Rules for replacement

Maintenance of sewerage systems made of cast iron is fundamentally different from maintenance of utilities made of polypropylene. Therefore, if we are talking about an apartment building, repairs are preceded by submitting an application to the management company.

All work is carried out only after obtaining permission for individual actions on a separate site.

In the event of unauthorized insertion of PVC pipes into a cast-iron communal riser, the house management legally declines responsibility for emergency situations.

General information

Features of installation of internal sewerage

It is necessary to install the pipeline so that when materials of different strengths come into contact, the structures will last for many years.

There are general rules for arranging sewer risers through structural slabs.

If metal-plastic pipes pass through the ceiling structures, they are placed in special tubular plastic cases of a suitable size.

Factors that determine the use of sleeves

1. Sound insulation of the sewer riser in the apartment is ensured using sleeves.

2. Polymer pipes are subject to changes due to temperature changes depending on different seasons and time of day. Sleeves protect pipelines when moving inside ceilings.

3.The use of sleeves allows you to dismantle the damaged section of the pipe without destroying the entire sewer system. It is not necessary to always place all the elements in the sleeve; this is due to the presence of emergency circumstances. For example, a cold water pipeline made of polymer will have to be completely replaced only after fifty years, when its service life expires.

4. If you properly seal the cracks formed by the sleeve with pipes that are laid through the walls of buildings, as well as their ceilings, then you can completely get rid of the smell and insects from neighboring rooms.

Dismantling

Replacing a cast iron riser with a plastic one requires knowledge and experience. If you are not sure of the presence of both, you should invite a plumber.

Before replacing a cast iron drain with a plastic one, you should make sure you have the following tools:

- perforator;

- Bulgarian;

- grinding discs;

- adjustable wrench;

- chisels;

- screwdrivers.

Stage 1. The junction of the cast iron elements is identified.

Stage 2. The connection method is determined. Combining the tee with the cross and the pipe can be done using:

- sulfur filling;

- mixtures of cement and polymer;

- caulking with mortar.

Stage 3.

The cast iron structure is dismantled. Using a pipe cutter or grinder, a pipe standing vertically is cut into 15-centimeter pieces. The cut should be made at an angle of 15-20 degrees, two-thirds of the perimeter.

The cut sections are dismantled using a chisel. In this case, care must be taken to ensure that residues do not get into the sewer.

The top edge is cut at a pre-measured height. The height parameters must correspond to the shaped product. The cut is made in accordance with the horizontal line. The location of the upcoming cut is marked with masking tape.

Stage 4. The lower part of the riser consists of several parts. Each part is cleaned in turn at the connecting seams and broken out from the overall structure. The connecting seams in the nodes are removed using a hammer drill. The remaining solution is removed with a chisel.

Dismantling cast iron sewer risers is often difficult due to the lack of a seam or strong gluing of parts together. To expand the joint, a metal blade is used. Otherwise, the pipe is cut 3–5 cm above the joint.

The riser pipes, sealed with sulfur, are preheated with a blowtorch at the junction. To replace a cast iron sewer tee, carefully rock the heated pipe until the elements separate. Sulfur has a strong unpleasant odor and its fumes are poisonous.

Don't touch cast iron unless necessary.

In general, I planned to write a continuation to the unexpectedly sensational article “Are Khrushchev buildings better than new buildings?”, but the topic turned out to be so vast that I decided to talk about cast iron pipes and radiators in old houses separately.

The vast majority of houses built in Soviet times use cast iron sewer risers and cast iron heating radiators. They are considered obsolete, unreliable, and many plumbers, when doing repairs to new residents, consider it their duty to replace sewer pipes with plastic ones and heating radiators with bimetallic ones. At the same time, improved performance characteristics are promised: increased reliability, comfort and aesthetic appearance. Let's figure out what this means.

Cast iron sewer risers

The service life of cast iron sewer risers is enormous. I couldn’t find exact data, but they usually talk about 80-100 years. The average Khrushchev building is 60 years old. It would seem that the residents of such houses have at least another 20 years left, and the sewer pipes do not need to be changed. 20 years is a very long time to operate. For example, new polypropylene pipes for hot water supply, which are widely used today, are designed for approximately this service life. So why do these pipes burst so often and cause so much trouble for all of us?

