Requirements for sewer pipes

Sewer pipes must be:

The ideal option for a cottage owner is to install a sewer system in the house and forget about it for the next half century. Changing pipes every five to six years will be expensive and labor-intensive. This process is not quick (it is unrealistic to completely change the sewer system in a couple of days).

Necessary pipe structures for sewer installation

Plus, during such repairs you will have to forget about comfort and the use of plumbing. This split air conditioning system or pool boiler may be turned off for a week or two. But if the internal sewage system does not work, then living in a cottage immediately turns into a serious problem.

Another important point is the resistance of pipes to the aggressive effects of drainage from sinks, bathtubs, washing machines and toilets.

Household wastewater contains fecal matter, fats and household chemicals. All of them form an explosive mixture with increased biological and chemical aggressiveness. And sewer pipelines must be made of materials that can withstand such effects for many years.

Kinds

There is simply a huge range of sewer pipes on the plumbing market today. There are options from different materials and with different characteristics. This diversity is due to the large number of manufacturers and the great demand for such products.

Cast iron

The most common and widespread is cast iron. Pipes made from it are characterized by high strength, fire resistance and durability (service life 60–80 years), as well as resistance to chemicals and temperature changes. Among the disadvantages of cast iron products are the high price and difficulties with installation due to their heavy weight. Plus, cast iron is characterized by a rough surface, which leads to a layer of fat inside the pipeline and its narrowing.

Methods for connecting cast iron pipes for sewerage

Steel

Steel pipes will cost less than cast iron pipes, but will last much less (maximum 30 years). They are much more susceptible to corrosion than their cast iron counterparts. In private homes, this option is extremely rare. If durability is not so important, then it is better to make the internal sewage system out of plastic.

Methods for connecting steel pipes

PVC pipes

The most common among plastic pipes are products made of PVC (PVC, polyvinyl chloride). They are cheap, light in weight, smooth inside and last about 40 years. Plus PVC pipes are resistant to corrosion and aggressive environments.

Their only serious drawback is the rather low maximum operating temperature. Water heated above +600 C with prolonged exposure gradually destroys polyvinyl chloride. In general, it is recommended to use a PVC pipe when laying an outdoor sewer section, where wastewater from different plumbing fixtures is already mixed and is not so hot.

Methods for connecting PVC pipes

Polypropylene

Compared to PVC, polypropylene is more durable and can easily withstand heat up to +1000C. Pipe products made from it are characterized by increased wear resistance and can last up to 100 years. But they are somewhat more expensive than PVC pipes for internal sewerage.

Methods for connecting polypropylene pipes

Polyethylene

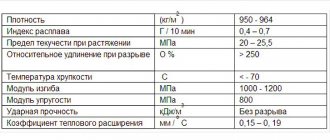

Polyethylene analogues almost completely repeat the characteristics of the polyvinyl chloride version. They are only slightly more resistant to aggressive chemicals, but at the same time they will cost more than PVC pipes. Plus, polyethylene products are softer and are more easily damaged from the inside by abrasive particles (grains of sand or rust contained in wastewater from a private home).

Methods for connecting polyethylene pipes

Asbestos cement

Asbestos cement sewer pipes are usually used to lay the street part of the drainage system. They are distinguished by increased corrosion resistance and low cost. However, they will last a maximum of 25 years. Then the asbestos-cement pipe will definitely have to be replaced due to wear.

Methods for connecting asbestos cement pipes

Ceramics

The most durable, chemical-resistant, smooth and at the same time expensive is ceramics. Pipes for internal sewerage made of this material belong to the premium segment. However, they are quite fragile and difficult to install independently.

Method of connecting ceramic and cast iron pipes

Modern technologies

However, many homeowners do not want to mess with either cast iron or ceramics. This is mainly due to the aggressive promotion of polymer and other “more modern” materials. They consider cast iron pipes to be “the century before last”, and ceramics seems to them to be a fragile and “primitive” material. This, of course, is wrong, but it is often almost impossible to convince such people. They prefer to use pipes made of polymer materials for the external sewer system. Some people also buy ordinary plastic pipes for internal sewerage, and, in principle, some types of plastic are more or less well suited for creating an external sewerage system, although, of course, the durability of such systems is relatively short.

Among the “new” materials that have appeared on the construction market today, we can highlight corrugated polyethylene or propylene pipes, which were specially designed for use as external sewerage. The strength of such pipes is given by the corrugated shell; therefore, they can be buried to a fairly large depth - up to 200-500 cm. The main (outer) layer is made of thick polymer, and the inner layer is made of smooth low-density polyethylene (HDPE) or polypropylene. Such pipes do not have many of the disadvantages of cast iron and ceramic pipes - they are quite strong, lightweight, quickly laid, installed without problems, no blockages are created inside them, and, thanks to their plasticity, such pipes can easily withstand the loads that arise from errors in installation and sewer design. However, the durability of such pipes directly depends on the correctness of the installation work, and what is not unimportant is the choice of pipe modification, both in design and in terms of stiffness class.

That is why, if a homeowner is truly interested in the durability of his sewer system, and not as an amateur, he will not use materials that are difficult to work with to create it - first of all, cast iron, no matter what type, and, secondly, short-lived materials such as galvanized steel. Traditional materials, such as copper, which is mainly used to create plumbing systems, and even then rarely, as it is expensive, are also not suitable for this.

