This takes into account: the distance from the station to the source; humidity and temperature conditions at the pump location; availability of space for repairs and maintenance; the ability to soundproof the room. As noted earlier, a coarse metal mesh filter can be installed here. Having installed high-quality pumping equipment, you will forget about the need for repairs and dismantling for many years. Of course, the temperature of water and soil at such a depth is invariably positive, but superficial, local freezing of water and ice formation are possible - even this is completely contraindicated for a pumping installation. What elements of a pumping station can be made independently? Can a pumping station be assembled and installed with one’s own hands, without involving third-party specialists? THE SIMPLE WATER SUPPLY SYSTEM FOR A HOUSE AND AREA UNDER PRESSURE!

An example of how equipment can be placed in a well. Each of these options has both positive and negative aspects, however, if you correctly approach the heat and sound insulation of the room, then the functionality of the equipment will only benefit from this, since the risk of unstable operation will be eliminated.

When calculating the volume of water consumption, one should also take into account the fact that in the summer, pumping units are used not only for domestic needs, but also for watering green spaces. Another connecting element is installed at the inlet of the pumping unit, allowing you to connect a pipe.

Pipe with insulation in a trench We make a hole in the foundation through which we insert the pipe into the basement or subfloor.

As an alternative to insulation, you can use a self-regulating heating cable. In this case, the pressure reaches a certain value and the system turns off.

Well characteristics Here we are talking about the depth of the source.

WATER PIPELINE at the dacha WITH YOUR OWN HANDS pumping station WATER Pipeline from the WELL

Why is a pumping station needed in an autonomous water supply system?

Having decided to install a pumping station on a well that already exists on a personal plot, you should first understand why such an installation is needed. If we talk about those tasks that can be effectively solved by pumping stations for wells and wells, then this should include:

- lifting water from a well or well and its uninterrupted supply to all points of the autonomous water supply system;

- ensuring stable flow pressure of the liquid medium transported through the pipeline system, as well as the absence of air pockets in the elements of such a system;

- ensuring the supply of water to the pipeline system for a certain period even in cases when the electric pump does not work, which can happen due to its breakdown or failures in the power supply network.

The summer pumping station will provide water supply for irrigation and household needs in the warm season

Unlike individual pumps, which are also used for pumping water from a well or a well, pumping units provide a more gentle operation of the equipment, since the electric pump included in such stations does not turn on every time the taps are opened at water collection points, but only at those moments when the level of liquid in the accumulator drops to a critical level.

Design features of the pumping unit

A pumping unit (station) is a whole complex of technical devices, each of which plays its own role in ensuring the efficient operation of the entire system as a whole. A typical design diagram of a pumping installation includes a number of elements.

Main parts of the pumping station

Pump

In this capacity, as a rule, surface devices of the self-priming or centrifugal type are used. They are installed together with a set of other equipment included in the station on the surface of the earth, and an intake hose is lowered into a well or well, through which the liquid medium is pumped out from an underground source.

Mechanical filter

The filter is installed at the end of the hose, which is lowered into the pumped liquid medium. The purpose of such a device is to prevent solid inclusions contained in the water pumped from an underground source from entering the internal part of the pump.

Well mesh filters

Check valve

This element prevents water pumped from a well or well from moving in the opposite direction.

Hydraulic accumulator (hydraulic tank)

The hydraulic tank is a metal container, the inner part of which is divided by an elastic rubber partition - a membrane. One part of such a tank contains air, and the other part is pumped with water, raised by a pump from an underground source. The water entering the accumulator stretches the membrane, and when the pump is turned off, it begins to compress, acting on the liquid in the other half of the tank and pushing it through the pressure pipe into the pipeline under a certain pressure.

Pumping station hydraulic accumulator design

Working according to the principle described above, the hydraulic accumulator of the pumping station ensures constant pressure of the fluid flow in the pipeline. In addition, the pumping station, the installation of which does not take much effort and money, eliminates the occurrence of hydraulic shocks that are dangerous for the water supply system.