In most cases, the reason, as always, is “bungling”. The cast iron riser cannot be replaced in pieces. If we’re going to change it, then change it along the entire entrance. But do plumbers warn you about this when making repairs in an apartment?

The photo shows an example of not only a problematic plastic insert, but also one made using a standard plastic coupling, which, of course, caused a leak

By cutting a plastic insert into a sewer riser, a plumber will invariably move the monolithic structure of the cast-iron riser, which, with a high degree of probability, will lead to cracks among neighbors several floors below. Even if not immediately, such a “touched” pipe will definitely crack in the near future. A neighbor two floors below will invite a plumber, who will say: “What did you want? How old is he! We need to change it to plastic." And, of course, he will also replace the problem area with plastic, thereby creating a new crack in the riser two more floors below (or above). And this will continue until the entire riser is replaced with plastic, simultaneously flooding the apartments and creating problems for the residents.

There is another trick - replacing sewer pipes with plastic ones on the lower floors, when the entire riser above is cast iron. This is absolutely forbidden to do! “Cast iron” has enormous weight, and a plastic pipe on the ground floor can simply be crushed, which will ensure that all the contents of the sewer passing through your apartment escape from the neighbors above. An unpleasant sight. And the cast-iron sewer riser that has sagged from such a tie-in on the first floor will certainly crack in the neighbors above - and everything will start all over again, and you will be flooded with sewage. The main rule with a cast iron sewer pipe is simple - it works, don’t touch it!

What are the advantages of a cast iron pipe over a plastic one? There are actually plenty of them!

Noise insulation

If you have an apartment building and people live above you, every flush of a toilet with a plastic sewer riser will be accompanied by a terrible noise.

At first, you will think that there was a flood and someone flushed the entire contents of the toilet directly onto your bathroom floor. Then you will get used to it or start doing additional soundproofing of the sewer risers. The most advanced will pay a lot of money for a soundproofed sewer pipe.

Photo: santehnika-online.ru

Such a pipe costs about 1,000 rubles per meter, and it’s not so easy to find them in Vladimir. Is it worth it? I would think.

Fire safety

When a fire occurs in lower-level apartments, plastic sewer pipes quickly melt, catch fire, and the fire, along with smoke, quickly spreads upward and begins to penetrate into other apartments. That is why clause 4 of Art. 137 Federal Law No. 123, clause 4.23 SP 40-107-2003, clause 3.1, 3.2 GOST R 53306-2009 require the use of special fire couplings when passing floor slabs between apartments when installing a plastic sewer riser.

Photo: fireman.club

Has anyone ever seen these couplings in houses? Me not. Even in many high-rise new buildings, where a plastic riser is installed initially. This is why many hazardous industries are still required to use cast iron risers. A cast iron sewer riser can save your life.

Structural rigidity, no thermal expansion

I recently went down to the basement, where a year ago we had a major renovation done, during which the sewer pipes were changed from cast iron to plastic. I saw this picture: a plastic pipe simply flew out, and the whole entrance was draining all its sewage directly onto the basement floor.

Photo: pbs.twimg.com

The thermal expansion of plastic pipes is very high, and therefore lightweight plastic pipes require good fastening, as well as the installation of expansion joints. As you probably already guessed, this rule is ignored everywhere. The result is in the photo above.

They also love to dismantle cast iron pipes, because cast iron can be returned. At a good price. You can make money not only from you, but also from your pipes and, of course, from new cracks in your neighbors’ sewers. Agree, is it convenient?

Cast iron radiators

Many more do not like cast iron radiators. They are old, ugly and leaking. This is also a myth. Yes, batteries leak, but most often they leak due to metal leads that have rotted over time, which are also used in modern bimetallic heating radiators. In this regard, the reliability of modern heating radiators is no better than the good old cast-iron radiators, because the hoses can be changed.

One day I walked into an apartment on the top floor of a five-story building. A plumber lives in it, and he changed all the pipes to bimetal. At the same time, he complained about the freezing corner. I took a thermal imager and saw that the new bimetallic batteries were only half warm.

