, the rod can become skewed and get stuck. You have to take it apart and put it back together again. It’s inconvenient, and time is running out.

There can be several forms - Presence of a ratchet . When working with strong rivets (steel), it is important to correctly calculate the force. A ratchet helps with this.

- Container for collecting broken rods . During operation, the excess rod breaks off. If there is no container, they often end up underfoot and then have to be collected. The presence of capacity solves the problem, but has almost no effect on the price.

Now you know how to choose a riveter for blind rivets. Having selected several models that suit you in terms of characteristics, inspect them and hold them in your hands. If possible, try it a couple of times at work. This will make it easier to understand which tool is more convenient for you to work with and it will be easier to make a choice.

Purpose and principle of operation of the rivet gun

The riveter is used to connect flat workpieces together, where the width of the contact points exceeds their thickness by 3 or more times.

For example, if you fold two identical strips of steel with dimensions 4x40 mm close together, their width will exceed the total thickness by 5 times.

In this case, the use of rivets as connecting elements is justified.

Riveting pliers, as riveters are otherwise called, are suitable for connecting parts with a total thickness of no more than 13 mm.

The tool is used in everyday life, in production, in construction and is indispensable in various repair shops.

A mechanical riveter is shaped like large pliers, and the principle of its operation is to transfer force from the handles - levers to the working mechanism, which installs the rivet element in the hole.

The fastening element itself consists of the following parts:

- A rivet is a tube with a cap located on one side.

- The core is a steel rod originally located inside the stave. It has an extension at its end.

As it works, the tool pulls the rod through the stave, expanding its tube.

At the moment when the force reaches a given value, the rod simply bites off.

The elementary principle of operation is what determines the high popularity of the riveter in the formation of strong joints.

Drill/screwdriver attachment and selection features

When doing a large amount of work using manual riveters, your hands get very tired. Of course, there are rechargeable ones, but the price for them is not at all pleasing. And if you only use it occasionally, it is not advisable to buy a power tool. In this case, you can compromise - purchase an attachment for a drill or a screwdriver for installing rivets.

This is a small adapter (nozzle) that is inserted into the cartridge. They are available for screw and blind rivets. If desired, you can find it for other types of fasteners.

Adapter (nozzle) for drill for installing blind rivets

The principle of operation of a drill with a nozzle for blind rivets is no different - the tool still pulls on the pin, then breaks it off. You just have to get the broken “tails” out yourself, switching the drill to reverse. In the case of using screw rivets, reverse is also required - to remove the nozzle from the installed fastener.

Drill attachment for installing screw rivets

The choice of rivet attachments for a drill is similar: in type, size and material of the attachments. Well, the shank must fit the power tool chuck. Also pay attention to the presence of a handle. This is a non-critical parameter, but it improves ease of use. A drill with a screwed attachment is heavy and unstable. Therefore, when working, be sure to hold the nozzle with your hand, fixing its position. To avoid holding on to the nozzle, put on a handle. In this version, the unit is more convenient to use, and you can more accurately control the position.

Types of riveters and their prices

The tool is divided primarily by drive type into:

Mechanical

Another name is a manual riveter, although, in fact, the following types of tools also belong to manual ones. Mechanical models are rightfully considered structurally the simplest. They are used both for work in workshops and at home.

Forming connections requires physical effort. The cost starts from 250 rubles, and the price of a quality instrument often exceeds 1,500 rubles.

Pneumatic

Operation is ensured by compressed air supplied from the compressor.

Pneumatic models are expensive, but at the same time the most powerful and productive.

The average cost is 12 - 20 thousand rubles for threaded options, and from 7 thousand for exhaust models.

Electric

Its performance is superior to mechanical options, and in addition, it requires virtually no effort during operation.

An electric riveter means a powered tool that is used in production and runs on a household network with a voltage of 220 V.

On average, the cost rarely falls below 10 thousand rubles.

Rechargeable

In fact, it is a subtype of electric riveter, with the only difference being that the power is supplied from a battery.

The price starts at 20 thousand rubles, and the cost of some models reaches 90 thousand rubles.

Pneumohydraulic

Or simply hydraulic - an industrial version, used for installing large threaded rivets.

Such models provide reliable fastening of parts with high clamping force, and are used primarily in the mechanical engineering industry.

The average cost is 3 – 7 thousand rubles.

