Preventing problems

As we can see from the above, in most cases, a change in the color of gas combustion is an acquired problem, and often due to an oversight or oversight of the owners themselves.

This means that if treated correctly, the problem could often be solved before it became obvious. To begin with, carefully approach the choice of stove model. Find out what type of gas is used in your home, and also find out from the consultants in the store whether the stove you like is designed for such fuel. By doing this, you will minimize the occurrence of a situation where the problem might not have existed if you had not personally paid for its occurrence.

In addition, there are several simple and logically obvious rules that for some reason are periodically ignored.

Studying the instructions

A gas stove is a kitchen appliance like anything else; it needs to be handled correctly, and the manufacturer even provides instructions for this. Knowing how to use the unit correctly, you will at least extend its useful life, and you will also adhere to basic safety rules, because you should not joke with gas appliances.

Timely maintenance of the stove.

Often, burning gas acquires unusual colors due to the fact that the insides of the burners become clogged, but this can be prevented through the efforts of the owners. It is clear that dust can get there without using the unit, but usually contamination appears as a result of careless culinary exercises.

A good owner should keep the burners clean after each use, especially if the dish has escaped - the instructions will tell you how to get to the most remote parts of the stove so that debris does not accumulate. Moreover, it makes sense to periodically wash the entire stove, even those surfaces that are located far from the gas burners, since these contaminants can cling to your hands and from there get under the damper.

Some problems may not seem as serious at first, but they can get worse over time. Anyone who thinks that he has the situation under control, in fact, cannot see all the processes occurring in the insides of the stove. The same dust that could be removed with a soft cloth can burn and melt under the influence of high temperatures, and then it will become a hundred times more difficult to clean it.

Further use of a device that is not completely healthy can lead to it becoming even more “sick,” and it’s good if the worst does not happen.

You can learn how to clean the nozzle (burner) in a gas stove from the video below.

Design [edit | edit code]

The design of a lighter directly depends on its purpose. The most widespread are pocket and kitchen lighters. Sometimes there are stationary lighters.

Kitchen

Lighters are designed for igniting household gas appliances and fireplaces. These lighters have an elongated nose so that you can get close to the burners.

lighters are small in size and easy to carry. The design is absolutely any, but the sizes are limited. Table lighters are quite rare. Such lighters are quite massive and are not designed to be carried. The design of such lighters can be any. There are also special fireplace lighters; while they are long, they have a small width and thickness, and even lighters from well-known brands. Not so long ago, touch lighters appeared, in which gas ignition occurs without mechanical influence, but by acting on a touch sensor.

Stationary

lighters are usually reserved for bars and smoking rooms - they are more difficult to steal. Sometimes they become an element of the interior. There are stationary flameless lighters for smoking rooms in hazardous industries and nursing homes.

Advertising [edit | edit code]

Recently, so-called advertising lighters have become increasingly popular. They are an ordinary pocket lighter with information, usually of an advertising nature, applied using silk-screen or pad printing. Widely used by large chain stores and hotel and restaurant companies to advertise services and promote goods.

Ban on souvenir lighters [edit | edit code]

The EU and a number of US states have adopted or are preparing to adopt legislation prohibiting the circulation of souvenir lighters made in the form of objects that are not lighters (animals, cartoon characters, lanterns, cameras, etc.), which may be mistaken by children for toys, and lead to injuries, burns and fires in their hands [2] [3] [4] [5].

Principle of operation

Temperature and conditions for melting copper at home

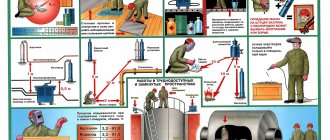

The vast majority of acetylene torches use an injection circuit. These devices are divided into barrel and tip. Additionally there are nipples for oxygen and acetylene, valves.

To start working, you need to fill the gas generator tank up to the top plug. Calcium carbide is placed in the basket, after which the lid is tightly locked.

Producing gas from 1 kg of carbide will require 6 liters of water. The resulting acetylene passes through the water seal and fitting into the welding hose. As soon as the pressure exceeds the level of 1.5 kgf per 1 sq. see, the safety valve begins to let excess gas into the atmosphere. The burners themselves, where acetylene is supplied, are divided into injection and non-injector types.

The flammable substance is sucked in by the oxygen stream. Oxygen moves from the injector nozzle, and the speed of its movement is very high. You can influence the supply level of acetylene and oxygen using valves. For all mouthpiece numbers, their own modes of gas use are selected. They are selected according to the thickness of the metal and the welding method.

