Due to their performance characteristics and low price, plastic pipes are gradually replacing metal ones. Easy installation allows you to assemble the pipelines yourself. If you need to attach polypropylene pipes to the wall, you need to study the installation nuances and choose the right fasteners.

Fastening for polypropylene pipes

Clips - their meaning and installation details

The clip is made from a special material - nylon.

It has such useful properties as high heat resistance and resistance to mechanical stress. Among the technical characteristics of the clip, you need to pay attention to the diameter; it must correspond to the size of the outer diameter of the polypropylene pipe. Installation of clips has its own rules, the implementation of which determines the service life of the finished communications system.

Single clips and double clip

The main issue that is important not to miss is the step size between the clips. If you install the clips too far apart, there is a risk of sagging at the support points.

When installing a communication system with two parallel pipes, use a double clip.

Correct pitch between clips

Mounting options

There are two ways to install water pipes around the apartment: hidden and external. To hide the pipe, a groove is made in the wall (a recess in the supporting structures). To do this, markings are applied to the walls, then a recess is made using a hammer drill or grinder. The size of the groove depends on the diameter of the water pipes. It should be taken into account that there should be a small space between the wall and the water supply. Plastic products are characterized by dynamic expansion during operation. The remaining gap can be filled with insulation.

USEFUL INFORMATION: Flexible bellows stainless steel water connection

Hidden pipe fastening is usually used for aesthetic purposes or to save space in rooms with a small area. The disadvantages of this method include the laboriousness of the installation process and dirt after gating.

External fastening of communications looks more practical. In addition, for this installation method you do not need to have skills in working with power tools or involve specialists. The entire work process can be done with your own hands. First you need to mark the walls and stock up on the necessary tools. You may need:

- screwdriver;

- construction level;

- special scissors for cutting polypropylene;

- soldering iron for welding water pipes.

When installing, the main thing is to take into account the distance between the supporting elements. Polypropylene pipes are a very flexible material, so if the clips are placed too far apart, the water supply will sag. This will reduce the throughput of the pipes and reduce their service life. When installing, try to reduce the number of bends and corners of the water supply system. This also negatively affects the quality of the water supply system.

Advice! To install communications in hard-to-reach places, it is recommended to assemble the structure in advance and install it ready-made.

The installation technology itself will not cause any difficulties. Using scissors, the pipes are divided into sections of the required length. The clips are installed in pre-marked places and secured to the wall with dowel nails. To do this, holes are pre-drilled into which fasteners are driven. You should not use excessive force when working with a hammer; a strong blow may cause the clip to crumble. After this, the pipes are snapped into the fasteners and connected to each other using a soldering iron.

The advantage of this fastening method is that if leaks or malfunctions occur, timely repairs or replacement of damaged elements can be carried out.

In what cases are clamps used?

It is recommended to fasten polypropylene pipes to the wall using clamps in cases where it is necessary to install large-diameter pipes with a fairly heavy weight. The clamps are a design with a screw tie and a rubber internal gasket, which is necessary to compensate for vibration. Thanks to this, they reliably hold the pipe even when strong vibrations occur.

The clamps are equipped with a dowel and a pin.

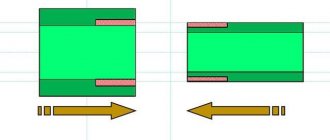

The mount can be made of metal or plastic. When laying polypropylene pipes, it is better to choose clamps from similar raw materials: this way you will ensure the same strength indicators for the entire structure. Installation of fastening material can be rigid or floating:

Rigid fastening is made by tightening the clamp extremely tightly around the pipes. A rigid coupling is required in areas below the bell.

Thanks to the rigid fixation, the possibility of displacement of the communication system is eliminated. A floating fastening indicates the presence of a gap between the pipes and the clamp. The fastening is tightened in such a way as to allow free movement of the pipe. The mobility of the fasteners allows the pipes to expand during temperature changes.

