Purpose of the locking device

The check valve is an important element of the “protective fittings” of any pipeline. Its main purpose in the overall technological system is to prevent a possible change in the direction of the flow of the working fluid. All valves of this type freely pass the working medium in the desired direction and prevent its movement in the opposite direction.

The purpose of check valves in sewer systems is similar - by releasing waste from the internal sewer system into the general house system, they prevent their reverse flow in the event of a plug, blockage or other problem on the subsequent section of the pipeline.

Additional functions of the products are to protect individual housing construction from wastewater that overflows the drain well; prevent rodents from accessing the sewer system (for this, a 50 mm sewer check valve is often used).

Installation subtleties

Installing a sewer check valve is not a difficult task, plus such work does not require expensive tools, a home kit, a drill, a hacksaw, a level, a tape measure, etc. is enough. But first you need to decide where to install the check valve.

Selecting a location

In this case, it all depends on where the system most often clogs.

- If blockages usually occur in the first sewer well from the house, then a 110 mm check valve is installed after the rotary elbow in the basement (before the pipe enters the wall).

Important! In multi-storey buildings, installing such a valve yourself may cause problems with the operating company. The fact is that according to SNiP 2.04.01 - 85, there must be a check valve in the basement with an electric drive and an emergency sensor, so that in case of flooding, a signal goes to the dispatcher’s console. Simple fittings are installed only in rooms with round-the-clock duty.

When installed in apartment buildings, the electric check valve of the sewer system may require approval

- It is best to install the sewer valve in an apartment on a tee or crosspiece near the central drain into the riser.

- If there is no space near the riser for centralized fittings, then you will have to install a separate 50 mm check valve for the sewerage at the outlet towards the bathroom, kitchen, etc. And a shutter with a diameter of 100 - 110 mm for the toilet.

Check valve PVC or polypropylene is considered the optimal solution for an apartment or private house

Incorrect mounting points

There are 2 recommendations here

- Before installing a check valve on the sewer, think about how you will maintain it, because such fittings need to be inspected every six months.

- In a multi-story building, there is no need to install a vertical check valve on the riser.

It is worth mentioning separately about vertical fittings; by installing such a valve, you can incur a lot of problems.

- If the riser is cast iron, then you cannot touch it at all, especially with your own hands; not every craftsman undertakes to repair or replace a cast iron riser. This is due to the fact that there is a danger of the entire pillar collapsing.

- Whatever the vertical check valve, it will interfere with the movement of drains, and sooner or later a blockage will occur at this point.

- If the drains rise from below and the valve blocks them, then in a multi-story building, they will still continue to drain from above, which will make installing the valve useless.

- The sewer riser in an apartment building is a public-use structure. If you, on your own initiative, install a valve on it, then if problems arise with this fitting, you will be required to dismantle everything at your own expense and return it to its original position, plus pay overhead costs, for example, cleaning the basement or repairing neighbors who were flooded after installation valve

A vertical check valve should not be installed in apartment buildings

Installation procedure for fittings

It is not difficult to install a non-return valve for sewerage with your own hands. The instructions consist of several simple steps, which I tried to reflect below in the photo and video in this article.

So, it is better for a simple home craftsman to buy a horizontal check valve with a manual locking function, made of PVC or polypropylene. The pipe diameter does not affect the installation instructions; check valves 50, 100 and 110 mm are installed in the same way

- First of all, just assemble everything as it should be.

- Next, measure the distance from the valve to the outlet into the riser.

- Take a connecting adapter pipe of a suitable diameter and, setting aside the required length on it, cut off the excess.

- After trimming, the edges of the pipe must be cleaned with a knife to remove burrs.

Advice! You should not put corrugation here, a lot of garbage accumulates in it.

Adapter fitting diagram

- Now find the central axis of the drain pipe and mark 2 points on it where the shut-off valves will be fixed.

- Use a hammer drill to drill 2 holes and insert plastic dowels into them under the studs of the clamps.

- Select the height of the studs and screw in the supporting clamps.

- Next, insert rubber gaskets into all the grooves and thickly coat all joints with sealants, after which the shut-off valves are finally assembled.

Installation of supporting metal clamps

- Now all you have to do is connect the system to the sewer drain and firmly fix it with metal clamps.

Fixing shut-off valves on clamps

- Depending on the type of walls and the size of the reinforcement, the system can be fastened in three ways; the photo below shows the principle of fixation.