With injectionless burners everything is somewhat simpler. In them, flammable acetylene and oxygen are supplied under constant pressure from start to finish. Conditions of use do not affect the composition of the mixture. Since the nipples have different threads, it is almost impossible to connect the hose to the source of the “wrong” gas. At the very beginning, both valves must be closed.

Start by unscrewing the oxygen valve 1 or 2 turns, only then release the acetylene. When oxygen enters the injection nozzle through the valve, an area of low pressure appears in the acetylene channel. From there, a small amount of gas begins to be sucked into the mixing chamber. The pressure of the acetylene jet does not exceed 0.02 kgf per 1 square meter. cm.

Through the tip tube, the mixed composition enters the mouthpiece. Then it is ejected from the nozzle. The welder ignites the oxygen-acetylene combination. Then, by manipulating the valves, he achieves a blue flame color (in combination with a red zone in the middle). For the welding itself, the middle section of the fire is used, located immediately behind the core (the temperature in this place is 3150 degrees).

Sometimes the acetylene torch fires. This is usually caused by a violation of the recommended pressure at the outlet of the cylinder. The flame is adjusted individually. In some cases, a slight shift in favor of oxygen helps.

Lighter maintenance

Refilling a gas lighter

Many gas lighters are disposable. But there are also refillable ones. Gas canisters are used for this. It may require an adapter. Gas cartridges come in different sizes, and the gas in them has different compositions. Some cheaper types quickly run out both in the can itself and in the lighter.

Before refilling with gas, be sure to empty the lighter of any air remaining in it. Of course, the gas itself must also be fully utilized. The gas supply regulator is set to “maximum”. The combustion level valve of most lighters is located near the base and it will not be difficult to find. In order to release the air, you simply need to take a needle, thin pin or any other similar sharp instrument and move the valve. After this, all excess will come out of the lighter. Then, to fully guarantee the result, you need to click the lighter. Of course, you won’t see any fire, but if air or butane residues are still in the housing, they will come out completely. If the lighter has a lid under which there is a socket for refilling, then it must be opened. The gas canister must be kept at room temperature. Usually, the canister comes with adapters, from which you need to select a more suitable size so that it fits tightly into the valve hole and does not allow gas to leak out. Place this adapter on the gas canister. After this, the gas canister is turned over and held tightly in your hand and shaken well. Next, insert the tip of the gas container into the valve located at the bottom of the lighter and press firmly. During refueling, a characteristic hissing sound will be heard. You need to hold the can in this way for 5-10 seconds. He is then abruptly pulled away from the lighter. Some cans are equipped with special dispensers. In this case, you will have to refuel in several stages. Filling the housing with gas is always accompanied by a slight decrease in temperature. Therefore, before you start using the lighter, you should wait a little until it warms up. It won't take much time - no more than five minutes.

Refilling a gasoline lighter

Gasoline lighters are all refillable. In this case, gasoline evaporates even when the lighter is not used. Therefore, it is recommended to refill the lighter before each long trip, as well as from time to time as needed. Usually special gasoline is sold for such lighters. But you can use regular automobile alcohol, alcohol, kerosene, etc. flammable liquids. But be aware that such substitutes cause digging and have a strong smell. Also, the wick will burn out quickly (maybe literally in a few days). I don’t recommend cologne - it will smell and you won’t get rid of the smell.

Please note that some lighters do not work with this replacement.

First of all, you need to use up all the gasoline that is already in the lighter. Remove the insert from the lighter body, lift the felt pad on the bottom of the insert. You can carry out all work with rubber gloves, especially if you are filling the lighter with gasoline for the first time.

This way you can protect your hands from accidentally spilling gasoline. Carry out all manipulations over the sink - this way you can prevent possible spilling of gasoline on a wooden table or other flammable surface. Now slowly saturate the insert material with gasoline until the top layer of cotton filler becomes wet. To control the amount of flammable liquid poured in, it is better to use a special measuring watering can. This will allow you to carefully pour gasoline without allowing it to overflow the edges of the tank. Pour the liquid little by little in small portions, allowing it to be thoroughly absorbed into the cotton wool. Insert the fuel chamber back into the lighter body. Make sure not a drop of gasoline has been spilled. Thoroughly dry the lighter body and hands before use. This is flammable! It is better to leave the lighter for a few minutes so that the gasoline is well saturated. If a gasoline lighter does not light, you can turn it upside down to allow the wick to soak thoroughly.

