“PVC” stands for polyvinyl chloride - a material that has good performance characteristics under heavy loads, as well as significant temperature changes. PVC pipes (white, orange, black, etc.) are very popular in today's communications products market. Often, on their basis, an external or internal sewerage network, a drainage system is built, cold and hot water is connected, and an electrical cable is laid.

Using PVC pipes, you can organize water supply and sewerage for a residential building or public facility without any special costs.

PVC: what is it

PVC pipe is highly durable. The material itself belongs to the class of plastics, which, upon completion of the formation of the product, does not lose its ability to be recycled; its melting point is 165-200 ° C. PVC is almost not subject to mechanical stress and other deformations, which is explained by the structure of the molecules and the structure of the polymer.

The material is thermoplastic, can be easily machined, and is easily welded when heated to a temperature of 200-300 °C. In addition, non-flammable PVC pipes are produced from it. Polyvinyl chloride is not sensitive to many acids, aliphatic, chlorinated and aromatic carbohydrates.

The strength of joints created by welding or adhesive is about 85-90% of that of the material itself. PVC is a good dielectric, meaning it does not conduct electricity. This property facilitates the use of the material in the production of smooth PVC electrical pipes.

Note! If the heating temperature of the pipe is more than 85 °C, the dielectric properties are lost.

The fire safety of PVC pipes determines their use when laying electrical networks for various purposes.

Electrical pipe made of polyvinyl chloride is used to protect television, electrical, and computer cables from all kinds of damage. The chlorine in its composition gives the polymer high fire resistance. The melting point of PVC pipes exceeds those made of polyethylene or polypropylene.

For water supply

The material used for the production of pipe products largely determines the quality and durability of the water supply system. Today, PVC pipes are used to lay water pipes. Why are these products so popular? The point is the positive qualities of the material.

Parts made of polyvinyl chloride differ:

- lack of toxic effects;

- strength;

- plasticity;

- wide range;

- low cost;

- long service life.

The ease of installation of PVC pipes for water supply, regardless of size, allows you to lay the pipeline yourself, which will save your family money.

Plumbing equipment stores and construction supermarkets sell plumbing plastic risers.

Classification and main characteristics

When installing cold water lines, products made of polyvinyl chloride (PVC) are used. Components for PVC water supply pipes must also be made of similar materials.

Ideally, plumbing pipes and PVC adapters for water pipes, fittings should be made not only from the same material, but also from the same manufacturer. In this case, the highway will function efficiently for decades.

These are the products of the famous French company Leroy Merlin, which produces sewer, plumbing products and fittings, shut-off valves, and other products for home improvement.

To organize the water supply, more often than others, they use PVC pressure pipes for water supply, the production of which is regulated by GOST R 51613-200.

Products are marked accordingly:

- standard size;

- bending radius;

- type of installation;

- working pressure.

For domestic needs, risers with a diameter of 25, 32, 50, 63 mm are most often used.

After plasticizers are removed from polyvinyl chloride, the material becomes safe and durable, and the elements made from it are called uPVC pipes. They may differ from each other not only in size, but also in color.

Products of gray and black shades are used for laying internal systems, orange (brown) - for external ones. Casing pipes have a blue or white tint.

PVC pipes are used in the construction of external sewer wells, thanks to which the presence and level of water runoff is controlled.

The diameter of PVC pipes for water supply is 9-630 mm, length is 1 m, 2 m, 3 m, 6 m. To obtain risers of a different length, you can cut the necessary pieces using special scissors.

To make a quality connection, you need to carefully clean the ends. Not everyone knows how to connect PVC pipes for water supply.

This procedure can be done using:

- couplings;

- flange;

- glue.

Often the risers are connected to each other in a socket. The socket joint is characterized by simplicity and speed of installation. This method is used to join polyethylene (PE) water pipes and other socketed plastic pipes.

Important!

Before making an adhesive connection, you need to check the joining parts for their compatibility. Algorithm for performing the work:

- Place the appropriate fitting on the main pipe.

- Cut off the required piece of pipe, clean the end, chamfer, blow, degrease.

- Coat the inner surface of the fitting (adapter) and the outer surfaces of the PVC pipes being connected with glue.

- Insert the section to be connected into the adapter, turn both ends of the pipes relative to the fitting by 1/3 of a turn to evenly distribute the adhesive, and secure the connection tightly.

If all elements are compatible, then after 25-35 seconds. the structure must be immovable. Wait 1 minute until the compound hardens completely.

