Do-it-yourself patination (blackening, aging) of copper, brass and bronze

Patination of copper, as well as other methods of its decorative processing (including at home), can make products made from this metal more attractive and give them a touch of noble antiquity. Items made not only from copper, but also from its alloys such as bronze and brass can be subjected to this treatment.

Using various methods of patination of copper alloys, you can achieve completely different shades

Patination and oxidation

The surface of many metals (and copper is one of them), when interacting with the surrounding air and various chemicals, begins to become covered with a thin layer of oxides and oxides. This process, which also leads to a change in the color of the metal surface, is called oxidation. For the most part, the process of metal oxidation occurs naturally, but people have learned to cause it artificially, in industrial or home conditions, which is done to give the product an aged look.

Oxidation should not be confused with patination, a process whose essence lies in the fact that a thin layer of sulfur or chloride compounds is formed on the surface of the metal when interacting with various chemical elements. Patination, which, like oxidation, is accompanied by a change in the color of copper and bronze, can also be performed artificially using special compounds.

Copper aging occurs naturally over time or immediately when the surface is treated with any preparations.

If under natural conditions the process of oxidation and patination of copper or bronze can take years, then when using special solutions, patination occurs in a very short period of time. The surface of a product placed in such a solution literally changes its color before our eyes, acquiring a touch of noble antiquity. Using various chemical compositions, you can perform such procedures as blackening of copper, patination of objects made of copper and bronze, and blackening of brass in production and even at home.

Preparation for processing

Having decided to perform patination or oxidation, you should not only carefully study the question of how to age brass, bronze or blacken copper, but also provide the necessary safety measures.

The vast majority of chemical compounds that are used to carry out such procedures are very toxic and emit vapors that pose a significant danger to human health.

Therefore, to store such substances both in industrial and at home conditions, you should use vessels with well-ground stoppers, which will prevent toxic vapors from entering the surrounding air.

Keep chemicals out of the reach of children

The procedure itself, carried out to change the color of the surface of a product under the influence of chemicals on it, should be performed in a special cabinet to which exhaust ventilation is connected. It should be borne in mind that the doors of such a cabinet should be slightly open during the process of oxidation or patination, which will ensure effective extraction of harmful vapors from its interior.

Products made of copper, brass and bronze should be thoroughly cleaned, degreased and washed in warm water before patination. After the patination or oxidation procedure itself, the treated objects are also washed and placed in sawdust to dry.

Using sawdust is a more gentle drying method, since performing such a procedure with a fabric material can damage the thin film of the formed patina, which has not yet been fixed with varnish.

In addition, using fabric after patination, it is almost impossible to efficiently remove moisture from the recesses on relief surfaces, and sawdust can easily be pulled out.

The varnished surface can be polished with a felt pad.

Changes in color of copper and its alloys from gray to black

The grey, dark gray or black color of copper and its alloys makes the appearance of the product more attractive and presentable. To obtain these colors, the degree of saturation of which can be adjusted, you need the “liver of sulfur” composition that has been used for decades. It got its name due to the fact that during the cooking process it must sinter, that is, turn into a caked mass.

To make such a composition for patination at home, you must perform the following steps:

- one part of powdered sulfur is mixed with two parts of potash;

- the resulting mixture is placed in a tin can, which then must be put on fire;

- After waiting for the powder to melt and start sintering, it is necessary to maintain this process for 15 minutes.

To prepare sulfur liver you will need soda and sulfur

During the sintering process of the powder, a blue-green flame may flare up on its surface, which does not need to be knocked down, since it will not deteriorate the quality characteristics of the sulfur liver. After sintering is completed and completely cooled, the resulting mass should be crushed to a powder state. This powder, if placed in a glass jar with a tight-fitting lid, can be stored for a long time.

In order to patina various metal alloys using liver sulfur, several basic methods are used. Method No. 1

This method involves the use of an aqueous solution of liver sulfur. It can be used to change the color of products made from the following materials:

- copper;

- sterling silver;

- bronze and brass.

The colors that can be used to paint the surfaces of products using this method also vary:

- copper and silver - purple, blue (very difficult to obtain), gray, brown-gray, black;

- brass and bronze – soft golden.

Testing the solution on copper, bronze and brass gives different effects

If you did not know before how to age copper and form a durable patina film on the surface of this metal, distinguished by a rich black color, use this method. To implement it, a copper product is placed in a solution consisting of a liter of water and 1–20 grams of liver sulfur powder.