Replacing silicon in a gasoline lighter

Remove the insert from the housing. Unscrew the screw at the bottom end that holds the spring. Then carefully remove the spring from the tube. Get rid of old flint particles. Check the tube carefully for any remaining spent flint. Install the new flint into the tube, then install the spring in place. Tighten the screw so that the lighter closes freely after setting the bet.

Replacing the wick in a gasoline lighter

If the wick has a disheveled and unkempt appearance, then it is worth tidying it up. To do this, you need to take regular nail scissors and tweezers. Using tweezers, pull the wick beyond the windbreak and cut off the frayed piece using scissors. After this procedure, the lighter should burn as expected. However, over time, you will still have to replace the wick with a new one. To do this, remove the insert from the casing. Unscrew the screw at the bottom end that holds the spring. Then carefully remove the spring from the tube. Get rid of old flint particles. Remove the layer from the felt. Using tweezers, you need to pull out the entire layer of cotton wool. Install the wick by pulling it from the bottom through the eyelet. Check that the wick does not protrude beyond the wind protection. Place the cotton filler back, while placing the wick between the layers of filler as shown in the picture below. Install the felt layer. Place the new flint in the tube and install the spring. Tighten the screw so that the lighter closes freely after setting the bet. Do not apply any serious force when screwing in the screw!

How to choose?

We melt silver at home: melting temperature depending on the sample + instructions

Choosing a propane torch is a very important and responsible task, since not only the final result of your work, but also the comfort and safety of your work depends on the quality of the design. When purchasing a device, you should consider several factors.

Price

In this regard, choose models that offer the best price-quality ratio. You should not choose the cheapest options (most likely, they have low quality and a short service life).

Manufacturer

Give preference only to those manufacturing companies that enjoy authority and respect among users and the professional community.

Salesman

To purchase a propane torch, contact only official stores and representative offices. Only here you can purchase high quality branded goods.

Before purchasing a specific model, be sure to read user reviews and make sure that the characteristics and features of the device that the manufacturer talks about correspond to the real state of affairs.

Compactness

The size and ergonomic design of the burner will determine the level of comfort during operation of the product. Thus, taking into account all the parameters described above, you will be able to choose and buy a unit that will meet all your needs and will serve you for the longest possible period.

Proper lighting of a fire

What temperature should the cellar be in winter and summer?

In order for a fire to flare up quickly, even with one match, and not go out to everyone’s disappointment, it must be lit correctly.

To do this, you need to adhere to the following algorithm:

- The tinder is ignited, and from it - kindling. The stage of igniting the tinder can be bypassed if it is possible to get an open fire from which to ignite the kindling directly.

- The thinnest brushwood or wood chips are placed on the burning kindling. The result is a small, unstable fire that can easily go out, so you need to approach this stage with all responsibility.

- As the thin brushwood burns, thicker brushwood is added to the fire until coals as thick as an index finger are formed. Only after this can the fire be considered stable, since it will no longer be blown away by the wind, and its extinguished coals can be fanned.

When thick logs flare up in a huge fire, you can throw even the dampest firewood into it: it will burn without risking the fire.

The video shows such a stable fire in a winter forest:

This is the principle of lighting a starting fire. The starting fire can then be transformed into another type, more suitable for the conditions and purposes. For example, a “pioneer” fire can be successfully transformed into a “star” fire, which is more economical and allows you to cook food or boil water with less wood consumption.

Application

Unlike a conventional stove, where the process of oxygen supply and combustion intensity is poorly regulated, in industrial stoves special attention is paid to controlling the supply of oxygen and maintaining a uniform combustion temperature. Let's consider the basic scheme of coal combustion

Let's consider the basic scheme of coal combustion.

- The fuel heats up and moisture evaporates.

- As the temperature rises, the coking process begins with the release of volatile coke gases. When burned, it provides the main heat.

- Coal turns into coke.

- The coke combustion process is accompanied by the release of heat sufficient to initiate coking of the next portion of the fuel.

In industrial boilers, the combustion of coke is separated into different chambers from the combustion of coke oven gas. This allows the flow of oxygen for coke and gas at different intensities, achieving the required combustion rate and maintaining the required temperature.

Safety rules for fire events

When lighting matches, a fireplace, or a gas stove, take care of the ventilation of the room. Provide oxygen flow to the fuel.