Automation block

It controls the operation of the pumping unit. The main element of the pumping automation unit is a relay that responds to the level of water pressure that fills the accumulator tank. In the event that the water pressure in the hydraulic accumulator drops to a critical level, the electric pump is automatically turned on using a relay, and water begins to flow into the hydraulic tank, tensioning the membrane. When the pressure of the liquid medium rises to the required level, the pump turns off.

Automation blocks allow you to automate the operation of the electric pump

Pumping units are also equipped with pressure gauges for measuring pressure and pipes, with the help of which they are connected and connected to the main circuit of the water supply system.

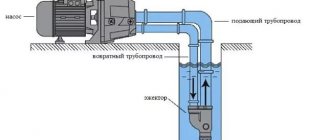

It should be borne in mind that a typical pumping unit, which is made on the basis of a surface pump, can be used to pump water from wells and wells whose depth does not exceed 10 meters. In order to lift water from deeper underground sources, you can additionally equip the pumping unit with an ejector or assemble a pumping station with a submersible pump, but this design scheme is used quite rarely.

Installation diagram of a pump with a remote ejector

The modern market offers many pumping stations of various models and brands, the prices of which vary quite a lot. Meanwhile, you can save on purchasing serial equipment if you buy the necessary components and assemble the pumping station with your own hands.

Pump mounting

Scheme of mounting the pump in the well

It remains to fix the device in a stationary state. For these purposes you will need a cable and a piece of reinforcement. Usually the device has a special eyelet to which the cable should be attached. If it is not there, then you will have to come up with another way to attach the cable. Use synthetic rope as it tolerates high humidity well and has a long service life.

There are two types of fastening of fittings - through a hole made in the well, or externally. In the first case, the straight edge of the reinforcement along with the cable is passed through the hole in the well. The curved edge is dug into the ground along with a protective sleeve for the hose. In the second case, the reinforcement is dug into the ground or welded to some metal object near the well. In this case, the cable is launched through the top of the well.

Where to begin

Before thinking about how to assemble a pumping station for a private home or cottage, you need to calculate the parameters of the water supply system that such equipment will serve. Listed below are the main characteristics of the water supply system, which determine the technical parameters of the pumping equipment, as well as the connection diagram of the pumping station.

Well production

This parameter will directly determine how much water the pumping unit can pump out from an underground source per unit of time.

Formula for calculating well flow

Volume of water consumption

The calculation takes into account the number of people who will permanently live in a house served by a water supply system, as well as the number and type of household appliances that require water to operate. Naturally, the volume of water consumption cannot exceed the flow rate of the well, since in this case the underground source simply will not be able to supply the amount of water that is necessary to maintain an autonomous water supply system. When calculating the volume of water consumption, one should also take into account the fact that in the summer, pumping units are used not only for domestic needs, but also for watering green spaces.

Well characteristics

Here we are talking about the depth of the source. The architectural features of the building that will be served by the plumbing system are also important. It is necessary to take these parameters into account in order to select pumping equipment that will be able to pump water from the lowest point of the source and lift it through the pipeline system to the highest point of water collection in the house.

After determining all of the above parameters, you can select and purchase all the necessary components and begin installing the pumping station.

Choosing a location for installation

It is not difficult to make a pumping installation for a private house or cottage with your own hands. However, it is necessary to resolve the issue of how and where to properly install the pumping station. The location for installing the pumping station, the correct selection and arrangement of which will determine the efficiency of the equipment, must meet certain requirements.

- If drilling a well or constructing a well on a personal plot has already been completed, then the pumping station is installed as close as possible to the source of water supply.

- In order to protect pumping equipment from water freezing in the cold season, the installation location must have comfortable temperature conditions.

- Since pumping units require regular maintenance, free access must be provided to their installation site.

Based on the above requirements, a caisson or a separate and specially equipped room is used as a place to install a pumping station in a country house or in a private house.