To color copper light gray, the solution is prepared according to a different recipe: 2-3 grams of sodium chloride and liver sulfur are dissolved in 1 liter of water. A copper product is placed in the resulting solution, the color change of which should be carefully monitored. After the color of the metal acquires the desired tone, the object to be patinated must be washed with water and dried in sawdust.

The duration of treatment of copper jewelry with a solution depends on the desired blackening effect

Method No. 2

To patina copper, you can also use a solution prepared according to the following recipe: ammonia is added to a saturated aqueous solution of copper sulfate and this is done until the liquid becomes transparent and bright blue. The cleaned and degreased product to be processed is placed in such a solution for several minutes, after which it is removed and subjected to slight heating. After such manipulations, the copper should acquire a rich black color.

Artificial copper color

In addition to the methods described above, there are other methods for patination and oxidation of copper, which make it possible to give the material the following colors and shades:

- brown-gray - when immersed in a solution of sulfur liver,

- dark gray – when the product is heated in a solution of liver sulfur and ammonia,

- brown-black - occurs under the influence of platinum chloride (if the result is not satisfactory, you can add hydrochloric acid),

- black – as a result of exposure to ammonium sulfur diluted in water,

- green - from the application of low concentration copper nitrate mixed with table salt, or from oleic acid,

- golden - from placing in a heated solution of copper sulfide, caustic soda and milk sugar.

The use of each method gives its own result and differs not only in the color of the patina, but also in the duration of preservation of the coating. Sometimes, to protect the product, varnish is applied, then the blackening does not disappear at all over time.

Methods for blackening copper at home

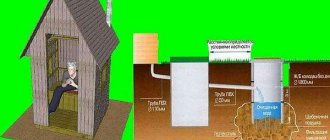

Copper is a metal that has low activity and for this reason is often used for decorative purposes. Copper is used to make jewelry, home decoration, art, furniture and much more. The metal surface oxidizes under the influence of oxygen, but due to its low activity, this may take decades. The consequence of this reaction is patina - a surface film that most often has a greenish tint. Patina prevents the metal from being damaged, so it is important to know how to blacken copper at home.

Copper before and after blackening

There are two types of reactions that lead to the formation of films on the surface of copper:

- oxidation - the process of formation of oxides and oxides, elements containing oxygen;

- patination - a film is formed under the influence of sulfur and chlorine.

If you dip a copper piece in a solution designed to create a patina on its surface, it will immediately be transformed and, while sparkling new, will look like an antique. There are two main types of methods by which this effect is achieved, some are based on improvised means, while others require chemical solutions. They can be dangerous, so you need to work in compliance with all safety regulations. The room must have a fume hood.

Before you start blackening, you need to prepare the metal: clean, degrease, rinse and dry. For drying, do not use the towel wiping method. This can lead to fabric residues on the products, water in the recesses of the relief, and damage to the decorative part. You can use sawdust for this purpose.

Methods using chemical reagents

One of the most common methods is the use of liver sulfur. It can be purchased at the store or prepared at home. To do this, mix powdered sulfur with potassium chloride in a ratio of 1:2 and put it on fire in a tin can. After a few minutes, the powder will melt and, after 15 minutes, will sinter, its color becoming dark brown. This process may be accompanied by a flame, which does not need to be put down.

https://www.youtube.com/watch?v=U_PbxZX1xCk

The first method, which uses liver sulfur to blacken copper, is as follows: 10–20 grams of powder are dissolved in one liter of water, or two to three grams if it is necessary to obtain a less intense color. The copper product is dipped into the solution until the color changes, then it is removed, washed and dried. The color turns out to be brown-gray and its shades.

The almost black color of the product is obtained by heating, after treatment in a solution of liver sulfur with water and the addition of ammonia. Alcohol must be added to the saturated solution until it turns transparent blue. A coin or copper jewelry is dipped into the solution and then heated until it turns black.

Another method for obtaining black-brown color is as follows. Platinum chloride is applied to the product, for example, wetted with a brush. If the solution is not acidic, hydrochloric acid is added to it.

A red-brown patina can be obtained using a one-to-one mixture of copper sulfate and zinc chloride. The mixture of powders will need to be mixed in the same amount of water and the copper product should be immersed there for a few minutes.