Three types of reinforcement fixation

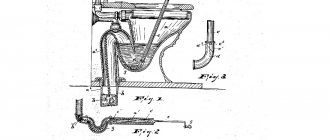

Design and principle of operation of the product

Check valve in operation

Standard check valve components:

- Housing with pipes (inlet, outlet) and inspection cover.

- A working shut-off element - disk, valve, membrane, ball - to shut off the pipeline over the entire internal cross-sectional area.

- Seal to ensure a tight fit of the working element to the body during reverse flow of drainage masses.

- Return spring of the locking element.

- Lever mechanism for forced opening of the valve manually. It makes it easy to adjust the position of the damper. It can be fixed vertically or horizontally.

The check valve works as follows. Initially, the damper blocks the entrance to the housing chamber. The pressure of the flow of drainage masses lifts it without obstacles, and the water or the contents of the toilet rushes to the sewer without delay. If there is a blockage or blockage in the pipes located behind the valve, a reverse flow of liquid occurs. Its pressure presses the working element against the support ring of the housing and reliably closes the passage - liquid waste does not return to the apartment or house.

Distinctive features

Check valves are selected for the diameter of the pipeline, which can be 32, 40, 50 mm or more, i.e., depending on which sewer pipe you will install it on.

In addition, these devices differ in their design, namely:

- Petal or rotary

The design of such elements has a plastic case, inside of which a round “flap” or plate is installed. When the drains drain, it rises so as not to interfere with the flow, but when the drain is complete, it slams shut, preventing backflow. Some of these locking elements have a second membrane, which is controlled using a button. The dimensions of such a device are larger than the pipe itself, which helps to expand the clearance in the pipeline. Therefore, it is equipped with a lid, by removing which you can remove the blockage.

- Lifting

This product also has a plate, which, when the wastewater moves correctly, rises due to the compression of a steel spring, and when the drainage stops, the spring straightens and the plate completely blocks the flow of wastewater back. This mechanism requires periodic cleaning. Replacing any part is quite easy; just unscrew the bolts on the cover and carry out all the manipulations.

- Ball

Here the operating principle is based on the movement of a ball, which, when drained, rolls into a special place in the body, providing free space for drainage. In other cases, the ball blocks the section and does not allow the runoff fluid to flow in the opposite direction. The disadvantage of this design is that the ball tends to not perfectly coincide with the side wall. There won't be a global flood, of course, but runoff can still leak out.

- Wafer

These models are popular because of their small dimensions. They look like a cylinder with a rotary valve inside. The damper may have 2 parts attached to the central rod, or it may also be a kind of plate attached by a spring to the wall of the housing. The compactness of this element does not allow it to be used on the sewer system, and therefore it is placed on the water supply system.

There is another type of design where the level of location of the inlet and outlet pipes is different. There is an air chamber between the nozzles, into which air enters when the membrane is opened. After the waste has drained, the air begins to press on the membrane, providing reliable protection against backflow.

In addition, a vertical sewer valve, no matter what size pipe it is installed on, for example, 50 mm, 72, 110 or larger, can be installed vertically or horizontally. Take this nuance into account when choosing, based on ease of installation and pipeline configuration.

Shut-off elements can be made of cast iron, plastic or steel, so it is advisable to select the same material as that of the sewer system pipes.

The main technical characteristics here are dimensions, material of manufacture, installation method. Pay special attention to the manufacturer. He must be famous. This will ensure that the locking element will last a long time. Today, brands such as Mplast, Carpicorn, FV-Plast and others are popular.

| Technical specifications | Check valve 50 mm |

| Manufacturer | Carpicorn |

| Diameter | 50 mm |

| Material of manufacture | Polyvinyl chloride |

| Purpose | For sewerage |

Source: vivoz-gbo.ru

Classification of products used

Based on the type of working locking element, the following design options for sewer pipe valves are distinguished:

- Lifting . The principle of their operation is described above. The passage through them is blocked by a damper or disk.

- Rotary (petal) . A distinctive feature is that the locking membrane resembles a petal. They work similarly with lifting type products.

- Ball . The locking element is a balloon filled with air. With the “correct” movement of waste liquids, it rises and rolls into the recess provided for by the design of the housing. The flow passes freely into the common drain system, and the ball then rolls back to its original place under its own weight. In an emergency, the reverse flow, with its pressure, presses the sphere harder, which reliably blocks the passage.