How to attach the clamp

Description of each option

Let's look at the main types of products and consider the advantages and disadvantages of each of them. I will tell you about my own application experience, especially since I very often in my practice dealt with pipeline fasteners and can tell you a lot of practical, rather than theoretical, information about each option.

Option 1: metal clamps

This option is used in a variety of fields

This option is the most versatile of all and can be used for both the thinnest pipes and large-diameter products. Let's look at the design of the products, especially since it is the same for both the smallest and largest options:

| Half rings of different diameters | With their help, the pipe is clamped, so it is important to choose an option of a certain diameter. The elements are fastened together using screws, with which you can adjust the clamping force, as well as vary the size within a small range |

| Rubber gaskets | They are put on half rings and are necessary in order to fit more tightly to the pipe, provide a more reliable fixation on the surface, and also dampen the vibration that inevitably occurs when liquid passes through the pipe |

| Stud fastening | It is welded to one of the half rings and is not a separate unit, but I want to pay special attention to this element, since problems often arise with it. The fact is that threads can be of two types - M8 and M10, so you need to make sure you don’t make a mistake when choosing studs. The best solution is a universal version with a stepped nut M8/M10 |

| Hairpin screw | This element can have different lengths - from 80 to 180 mm and even more. When purchasing, the optimal length is selected depending on the design of your pipeline |

A stepped nut with two types of threads can be easily distinguished by its long length

The advantage of this option can be considered reliability and durability, the disadvantage is that it does not have a very attractive appearance; such elements do not look very good indoors.

The price of the products is quite affordable, so a 32-35 mm option will cost about 15 rubles per set, and a larger product, for example, a 210-219 mm clamp will cost about 90 rubles.

Let's figure out how to fasten from a pipe using similar units; below is a process diagram, according to which it will not be difficult to understand the work:

This is what the work sequence looks like

- First you need to draw a line on the wall along which the pipe will be attached . After this, you need to mark the locations of the clamps, usually they are placed every 50 cm; if the structure has turns, then these areas are additionally reinforced. The clamps must be placed no closer than 150 mm to the corners;

- Using a hammer drill, holes are drilled for dowels ; if the pin has a diameter of 8 mm, then a 12 mm dowel is used, and if you have an option with a diameter of 10 mm, then it is better to use a 14 mm dowel;

Using the stop, you can set the degree of recess into the wall, which is very convenient

- Next, dowels are hammered into the holes and screws-studs are screwed in, after which clamps are screwed onto them (you can screw in studs with already secured clamps, there is no big difference), the structure should be located perpendicular to the future pipe;

- One screw is unscrewed, the upper half-ring is removed (do not lose the gasket that is between the halves), after which a pipe is inserted into the structure . The half-ring is put into place and tightened with a screw, and the work can be considered successfully completed.

In especially critical structures, double clamps are used

Option 2: plastic clips

This element is also well known to almost all people, because with the help of such units the vast majority of polypropylene pipes, which are widely used in heating and water supply, are secured. As for the main features of this type of product, they are as follows:

- The manufacturing material is polystyrene - a durable and reliable material that ensures the durability of the fastener and its resistance to adverse influences;

- The designs are single and double; the second type is ideal for plumbing, where hot and cold water supply lines run parallel . This design allows you to speed up the work process and lay the pipes perfectly straight, because the distance between them will always be the same;

The double option is used very often

- Even if you have single elements, you can fold them into a structure thanks to the special grooves that are on the products . With the help of connecting nodes you can combine elements of different diameters, which is very, very convenient when laying communications;

The special design allows you to quickly and reliably connect elements

- The diameter of the elements varies from 16 to 50 mm , that is, they are intended for use in lightweight structures;

- As for the design, the elements can be in the form of clamps that are attached to the wall using a dowel and a self-tapping screw, or they can be made in the form of a single unit , which already has a dowel, this greatly simplifies installation.

Great option for quick work

As for the cost, a clip for attaching pipes costs from one and a half rubles and more, in some regions the price may be even lower. That is, you definitely won’t incur large costs.