Patination of copper with ammonium sulfide produces a black color. The substance (20 g) is diluted in a liter of water. You can either dip the product into the solution or apply it with a brush. A reaction occurs on the surface, resulting in the formation of copper sulfide. If you heat the plate before patination, then depending on the temperature, you can adjust the shade of the resulting color.

Blackened copper product

Another way to obtain black color is to heat a coin or jewelry at a high temperature in a solution of ammonium persulfate (9.25 g/l) and caustic soda (50 g/l). The temperature should be 90–95 degrees, the warming time should be 5–25 minutes. Repeat two to three times until the desired effect is achieved.

A light brown patina can be obtained by covering the product with the following solution:

- 124 g/l sodium dichromate;

- 15.5 g/l nitric acid (1.4);

- 4.65 g/l hydrochloric acid (1.192);

- 3–5 g/l 18% ammonium sulfide solution.

Apply the newly prepared solution with a brush, leave for four to five hours, rinse and dry. The procedure must be repeated three times.

Green patina is obtained by two main methods:

- Using a sponge, the copper surface is lubricated with a low concentration solution of copper nitrate with the addition of table salt. After drying, lubricate it with a solution containing: 94% table vinegar, 5% ammonia, 1% potassium oxalate. After drying, lubricate first with the first and then with the second solution again. The procedure is carried out until the copper reaches the desired color. After painting is completed, the surface is rubbed with brushes.

- In the second method, the surface of the copper product is rubbed several times with oleic acid. This produces a dark green substance on the surface - oleic copper. Over time, the shade changes to light green, as under the influence of moisture and oxygen, oleic copper is converted into carbon dioxide. A solution of five grams of potassium permanganate and 50 grams of copper sulfate gives a golden-brown patina. Dilute in one liter of water and heat to a temperature of 70–80 degrees. Lower the product and hold until the desired color is obtained.

Getting patina with an egg

A black-brown patina can be achieved using a boiled egg. The effect is the interaction of the metal surface with sulfur, which is released in the yolk at high temperatures. To do this, you must first boil the eggs, and only then add the copper product to the water. Depending on the size of the product, a different number of eggs will be required.

Another option. After the eggs are hard-boiled (10 minutes), they must be removed from the water and cooled. The peeled eggs are crushed and placed in a container with a wide bottom, and copper is also placed there. The container is closed for 20-30 minutes or more, depending on what color you want to get: over a longer time, the product will become darker. The main advantages of this method are simplicity and accessibility. The main disadvantage is that the effect most likely will not be long-term and the coating will come off.

Patina has excellent properties. For example, in numismatics, the value of an item depends on how uniform it is. Artificial turf cannot replace natural turf.

If the patina has a uniform structure and evenly covers the surface, then it is better to preserve it on the product. This especially applies to antiques and coins. To prevent damage to the top layer, it is necessary to care for the product and handle it with special care. Do not clean with abrasive products or tools. And it’s better not to touch the product with your hands.

But if it has chips, stains, looks ugly or is not uniform, then such methods will do just fine. If you want the patina to lay down evenly, then the old layer must be cleaned to a metallic shine.

How to darken copper at home - Metals, equipment, instructions

Copper plating is the process of applying a copper layer to the surface using an electroplating method.

The copper layer gives the product visual appeal, which allows the use of copper electroplating in design projects. It also gives the metal high electrical conductivity, which allows the product to be subjected to further surface treatment.

Copper plating can be used as the main process to create a surface layer, and also as an intermediate operation for the subsequent application of another metal layer. This method includes, for example, the process of silvering, chrome plating or nickel plating.

Copper plating can be done at home. This makes it possible to solve many everyday problems.

Electroplating at home: equipment and materials

To perform copper coating yourself, you need to purchase the necessary equipment and materials for the process.

First of all, you need to prepare a source of electric current. Various home craftsmen advise using current strength, which varies over a wide range. Work must be carried out on direct current.

As a current source, you can take a KBS-L battery with a voltage of 4.5 volts or a new Krona brand battery with an operating voltage of 9 volts. You can also use a low-power rectifier instead, which produces a voltage of no more than 12 volts, or a car battery.

It is mandatory to use a rheostat to regulate the voltage and smooth exit from the process.

For the electrolyte solution, a neutral container should be prepared, for example, made of glass, as well as wide plastic dishes that are sufficiently sized to accommodate the part. Containers must withstand temperatures of at least 80°C.