Technical characteristics of PVC pipes

A comparison of the technical parameters of pipes made of PVC and other materials is given in the table.

Table 1

| Characteristic | PVC | Fiberglass | Stainless steel | Aluminium alloy | Unit |

| Density | 1,3-1,43 | 1,6-1,9 | 7,7-7,9 | 2,7 | kg/cm3 |

| Elastic modulus | 2,0-2,7 | 17-22 | 210 | 70 | GPa |

| Tensile strength (yield strength for PVC and metals) | 4-7 | 170-227 | 200-226 | 100 | MPa |

| Thermal conductivity | 0,13-1,63 | 0,58 | 17,5-58 | 201,3-221 | W/(K*m) |

Pipe production is based on GOST R 51613-2000, terminology is established by GOST R 52134-2003, weight, wall thickness and diameters are determined by GOST 18599-2001.

Pipes with the thickest walls can withstand heavy loads and are suitable for industrial use

The products have high elasticity and are resistant to deposit accumulation and rust formation. The smoothness of the inner surface prevents a decrease in pressure, and if it is an electrical pipe (white or gray), it does not interfere with cable pulling.

PVC pipes are resistant to stray currents, microorganisms, and ultraviolet rays. The white pipe is used to protect against electric shock if the wire insulation is damaged.

The minimum wall thickness for a polyvinyl chloride pipe is 1.3 mm; maximum – up to 36.7 mm for products used in industry.

External sewerage: features

When an external sewer system is being installed, pipes of different colors are laid for these purposes:

- orange;

- yellow.

They work in particularly harsh conditions. Especially for them, in accordance with the diameter, the corresponding wall thickness has been developed. For example, for products with a diameter of 200 mm:

- When lying at a depth of 4 meters, a thickness of 3.9 mm is taken.

- For a 6-meter depth, the wall will have a thickness of 4.9 mm.

- Under particularly difficult conditions (with a depth of 8 meters), the thickness should exceed 5.9 mm.

All this data is provided by GOST. When sewer systems are designed, these values are indicated in the project.

Types of PVC pipes

There are several classification criteria that determine the classification of polyvinyl chloride pipes to one type or another. All types of products have different appearance, characteristics and properties. Smooth PVC pipes are:

- casing;

- sewer;

- electrical.

According to the bending radius, the PVC pipe can be flexible, very flexible and rigid, and according to the standard size - small, medium and large.

For external sewerage, you should use PVC pipes that can withstand the load, because such systems are laid underground

When installing the system in a house, you will need two types of products: external and internal PVC sewer pipes. The division of pipes is made based on the location of the system. The characteristics of PVC pipes for internal sewage allow them to be used for draining wastewater from apartments and private houses.

Note! The outer pipe is used for sewer networks with a large cross-section, as well as for drainage structures.

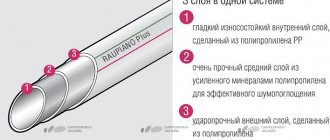

Characteristics of the work environment is another classification criterion. According to it, pipes are divided into non-pressure pipes, used to supply media without pressure, and pressure pipes, which provide for the creation of pressure. There is also a type of pipes that transport rarefied media. Corrugated PVC pipes (black, white, gray) can often consist of two layers - an outer corrugated one and an inner smooth one.

GOST 28117-89 defines the range of polyvinyl chloride pipes. Information about PVC pipes (what they are, explanation of symbols, assortment, requirements for production and use, technical parameters and features) can be found in regulatory documents.

Requirements for PVC products

The production and installation of pipes is carried out in strict compliance with technical regulations.

- pipe marking is carried out strictly according to approved state standards;

- all pipes are subject to preliminary tests that confirm their functional performance;

- Packing and moving of PVC pipes is carried out in accordance with technical requirements.

- for outdoor use, the elements are painted orange. This characterizes the increased strength of the pipes and increased diameter for a larger volume of flows;

- for use in internal water supply pipes are painted gray.

Characteristics and features of flexible PVC pipes

Often there is a flexible pipe, the technical characteristics of which are determined by the properties of PVC. Such products have high ring rigidity. Thanks to this, the flexible pipe can withstand pressures of up to 120 atm. When heated, the elongation of the product is 5%.

Since the frost resistance of the material is low, thermal insulation is required. Flexible pipe is not able to maintain its properties if the temperature is below -15 °C.