Fastening pipes using clips is not difficult:

- The future location of the clips is marked; it is important to carry out this work accurately and carefully so as not to drill unnecessary holes;

- Next, drilling is done using a hammer drill with a drill with a diameter of 8 or 10 mm, depending on the size of the dowels used;

- After this, dowels are inserted into the holes and clips are attached; the screws must be carefully screwed in so that the spacer part is securely fixed in the wall;

- Lastly, the pipe is snapped into the clip; this is done with little effort. If everything is done correctly, your design will be neat and durable.

Clip - a simple but very reliable unit for fixing a pipe

Option 3: Pipe Clamps

This option resembles clips, but has its own characteristics:

- The main difference between this group of products is the closed design , that is, you do not snap the pipe, but securely fix it. This gives the system additional reliability, which is especially important on vertical sections of the pipeline;

The clamp provides a more secure pipe fastening

- The design can be of two types, the first option is shown above and is a system in which a self-tapping screw simultaneously fixes the dowel in the wall and clamps the pipe fastening . The second differs in that the snap-on part is not connected to a self-tapping screw and, in order to remove the pipe, you do not need to unscrew the fasteners, which is very convenient for repair and maintenance;

Pipe fastening technology - step-by-step instructions

Before installation work begins, the pipes are connected using butt welding, polyfusion welding or the electrofitting method. If you carefully familiarize yourself with the pipe laying technology, the process will not take you much time:

- The first step is to mark the path of the future pipeline along the perimeter. Please note that it should be installed with a slight slope - this way you will eliminate the possibility of water freezing in the pipeline even in an unheated room (for example, in a country house). Using a drill, you need to make holes for the dowel-nails. Pre-prepared mounting clips for polypropylene are inserted into the holes pipes. We insert the dowel into the hole using a hammer and screwdriver. The final stage of the work is installing the pipes into the clips.

Appearance of the finished fastener

Is it possible to install PP pipes in the wall?

Polypropylene is a material that has high resistance to chemicals and corrosion.

Therefore, installing pipes in the wall is quite acceptable. In order for the communication system to last for a long time, it is important when laying to leave the necessary space gap for the expansion of the hot water pipe. In addition, the system itself should be as monolithic as possible, with the least number of connections.

The pipe along its entire perimeter must be additionally protected with thermal insulation. This can be corrugated cardboard, glass wool, mineral wool or other insulation. This way you will protect the structure from fogging.

Laying PP pipes in the wall

We install pipes in the wall

Any installation work begins with marking. You can do it with a simple pencil. Next, proceed to the main work:

- Using a grinder (perforator), you need to make 2 parallel grooves in the wall strictly according to the markings - grooves. To work with an angle grinder, you should use a disk with diamond-cut teeth or a simple disk for cutting stone. Using a chisel or hammer drill, remove the material between 2 markings, connecting them into one. A polypropylene structure is inserted into the finished grooves. The polypropylene pipes in the groove are covered with cement mortar on top. The finishing is done with plaster or other building material.

The final action, an hour after installation, is to test the system. The pipes must be filled with water and checked for leaks, sagging and other malfunctions in the operation of the water supply system. If none are found, congratulations, you have correctly attached the PP pipes.

Leaky sewer pipes can instantly turn a house or apartment into a garbage dump with all the accompanying stench and dirt.

It’s unlikely that anyone enjoys leaks and disgusting odors. The pipelines need to be replaced immediately. But how can sewer pipes be secured so that they last as long as possible?

Fastening material: plastic vs metal ↑

The vertical riser and horizontal pipelines of the intra-house sewerage system can be laid inside the walls in a closed installation or fixed to the walls and ceiling. The first option involves gating, which is accompanied by dust and is not applicable in all homes. Using special fasteners is more practical.

Various mounting options

For open installation, pipelines must be secured.