You will also need anodes to ensure coverage of the entire surface of the part. They are designed to supply current to the electrolyte solution and distribute it over the entire area of the part.

To carry out electroplating at home, you will also need chemicals to prepare the solution:

- copper sulfate,

- hydrochloric or other acid,

- distilled water.

Having prepared everything you need, you can start working.

:

Copper plating of steel products

Copper plating of steel with copper sulfate is one of the main processes in the field of electroplating because it is used to pre-plate copper. It has high adhesion to the steel surface, unlike other metals that do not have good adhesion to steel. If the technology is followed, the copper layer adheres perfectly to steel products.

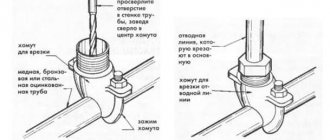

There are two coating technologies: with immersing the product in an electrolyte solution and a method of non-contact coating of the surface with copper without placing it in a liquid electrolyte solution.

Copper plating by immersion

The process is carried out following the following steps:

- The oxide film is removed from the surface of the steel part using sandpaper and a brush, and then the part is washed and degreased with soda and a final rinse with water.

- Two copper plates are placed in a glass jar, connected to copper conductors, which serve as the anode. To do this, they are connected together and connected to the positive terminal of the device used as a current source.

- The workpiece is suspended freely between the plates. The negative pole of the terminal is connected to it.

- A tester with a rheostat is built into the circuit to regulate the current.

- An electrolyte solution is prepared, which usually includes copper sulfate - 20 grams, acid (hydrochloric or sulfuric) - from 2 to 3 ml, dissolved in 100 ml (preferably distilled) water.

- The prepared solution is poured into a prepared glass jar. It should completely cover the electrodes placed in the jar.

- The electrodes are connected to a current source. Using a rheostat, the current is set (10-15 mA should be per 1 cm2 of part area).

- After 20-30 minutes, the current is turned off, and the copper-plated part is removed from the container.

:

Copper plating without immersion in electrolyte solution

This method is used not only for steel products, but also for aluminum and zinc products. The process goes like this:

- A stranded copper wire is taken, the insulating coating is removed from one end, and the copper wires are given the appearance of a kind of brush. For convenient use, the “brush” is attached to a handle-holder (you can take a wooden stick).

- The other end of the wire without a brush is connected to the positive terminal of the voltage source being used.

- An electrolyte solution is prepared based on concentrated copper sulfate with the addition of a small amount of acid. It is poured into a wide container, necessary for convenient dipping of the brush.

- The prepared metal part, cleaned of the oxide film and degreased, is placed in an empty bath and connected to the negative terminal.

- The brush is moistened with the prepared solution and moved along the surface of the plate without touching it.

- Once the required copper layer has been achieved, the process ends and the part is washed and dried.

Blackening of brass, one of the methods

Recipe taken from here

Additional material on the topic: One of the methods of blackening brass

Let me make a reservation right away that I am not a chemist, and all my knowledge is only what I have left over from school. Therefore, the recipe was not fully followed and some deviations were made.

Blueish-black color

| 25% ammonia solution (ammonia) | from 100 g/l to 1 l |

| Copper carbonate (CuCO3) | 40-200 g/l |

Treatment lasts 25-30 minutes. at a temperature of 15-30°C.

Preparation of copper carbonate.

In this case, when recipes mention copper carbonate, in fact, they are usually talking about basic copper carbonate. To obtain it, you can use copper sulfate, acetate or nitrate. A solution of potassium or sodium carbonate (potash, soda) is added to an aqueous solution of one of these salts. The green-blue precipitate that falls consists of basic copper carbonate of variable composition, nCuCO3 x mCu(OH)2, where n and m can vary within some limits, which for us, in this case, is not very important. The precipitate is filtered off, washed with water and can be used.

The process itself.

To blacken brass using this method you will need:

- copper sulfate;

- baking soda;

- ammonia;

- two glass jars, preferably the same volume;

- filter paper or something similar;

- stirring stick.

The vitriol was purchased at a nearby hardware store in the department that sells all sorts of pesticides for controlling garden pests. Soda - in the nearest grocery store, where there is simply plenty of it.