- Wafer . These check valves are suitable for sewer pipes with a pipe size of 50 mm. Products in the shape of a low cylinder with a rotary valve are placed inside the pipe. They are capable of passing only water without any solid particles or inclusions - therefore they are designed for discharging liquid from sinks and bathtubs.

check valve types

Types of check valves and their operating principle

The main purpose of a check valve is to block flow in the opposite direction. To do this, a movable barrier is installed in these mechanical devices. The basic principle of operation is that in a quiet state, the mechanical damper is lowered down, blocking the lumen of the sewer pipe and preventing reverse flow from passing through. When drains appear, it rises (moves to the side), the drains go away, and it closes again. This equipment differs by the type of this barrier and the principle of its operation.

Rotary (petal)

This type of sewer valve has a spring-loaded round membrane (plate). If the flow moves in the “right” direction, it turns, rising upward does not interfere with the drainage. If the movement begins in the other direction, the membrane (plate) is pressed against the rim inside the valve, tightly and hermetically blocking the lumen of the pipe. Some models have a manual shutter. This is the second membrane, which can be controlled using a button mounted on the body.

Due to the shape of the membrane, such shut-off valves are also called petal valves, and sometimes you can hear the term “flaps” - this is because of the way they work - the membrane slams shut if there is no drain.

The figure shows how a sewer check valve works

The device itself is larger than the pipe on which it is installed. So in the pipeline there is first an expansion and then a narrowing of the lumen, and these are potential places for blockages to form. To make it possible to quickly remove blockages, a removable cover is made in the upper part of the check valve body. By removing it, the problem can be quickly resolved.

Lifting check valve for sewerage

This type of shut-off device for a sewer pipe is so named because when the sewage flows in the “correct” direction, the shut-off element rises up. The drains put pressure on the plate blocking the passage, compressing the spring and it rises. There are no drains - the spring unclenches, the passage is locked. When wastewater enters from the “wrong” side, there is no way to open the passage. This is achieved by the nonlinear shape of the body.

The valve installation method allows us to distinguish the following designs:

- Flanged . Suitable for connection to large cross-section pipes that have a similar fastening element. The valve with flanges is conveniently mounted on pipeline sections with a vertical or horizontal arrangement.

- Bell- shaped The valve with a conical socket and a rubber sealing ring easily mates with other pipeline elements.

- Couplings . The products are designed to mate with pipes (mostly metal) of small diameters - up to 2.5 inches.

Flanged and Union Check Valve

The material for the manufacture of check valves is:

- Stainless steel . Used for the production of interflange products. Other types of valves can also be manufactured for inclusion in a metal pipe system. In products made from other materials, stainless steel dampers can be used.

- Polyvinyl chloride (PVC) . The most common material for large cross-section sewer valve bodies.

- Polypropylene . The sewer check valve 110-315 mm polypropylene remains operational at +95°C without deformation. The housing material includes components that can partially suppress the operating noise of the product.

- ABS plastic . This thermoplastic resin produces durable and impact-resistant housings for check valves.

- Cast iron . Such designs are recommended for installation in loaded systems (usually external) made of large-section cast iron pipes.

Kinds

The device comes in several varieties:

- Membrane (KESSEL, McAlpine for vent pipes);

- Lever or ball (Redi);

- With lid (Karmat);

- Cast iron and metal flanged.

The membrane works due to a special membrane that opens the duct only in one direction. If water starts flowing in the other direction, the diaphragm will bend, but no leak will form. This will hold back the fecal or water flow for a while, but it cannot be used as a permanent method of protection - with strong pressure from the water flow, the diaphragm may not be able to withstand it. The system is used more often in non-pressure sewer systems, since the diaphragm cannot withstand strong pressure.

Photo - cast iron valve

The diaphragm valve for sewage can be 50, 110 mm or more, it can be double-leaf and single or spring. Such plumbing fixtures are not equipped with a plastic or rubber membrane, but with a metal one, which provides more reliable control of the back pressure of the pipe. It is recommended to install it on communications with strong pressure, but where it is not possible to equip other types of constipation.

Photo - air fungus

The lever-type device operates using a handle and a locking mechanism, like a ball valve. The principle of operation of the system is very simple. When you turn the handle, the ball (locking mechanism) rotates in a certain direction, closing the duct. In addition, there are models equipped with a spring or electric drive. Mechanical and electrical taps are often used for a common riser, this allows the valve to automatically close when back pressure (from the pipe) increases. The clutch check valve operates in a similar way.

