[contents]

How to properly solder polypropylene pipes

Polypropylene material has pronounced thermoplastic properties. Therefore, PP products become plastic when heated. As the temperature rises, their structure softens. In this state, polypropylene resembles plasticine.

Soldering

Heating and cooling the material allows you to obtain a reliable joint. The connection is made quickly. If it is executed slowly, the quality of the connection deteriorates.

Soldering a polypropylene pipe is polyfusion welding. Therefore, it is carried out using a special soldering iron. The tool allows you to quickly heat the material to the desired temperature. Typically its value is from 300 to 320°C. However, polypropylene begins to melt at 149°C.

It is not recommended to heat PP pipes beyond permissible limits and to use overheated tools on them. As a result of such actions, the material will lose its properties and the products will easily bend.

Description of welding technology

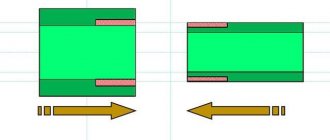

In practice, two methods are used to connect tubular products made of polypropylene: the coupling method and the butt method.

The principle of the technology for soldering polypropylene pipes is simple, because it allows you to perform high-quality welding with minimal skills. The performer will need to spend a little effort and money to achieve the result.

Beginners often use the coupling method of connection, which requires less skill. It is based on the use of shaped parts. This is a straight piece of pipe or coupling.

Sleeve soldering

The connecting elements have a larger diameter than the main pipeline. Straight-line communication elements are inserted into them on both sides to a certain depth depending on the diameter.

At home, this is the docking option that is used. It is used to connect pipelines with a diameter of up to 63 mm.

The principle of the coupling method is to melt part of the outer surface of the workpiece. In addition, the internal area of the connecting piece. After heating, the two elements are tightly connected.

The butt method is a direct option for connecting system parts. It is also realized by melting the PP elements, but only in this case are the ends of the same large diameter heated. This method does not involve the use of fittings.

When welding large-diameter polypropylene pipes, deviations from the axis of the elements being connected are not allowed. Even a small shift leads to a decrease in the internal cross-section of the system in this area.

Butt welding

This causes the fluid movement in the communication to slow down. For precise joining of parts, in addition to the heating tool, a centering system is additionally used.

Welding equipment

Structurally, all machines for socket welding of polypropylene pipes are similar to electric irons. The devices have heating elements and replaceable nozzles of different diameters. Such a tool is commonly called a welding iron.

Soldering iron type

For end joining, more complex welding machines are used. Direct connection equipment is used in industrial facilities.

Butt welding machine

When working with any type of heating tool, you must use gloves made of thick material.

Welding process

To reduce the possibility of error, all operations must be carried out carefully, accurately and exclusively consistently.

Soldering polypropylene pipes instructions:

- Effective ventilation in the room is ensured or checked, since toxic substances are released during soldering of polymer materials. Therefore, it is necessary to create effective air circulation to protect the body from high concentrations of harmful elements.

- The edges of the cut workpieces are processed using a trimmer or a special chamfering tool to simplify the process of joining parts.

- The surfaces to be joined are cleaned from dust and degreased using white spirit, which must dry completely naturally. The presence of drops of water is not allowed, because when the temperature rises, steam is formed, which will cause pores to appear in the material. They will worsen the quality of the joint.

- The recommended soldering temperature is set on the soldering iron and the device is turned on. Heating is carried out up to +260°C regardless of the diameter. Only the heating period changes.

- After the green light comes on, welding begins by installing the straight section on the sleeve nozzle and the fitting element on the mandrel. This allows you to simultaneously heat two parts to the required temperature.

- Warming up is carried out during the specified time for soldering polypropylene pipes, indicated in the table. After this, the straight and shaped element are removed from the device and quickly connected to each other.

Heating of elements

Connection and fixation

It is necessary to hold the joined parts motionless without twisting until the material cools down. It is allowed to correct their alignment within 1-2 seconds. Other movements will lead to disruption of molecular bonds, which often causes leaks during system operation.

Before performing this operation, you must first draw a line on the pipe section indicating the depth to which it will be inserted into the fitting until it stops. The indicated distance also allows you to heat only the required area using a soldering iron. Each pipe diameter has its own value.

Soldering table for polypropylene pipes

If you do not maintain the heating time, you will not be able to solder the connection properly. Underheating prevents the diffusion of the material. Overheating will cause deformation of the products. Therefore, you must always use the values from the table.

Soldering time for polypropylene pipes table

When soldering thin-walled pipe products, the heating time of these elements is reduced by 2 times, but the heating period of the couplings cannot be changed. It must correspond to the recommended values. When working outdoors or in an unheated room where the temperature is less than +5°C, the PP product needs to be heated 50% longer.

If the heating time, removal from the soldering iron and joining of parts, their fixation and welding temperature of polypropylene pipes around the circumference inside the joint are observed, a neatly shaped bead is formed. Its height is usually 1 mm. It does not interfere with the movement of fluid. A neat collar is also created on the outside. It does not spoil the appearance of the joint.

DIY welding

Work should be carried out in a room with good ventilation. When heated, polypropylene can release toxic substances, which can cause harm to health, causing poisoning.

Step-by-step welding instructions:

- First, install the required nozzle of the correct size on the soldering iron;

- To melt polypropylene, a temperature of 260 degrees must be reached;

- Prepare parts for connection, clean them and place them correctly;

- Then the soldering iron is put into operation;

- It is necessary to wait the required time for heating, and this is indicated by the green color of the sensor.

When soldering, it is better to place the device in such a way that it stands stable.