Ammonia - in the nearest pharmacy. But only 10%. As they explained to me, 25% is not for sale due to its danger.

| First we prepare copper carbonate. For this we need copper sulfate and ordinary soda. |

| Dissolve the vitriol in warm water. The solution needs to be saturated, i.e. add vitriol until it still dissolves. The solution must be made so that it occupies only half the container. |

| Then slowly, a little at a time, add soda to the saturated vitriol. It is precisely because the solution begins to bubble like soda that I recommend making vitriol in only half the container. |

| Stir. Over time, the seething subsides. I poured in soda until the bubbling stopped. After a while you will see that the result is a fine suspension of a pleasant turquoise color. On the surface you can see that the fry are still seething there. |

| Now the resulting suspension must be filtered. There was nothing worthwhile at hand except napkins. The recipe says to dry it. But I didn't do this. |

| Now we need a 25% ammonia solution. As I already wrote, only 10% is available in the pharmacy. This is what we will use. |

| Little by little add turquoise porridge to ammonia. The solution turns blue. |

| We also need a saturated solution. Therefore, we add, without sparing, copper carbonate. You will end up with a blue-black liquid. This is what we need. |

The solution is ready, all that remains is to put the necessary parts in there. Blackening time, according to the recipe, is 25-30 minutes.

After removing the part, rinse with water and dry/wipe.

This is the final result (blue-black, blued steel color):

Some notes:

- Vitriol is not suitable for impregnating wood against fungi;

- It is convenient to use two containers, because you will have to filter the solution;

- You only need to prepare half a container of vitriol, because then there will be a violent seething;

- You can also use 10% ammonia;

- If you rinse the copper carbonate well, the reaction proceeds much faster;

- Flat parts blacken faster than rings, nails, eyelets and the like;

- If the part is kept in the solution, copper carbonate will settle on it in the form of turquoise crystals, which, in principle, can then be easily scraped off with a fingernail without damaging the blackening;

- If you have difficulty removing blue sediment from a part, I recommend simply heating it in the flame of a candle or lighter. The sediment will immediately fall off on its own.

from www.shipmodeling.ru

Source: https://m.shipmodeling.ru/tooling/brassblacking2

How to age copper using ammonia

Sunday, January 29, 2012 11:09 + to quote book

Vintage copper

Nessime tells from the forum https://www.ufamama.ru

I love copper, I love wire. In some cases, copper looks better if you give it a vintage touch and age it. There are several methods of aging (boiled egg, sulfur ointment), but the fastest and easiest, in my opinion, is aging with ammonia. This is not my invention, but I will show how it works for me.

Important: Before starting to work with wire, I carefully process it with a needle file. This helps get rid of varnish, dirt, and makes the wire a uniform, pure color. Plus, micro scratches remain on the wire from the needle file, which better hold the darkened layer.

We make from wire everything that our imagination dictates and we can proceed directly to darkening.

We will need: – A hermetically sealed container (in my case, a herring jar – A cotton pad – A lid from a small jar (mayonnaise, mustard or baby food) – Ammonia (from the pharmacy)

I put a cotton pad in a small lid from a mayonnaise jar and soak it in an ammonia solution (ammonia). The ammonia is evenly distributed over the disk and the evaporation area increases. This allows you to use ammonia more economically, plus the ammonia from the cotton pad does not spill when removing the finished product from a tightly closed jar.

Place the copper product and the lid with ammonia into a container and close the lid tightly. Darkening occurs quite quickly (5-10 minutes), you can read the forum for now

Time has passed, you can get the finished product of a beautiful chocolate color. Just be careful when opening the jar, don’t inhale the escaping cloud of ammonia

This is what the finished cuff looks like

Blackening copper at home

Patination of copper, as well as other methods of its decorative processing (including at home), can make products made from this metal more attractive and give them a touch of noble antiquity. Items made not only from copper, but also from its alloys such as bronze and brass can be subjected to this treatment.

Using various methods of patination of copper alloys, you can achieve completely different shades

General information about metal color

OXIDATION of copper and brass

Copper is often used as a decorative element on buildings, including in the manufacture of furniture, jewelry, and art. The surface of the metal enters into a chemical reaction when it comes into contact with oxygen, however, it takes several decades for it to be completely completed.

The result of the interaction of copper and air is patina - the same material, only with a greenish tint. Less common is a black or brown patina. Practice has shown that the color of patina can be corrected if it is treated with special means or methods.