Otherwise, they may sag under their own weight and become depressurized. The quality of fasteners directly affects the durability of the sewerage system. Sewage pipe manufacturers produce a wide variety of fasteners for installation. All of them are divided according to the material of manufacture into two groups:

- Metal. Plastic.

Fastenings for sewer pipes made of metal are stronger than their plastic counterparts.

But this strength is in many cases excessive. Plastic products are now quite reliable. Plus, plastic fasteners are more aesthetically pleasing and presentable.

In addition, they will not rust in conditions of high humidity in the bathroom. The two main options for pipes for internal sewerage systems are cast iron and plastic. Often, galvanized fasteners are selected for cast iron, and polymer fasteners for plastic.

In many ways, the choice between metal and plastic depends on the preferences of the home owner. Both options allow you to securely fasten sewer pipes at the desired slope both on the walls and on the ceiling. However, metal fasteners do not look as elegant as plastic ones, so they are most often used for installation work in utility rooms and basements.

Metal and plastic clamps

Fastenings for plastic sewer pipes: a - targeted; b - for driving; c - for screw connection

Clamps used to secure sewer pipes today are made of plastic or metal. Fasteners made from one or the other material are quite convenient and simple when it comes to their installation.

Most manufacturers of sewer structures often produce pipes complete with fasteners. Therefore, the question of choosing a specific type of clamp fastener is not considered.

The first thing you should pay attention to when choosing between metal and plastic clamps is the aesthetic component of the room where the sewage system will be installed. Particular attention must be paid to this issue if communications are open and not hidden in walls or interior structures. Here we need to talk about choosing plastic clamps, which are less noticeable and have an attractive appearance. In most cases, sewerage is located in places that are inaccessible to public viewing. Metal clamps are suitable here, they are a universal connection that can be either loose, not tightly tightened, or deaf, motionless.

According to their design features, all clamps are divided into 2 types - solid and double. One-piece ones are usually made of plastic, while double ones can be either plastic or metal. A distinctive feature of double clamps is that the diameter can be adjusted using a screw, so they can be used for pipes with different diameters. Double pipe clamps, in turn, are divided into single-screw and double-screw, depending on the number of screws.

Types of fasteners for sewer pipes ↑

When choosing the method and type of fastening, it is necessary to take into account the material of manufacture and the diameter of the sewerage pipelines, as well as the length of the secured segment. The weight that the fasteners must withstand depends on these parameters.

Types of fasteners for fixing drains

Sewer pipes can be secured using:

- hangers-hooks; brackets; clips; clamps.

The first option is intended for attaching pipelines exclusively to the ceiling, the second - only to the wall, and the third and fourth can be used in both cases. The choice of holders is quite varied, but the most popular and reliable are all kinds of clamps.

Types of clamps ↑

A standard clamp fastener consists of an installation unit and a clamp bracket in which the waste pipe is fixed. It is attached to supporting structures using dowels, self-tapping screws, studs and anchors. The clamping bracket is tightened with latches or screw ties.

Clamp diagram for fastening pipes

Depending on their purpose, pipe clamps are divided into:

- Support. Crimping. Guides.

The first ones are designed for attaching vertical risers and hanging sewer pipes from the ceiling. The latter are used when compressing the joints of drains and their connections with fittings.

And still others help fix the pipes at the required angle and keep them in this state. Most clamp products have a rubber insert that securely grips the pipe on one side and allows it to move slightly on the other. But there are options without rubber gaskets. The choice here depends on the method and technology of installing the sewer network.

Types of ring staples

Today the market offers the following types of such mounts:

:

1. Ring clamps for fixing cable lines. At manufacturing plants they are equipped with special fastening parts that are located inside them. They are designed specifically for attaching cables to completely different bases, both located in the vertical and horizontal planes. To produce this type of staples, synthetic fibers are used, which have many advantages. In addition to strength and reliability, this material has breathable properties, wear resistance and the ability to dry quickly.