Do not attempt to repair gas equipment yourself. Gas does not tolerate amateurs.

The appearance of orange and yellow shades in the fire of the burner indicates the need for preventive manipulations with the stove. Masters will clean the equipment, remove dust and soot, the combustion of which changes the usual color of the fire.

Sometimes the fire in the burner turns red. This is a signal of dangerous levels of carbon monoxide in combustion products. The supply of oxygen to the fuel is so low that the stove even goes out. Carbon monoxide is tasteless and odorless, and a person near the source of the harmful substance will notice too late that he has been poisoned. Therefore, the red color of the gas requires an immediate call to specialists for preventative maintenance and adjustment of the equipment.

Lighter

- a device for producing fire. Depending on the design and fuel used, the lighter can be gas, gasoline or electric.

Types of wood

There are several patterns that cause differences in the combustion of different types of wood. First of all, this is the presence of resins - they significantly add the calorific value of firewood. Soft wood burns more easily due to its low density. Heavy rocks maintain combustion for a long time.

While the density of wood varies significantly from type to type, their calorific value per unit mass is almost the same (with the exception of resinous softwoods). Regardless of what types of trees are used for firewood, humidity is the main factor influencing both the combustion process and the thermal result.

Knowledge of different types of wood allows you to get comfortable burning with less wood consumption

List of features of wood of some species:

- acacia - burns slowly and gives a lot of heat, dries quickly, makes a characteristic crackling noise in the fireplace;

- birch - burns quickly, ignites easily even when wet, gives an even and steady fire;

- beech is a high-calorie fuel and leaves little ash;

- oak - high calorific value, emits a pleasant smell when burning, dries for a very long time;

- poplar - low heat of combustion;

- fruit trees - burn slowly and evenly;

- conifers - aromatic smoke, can shoot resin, produce a lot of soot.

It is only important not to forget the main thing: an uncontrolled open flame can be very dangerous for living beings. In addition to burns from flames and smoldering coals, fire can cause incomparably more trouble if it breaks out into a fire

Candle flame

The flame, which every person can observe when a candle, match or lighter burns, is a stream of hot gases that are pulled vertically upward, thanks to the force of Archimedes. The candle wick first heats up and the paraffin begins to evaporate. The lowest part is characterized by a slight blue glow - there is little oxygen and a lot of fuel. It is because of this that the fuel does not burn completely and carbon monoxide is formed, which, when oxidized at the very edge of the flame cone, gives it a blue color.

Due to diffusion, a little more oxygen enters the center. Subsequent oxidation of the fuel occurs there and the temperature increases. But this is not enough for complete combustion of fuel. At the bottom and in the center there are coal particles and unburnt droplets. They glow due to intense heat. But evaporated fuel, as well as combustion products, water and carbon dioxide, practically do not glow. At the very top there is the highest concentration of oxygen. There, the unburned particles that glowed in the center are burning out. It is for this reason that this zone practically does not glow, although the temperature there is the highest.

Metal cutting with gas

Gas cutting of metal (oxygen/autogenous) is the process of cutting steel and metal products/blanks with an oxygen flow supplied from a special apparatus. The essence of the cutting procedure is the combustion of the metal, using a gas mixture and oxygen supplied to the element being processed. The product is first heated to 1300 degrees with an open flame, then an oxygen stream is supplied, cutting the metal in accordance with the diagram. Modern gas cutting technology allows cutting sheets of any configuration with a thickness of up to 300 mm, in some cases up to 1000 mm.

Autogenous turbo lighter. Gas lighter handle.

Lighter length: 16 cm. Lighter width: 2.5 cm. Lighter thickness: 2.5 cm. Lighter body material: metal alloy. Fuel required for the lighter: gas. Lighter brand: Jobon. Lighter weight: 90 g. Description of the lighter: gas turbo lighter in the shape of a pen, convenient folding stand, constant fire mode (switched on on the top of the lighter body), convenient adjustment of flame height and power, stylish gift packaging. Scope of application of the lighter: for minor repairs. Lighter color: graphite. Type of lighter: gas turbo lighter autogen. Lighter flame temperature: 1300 degrees Celsius. Lighter packaging: gift packaging. Can it be used as a ready-made gift: yes, the lighter is enclosed in a cardboard box. Availability of flame adjustment: yes, a convenient flame adjustment unit, there is also a switch for constant burning mode.