So the best materials for these purposes are materials that meet modern construction standards, multilayer polypropylene pipes, double-wall corrugated pipes, as well as monolithic ones made of polyvinyl chloride. You shouldn’t look for something else to create an external sewer pipeline - it simply doesn’t exist.

Diameter selection

When deciding what and how to install a sewer system in a private house, special attention should be paid to the correct choice of pipe diameter for it. For the riser and street area, it is recommended to take products with a cross-section of 100–110 mm, and for bends to plumbing fixtures, 40–55 mm is enough. But here a lot depends on the volume of wastewater, the length of the pipelines and the number of connected plumbing fixtures. Ideally, it is necessary to prepare a project with a full calculation of the amount of wastewater. However, for small cottages the above figures are quite sufficient.

You should not use pipes that are too wide for the installation of internal sewerage, as they will clutter the space of bathrooms and kitchens. At the same time, there is zero benefit from such “breadth”. And narrower options than the recommended ones are dangerous due to constant blockages. This is definitely something no one needs.

Recommended pipe diameters for the home sewer system

The same electrical wiring in an apartment or house also does not tolerate wires that are too thick or too thin. Each electrical appliance must have its own cable with a rated cross-section; sewerage in a private house at this point is no different from the electrical network.

Fan pipe: what is it?

How the fan pipe is arranged can be understood from this diagram.

In a sewer system, this is the element of the pipeline structure that is the connecting link between the septic tank and the atmosphere.

And it doesn’t matter whether you use an autonomous sewage system on your site or whether you made a septic tank yourself from concrete rings.

It should be remembered that in most cases the installation of this sewer element is simply necessary, since when wastewater passes through the riser, a vacuum is created. The water in the siphons of your home's plumbing fixtures, under the influence of a vacuum, begins to be sucked into the sewer system, and this can lead to a sharp decrease in pressure, failure of the water seal and the appearance of an unpleasant odor in the premises.

A siphon or water trap is a curved tube located under the sink or behind the toilet and filled with water. The liquid, which is constantly located in the curved part of this device, plays the role of a water plug, preventing the penetration of unpleasant odors from the sewer into the room.

At FORUMHOUSE you can get all the information you need on how to approach the choice of a pumping station for a private house near Moscow, in the southern regions, and in permafrost conditions.

Review of sewer pipe manufacturers

The leading manufacturers of plastic sewer pipes on the Russian market are:

- Rehay and Ostendorf (Germany);

- Wavin (Netherlands);

- Politek and Europlast (Russia).

There are no fundamental differences in quality and price between these manufacturers. Fierce competition in the market dictates its own rules. No one seeks to unnecessarily inflate the cost of their goods, and everyone has to use the same technology for manufacturing pipe products. Here you need to look more at what specific plastic the pipe is made of. The price range for PVC, polyethylene and polypropylene is high. But their characteristics are somewhat different.

Decoding the markings of PVC pipes

If preference is given to cast iron pipes, then it is worth taking a closer look at the products of Russian metallurgical plants in Lipetsk and Novokuznetsk. They are the undisputed leaders in this segment.

Decoding the markings of cast iron pipes

Pressure pipe material

The variety of materials used for manufacturing is quite large, each of them has its own specific properties. Here are just a few of them:

- Cast iron;

- PVC;

- Polyethylene;

- Concrete;

- Asbestos cement.

Cast iron

The use of cast iron for sewerage is time-tested. In many apartments, cast iron pipes are installed, which after 50 or more years have not lost their functionality. Of course, today, with the advent of modern, cheaper and more practical materials, cast iron products have faded into the background and are practically not used.

This is a fairly heavy material, and installing the pipeline will require a lot of effort. In addition, a cast iron pipe is a rather expensive product, so not everyone can afford the creation of a completely cast iron sewer system.

However, they can only be used in certain areas of the system, where there is a need for it. For example, they are simply irreplaceable if part of the pipeline passes under a road with heavy traffic.

Reinforced concrete

Reinforced concrete pressure pipes are produced only in large diameters. They can withstand much greater pressure. But, in order to install at least one such pipe, it will be necessary to use heavy construction equipment. Therefore, such products are used only for industrial sewerage, for example, in areas approaching sewer collectors.

Asbestos cement

The use of asbestos-cement pipes for sewerage is not the most common occurrence. Most often they are used in areas without heavy load, other than internal pressure. In addition, this material becomes brittle at low temperatures.

PVC pressure pipe

Used in systems with low pressure, mainly in small houses. PVC itself is a fragile material, and also has poor elasticity, so you need to be careful when calculating the strength of the sewer.

However, with their help you can easily install almost any pipeline with a large number of branches and turns. And due to the fact that this material is lightweight, 1 - 2 people are enough to install even long elements of large diameter.

Polyethylene

Pressure pipes made of polyethylene are considered the best option today. This is due to the presence of a large number of advantages:

- practically do not differ from PVC pipes - they are similar in appearance, have a greater margin of safety due to ductility and wall thickness;

- installed in the same way as PVC pipes;

- excellent sound insulation;

- can bend at a slight angle without losing strength;

- debris does not settle on the outer surface, which prevents the formation of frequent blockages;

- service life is 100 years.