Photo - coupling

Such a device has many advantages :

- Excellent maintainability. This property allows you to repair and replace flanged and lever valve models in case of any breakdowns;

- Easy installation and operation;

- Availability.

The model with a lid is similar to the membrane type, but instead of a diaphragm, such a device has a special lid installed. It opens only in one direction and even under pressure from the reverse side it will not let flow through. This is due to its special design (the dimensions of the lid exceed the diameter of the hole being closed, as a result of which it cannot move in the opposite direction). Such models are very easy to manufacture, so a simple homemade valve of this design is often used in domestic sewers.

Photo - operating principle of the lid model

For external pressure sewer systems, a flanged check valve is often used. Its installation is carried out exclusively in a static (permanent) way, i.e., if it breaks, it will be necessary to cut off an entire section of the pipe in order to remove the device and reinstall it in another location. This type of sewer shutoff is the most reliable, since it eliminates the possibility of leakage or breakdown, but at the same time, it is difficult to operate and install. It cannot simply be removed and replaced if necessary and cleaned.

According to the type of installation, lights are divided into:

- Horizontal;

- Vertical.

Accordingly, the horizontal one is installed exclusively in the horizontal direction; this design is mainly used on large-diameter pipes. Vertical - on communications where the dimensions of the control pipe do not exceed 50 mm.

In addition, valves with a shutter and a locking mechanism are classified according to the materials from which they are made. It can be HDPE, PVC, steel, cast iron and even copper. The metal valve is often made of the ball type; it withstands physical stress well, but the steel locking mechanism fails relatively quickly.

In this regard, a float or polypropylene (PPN) valve is much more profitable. It does not rust, and the shut-off equipment is more resistant to constant friction. Also, propylene and plastic valves are of the membrane type.

Valve Selection Tips

- To install the valve, before connecting the apartment sewer system to the common house sewer system, select a product for a non-pressure system.

- Any type of valve can be installed in front of the bathtub or sink. The main requirement for it is compliance with the fastening and diameter of suitable pipes.

- When installing the valve in a vertical riser, use a product with the appropriate mark on the packaging.

- Valve models designed only for vertical installation should not be used on horizontal sections of the pipeline, and vice versa.

- You cannot install a valve designed for pressure in a non-pressure system - it works with crushed waste materials and will quickly become clogged with waste from the toilet.

- To install a plastic valve on a pipeline made of cast iron or steel, special plastic adapters will be required.

- Models of products with flanges must be placed on pipes with the same type of fastening.

- It is not advisable to install metal valves on plastic pipes.

- The cost of check valves can vary by an order of magnitude. However, expensive models do not guarantee great advantages during operation.

Before purchasing

Before purchasing a check valve for the sewer system, you need to decide on the exact location of its installation and know the type of sewer system - free-flow or pressure (with a pump in the pipe system).

When choosing the required model, they also take into account the dimensions of the product, the manufacturer’s warranty period, build quality, complexity of the upcoming installation, material, functionality, and recommendations of practitioners.

Why do you need a non-return valve for a sewer?

Installation of vent valves

The installation procedure for the device in question is carried out in several steps:

- Selecting a place to perform the operation.

- Leak testing.

- Direct installation.

The device should be installed above the area where plumbing fixtures are connected to the sewer main. This setting will allow the valve to operate most optimally.

In buildings with a good ventilation system, it is advisable to install the device in the attic. Provided that it is well ventilated. If installation needs to be done in an apartment, it is done in the bathroom. node. But at the same time it is equipped with a hood.

At the installation site of the device, the temperature level should not drop to negative values. Otherwise the part will break. Installation must be done vertically.

If it is not possible to install the device on the channel, you must use an adapter.

If there is a drain ladder, the part is placed at the highest possible height. The distance between the toilet and the floor should be at least thirty-five centimeters.

It is important that you have constant access to the device. This is necessary for its maintenance and forced activation (if the need arises).

Next, the device is checked for leaks. This is quite easy to do. You need to fill the device with air and treat it with soap. If there are cracks on the surface of the device, bubbles will appear. You can fill the valve with air using an ordinary bicycle pump. The device can also be placed in water. Again, if there are holes, bubbles will appear on the surface of the case. Filling the device with water will also reveal cracks. Liquid will begin to drip from them. Installation depends on the design of the device.