Then the pipe and fitting are simultaneously put on the blank and the soldering tool. The pipe is inserted inside the blank. The fitting is placed on the outside. It is pushed in all the way, and the pipe is pushed in to the finished mark. The main thing is to keep the timing right.

If the tool does not warm up well, then the level of diffusion will be low, and this will compromise the quality of the alloy. A high temperature will lead to overheating of parts. The optimal time depends on the diameter of the pipe and fittings.

After heating, it is important to immediately perform docking. The main rule of procedure is tolerability

The first few seconds allow you to make a correction, but making turns is prohibited. At the same time, you need to take your time and take your time, sticking to the golden mean.

Connection of aluminum reinforced pipes

It is required to follow the rules when welding polypropylene pipes with reinforcement. The reinforced layer is made of aluminum or fiberglass.

They are used when installing systems that move water at high temperatures, because under the influence of heated liquid, linear expansion of the material and bending of the pipeline occurs.

When performing soldering, the aluminum protective material must be removed. In addition, this layer affects the quality of the connection, and the welding time depends on the heating period of the polypropylene parts.

Reinforced pipelines have a larger diameter. Therefore, it will not be possible to use standard nozzles on a heating tool without first preparing the products.

This is done by stripping parts. It is not carried out for glass fiber reinforced products. They are connected in the same way as unreinforced pipelines.

Stripping is performed using different methods, because there are many technologies for reinforcing polypropylene products. Processing is most often used when using a shaver. It is a metal device in the form of a sleeve with blades.

Shaver

The tool is placed on the end of the tubular product and rotated, allowing the aluminum protective layer to be removed. The process continues until only one piece of plastic remains.

PP pipes can be designed when the reinforced layer is in the middle of the wall thickness. In this case, a trimmer is used. This instrument is very similar to a shaver. Different arrangement and design of knives.

The tool allows you to make the ends smooth and remove 2 mm of the reinforced layer located in the middle of the pipe wall thickness. Thanks to this processing, you will be able to perform high-quality soldering.

Tips for choosing and using tools

It is very important to choose the right tool for soldering polypropylene pipes. The fewer plastic inserts and parts there are in the device, the more reliable it will be. The presence of a high-quality thermostat in the device will allow the elements to be more firmly connected to each other. The power of the soldering iron is also important. For home soldering of small-diameter pipes, 700 W will be enough, but for professional use, choose a higher power.

Metal soldering iron tips are usually Teflon coated. To protect it from scratches, store the device with attachments only in a special box.

We hope you are convinced that, having the instructions available, soldering polypropylene pipes with your own hands is a completely doable job even for an inexperienced craftsman in such matters. The main factors for success are accuracy and precision, as well as the use of high-quality tools and components.

Read about how to choose a welding machine for polypropylene pipes in a separate article.

We talked about the types of polypropylene fittings here.

For installation of metal-plastic pipes, we recommend using press fittings. With them, the connections are permanent, but very reliable. Read more about this at the link https://okanalizacii.ru/truby/fitingi/pressfitingi-dlya-metalloplastikovyh-trub.html

Mistakes when soldering polypropylene pipes

It is necessary to follow the recommendations for welding polypropylene pipes and follow all steps of the instructions.

Defective nodes in systems appear due to the following errors:

- Dirt and grease film are not removed from the surface of the parts being joined.

- Pipe products are not cut at right angles.

- The end of the pipe is not tightly inserted into the fitting.

- The time delay is not observed when heating elements on a soldering iron.

- The reinforced layer is not completely removed from the products.

- Correction of parts takes longer than the specified time.

On high-quality materials, an external defect may not be visible when overheated, but deformation still occurs inside. It leads to a reduction in cross section.

Therefore, when operating utility lines, the network capacity is reduced. The narrowing of the passage also causes faster clogging. This also blocks the movement of water.

If the cut is not made at a right angle, the pipe products are joined in a beveled plane. As a result, the elements' alignment is disrupted. It becomes especially noticeable when installing long sections.

As a result, it is often necessary to dismantle and carry out the entire process again. If the alignment of the product is disturbed, it is difficult to lay it in grooves.

Be sure to degrease the surfaces before soldering. Otherwise, so-called rejection islands appear. In such areas, polyfusion welding is poorly performed or does not occur at all.

This error will allow you to start using the utility line, but after a certain period of time a leak will appear. It also often occurs when the soldering iron temperature is set incorrectly.

If insufficient removal of the reinforcing layer occurs, residual aluminum foil contributes to the formation of unwelded areas. Leaks most often occur in such areas.

A serious mistake is scrolling through details. This action does not allow obtaining a uniform structure along the entire circumference of the joint. The connection made will not be complete, because it will collapse when the pressure in the system increases.

How to solder polypropylene pipes video

You need to learn exclusively from professionals. So take a look at the video posted.

How to solder reinforced polypropylene pipes video

Installation of utilities made of polymers using soldering is a popular way to create reliable systems. The method allows you to install sewerage, water supply and heating networks in private houses and apartments.

Why polypropylene

Today, pipe manufacturers provide a huge range of products for laying water pipes, sewerage or installing heating systems. You can purchase metal-plastic, metal, or polypropylene pipes. Today, an increasing number of consumers prefer to choose polypropylene pipes, which have many advantages:

- do not corrode;

- easy to install;

- do not require constant repairs;

- durable and reliable in operation;

- can be laid inside a wall or floor;

- are significantly cheaper than metal pipes.

Polypropylene pipes can be used for installing heating systems, for water pipes and for sewerage.