The main purpose of the tee

Sewer tee

A sewer tee is a socket, each individual sleeve of which is located at a certain angle relative to the other. All hoses have different cross-sectional diameters. A pipe with rolled edges is the inlet part of the fitting, two additional holes are the socket, to which the sewer pipes are directly connected.

Tees are perhaps the most important and indispensable element in the construction of sewer systems. Using such devices, you can change the slope of the pipes and their direction. Tees will help connect pipes of different diameters and ensure a tight connection of all structures in the overall system.

The advantage of such structures is their affordable cost, wide range of applications, excellent resistance to corrosion, easy and simple installation, durability and practicality.

Without fittings, it is impossible to equip a septic tank, install a water drainage system, and even connect some household appliances.

How to install a tee on a PVC sewer pipe

PVC tees for sewer pipes can be used for both internal and external sewerage.

You can consider how to install a tee on a sewer pipe using the example of connecting a sink and toilet:

- first of all, you need to place the toilet in its designated place in the toilet and mark the place where you plan to install the tee;

- then the toilet needs to be removed from its future location or simply put aside;

- using sealant, the tee should be inserted into the socket of the riser;

An example of installing a tee for connecting to a toilet

- After this, you will need to take a sewer outlet pipe of the required length, coat it with sealant and insert the end into the tee hole. But first, make sure that there is a seal in the tee hole;

This is how sealant is applied to connect a toilet

- Now you can start working on the sink. This will require laying several short pipes that are connected to each other by tees;

- After this, the toilet is installed in place, it needs to be bolted and cemented. Then we connect it to the tee with corrugation, but first, lubricate the toilet flare with sealant.

This is what a toilet connected to a corrugated tee looks like

As for installing a tee on a water supply pipe, this process is quite easy.

For example, if you need to make only one branch from a water pipe, then using a regular tee will be the most optimal and convenient option.

If the plumbing system consists of metal pipes, then you will need to find their connections and unscrew them.

So, installing a tee on a water supply pipe is carried out as follows:

Using sewer pipe tees

- first you need to turn off the water along the riser and, of course, warn your neighbors that you will be carrying out repair work that requires turning off the water;

- then you need to find the pipe connection where you want to actually install the tee and make a branch;

- the connection point should be unscrewed, and this is where the tee should be inserted;

- to do this, you will need to move the pipes apart somewhat and, perhaps, even one pipe will have to be shortened and a thread cut into it;

- After this, you can safely install the tee and it is better to coat the joints with sealant in order to avoid water leakage. However, if you do everything correctly, select the appropriate type of tee to match the size of the water pipes, then the connections themselves should be sealed and should not leak.

This is what the installation of PVC tees looks like

As you can see, installing a tee is not an impossible task, and every owner can cope with it, even without any knowledge and skills.

In addition, installation of a tee does not require the use of any equipment, such as welding, and installation lasts a matter of minutes.

Types of fittings

Direct connection

Modern manufacturers present several different types of tees. They differ in size, shape and purpose:

- Straight fittings. Such structures are equipped with sleeves located at right angles to each other. With the help of such devices, you can easily connect water risers, vertical and horizontal, to each other.

- Inclined cast iron sewer tee. The sleeves of such structures are located at an angle of 45 degrees. Such products are usually used for arranging pipelines in bathrooms, bathrooms, and kitchens. They eliminate the possibility of blockages, since they completely lack difficult areas.

- Revision couplings. They allow you to quickly and easily check the condition of the sewer system and, if necessary, clean it. The designs are equipped with a convenient screw-on valve. Such devices are used in difficult areas where the likelihood of clogging is quite high. These areas, as a rule, have complex transitions.

The sleeves of equal tees have equal diameters. Using such structures, pipes of the same diameter are connected.

The sleeves of multi-bore fittings have different diameters. Such products allow you to reliably connect pipes of different diameters. In most cases, these structures are used for the construction of sewer systems in apartments and private houses.

There is another difference between different types of tees - the method of fastening the products. Some models are equipped with a special press sleeve and nut. Combined designs have an internal thread or a union nut.