It is done as follows:

- In the bell. When installing the device, use a rubber cuff. It seals the connection and connects the valve to the pipe.

- By means of a threaded connection. A thread is cut on the device and the channel section. Next, it is treated with a special sealant, which eliminates the possibility of leaks.

The first installation option is simpler. It is quite reliable and sealed.

The installation is carried out in several stages:

- Shutting off the water supply.

- If there is no suitable place for installation, an adapter is inserted.

- The device is mounted in a socket or via a threaded connection.

- The joint is tested for tightness.

The nuances of installing sewer valves

- Before installation, you must perform a visual inspection of the purchased product. For further work, leave the structure without visible defects, chips, cracks and deformations.

- After this, the functionality of the valve in the bath is checked using water, which is alternately supplied from different sides through the body pipes. If necessary, at this stage it is easy to eliminate minor faults or replace the product under warranty.

- There is always an arrow on the body of any model. It helps to correctly orient the product during installation - with an arrow towards the common collector or drain well.

- Before work, you must definitely agree with the residents of your riser (from apartments on the upper floors) about a temporary refusal to use water supply and sewerage. Such forethought helps to avoid unexpected troubles.

- If the materials of the product and pipes are different or have different diameters, you will need to install special transition elements that are purchased in advance.

- Each connecting joint must be sealed.

- After installing the valve, the functionality of the drain system and the tightness of the connections are checked. Deficiencies are immediately eliminated. If there are no problems, the sewerage system is suitable for use.

For self-installation

Every home craftsman can independently install a valve of any type. You don’t need a professional or any expensive tool for this. The non-return valve for sewerage is not yet a well-known and widespread device. Therefore, for those who first encountered the product and decided to install it, the following tips will be useful.

Installation of a check valve is simplified if it is sequentially assembled together with all elements of the future sewer system into a common chain. This happens when the entire drainage system of an apartment or house is completely replaced during a major renovation or during the construction of a new home.

When installing the device in an operating sewer system, the role of preliminary marking and careful removal of the pipe section for inserting the valve in this place is important. Installation on metal and cast iron pipes is more complicated than on plastic ones - it may require the involvement of specialists with practical experience in performing such work.

You may also like - Slope of sewer pipes according to SNiP

Product materials and sizes

The dimensions (mounting diameter) of a check valve for sewerage in an apartment depend on the cross-section of the pipeline for which it is intended:

- for toilets choose check valves DN110 mm,

- for main pipelines of internal systems DN50 mm,

- for external sewerage systems - DN150-DN200 mm and more if necessary.

32 mm and 40 mm products are also used.

For the manufacture of sewer check valves, the same materials are used as for the production of pipes:

- plastic,

- steel,

- cast iron.

Plastic models are often installed in internal systems made from appropriate pipes with a small diameter.

Cast iron pipes and, accordingly, cast iron check valves are recommended for powerful (mainly external) pipelines with a large cross-sectional area that experience heavy loads.

Valve Maintenance

Timely inspection and periodic maintenance of the check valve increases the service life of the device and ensures its reliable operation.

Important! At the stage of designing the drain system and installing the valve, it is necessary to provide for ease of access to the product for the necessary maintenance.

The sewer valve is serviced quarterly. To do this, remove or unscrew the top inspection cover. Then a visual inspection of the condition of the product is carried out, the debris accumulated in it is removed, and, if necessary, the edging and/or damper is replaced. The reason for unscheduled maintenance of the check valve may be the deterioration of the drain system, the presence of additional unnatural noise and vibrations in the valve when draining waste.

When servicing the valve in use, you should also follow the manufacturer's recommendations specified in the product instructions.

Installation

Let's look at how to install a DU-50 ball check valve for domestic sewage with your own hands:

- The valves are mounted in the main riser. This allows them to control the pressure of the entire system;

- To do this, you need to cut out a certain section of the pipe, into which a shut-off device is then installed. The hole must match the valve both in diameter and in other geometric parameters;

- Afterwards the device is set up for communication. To do this, you will need a design diagram and manufacturer's installation recommendations. The preferred position of the lock and its features (direction of the membrane, type of opening, etc.) must be taken into account;

- Operation of the device is only possible after 12 hours of installation. This is necessary for the sealant to harden, which lubricates all holes and areas where the valve is embedded.