2. Ring clamps for fixing PVC pipes. The specific gravity of such products significantly exceeds the weight of other representatives of fastening elements. The staples are quite heavy, since a metal such as steel is used for their production. The design of the fastening element for PVC pipes consists of two individual parts, which are fastened together with a metal rod having a screw thread mechanism. This type is available for sale, both with and without a rubber seal. But, it should be noted that it is the rubber seal that gives the mount the properties of tightness, reliability and strength.

3. Ring brackets for fixing scaffolding. This type is perhaps the most durable, since it is used to connect elements of forestry production, and also carry out the process of attaching these dimensional elements to surfaces that absorb loads from other parts of the structure.

4. Clamp tape. This type of fastening is used in the case of the necessary connection of small hoses and short PVC pipes, which are branches in the pipeline structure. In addition, this type of fastener has found its application for fixing parts to partitions and ceiling surfaces.

We must not forget that such minor fasteners are capable of not only fixing products, but also conscientiously preventing the interchange of the internal and external environment of the hoses.

In addition to the criterion for the type of system, such fasteners have varieties, depending on what material they are made of

:

1. Fasteners made of metal;

2. Fasteners made of plastic.

Rigid and floating mounting schemes ↑

Sewer pipes can be fastened with the same clamp firmly, tightening the clamps all the way so that the drains cannot be moved from their place. Alternatively, the bolts can be left slightly loose so that the riser can “float” in the fastener.

Clamps are needed to fix both horizontal and vertical pipes

When heated and cooled, plastic tubular products slightly change their geometry. To ensure their integrity, a floating fastening method is used. In this case, during linear expansion, the pipelines will not be damaged or depressurized.

Advice! The rigid version of fixing waste pipes is recommended to be used only in heated rooms with minimal changes in air temperature.

If the sewerage system is laid in a room without heating, then the pipes should be attached to the walls and ceiling using floating technology. The temperature inside will vary widely, heating and cooling the pipes. And they should not be damaged.

Conclusion

Of course, there are many more mounting options; I talked about those that are used most often. All the options considered can be used when doing the work yourself; for this you do not need to have any special skills and you do not need to use a special tool.

The video in this article will tell you in more detail about some of the important nuances discussed in the review and will help you understand the topic even better. If anything is unclear to you, feel free to write questions in the comments below.

In the process of installing structures made of PVC pipes, in addition to the quality of the selected material, an important nuance is the choice of high-quality fasteners for PVC pipes, which can ensure full, high-quality and reliable operation of the pipeline product. It is necessary to familiarize yourself in detail with the methods of fastening plastic products, as well as with the types of installation of routes made of plastic pipes. It is necessary to clearly distinguish between the types of fasteners, such as plastic clips and ring clips.

Installation of sewer pipes to the ceiling and walls ↑

The sewer network consists of a variety of elements that are subject to vibration, temperature influences and mechanical loads during operation. There is a whole set of rules, compliance with which during installation ensures reliable operation of the entire system.

Wall and ceiling mounting diagram

When installing sewer pipes you should:

- Make markings on the walls indicating the fastening points and the slope axis. Fix the fasteners on the walls and ceiling. Place the pipelines in the holders.

Fastening sewer pipes using clamps requires a minimum clearance between the drain and the wall. If you need to leave a larger gap there, it is better to choose brackets or hooks.

Important! Only with the help of fasteners can you accurately set the slope of the collector to the two to three degrees recommended by building codes and protect the sewer from blockages.

The distance between the fasteners depends on the diameter of the drain and the material from which it is made. Plastic pipelines are quite lightweight; for them, fasteners in horizontal sections can be spaced 1.5–2 meters apart. And to fasten cast iron sewer pipes, holders will have to be installed every half a meter.

Fasteners are installed on bends and branches of pipelines

However, in practice, fastening is carried out in places of branches, connections and bends, where communications are subject to the heaviest loads. You should not attach sewer pipes where it is most convenient for the technician. The placement of the holders should maximize the reliability of the entire system.