Depending on the type of rivets used, there are:

• Blind (traction) – designed for installation of blind rivets. The main advantage is the low cost of consumables.

This type of rivet completely closes the hole in the workpiece. The tool is rightfully considered the most common due to its simplicity of design.

• Threaded – for mounting threaded rivets. It operates on a slightly different principle. Thus, a rivet has the form of a hollow tube, at one end of which there is an internal thread, and the opposite part is flared, in the manner of blind nuts.

A pin is screwed into the thread and pulled towards itself, as a result of which the thin metal between the thread and the flaring is crushed, firmly pressing the parts being connected to each other.

The connection is much stronger when compared with the previous version, but at the same time the cost of the rivets themselves is higher.

• Versatile. Suitable for working with blind and threaded rivets, supplied with appropriate replaceable heads.

According to the location of the working head relative to the body (handles), the tool can be:

- Direct type - the head is fixedly directed along the tool body, located in its end part. An alternative name is end riveter.

- Angular type - the head is fixed relative to the body at a right angle, or less often at another angle.

- Double-sided - a type of corner riveter, where the head can be moved to the back of the body by unscrewing it and screwing it into the seat with a key.

There are models where the head can be moved both to the top and side of the tool, which allows you to work in hard-to-reach places.

- Two-position - the head is installed in a position of 90°, or 180° relative to the body. In other words, it can be both straight and angular. Considering that the working part can be rearranged without the use of additional tools, this option has another name - an adjustable riveter.

- Rotating - the head relative to the body rotates at an angle of up to 360 degrees using a special hinge mechanism. A riveter with a rotating head is also preferable in cases where you plan to install rivets in hard-to-reach places.

Mechanical riveters are divided into several more types based on the design of the handles, and therefore the entire working mechanism as a whole.

The tool is:

One-handed

Outwardly it resembles a stapler for staples. It is for this reason that this option is called a rivet stapler.

A cheap rivet gun is made of silumin (an alloy of aluminum and silicon), which is not durable.

This option is suitable exclusively for installing aluminum rivets.

This material is also often used to make tools designed for plastic rivets.

A more expensive tool has a cast steel body, which has a positive effect on durability.

Single-handed rivet pliers are not intended for installation of fasteners made of hard materials, where great force is required by hand.

Therefore they are ideal for amateurs. As a rule, the diameter of the tightened fastener does not exceed 4.9 mm.

Two-handed

A tool designed to work with rivets made of any materials, including steel and stainless steel, as it develops a large working force.

Another name is a lever riveter, which in appearance vaguely resembles a bolt cutter.

Both of its handles are movable and made of durable material, which allows it to withstand significant loads for a long time.

This reinforced version of the tool is professional and allows you to work with rivets up to 6.5 mm thick, which affects its cost.

The power riveter is suitable for long continuous operation.

Rocker (accordion type)

A specially designed tool designed to perform work in hard-to-reach places.

Another name is a lever-folding riveter, which is due to its elongation when installed in a fastener cartridge, and folding when pressing on the handle.

Such models allow you to work with one hand, however, force can be applied by pressing with the whole body, and not just with the hand.

In addition to the standard rivet guns described above, a less common tool is also used for installing rivets:

Riveter

A pneumatic multifunctional tool, structurally reminiscent of a jackhammer.

The material is riveted using powerful impulses.

This impact tool can be easily converted into a chasing or chipping hammer by installing the appropriate attachment.

The price is rarely less than 5 thousand rubles.

Riveter adapter

Transforms an ordinary drill or screwdriver into an electric riveter.

Used primarily for small amounts of fastening work.

The attachment for a screwdriver costs about 2 – 5 thousand rubles.

How to choose a riveter: manufacturers and prices

When choosing a specific model, many rely on prices. But the spread is very wide - there are very cheap ones and almost identical in appearance, but many times more expensive. Even ten times more expensive. It’s worth saying right away that even for one-time work, buying a very cheap riveter is too risky. It may not work at all or work through the stump-deck.

If you only want to rivet a fence, for example, even then you will have to install hundreds of rivets. If you have to disassemble the tool after every 2-3 rivets, you definitely won’t like it. To choose a riveter that works well, look at the average price range.

- Stanley MR 99. Stanley is the oldest American company.

- NOBUS. Inexpensive tool, works reliably.