Ideally, a place for a pumping station should be provided at the stage of building a house, allocating a separate room for this

Sometimes pumping units are installed in buildings that already exist on the territory of a personal plot. Each of the listed options has its own pros and cons, which should be discussed in more detail.

Placing a pumping station in a separate room in a building with a well drilled under the house

The installation diagram of a pumping station in the basement of a house is an almost ideal option for the location of such equipment. With this installation scheme, easy access to the equipment is provided, and the issue of reducing the noise level created during operation of the station is also easily resolved. This option will be most successful if the room for the pump is heated.

Placement of the pumping station in a warm, equipped basement

If the pumping unit is located in an outbuilding, quick access to it is somewhat difficult. But with this scheme for connecting the pumping station, the problem with noise from the operation of the equipment is radically solved.

The station can be installed on a bracket in a fairly wide and deep well

Particular attention should be paid to the issue of laying the pipeline system. The pipes through which water will be transported from the pumping station to the residential building are placed in the ground below its freezing level or, if they are installed on the surface of the ground, they are well insulated. This approach to pipeline installation will protect water from freezing in winter.

Installing the station in a caisson will provide protection against freezing and complete sound insulation

Quite often, pumping stations are mounted in a caisson - a special tank that is installed above the well head, directly into the pit. The caisson can be either a plastic or metal container buried in the ground below its freezing level, or a permanent underground structure, the walls and base of which are made of concrete or finished with brickwork. It should be borne in mind that when installing a pumping station in a caisson, access to the equipment is quite limited. In addition, if a connection diagram of this type is used for a pumping station, then the section of pipeline between the pumping equipment and the building it serves must be carefully insulated or placed in the ground at a depth below the freezing level.

Choosing a device for a well

To supply drinking water to a house from a source more than 10 m deep or located far away, submersible pumps are used. Their productivity is higher than that of surface devices; they create high pressure. The body is completely immersed in water, which is cooled to prevent overheating. Surface devices need protection from precipitation. Deep pumps operate silently and stably in any weather, never freezing.

Vibrating

Such devices are budget ones. They are installed in a few minutes and dismantled just as quickly. They require no maintenance because there are no rotating parts. It is only necessary to occasionally check the tightness of the housing and rod fastenings - the nuts can become unscrewed due to vibration during operation.

Inside there is a core with a winding that creates an electromagnetic field. It appears and disappears dozens of times per second. When it appears, the electromagnet attracts the rod connected to the piston, a rarefied space is formed, which is filled with well water. The electromagnetic field has disappeared - the piston and rod return, the inlet valve closes. The water remains in the chamber, and when the rod is once again attracted by the magnet, the piston squeezes it into the hose.

The vibration pump consists of non-rotating elements. This type of device supplies water using an electromagnetic field that opens the stem for a split second.

The operation of such pumps is accompanied by vibration, which is why they got their name. They do not cause harm to the well; they do not have parts that can collapse. You should refrain from using them in a well with quicksand: the vibration will raise the smallest particles of sand from the bottom, which, along with the water, will fall into the pipeline.

Centrifugal

These devices have an electric motor that rotates an impeller with blades. The unit is designed so that it draws water into the pump chamber and pushes it to the outlet. Work occurs due to the pressure difference resulting from centrifugal force.

Operation is only permitted when completely immersed in water. The pumps are equipped with automatic equipment to protect against dry running, voltage surges and other emergency situations. On some models, a float is installed to signal that the water level is becoming insufficient.

Housing made of plastic or stainless steel. The latter are more expensive and durable, they are not afraid of abrasives and sand, and they have good performance characteristics. They can pump water with sand if its concentration does not exceed 185 g/m³.

How the assembly process works

It is best if the pumping station is assembled and connected in dry and warm weather. This will allow you to carry out all procedures carried out outdoors without haste, correctly and accurately. This recommendation should also be followed because assembling, connecting and adjusting the pumping station may require a significant amount of time.