If you are loyal to your lighter with a directional turbo flame, it is worth considering that they are not the best for lighting a pipe. After all, the fire temperature of such a lighter is much higher than the temperature that conventional gas models can provide.

Using a turbo lighter, you increase the combustion temperature of tobacco and thereby deprive even the highest quality product of taste . And such negligence does not have the best effect on the handset. Turbo lighters are especially harmful to briar models; they leave burns and over time can even burn through the walls of the tobacco chamber.

How to choose a gas burner

First of all, you need to build on versatility. There are multi-fuel burners (gas and liquid fuel) that use only one of these two types of fuel. Power is also a determining factor. Values up to 2 kW - low-power devices. From 2 to 3 kW - respectively, medium power burners, more than 3 - high power.

Dimensions are also important, primarily for a camping burner. Unnecessarily large or small variations should be avoided. You need to start from the number of people and personal calculations

You should pay attention to functionality and equipment, although the latter indicator will certainly affect the price. Operating time, flame temperature and power are significant indicators for soldering irons

You should pay attention to the presence of such amenities as piezo ignition and preheating. Many products of this profile can be found on Aliexpress. You need to choose a burner after studying the nuances that will certainly affect its operation.

For tourist purposes

These are stand-alone devices that can serve as kitchen utensils. Based on power, they are divided into 3 categories. The lowest rates are acceptable for solo hikes and winter fishing; medium rates are suitable for groups of up to 3-5 people; large figures are for eight to ten people. The non-stick coating on the pot will improve efficiency. On long trips, the cost of fuel used increases. You also need to take into account that not all types of fuel can be transported with you (for example, by plane). In this case, liquid fuel is preferable to gas, and it also takes up less space. Weather conditions such as frost, terrain and altitude are key to ruling out certain options. There are two most important aspects to consider: the number of people up to 3 or more, mild or extreme weather conditions.

For soldering

Fuel consumption decides a lot - both material costs and operating time. Therefore, his choice is one of the key nuances. The type of fuel also affects the maximum flame temperature. Gasoline will give a higher indicator than gas, however, it is consumed faster. Consequently, the duration of work will be reduced, and even a more capacious cylinder will not help much. We should not forget about the ideal weight of the structure and, accordingly, the comfort of manual work. The preheating system also increases it. It is worth dwelling separately on fuel containers: they come with or without a valve, disposable and reusable, stationary and removable. There are options with fuel supply regulation, which allows you to control the temperature. Their efficiency is much higher, as is their price. The presence of piezo ignition is an additional argument in favor of purchasing a blowtorch.

Electric lighter

We should also highlight lighters that work without fuel. It creates the required temperature by passing current through a wire or a long-term electrical discharge. Initially, such lighters were stationary, operating from an electrical outlet. And there could be no talk of a pocket version. But in the 21st century, battery-powered pocket lighters began to appear. Electric lighters come in two types

- A pulse-arc lighter is a plasma lighter that operates on the conventional principle of an electronic arc. It will not go out in the wind, will never ask for fuel, and can be used like an ordinary lighter.

- There is also an option with a filament - this is an option that is familiar to all motorists who use a cigarette lighter. Setting fire to everything except cigarettes will be quite problematic.

In arc lighters, miniature electronic circuitry generates a high voltage sufficient to pierce the air between the electrodes with enough power to maintain a miniature electric arc. It is a pulse converter with a step-up electromagnetic or piezoelectric transformer.

| Electric arc lighter |

| Electric arc lighter |

In wire lighters, a piece of nichrome wire is heated to red heat by current from a battery, similar to a car cigarette lighter. The temperature of the heating element and the design features of such lighters make it difficult to ignite vapors of flammable gases and flammable structural materials such as paint, wood or plastic. That's why they got the name flameless lighters.

and are common in places where the use of open fire is limited.

| Electric flameless lighter |

Separately, it is worth highlighting touch-sensitive electric lighters

. They differ in a special way of ignition - you just need to swipe or touch the sensor with your finger.

How to make the burner work more efficiently and last longer

Keep gas cylinders warm

The simplest thing you can do is to prevent the cylinder from overcooling. A proven method is to warm the balloon before use. For example, put it in a sleeping bag at night or store it wrapped in warm clothes. Another trick is to warm up several cylinders (at least two), and when one starts to cool down, replace it with a warm one and continue cooking.

One more tip. If you have a small amount of water on hand, you can place the cylinder in a pan or other container with water, then the temperature of the cylinder will not be lower than 0°C, which will also allow it to be used in extreme conditions.