Photo - installation location

Video on the topic:

Causes and consequences of sewer blockages

Possible destruction or mechanical damage to pipeline elements creates an emergency situation. But most often, emergency situations in sanitary systems for the removal of products from human household activities are associated with the occurrence of internal blockages, which necessarily provoke a stop and reverse movement of the discharged wastewater.

A simple malfunction leads to serious problems, which usually affect the lower floor apartments of apartment buildings or the sanitary premises of the lower level of private buildings. The location of the blockage in these cases is in the horizontal sewer pipes passing through the basement. Residents of the upper floors can also suffer, which happens less frequently. To do this, it is enough to have a plug in the vertical riser between floors. Installing a sewer check valve eliminates the possibility of such domestic accidents in apartments. This device will also protect private homeowners.

Causes of plugs and blockages in drain pipes:

- Blockage of the drain pipe due to violation of the rules for using the sewer system. In this case, the traffic jam is created by large food waste, diapers, plastic bags, cotton wool, pieces of thick cardboard, rags and other bulky items that are not sent to a special garbage container.

- Long-term operation of pipes is accompanied by the gradual formation of sediment on their inner walls and a decrease in the working clearance (section). Subsequently, the rough inner surface of the pipes more easily retains solid particles, which settle and gradually form an impenetrable plug in the overall system.

- Incorrect pipeline slope allows solid particles to settle on its walls. To avoid this, the flow of discharged liquids must have a certain speed. To change the slope of the pipes, you will have to completely redo the problematic system.

- The formation of plugs is also facilitated by bends located perpendicular to the main pipeline. The flow of liquid in these areas slows down sharply, delaying large inclusions - the reason for the formation of plugs.

The consequence of an internal blockage of a sewer pipe that occurs for any of the reasons listed is the accumulation of liquid and its reverse flow. Immediately, the toilet bowl (closest to the plug site) accumulates with the contents of the waste system, with possible overflow of the liquid mass over the edge. In this situation, the unpleasant smell ceases to be a problem, in comparison with the upcoming cleaning, repairs and expenses for purchasing new things to replace the damaged ones.

What is it and what is it for?

If the home sewerage system is not used correctly (for example, disposing of large garbage and hygiene items), it becomes clogged, as a result of which wastewater cannot flow freely through the pipeline. Horizontal pipes, which are located in the basements of residential buildings, are prone to the formation of plugs from the solid fraction of the runoff.

If there is an obstacle to downward movement, the wastewater flows to the first available exit. In this case, the toilets on the first floor may overflow.

If the pressure in the drain is too high or shut-off systems are installed on the first floor, then the drained liquid may reach the second floor. The drains do not rise higher, because... under their own pressure they push through the blockage in the basement communications and flow down.

A check valve is installed in order to prevent the reverse outflow of waste water in private houses and apartments located on the lower floors. This device is also installed in drainage systems, water supply networks under pressure, etc.

Device

The valve design consists of a hexagonal body, the cavity of which is divided into several zones:

- the receiving part located before the shut-off organ. This area is intended to connect the inlet to the wastewater pipeline;

- limiter. Provides unhindered passage of drain water in only one direction and locks the valve in case of reverse movement;

- a locking device fixation system with an additional function of an inspection hatch;

- graduation part. It is designed to ensure the exit of liquid from the restrictor area and the connection of the device to the outlet line.

The design of all working zones comes in different design options, but the operating principle is the same for all models of check valves.

Types of how devices work

There are several types of sewer check valve. Depending on the installation location and the nature of the network.

1. Rotary , they are also called petal (clackers).

The body is square or oblong with a bell joint on one side and a blank end on the other. Inside, a round washer with a diameter larger than the through hole of the pipe by 2-4 mm is attached to the upper part of the wall.

A loose spring is installed at the fastening point, allowing the passage to be more tightly covered.

In a quiet state with horizontal installation, the firecracker is closed and opens when wastewater from plumbing fixtures enters the system. If there is a blockage, overflow and water rushes up, the throttle closes and blocks access.

Some models additionally have a manual hydraulic lock of the same operating principle. It is located on the same line, immediately after the first plug. Its task is to mechanically block the drainage passage if the first sewer valve does not work.