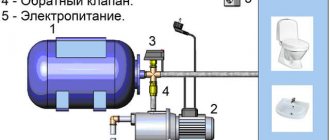

Pumping station connection diagram

The diagram for assembling and connecting a pumping station with a storage tank-hydraulic accumulator is as follows.

- First, a check valve and a coarse filter are installed on the intake hose, which will protect the pump from solid inclusions contained in the pumped water entering its internal chamber.

- Then the upper end of the intake hose is connected to the pump inlet.

- After connecting the intake hose and the pump, we assemble the entire structure of the pumping station. To do this, using a hose, we connect the pressure pipe of the pump to the inlet pipe of the hydraulic accumulator.

- To ensure automatic switching on and off of the pump, a relay is mounted on the hydraulic accumulator, which sets the appropriate parameters for the water pressure in the hydraulic tank.

- After completing all the procedures described above, the assembled and installed pumping station is connected to the water supply system, for which a hose (or rigid pipe) can be used.

- After connecting all elements of the system, the pumping station is connected to the power supply network. A test run of the equipment is being carried out.

Connecting the pressure switch of the pumping station

Ball valves must be installed on the inlet and pressure lines of the pumping station, which are necessary in order to isolate the equipment from the system it serves in cases where it is necessary to dismantle it for maintenance and repair.

Automation for a pumping station, which ensures more efficient operation of the equipment and its protection from emergency situations, in addition to the pressure switch, may additionally include a number of other technical elements. Such elements, in particular, include a sensor for the presence of water in the system and a sensor that controls the degree of heating of the electric pump housing.

When starting up a pumping station and its further operation, it is also important to know how to adjust the pressure switch to the required response parameters. You can set such a relay to upper and lower pressure values, at which it will automatically turn off and turn on the pump, using two springs. The degree of their compression is adjusted using special screws. A correctly adjusted pressure sensor starts and turns off the station pump exactly at those moments when it is needed, and also ensures that water flows into the accumulator with a uniform flow and without interruptions.

Correct connection

Installation of the submersible apparatus and installation of the surface apparatus are carried out with a connected pressure pipe. Despite the difference in use, both hoses, pressure and suction, in their parameters must meet the requirements:

- rigidity - pressure differences should not affect the shape of the pipe;

- wear resistance - abrasive elements in water should not damage it;

- frost resistance – not to deform during operation at low temperatures;

- environmental safety - the drinking hose must be made of materials that do not emit toxic substances;

- operating temperature range from +1 °C to +40 °C.

Products made of polyvinyl chloride (metal-plastic and polypropylene) shown in advertising photos meet these requirements. Hoses are used to lift water and move it into a house or storage tank in the country, and they are fixed to the pipes of the pump, tee, or adapter using fittings.

Installation recommendations

Before connecting the pumping station to the power supply network and lowering the intake hose into the shaft of a well or well, it is important to correctly install such equipment. To get a more complete understanding of the pumping station installation process, you can not only study theoretical information on this topic, but also watch the corresponding video.

A pre-poured concrete base, as well as an ordinary concrete slab or wooden shield, can be used as a support platform on which the pumping station is installed. The main thing that should be monitored when installing a pumping station is that the equipment is located absolutely level on the supporting platform, without distortions.

Advantages and disadvantages

Pumping stations mounted to wells have the following advantages:

- The presence of a single block in which all working units are arranged. The equipment does not take up much space.

- Complete assembly and readiness of stations for installation. The master does not need to look for components and assemble the entire system himself.

- Constant pressure in the system, eliminating water hammer.

- Operation of the water supply system in autonomous mode in the absence of electricity, if there is a tank with a volume of 50 liters or more.

The disadvantages of pumping stations include relative noise (which can be dampened by a caisson) and the inability to lift water from a depth of more than 10 m. If necessary, the station will have to be equipped with a remote ejector.