Photo by the author

The fact is that the internal diameter of the sections in bimetallic heating radiators is much narrower than in cast iron radiators. This is done for the purpose of energy saving: heating the room requires less coolant, and, therefore, living in a private house, you will, at a minimum, pay less money for coolant, and at a maximum, you will also save on heat due to more efficient heat transfer from bimetallic heating radiators.

But in apartment buildings the situation is completely different! On high floors, due to the obvious laws of physics, the coolant pressure is always less than on lower floors. By narrowing the ducts in heating batteries, you increase hydraulic resistance, and the battery simply stops working! We bought a new beautiful heating radiator, installed it instead of the old cast iron one and ended up with a cold apartment and damp walls. Think about this before you run out for new radiators next time.

So not everything old is necessarily bad. The main thing is proper operation.

Victor Volchek

Main photo: trubamaster.ru

Installation

Before starting work, you should purchase all structural elements:

- The seal is a rubber cuff that ensures tightness at the joints when replacing a tee in a sewer riser.

- Plastic tee.

- Sewer pipe with markings corresponding to the size of the tee.

- Compensators with a diameter that matches the size of the pipe - base.

- Pipe adapters, clamps, fastenings.

- Bends, sockets.

- Protective equipment: respirator, gloves, goggles.

The replacement process begins by installing a rubber cuff into the pipe socket. To do this, a cross or tee is inserted. For a tight connection, the end is washed with a dense layer. Additionally, you can treat it with a silicone mixture applied to the linen winding.

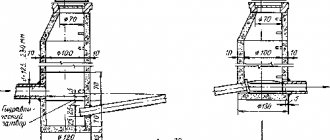

Next, the pipes are cut into calculated pieces, and the end is chamfered. The exact length is determined by inserting the product into the pipe. The resulting structure is inserted into a pipe located in the upper ceiling.

The distance between the tee and the structure should not exceed 30 mm. Preparatory assembly is performed without the use of cuffs and gaskets.

Sliding couplings are used to tightly join the cast iron section with the plastic section.

At the final stage of assembly, gaskets, couplings, and cuffs are installed. Fasteners and clamps are clamped. The joints are checked. Polyurethane foam fills the voids between the floors. The throughput functionality of the assembled system is checked.

How to choose sleeve sizes

When it is necessary to select the appropriate sleeve size and determine the size of the sleeve protrusion on the surface of the ceiling or wall, ceiling,

Features of the use of sleeves, depending on their material and material of construction.

To choose the right sleeve material, it is worth considering the material from which the building is constructed. For reinforced concrete structures, steel sleeves are suitable. They can be easily concreted directly at the factory, where panels for floors and walls are made, or during pipeline laying using special formwork.

The inner surface of the steel sleeve is sharpened to remove burrs, which can damage pipes made of polymer material; the presence of roughness is dangerous for a pipeline system operating under pressure.

The edges on steel sleeves are flared, that is, they are bent outward, removing burrs from the surface.

Sleeves made of polymer materials have a low level of adhesion to cement mortar. Sleeves in elements made of wood and polymer are hermetically sealed using special technologies.

Ruberoid is not suitable as a material for sleeves, since it contains elements of oil, and this substance cannot in any case come into contact with polymer pipes. The material from which the sleeve is made must prevent the spread of fire from room to room.

When pipelines cross the foundations of buildings, requirements must be followed to prevent groundwater from entering the basement. In this case, it is necessary to take into account the shrinkage process of the sewer system and foundation. The gap between the sleeves and the pipes should be treated with mastic or sealant, and the outer cross-section of the sleeve should be twenty centimeters larger than the same parameter of the pipe (according to SNiP 478-80).

When passing through ceilings, sewer and water pipes are also hidden in cases designed for protection. The space between the case and the concrete floor is filled with cement. If the partitions are wooden, then the space is filled with asbestos.

To compensate for changes in the pipe due to temperature changes in horizontal copper water pipes, a sliding support is used as they pass through walls and ceilings. During the development of the project, locations are determined. In the place where the pipe comes out of the wall, tees and elbows are installed to help maintain the location of the water pipes of the new room close to the wall surface.