Use mixtures with isobutane

Photo: OnLocation.

Isobutane evaporates, maintaining pressure in the cylinder, at temperatures approximately 20 degrees lower than butane. And when other cylinders give up, your isobutane burner will continue to work.

Does pure isobutane in the gas composition really ensure combustion at sub-zero temperatures and allow the cylinder to be used for four seasons, as the manufacturer promises? We tested the MSR Iso Pro gas cylinder, which contains 80% pure isobutane and 20% propane.

Use the burner in liquid gas mode

Some burners, such as the MSR WindPro II and WhisperLite Universal, allow the cylinder to be installed upside down. Thanks to this, liquefied gas will be supplied to the burner, and the need for evaporation will disappear. (Before you try, make sure your burner has this feature!)

Make a wind protection

Gusts of wind can knock out the burner flame. Even a slight wind of 5 km/h can triple gas consumption per unit of time. To protect from the wind, you can build a fence of stones around the burner. (Keep in mind, modern metal windbreaks are not recommended for use with propane tanks as they increase the risk of explosion!)

Isolate the cylinder from the ground

A lining of non-flammable material between the cylinder and the cold soil will allow the cylinder to retain heat better, and therefore supply gas to the burner more efficiently.

Photo: Kennan Harvey.

Do not bring to a boil

In fact, there is no need to boil water if you are making drinks. It is unlikely that anyone will drink boiling water. Moreover, try diluting hot water with cold water. For example, if you need a liter of hot water, heat two-thirds and add one-third cold. This way you will have hot water and will use much less gas.

Let the pasta and rice finish

Pasta and rice do not require constant cooking. It is enough to let them simmer for a few minutes, and then turn off the gas and leave under the lid. The food will reach a state of readiness, and you will be able to save fuel.

Adjust the flame

Finally, to get the most out of the cylinder, lower the burner flame. It sounds simple, but the performance will remain virtually unchanged, and the amount of gas consumed will be reduced significantly - this will increase the service life and efficiency of the cylinder.

Consider a Cooking System Option

Photo: Eric Larsen.

For preparing hot food in cold temperatures, the Reactor and WindBurner cooking systems are ideal. They heat water exceptionally quickly and use gas more efficiently than conventional burners. Wind protection and adjustable flame force ensure high performance even when the pressure in the cylinder decreases. So you can get the most out of your cooking system in a wide range of conditions.

Safety and regulations [ edit | edit code]

There are international and national requirements for lighters aimed at safe handling. International standard ISO 9994:2005(E) “Lighters - Safety specification”, which describes the technical requirements for lighters and testing methods. For example, to produce a flame, a minimum of two user actions with a force of at least 15 Newtons is stipulated. The maximum flame height, resistance to falling and continuous burning, resistance to ambient temperatures, requirements for warning symbols, etc. are also specified. [6]

Some regional standards, such as the European EN 13869:2002, limit the design of lighters so that they are not attractive to young children. For example, made in the form of objects that are not lighters (animals, cartoon characters, lanterns, cameras, etc.), which can be mistaken by children for toys and lead to injuries, burns and fires in their hands [2] [3] [4] [5] .

Types of welding flame

A welding flame is formed as a result of the combustion of flammable gases or vapors of flammable liquids mixed with technical oxygen. In this case, the flame has a complex structure and structure, which is shown in the figure below. The quality of gas welding largely depends on the correct adjustment of the flame, which the welder sets “by eye” in shape and color

Therefore, it is very important to know the structure and structure of a gas burner flame in order to take this into account in everyday work. The shape, color and structure of the burner flame are changed by the ratio of acetylene and oxygen supplied to the combustion zone

As an example, consider the structure of an acetylene-oxygen flame.

Components of acetylene-oxygen flame: 1-core; 2-recovery zone; 3-torch flame

The flame core has the shape of a cylinder with a pointed end, around which there is a brightly luminous shell. The length of the flame core is regulated by the supply rate of the gas mixture and its qualitative composition. The diameter of the core depends on the size of the mouthpiece and the flow rate of the combustible mixture.

The structure of the flame changes when the mixture ratio changes and can be: normal, carbonized and oxidizing.

Normal (recovery) type of welding flame

A normal flame is produced when one volume of oxygen is supplied to one volume of combustible gas. If acetylene is used as a flammable gas, then the process of its normal combustion can be written in the following form: C2H2+ O2 = 2CO+ H2.