Types of tees for water supply

Fittings are classified according to several parameters. First of all, products are distinguished by material of manufacture:

- Metal water tees. Steel, cast iron, brass, bronze. The first two types are more often used for municipal construction of public highways. Steel and cast iron are durable and corrosion resistant. As a rule, these types of fittings are installed by welding or flange connections. Brass and bronze fittings are more often used in private construction. Both materials are strong and durable. The brass tee is also universal. It can be installed not only on metal water pipes, but also on plastic ones.

- Polymer. These fittings are used exclusively indoors for installing a water supply system made of PVC, HDPE or polypropylene pipes. They produce fittings from polyethylene, polypropylene and polyvinyl chloride. Plastic tees are easy to install, have a high level of tightness and durability.

Metal fittings are produced using one of several methods - welding, hot stamping or hydraulic stamping. The workpiece initially looks like an electric-welded or seamless pipe. To shape the ends of the reinforcement, threading or end cutting machines are used.

According to the method of installation and connection, all tees are divided into the following types:

- Threaded. Fastened using internal or external threads.

- Welded. Can only be welded. Moreover, these can be metal fittings or polymer ones.

- Crimping. They are also called collet ones.

- Press fittings.

- Combined.

Transition fitting

In terms of design features, experts divide all fittings into the following types:

- Equal bore fitting. The tee has three outlets, all with equal cross-section.

- Transition fitting. Helps to branch the system by providing a different pipe diameter at one of the outlets. For example, water supply to a washing machine can be done using a flexible hose with a smaller cross-section than the entire water supply.

- Combined tees. They differ from the first two types by the presence of diverse threads at the outlets. There may be two external and one internal.

Reinforcement diameter sizes range from 15 mm to 1000 mm. You can choose a fitting for any pipe.

Plumbing tee with tap

Special attention should be paid to a special adapter fitting with a tap. It allows you to simultaneously provide a branch line and immediately have another water intake point. The components of a tee with a tap are a body, a ball valve, O-rings, a union nut, and a handle. Such fittings are installed to supply water to washing household appliances. The main advantages of the tap fitting are as follows:

- ability to work at temperatures from -10 to +95 degrees;

- minimum weight – 100 g;

- possible diameters of pipes are 15 and 20 mm;

- designed to operate at system pressures up to 8 bar;

- the ability to purchase a faucet with internal or external threads, which provides maximum convenience to the technician at the time of installation;

- long service life up to 4,000 cycles.

The tee with the tap can be placed at any convenient angle.

Construction materials

Manufacturers use different materials to make tees. Polymer products are very popular and in demand. However, in some areas metal and ceramic fittings are used, as well as structures made of asbestos cement. According to the standards stipulated by the relevant GOST, similar products are used to connect pipes made of identical materials. Only in this case will all systems be sealed.

However, most often tees made of special, durable plastic are used to connect different pipes. It can be polyethylene or polypropylene.

Fittings made of polyethylene are intended for the installation of a non-pressure sewer system. Such products are used to connect various pipes without welding. For manufacturing, a certain casting method is used, in addition, the workpiece is additionally machined.

To connect tees to pipes, special compression couplings equipped with reliable clamps are used. Thanks to this connection method, the installation process is greatly simplified and accelerated. It is completely unsuitable for arranging various pressure systems. Liquids in such systems pass under high pressure; the locks may not withstand the pressure and may be dismantled.

The scope of application of tees made of polypropylene is quite wide. Such designs are characterized by increased resistance to temperature changes and the negative effects of low and high temperatures. A plumbing sewer tee made of polypropylene can be used to connect any pipes. It is very important to take into account when selecting and installing that such structures expand slightly with prolonged contact with hot water.

Determining the maximum permissible load level is very simple. The color of the tee will tell you about this parameter. Gray structures have a soft single-layer structure. The level of thermal conductivity of products is quite high. Thanks to this quality, you don’t have to worry about the tightness of all connections, even if very hot water gets into the system.

Red tees are intended for the construction of external pipelines. Such products have excellent resistance to various mechanical loads. Such tees can easily withstand loads arising from slight movements of soil layers, negative impacts caused by the movement of various vehicles, and so on.