2. Lifting.

The main element blocking the passage is also a round disk. It is attached to the ceiling of the housing with a bolt, and a metal spring is wrapped around it. It creates tension to hold the membrane closed. The water pressure entering the system is enough to lift the washer with the spring and move on.

The throttle device allows you to stop the reverse flow, which presses on the disk from top to bottom. The design is used in any sewerage system. A distinctive feature of the housing structure is the flange connection of the top cover. By unscrewing it, you can easily clean and repair the device.

3. Ball.

Installed only on internal networks. There are special recesses inside the body: water passes into one, and a ball is placed in the other. As the waste moves from the device to the receiver, the ball rolls into the cavity.

What are they made of and what sizes do they come in?

The check valve can be designed for installation in an internal or external sewer system. The material and dimensions of the device’s nozzles are selected in accordance with the material and diameter of the pipe.

Manufacturers of sanitary fittings produce valves with the following diameters:

- 50 mm (manufacturers: Capricorn, Ostendorf, MC Alpine);

- 110 mm (Capricorn, Viega, MC Alpine, Ostendorf, Polytron, Politek and Italian Redi Ottima - the official representative of which in Russia is the Agpipe Group of Companies (agpipe.ru);

- other sizes (32 mm, 40 mm, 90 mm, 160 mm, etc.).

In the internal network of private and apartment buildings, valves with a diameter of no more than 50 mm are most often installed (for toilets - 110 mm). They correspond to the dimensions of a standard PVC pipe and can withstand the pressure of wastewater in household networks.

Universal models that are suitable for any type of wastewater networks have the largest range of inlet and outlet sizes. Depending on the configuration and purpose, they can be placed on either a horizontal or vertical pipe.

Valves that prevent the backflow of fecal matter can be made of the following materials:

- polyvinyl chloride (PVC);

- polypropylene;

- plastic, ABS plastic (impact-resistant material);

- bronze;

- cast iron;

- stainless steel (for the locking part).

The damper and body of the device can be made of various materials.

When and where to put

In most cases, a check valve is installed during a major renovation of a room with partial or complete replacement of pipes, bathroom cladding, etc.

Installation can be done later, but this may require dismantling part of the floor.

When living on the first floors of an apartment building, the valve can be placed at the following points:

Installing a check valve on the toilet outlet.

- After each plumbing fixture (bathtub, toilet, sink, etc.). In this case, small valves (50 mm) are installed on the sink outlets, and a wider one (110 mm) is installed on the toilet outlet. The advantage of this option is the ability to install a locking device at any time without major repairs to the floor.

- After the general branching for the apartment (cross or tee). The large valve (110 mm) is mounted on the floor. The advantage of this option is the purchase and maintenance of only 1 valve, but the disadvantage is the need to ensure constant access to the device.

In a private house, the valve can be installed before the outlet to the well of the central network or septic tank. An important condition for installation in a foundation is ease of maintenance.

To prevent flooding in the basement, valves are also installed on public sewer networks.

According to SNiP, in this case the device must be equipped with an electrical device that gives a signal about the formation of a traffic jam. The signal is sent to the emergency control panel of Vodokanal or another service company.

Some residents of the first floors, who do not want to dismantle the floor or install several valves at once, cut it into the sewer riser. With this installation method, accumulations of large debris and expansion of the pipe can create a plug already at the level of the obstacle itself. As a result, fecal matter will rise into the drains of neighbors higher up, and flooding of the enterprising resident of the house will occur through the ceilings.

Installing a check valve in a sewer riser.

In addition, when cleaning a riser with an incorrectly installed valve, the damper is guaranteed to break. When examining the causes of clogging, the apartment owner may be fined for unauthorized changes in the network configuration and unscheduled repairs of sewerage networks.

Based on the examination, flooded neighbors can go to court for compensation for the costs of repairing their apartment.

By bank card

Today, many buyers have bank cards. This can be any card: debit or credit. Using a card to pay for goods purchased from us is the most convenient method of payment, because payments are made directly on the website. There is also a specially designed form that must be filled out so that the payment amount for the selected product will be charged to your payment card. The data exchange channel is absolutely safe, protected by special encryption. All data about you and your card cannot be transferred to third parties. Therefore, there is no need to worry or worry about using a card to pay for goods from our company.

We care about the comfort of our customers and therefore provide them with different options for paying for the selected product! Make purchases, pay for goods in the way that seems most convenient and acceptable to you!