Flexible pipe also has high strength and resistance to stress, but its scope of application is limited to a certain temperature range

Polyvinyl chloride has high light transmittance. For this reason, flexible pipe is often clear or painted in a variety of colors. Products made from this polymer have higher resistance to ultraviolet radiation compared to other plastics. They are very smooth outside and inside. If the temperature exceeds +78 °C, the rigidity of flexible pipes decreases.

Product advantages

Polyvinyl chloride is clearly the leader among similar products for draining waste streams and organizing a storm drainage system.

- affordable price is a priority for a wide range of consumers;

- a simple device that any user of the system can perform independently;

- installation does not require the use of expensive equipment. Installation into the socket is quite easy. Accordingly, the low cost of saving attracted specialists;

- the ability, if necessary, to dismantle sections of the pipeline for reconstruction or replacement;

- PVC does not corrode, no plaque is deposited on the internal smooth shells;

- possibility of use in chemical and gas environments;

- if increased loads are required, it is possible to use corrugated pipes with a three-layer shell;

- Backbone networks can be laid at a depth of up to 8 meters. At the same time, pressure is maintained up to 16 bar.

The main negative quality of PVC pipes is the limitation in the temperature of the flow. The maximum temperature should not exceed 65°, the minimum – 10°.

Flared and square PVC pipes

A square PVC pipe with a wall of 2 to 3 mm is used for the construction of greenhouses and greenhouses. The frame is made from polyvinyl chloride tubes and attached to a wooden foundation. In agriculture, a square pipe is used to create and connect nipple drinking systems.

This shape of the pipeline holds the entire system vertically well, which is difficult to achieve with round products. It is very important to ensure that the nipple is installed perpendicular to the line on which the square pipe is placed. The range of products involves their production in different sizes and wall thicknesses.

Note! The standards do not prohibit coloring profiles by adding pigment. This is how you get, for example, a white or orange pipe.

Socketed PVC pipes differ from other types of products by the presence of a socket, which is equipped with an O-ring. This structure makes it possible not to use welding equipment when installing the system. The socket pipe is suitable for water supply and sewerage networks. It is made from unplasticized polyvinyl chloride, which is durable and resistant to aggressive environments.

Bell pipes are easy to install and require no tools.

The bell-shaped pressure pipe has a wide range. The operating pressure range is presented in the table.

table 2

| Dimensional relation | Pressure | Unit |

| SDR41 | 0,63 | MPa |

| SDR33 | 0,8 | |

| SDR26 | 1,0 | |

| SDR21 | 1,25 | |

| SDR17 | 1,6 |

The socket pipe is joined to other products to form a tight connection that is not affected by low or excess pressure in the pipeline.

Scope of application

The use of pipe materials in everyday life and industry is not limited to laying communications. However, the main areas of use remain pipelines for supplying drinking water, drainage, protecting electrical wires and communications.

PVC electrical pipes

Corrugation for laying electrical wires is a convenient, inexpensive, fireproof insulator that is used for wiring electrical networks in individual and industrial construction. PVC corrugation is laid indoors in an open way, on top of walls (fastening to the walls with clips) or the channels are walled up in concrete (hidden wiring).

Flexible materials are easy to install. They perform two functions:

- serve as an insulator for wires from external damage;

- perform the function of fire protection, since they do not support combustion in the event of a wiring fire.

We recommend that you read: How to make a bed frame from a profile pipe with your own hands

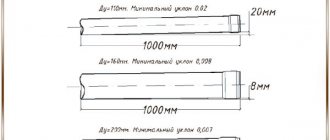

Corrugated pipes differ in diameter (the range varies from 16 to 50 mm) depending on the power of the wires being laid. So 32 diameters are used to insulate wiring between electrical panels, 25 for wiring to distribution boxes, and smaller diameters to sockets and switches. Corrugation 16-20 mm in diameter is also used for laying communication networks (Internet, telephone). Available in coils of 20, 50 and 100 m or linear meters.

Note! Corrugated pipes are equipped with a special device - a broach, for easy cable placement.

For laying electrical communications in office and industrial buildings, rigid PVC pipes are used. They are sold in segments of 2-6 m.

Water supply

For the installation of water supply networks, uPVC pipes are used, which are resistant to pressure from a centralized water supply. These pipe materials have high chemical resistance and antibacterial properties, which, coupled with their smooth walls, makes them not only environmentally friendly and safe, but also recommended.

PVC-U pipes for water supply systems are light gray. Installation is carried out in a socket, without the use of threaded connections or glue. External communications need insulation.