Special tees are used to connect corrugated pipes. Such products, as a rule, are made of durable plastic and have a certain structure consisting of two layers. All internal surfaces are smooth and even. These structures are connected to pipes using sockets.

Installation methods

Installation should not be difficult even for inexperienced craftsmen. Typically, only socket connections are used, in which a pipe is inserted into the socket. Another common option is an adhesive connection.

Often these fittings are installed during the assembly of the entire pipeline. Other cases are associated with an urgent need to replace parts. They require additional time and money.

To correctly install a tee in a PVC pipe, follow these recommendations:

- Place the pipe in the socket. First, check if the seal is good, make a chamfer, and apply a little lubricant to the end of the pipe.

- Using a brush, apply a small amount of glue to the outside of the pipe.

- The fitting is installed with a socket against the flow of the working medium. It only takes a few hours for the glue to harden.

After this, the connection will be almost impossible to disassemble. This is due to the fact that under the influence of the adhesive solution, a chemical melting of the surface of the plastic occurs and when it hardens, a single monolithic mass is formed. This technique is also called cold welding.

These installation methods are the most popular and simplest. They provide a tight connection.

Connection options

Pipe outlet using a tee

Depending on the material from which the tee is made, the method of installation of the structure and pipes is determined. The main purpose of the tee and its dimensions also play an important role in this. Fittings made of polyethylene and pipes are fixed using special couplings and welding. Tees made of polypropylene are connected to pipes with sockets. The connection of products made of metal-plastic is usually carried out by crimping or pressing.

What should be considered when selecting tees?

When choosing fittings for sewerage, it is important to consider the following points.

- Dimension. The diameter of the tee must correspond to the diameter of the pipeline, otherwise it will not be possible to install the product.

- Type. The market offers products made of steel, PVC and cast iron. The material of the tee should not differ from the material of the pipeline.

- State. Products without defects are allowed for installation. The presence of the latter will reduce the tightness of the line and increase the risk of blockages.

Experts recommend using certified tees. The products comply with international standards and have a significant service life.

Recommendations for installing sewer tees

The process of performing work to replace deteriorated pipes, risers and other structures, as well as constructing a new sewer system, will not cause any particular difficulties even for an inexperienced craftsman. Everything can be done quickly and easily with your own hands.

First you need to dismantle the old equipment. Only after this can you begin to install a new system or replace individual elements. To do this, you should use the following recommendations:

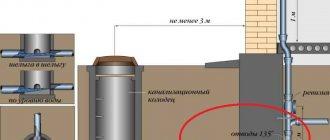

- To arrange horizontal wiring, you must use special oblique tees with an inclination angle of 45 degrees. This will help in the future to avoid possible blockages of the system, significantly increase the service life of the pipeline and reduce the risk of unforeseen emergency situations. It is strictly not recommended to use straight tees for arranging such horizontal systems. This will greatly increase the likelihood of system clogging and reduce service life.

- Before you begin replacing a fitting, gasket, or installing a new tee, please note that the O-rings must not be cut or removed under any circumstances. This can lead to seal failures and, as a result, increase the likelihood of various emergency situations. To facilitate the process of dismantling old parts and installing new ones, you just need to thoroughly lubricate the internal surfaces of the structures with a strong soap solution.

- Installation of special inspection couplings must be carried out in open sections of the pipeline. Only this way will it be much easier to dismantle the plug. In addition, this will allow you to easily penetrate the system and clean it thoroughly.

- To ensure a more reliable and tight connection of thick sections of the pipeline, the cross-sectional diameter of which exceeds 50 mm, it is necessary to use special brackets that are fixed to the load-bearing surface of the structure.

- Correct installation of all structures will help reduce the likelihood of blockages and ensure the correct direction of fluid flow. In this case, it is very important that the coupling-socket end of the tee faces the starting point of the pipeline.

Using the above rules and recommendations, you can easily and simply replace structures, perform all work efficiently and extend the service life of the pipeline. Sewer fittings are a very important element of the pipeline; they ensure the tightness of the system.

What are tees made of?

Most modern facilities use PVC sewer tees. The products have many advantages.