- Gesipa. A well-known company, but not everyone praises it. There are definitely cheaper ones that work at least as well.

- YATO copes with steel rivets better than Chinese ones with aluminum ones.

To be able to estimate the price range - NWS is a German company. The quality of the instrument is excellent.

- Topex. In some models I liked the ability to move the “spout” 90 degrees. Convenient if you have to work in hard-to-reach places.

- KRAFTOOL. All the tools are good and so are the riveters.

If you plan to use a riveter in professional activities, you need to choose a more expensive one. The company - at your own discretion, but from the category of professional or semi-professional models. Perhaps they do not differ structurally, but they have a longer resource and service life. That is, they are made more reliably and efficiently. And this explains the difference in price - more expensive/high-quality materials were used.

Description and scope of use

First of all, any electric riveter is a modern construction tool, the main task of which is to fasten individual parts. Externally, this automatic unit is in many ways similar to a screwdriver familiar to many. At the moment, the market offers more than a wide range of models that operate from household electricity or rechargeable batteries.

The use of such a tool during installation work can significantly reduce time costs and simplify the entire assembly process. It is also worth noting that, unlike manual riveters, their electrified counterparts do not require significant physical effort. When starting the device, uniform pressure is created on the shank of the rivet without any jerking. This ensures that the sleeve is tightened as smoothly as possible until the rod is bitten off.

One of the key advantages of electric models is, of course, the high quality of the connection created. At the same time, if you have physical strength and a certain practical experience, similar results can be achieved using a manual (mechanical) riveter. However, the automated tool is designed to make the riveting process easier. This is most relevant in conditions of limited space.

It should be noted that relatively recently the described tool has a worthy competitor. We are talking about special rivet attachments for screwdrivers and drills.

To be fair, it should be taken into account that a specialized power tool still has one significant advantage. The fact is that these devices are equipped with containers for tear-out rivet shanks, which do not have to be removed manually. This in itself significantly increases productivity and installation speed.

It is important that this waste does not fall on the workshop floor. However, despite the undeniable advantages, not all models are equipped with such containers

Electric riveters are used wherever the fastening elements are rivets of various types. Most often we will talk about the assembly of structures and their individual elements, the parts of which are made of sheet materials. By the way, these can be not only metal structural elements. Today, this type of tool has found application not only in construction, but also in the furniture industry and automotive industry.

The best manual thread riveters

Absolut SKytools SK5002

Main characteristics:

- Rivet sizes - M6, M8, M10 and M12

- Rivet material: steel/aluminium/stainless steel/copper

Design and ergonomics. This riveter works on the ratchet principle. It has two cylindrical side handles, one of which is fixed on the body, and the second master makes oscillatory movements, squeezing the rivet. The scale printed on the side wall accurately shows the position of the rod, helping to navigate the degree of compression and protecting the tool from overload. The unique design of the gearbox speeds up the process of screwing on and unscrewing the stud. The weight of the product does not exceed 1.1 kg.

Uses and attachments. The tool is designed for installation of threaded rivets made of copper, aluminum and various grades of steel with diameters M6, M8, M10 and M12. Corresponding attachments are included.

Absolut SKytools SK5000

Main characteristics:

- Rivet size - M3; M4; M5; M6; M8; M10

- Rivet material: aluminum/steel

Design and ergonomics. The two-handed riveter is made of hardened steel, which provides a long service life during professional work. The plastic handles with rubber pads fit comfortably in the hand and do not slip out. Weighing 1.86 kg, the length of the product is less than 40 cm.

Uses and attachments. This model is used for installing threaded rivets made of steel and aluminum with a diameter of 3 to 10 mm. It is sold in a plastic case complete with 6 types of attachments and an installation key.

Absolut SKytools SK5000 kit.

JTC 5821A

Main characteristics:

- Rivet size - M3; M4; M5; M6

- Rivet material: steel/aluminium/stainless steel/copper

Design and ergonomics. The one-handed riveter is made of high quality steel. It has a comfortable, slightly curved handle 270 mm long with a lever secured when folded with a special bracket. The rotary handle of the rod has side notches, which simplifies screwing in the stud.

Uses and attachments. The tool is suitable for installing threaded rivets made of any materials from copper to stainless steel with a diameter of 3 to 6 mm. Corresponding attachments are included. The product is sold in a small metal case with a clasp and compartments for storing fasteners.