Basic rules for installing sewer fasteners

Fastening of retaining elements must be carried out in accordance with generally accepted standards, rules and requirements. The sewer pipe system is a complex set of different elements, which in the future will be influenced by various factors: load, corrosion, vibration and possible blockages. Therefore, it is important to adhere to generally established rules and recommendations during sewer installation:

- Location of fasteners. It is necessary to correctly calculate the location of each clamp. It is necessary to make fastenings in every place where the sewerage branches, has bends, pipe connections or fixing fittings. Before starting work, we recommend that you draw up a diagram of the laying of sewer pipes, on which the locations of the clamps will be marked. The scheme can be marked directly on the walls using center lines.

- Pipe slope. The clamps must be fastened so that the minimum slope of the pipe is 20 mm for each linear meter of the sewer pipeline. To avoid frequent sewer blockages in the future, frequent perpendicular turns should be avoided.

- Alternating floating, fixed and rigid fasteners. Important rule! Each pipe must be secured with a non-slip clamp, which, as a rule, is located at its base, where the pipe connects to other parts of the sewer system. In other cases, both rigid and floating mounts can be used alternately.

- Distance between clamps. When installing metal-plastic or plastic pipes, they are fastened based on a two-meter distance between the fasteners. Heavier pipes must be fastened more often, with an interval between clamps of a meter or one and a half.

- Reliability of fastening. During use, sewer system pipes are subject to certain loads, temperature changes and vibration. To ensure that the quality of operation of the system is not affected by any of the listed factors, each pipe must be securely attached to the load-bearing surface. Anchors and dowels of fasteners must adhere tightly to the material from which the surface is made. It should not crack or crumble. Often, in cases where it is not possible to firmly secure the clamp, the sewer laying scheme is completely changed.

As a result, we can say that by adhering to basic rules, you can install a fastening for sewer pipes with your own hands in your own home. In addition, every modern manufacturer of structural elements takes utmost care of simplicity and ease of installation. The installation of a sewer drain does not require professional knowledge, skills or expensive equipment.

Laying communications in channels ↑

To make it possible to cover the sewer with decor, grooves are punched into the walls. Inside them, the pipelines are secured using the technology described above using clamps. It should be taken into account that there should be no interference with the linear expansion of the collectors.

In the grooves, the drain should also be secured with clamps

Grooving is quite a troublesome task, but with this installation method, the fastening of communications is more reliable. In this case, the pipes are held not only by fasteners, but also by the edges of the groove in the wall.

Video: device of a universal clamp for fixing pipes ↑

To secure cast iron and plastic sewer pipes, it is enough to use special clamps with rubber gaskets. Their installation is extremely simple and does not require special tools. You just need to correctly prepare a plan for laying out sewer pipelines and mark on it all the installation locations of fasteners.

Content:

Sometimes, when performing repair work, it is necessary to attach polypropylene pipes or other means of communication to the wall, for example, to set up a pipeline. The task, at first glance, looks quite simple, but it is not. How and with what to attach the pipe to the wall will be discussed in this article.

Tools and materials required for pipe fastening

To attach pipes to the wall, various tools and accessories are required. Their choice depends on the materials from which the communication system is made. In this case, it is necessary to take into account the length, diameter and weight of the line.

Used fasteners for pipes in the wall:

Clamps. Their internal diameter must be larger than the external diameter of the pipe. For a more reliable grip, there should be a rubber liner on the clamp.

Its popularity is due to the fact that the diameter is easy to adjust. Clamps can be metal or plastic. It is advisable to purchase a product made from the same material from which the pipe is made.

Clamps are divided into four types: fixing, supporting, guides and for protection. Brackets. They are used for installation of steel products. However, instead you can use special brackets, as well as metal clamps with gaskets.

If it is necessary to place the pipe at a certain distance from the wall, then brackets and clips are used. These fasteners are most often plastic. Therefore, they are often used to secure pipes made of the same material.

But they are also used for water pipes or areas of hot water heating systems. For these purposes, experts advise choosing double clips. But they are not suitable if the diameter of the corrugated pipe or other element exceeds 50 mm.