- Easy to install. Any craftsman can install a polymer tee. This does not require additional devices or sealing elements.

- Reliability. The products hermetically connect sewer pipes. They are not subject to corrosion and are resistant to aggressive environments.

- Reasonable price. Plastic products are available to private craftsmen and commercial organizations.

- Light weight. Low weight simplifies storage, transportation and installation of tees.

Plastic does not require maintenance and retains functionality throughout its entire service life.

Plumbing fittings for polypropylene pipes

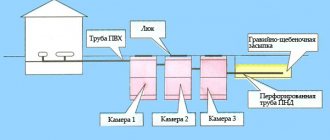

The construction of sewer systems, regardless of their scale, always involves the use of auxiliary connecting elements called fittings. With their help, they not only connect sewer pipes, but also various bends, turns and other manipulations that make it possible to build a complex sewer pipeline.

In this article we will look at which pipes and fittings for sewerage are used more often than others today, and we will talk about the types and features of sewer fittings.

Fittings for installation of sewer system

Pipes in sewerage systems

Previously, most domestic sewer systems were made of cast iron pipes connected by metal fittings. At the same time, installation almost always involved the use of various types of welding (more often than others, electric welding).

In addition, as practice has shown, sewer systems made of cast iron, despite their apparent durability, over time lose their original performance qualities, since they are prone to lime build-up on the internal walls.

From a practical point of view, cast iron systems are not very convenient - their components have an impressive weight, and the material itself, moreover, is not very durable.

A modern alternative to old systems has become polymer systems, which are usually based on sewer pipes and PVC fittings.

Schematic illustration of the most commonly used sewer fittings

Features and advantages of polymer sewer pipes

Among the polymer products used in the installation of sewerage systems, polyvinyl chloride, polyethylene, polybutylene, polypropylene or simply PP pipes and fittings for sewerage are most often used.

The reason for this was the high level of practicality of plastic pipes in comparison with any type of metal pipes and their relatively low cost.

Since PVC sewer pipes and fittings for them are the most popular solution due to the price/quality ratio, we will dwell on their features in more detail.

PVC sewer pipes and fittings have the following undeniable advantages:

- Installation of sewerage systems using these components can be done manually without the use of equipment for gas or electric welding . The main method of connecting pipes in such systems is a socket, the tightness of which is ensured by a rubber sealing gasket embedded in the socket.

- Low weight of parts.

Selection rules

When selecting shaped elements, it is worth considering the following points:

- Before purchasing, you should create a project marking all drainage points and plumbing fixtures. It will help you determine the required number of fittings.

- The material of the connecting elements must be similar to that from which the sewer pipes are made.

- To connect the metal part of the pipeline with a polymer branch, you will need shaped parts for a threaded connection on one edge.

- It is advisable to purchase fittings from the same manufacturer as the pipe sections. When purchasing products, you should pay attention to the exact size match.

As the number of fittings installed on a pipeline increases, the likelihood of blockages increases. Try to simplify the main geometry as much as possible, and install fittings so as to ensure free drainage of water.

Application area and materials

Fittings are used to connect, turn, branch pipes, and switch to another section.

Previously, sewerage installations were carried out on the basis of cast iron pipes with metal fittings. Assembly required the use of various types of welding.

Modern utility pipelines inside and outside buildings, as well as drainage lines, are made of plastic parts.

Polymer products are resistant to almost all types of aggressive environments, weigh little, have a long service life and are easy to install. Their use significantly increases the performance indicators of engineering communications and reduces the cost of their arrangement.

Products made from polyvinyl chloride are popular due to their low weight and budget cost. PVC shaped elements are used to drain:

- permanent wastewater in the sewer with a temperature of no more than 80 degrees;

- short-term effluents with a temperature of 95 degrees;

- chemical liquids with a pH value from two to twelve.

Fitting elements made of polypropylene and polyethylene are more durable, flexible and less susceptible to temperature changes compared to their polyvinyl chloride counterparts. Pipes made from these materials can be used for any type of sewer installation, including hidden ones - under plaster. High-strength PPRC fittings are allowed to operate under pressure up to 25 MPa, which is important for pressure sewers.