In this case, the products of incomplete combustion burn out due to the oxygen present in the atmospheric air. Since there are no absolutely pure substances in nature and oxygen contains a certain amount of impurities, a normal flame is obtained at a certain increased value, that is, at a ratio of acetylene and oxygen equal to 1.1 -1.2. The core of a normal flame is light with a slightly darkened reduction zone and torch. The shape of the flame core resembles a cylinder with clear outlines and a rounded end. The diameter of the core depends on the size of the welding torch mouthpiece, and the length is determined by the rate of release of the gas mixture. Around the flame core there is a light shell in which the combustion of hot carbon particles occurs. At a high gas supply rate, the flame promotes the combustion of the metal and blows it out of the weld pool.

The reduction zone of the gas flame is darker in color and is located in the space within 20 mm from the end of the core. The flame temperature in this zone can reach 3150°C (during the combustion of acetylene). The size of the reduction zone depends on the number of the welding nozzle. Using this flame zone, the metal is heated, melted and welded. The rest of the flame, located behind the reduction zone, consisting of carbon dioxide, water vapor and nitrogen, has a significantly lower temperature.

Carburizing view of welding flame

A carburized flame is produced when the ratio of acetylene to oxygen exceeds the specified ratio, that is, it becomes greater than the value of 1.1. Theoretically, a carburized flame is obtained when 0.95 volumes of oxygen or less are supplied to the burner. In this case, the flame core increases in volume and loses its outline. The lack of oxygen in such a flame leads to incomplete combustion, and it begins to smoke. Excess acetylene in a carburized flame causes it to decompose into carbon and hydrogen. Carbon from the flame passes into the metal, carburizing it. Typically, a carburized flame is used for welding aluminum and surfacing hard alloys.

The reduction zone of a carburized flame is light and practically merges with the core. The temperature of such a flame is lower, so it is more difficult to work with it. To return the flame to a normal state, increase the supply of oxygen or reduce the supply of acetylene.

Oxidative type of welding flame

An oxidizing flame occurs when there is a lack of acetylene, that is, the acetylene:oxygen ratio becomes less than 1.1. A practically oxidizing flame is obtained when the volume of oxygen exceeds the volume of acetylene by 1.3. The core of such a flame shortens and sharpens, and its edges become blurred and the color fades. The temperature of such a flame is higher than the normal temperature. Excess oxygen oxidizes iron and impurities found in steel, which ultimately leads to brittleness of the weld, porosity of its structure, depleted in manganese and silicon. Therefore, when welding steels with an oxidizing flame, filler wire with a high content of these elements, which are deoxidizing agents, is used. The highest normal flame temperature is achieved in the reducing zone.

Chemical composition and color of flame

Pocket lighters are small in size, which allows them to be carried without any problems. It is quite rare to find a table lighter. After all, due to their large size, they are not intended to be carried. Their designs are varied . There are fireplace lighters. They have a small thickness and width, but are quite long.

Today, promotional lighters are becoming popular. If there is no electricity in the house, then it is impossible for it to light a gas stove. The gas is ignited by the resulting electric arc. The advantages of these lighters are the following qualities.

- Durability and simplicity of design.

- Fast and reliable gas ignition.

The first lighter with modern flint was created in Austria in 1903 after the invention of ferrocerium alloy by Baron Karl Auer von Welsbach.

The development of lighters accelerated during the First World War. The soldiers began to use matches in order to see the road in the dark, but their location was revealed by the intense flash when ignited. The need for fire without significant flash fueled the development of lighters.

At that time, the leaders in the production of flint lighters were Germany and Austria. Such a portable device, which is designed to produce fire, found in the pocket of many smokers, can be fraught with many dangers if handled incorrectly.

The lighter should not spray sparks around itself during operation. The fire should be stable and even. The fire temperature in pocket lighters reaches approximately 800-1000 degrees. The red or orange glow is caused by carbon particles that have become hot. For household burners and turbo lighters, butane gas is mainly used, which burns easily and is odorless and colorless. Butane is obtained by processing oil and its fractions at high temperatures. Butane is a flammable hydrocarbon, but it is absolutely safe in modern lighter designs.

Such lighters are very useful in everyday life. They can set fire to any flammable material. The set of turbo lighters includes a table stand. The color of the flame depends on the combustible material and combustion temperature. The flame of a fire or fireplace generally has a motley appearance . The burning temperature of wood is lower than the burning temperature of a candle wick. It is because of this that the color of the fire is not yellow, but orange.