Any of these things can be easily bought at the market or at a hardware store. Anchor bolts are well suited for securing pipes to the ceiling. The type of communication depends on which fasteners will be used.

Do not forget about the purpose of the installed products. This could be a water supply system, sewerage system or heating system. It is important to choose the right fastening tools and also read the instructions for their use. In this case, you will get a reliable design with a long service life.

Types of fastenings for PVC pipes

In order to fix the pipeline structure during its installation, you do not need to use special equipment or tools. To ensure the creation of high-quality and reliable fixation of polyvinyl chloride pipes during the laying of main channels, special building elements are used, the function of which is to support the pipes.

In turn, they are divided into the following types:

1. Plastic clips, in the form of clips;

2. Ring staples, in the form of a clamp.

Main features of fastening

When installing the fastening parts of the structure yourself, it is necessary to adhere to certain principles and instructions to fully ensure the longevity of the pipeline channel and the effectiveness of its use. By maintaining the required and permissible distance between the fastening elements of the structure, it is possible to ensure that there are no bends or damage to the routes.

So, you need to remember that fastening clips and ring brackets for fixing plastic products must be installed according to the following principles:

1. The installation distance for PVC products of small diameter should not exceed 2 cm:

- use of a pipeline system in conditions of low temperature 85 cm;

- channel for supplying water that is heated by more than 60 degrees 70 cm.

2. During the installation of a pipeline product with a diameter of no more than 4 cm, the distance between the fastening elements must be ensured of about 100 cm for a hot water supply system and about 110 cm for a cold water supply system;

3. PVC structural elements that have a diameter of more than 110 cm are secured with fasteners that have a distance between them equal to 190 cm in the case of cold water supply, and a distance equal to 160 cm in the case of a hot liquid flow.

The principle of attaching pipes to the wall

Now let's look at how to attach heating pipes to the wall. There are two ways to accomplish this task: hard and floating.

The first is intended for sewers, heating systems and other pipelines through which hot or cold water will be transported. In this case, the fastenings completely fix the movement of communication elements. The fitting here is a rigid support.

Floating mounts most often use clamps that are not tightened all the way.

In this case, slight mobility of the system elements is maintained. This fastening option is only possible if the inner diameter of the clamp is larger than the outer diameter of the pipe. When installing a pipeline, one should never forget about the influence of temperature changes. If the room is heated, then this phenomenon will not occur, then the fastening is best done in a rigid way (about

How to attach a pipe

Attaching communication elements can be done in two ways:

- Tough. It is used when installing sewerage systems, heating systems and water supply systems through which cold and hot water will be supplied. Here, communication elements are completely blocked and are unable to move. In this situation, the fitting will act as a rigid support for fastening.

- Floating. You can use clamps here, but do not tighten them completely. This ensures a certain mobility of communications passing through it. A floating joint is achieved when the internal cross-section of the clamp is slightly larger than the external diameter of the attached pipe.

When laying pipelines, it is necessary to take into account such a parameter as temperature changes. In a heated room, where there will be no such temperature changes, the products must be fixed to the wall or ceiling without moving. This is due to the fact that here the pipes will not move along their axis. In such a situation, fixation of communications is carried out in the place of bends, fastening of reinforcement and turns.

The moving method is used in situations where temperature changes can lead to an expansion or contraction of the diameter. In this case, the pipes still have the opportunity to change their sizes, but at the same time not deviate from the laid course.

As you can see, the choice of fastening method depends on the purpose of the communications system being formed inside the house or apartment, as well as the temperature conditions of the premises.

Related article: Decorating a room in summer

Sewer pipe fastening

To fix plastic pipes, all kinds of fittings are used (splitters, corners, etc.).

You may also need various terminal devices to complete a task. This is what taps and drain valves are called. Their choice will be based on the purpose of the communication system.

If you plan to install a serious engineering system, you will need hydraulic accumulators, valves and similar devices. It is also possible to attach a clip for polypropylene pipes (pro