Installation of pressure water pipes is carried out using special glue, in a socket on fittings. To do this you need:

- cut the pipe perpendicular to the guide axis;

- chamfer;

- coat the cut with a special cleaner, which pre-softens the material;

- coat the pipe and fitting with glue, connect with physical force, inserting the pipe until it stops;

- rotate the pipe a quarter turn for better distribution of the adhesive base;

- the result of the manipulations will be an even bead of adhesive mass at the border of the fitting, which is removed with a clean rag.

Note! When mechanically damaged, PVC pipes become vulnerable to stress. Transportation should be carried out without dragging, only in a horizontal position.

The disadvantages of PVC products include their difficult disposal, since at insufficient combustion temperatures this material releases toxic substances.

Sewerage

PVC-U sewer pipes for external installation are distinguished by their bright orange color. These are products made from unplasticized polyvinyl chloride, which are resistant to mechanical loads. There are pressure and non-pressure materials. For sewerage and removal of atmospheric water from the site, non-pressure varieties are mainly used.

Manufacturers offer corrugated and smooth PVC sewer products. Corrugated ones are made with a double wall (smooth pipe inside) and simple ones, the inner wall of which is also corrugated. Corrugation is used here to increase resistance to mechanical loads.

Note! For drains from washing machines and dishwashers, gray corrugated hoses with a diameter of 25-40 mm are used.

Installation of sewer pipes is carried out in a socket. For internal installation, gray pipes with a diameter of 50-110 mm are used. The outer pipe can be from 110 to 250 mm in diameter. Segments of finished products on sale vary from 50 cm to 8 meters.

We recommend that you familiarize yourself with: Dimensions and types of PVC sewer pipes and adapters for connecting them

When installing drainage systems, remember the required slope of 2 degrees. A smaller angle of inclination can cause water stagnation and freezing of the system. At a higher rate, the flow flows at such a speed that it does not have time to entrain heavy particles of mechanical impurities (for example, sand), which contributes to the formation of blockages.

Features of pipe selection

When selecting products, special attention is paid to the marking of PVC pipes. Deciphering it is not difficult. Usually indicated:

- PVC type;

- type of bell;

- size ratio;

- outer diameter size;

- wall thickness;

- appointment;

- manufacturing standard.

The color code for PVC pipes is as follows: gray (or black corrugated) - for internal sewage systems; orange or yellow – for external networks; polyvinyl chloride pipe for casing wells - white or blue. The inner surface of corrugated PVC pipes is white or light gray.

Pipes used for casing wells are most often produced in white or blue.

Additional characteristics of PVC pipes can always be found in the documents for its manufacture.

According to their strength class, products are divided into 3 groups:

- light (L);

- average (N);

- heavy (S).

The permissible depth of its occurrence when laying a pipeline underground depends on whether the pipe belongs to a particular strength class. The light group is capable of withstanding 2 kN/m2 and is designated SN-2, medium - 4 kN/m2 (SN-4), heavy - 8 kN/m2 (SN-8).

Black PVC pipe is usually used for open laying of cables and wires. This color reduces exposure to ultraviolet rays.

Internal sewerage pipes

Internal sewage system for home

Typically, plastic products painted gray are used for such work. These parts have characteristic differences:

- The wall is always smooth.

- The connection is made only in the socket.

The most popular are PVC 52, PVC 110, PVC 50 with a maximum length of 3000 mm. PVC pipe 25 is used less frequently.

The wall thickness is selected in accordance with the required stiffness conditions. Typically, all gravity systems install parts with a thickness of more than 1.8 mm. All sizes can be viewed in GOST tables.

Characteristics of fittings

PVC is used to make fittings for plumbing systems. They are produced in a wide range, and products of a wide variety of sizes can be found on the market. They are selected depending on what functions they must perform.

For example, a coupling is purchased for straight sections of the system. The coupling is a double socket type. It is suitable for joining elements with smooth ends.

Repair sliding couplings are distinguished separately. They are equipped with special grooves for a rubber sealing ring. Such products slide easily along the outside of the pipe.

For branches, tees will be required, and for pressure networks, products with three-sided sockets are needed. Tees are also used to connect PVC pipes with elements made from other materials.

Nozzles can be used to connect PVC pipes to shut-off valves. They are important when you need to join elements of different sections. Then you will need pipes for the transition. If you need to install a network with a deviation in the direction of water flow, then use elbows or bends. The quantity of all these elements needs to be calculated