Copper, sodium and calcium glow in different colors at high temperatures.

The electric lighter was invented in 1770. In it, a hydrogen jet was ignited by a spark from an electrophore machine. Over time, gasoline lighters gave way to gas lighters, which are more convenient. They must contain a battery - a source of energy.

Not very long ago, touch lighters appeared, in which, without mechanical action, gas is ignited by acting on a touch sensor. Pocket-type touch lighters. Basically, they contain advertising-type information, which is printed using pad or silk-screen printing.

How to put out a fire

The ability to properly extinguish a fire is often no less important than the ability to build one. Smoldering brands forgotten in the ashes can lead to a fire.

Therefore, you should always approach this seemingly simple and at first glance safe issue with full responsibility.

The most effective way to extinguish a fire is to use water. The coals move away from each other and are filled with water. If the fire is left in a folded state, extinguishing may not have the desired effect, and seemingly extinguished coals will quickly dry out, heat each other and ignite again. This is especially true for fires such as the “hunting trough”.

If the fire consists of thick logs, you can try to dip them into a pond or deep puddle. This is a reliable way to extinguish fires such as Nodya.

When there is no body of water nearby, you can urinate on the fire. And if the size of the fire does not allow you to extinguish the coals with such an amount of liquid, then you should either wait for the smoldering brands to cool completely, or, if necessary, urgently leave the parking lot, sprinkle them with a thick layer of sand or earth: the lack of oxygen will not allow the wood to ignite again.

However, you should not urinate in a fire organized at a centralized parking site: after that, other people can use the same fire pit. I don’t think anyone would be happy to make a fire and cook food on the site of a former toilet.

Burns like a match

Briefly about the structure of a match. It consists of a stick and a head. Sticks are made from wood, cardboard and cotton cord impregnated with paraffin. The wood chosen is soft species - poplar, pine, aspen. The raw material for sticks is called match straw. To avoid smoldering of the straws, the sticks are impregnated with phosphoric acid. Russian factories make straw from aspen.

The head of a match is simple in shape, but complex in its chemical composition. The dark brown head of the match contains seven components: oxidizing agents - Berthollet salt and potassium dichromate; glass dust, red lead, sulfur, bone glue, zinc white.

- poplar – 468;

- aspen – 612;

- pine – 624.

The fire temperature of a match is equal to the fire temperature of wood. Therefore, the white flash of the sulfur head is replaced by the yellow-orange tongue of the match.

If you look closely at a burning match, you will see three zones of flame. The bottom one is cool blue. The average is one and a half times warmer. The top is the hot zone.

Temperature conditions of different types of burners per cylinder

You can choose a gas burner for a cylinder in specialized stores or use the online purchasing service. This significantly saves time, and on the online store page everyone has the opportunity to get acquainted with the information they are interested in about the product. The Pathfinder brand provides a huge selection of special equipment and gas burners, among others. Among them, the following three types are distinguished:

- refillable - they have a compact size and ergonomic design, are simple and easy to use, and the presence of an automatic piezoelectric ignition function allows instant use of the device. In addition, it is worth noting that this particular type does not belong to the cylinder series of gas burners;

- threaded - have a directional source of fire with a torch structure. Mixtures with a high propane content are used as fuel, which ensures that the temperature in the main flame zone is maintained at a constant temperature of about 1800 °C. Some models have separate gas and air mixture control systems. This allows you to get a fire torch of different power and the ability to perform work in a wide range of temperatures;

- with a collet cylinder – used as a source of directed flame with a torch structure, the temperature of which reaches 1500 °C.

The devices are equipped with a piezoelectric ignition system, some have the function of additional fuel heating, which allows the use of the equipment at different angles. Gas consumption ranges from 50 to 250 g/hour.

Construction [edit | edit code]

Fuel lighters [edit | edit code]

Most lighters work on the principle of igniting a special flammable fuel poured into the lighter. The burning fuel serves as a source of fire for the lighter user.

Fuel [edit | edit code]

Easily evaporating liquid hydrocarbons are most often used as fuel, most often gasoline for so-called gasoline lighters and liquefied hydrocarbon gases for gas lighters. The fundamental difference between them is that the fuel of gas lighters evaporates very quickly and is therefore contained in sealed containers under low pressure formed by evaporating gas vapor. Gasoline evaporates relatively slowly and therefore does not require a sealed container.