Connection to sewerage

Before visiting a specialized plumbing supply outlet and purchasing equipment, it is worth remembering that the design of the toilet bowl may have different flush shapes. The list includes:

- Vertically located drain;

- Horizontally located drain;

- Drain obliquely.

All new buildings are equipped with plumbing equipment that has a connection between the toilet and the sewer pipe using the principle of a horizontal drain. You can come across the option of a vertically located or oblique drain only during the process of replacing the device in buildings called Stalinka or Khrushchev buildings.

But, nevertheless, it is better to check the water flow in the sewer before purchasing a toilet. This simple action will allow you to avoid the painful procedure of remaking the system and significantly reduce the time for installation work.

Check the water flow into the sewer

Connecting fittings

The toilet is connected to the sewer system using special connecting fittings:

- compressed plastic pipes ( corrugated );

- fan pipes;

- cuff.

The use of a drain pipe during the installation of plumbing allows you to visually create the effect of one whole structure of plumbing and connecting element. This is achieved by using identical material for the manufacture of both parts, for example, porcelain, earthenware, or ceramics. An important nuance is that it is necessary to clearly select the length of the connecting fittings, because it is not possible to trim the part.

It’s another matter if an eccentric cuff is used for the connection. This part is made of polymer material and is a structure that includes two outlets with offset axes. The connection fittings are sold in completely different lengths, which allows you to choose the ideal option for connecting plumbing and pipes.

toilet connection

Choosing a toilet

Buying a toilet is a responsible decision, therefore, in order to avoid mistakes, it is important to evaluate in advance a lot of nuances and selection criteria.

Interesting models of sanitary ware for the toilet are appearing on sale. Depending on the mounting method, there are the following options:

- Hanging.

- Floor-standing.

The features of the drainage system also differ, and leading manufacturers also practice innovative solutions. The following types of drainage are common today:

- Single-mode. After pressing the button, the tank instantly drains the water.

- Dual mode. This option is equipped with 2 buttons: the first allows you to drain all the liquid from the tank, the second - only part of it.

- Contactless. The model is a kind of “know-how” in the world of plumbing, but due to its high cost it is not in wide demand.

When choosing equipment, it is important to consider the following features:

- Release type. Having studied in detail the layout of sewer pipes in the toilet, you can choose the optimal type of outlet.

- Material of manufacture. Porcelain, metal and earthenware models are common on the market. The first group is hygienic, because... porcelain is not capable of accumulating dirt. However, the material is more expensive than earthenware or steel.

- Dimensions. Selected based on the area of the room. If the bathroom is compact, it is better to opt for wall-hung models, which will allow you to keep the room clean and clean the flooring without any problems.

- Bowl. Depending on the shape of the bowl, there are models with a slope at the back, with a shelf and funnel-shaped.

- Type of flush in the toilet (cistern). This point needs to be given special attention, because... The reservoir is practically the key component in the toilet. There are hanging and built-in tanks. The first type is installed at a short distance from the equipment and provides a good water supply. The built-in version is fixed on the wall and makes virtually no noise during operation.

- Lid. Devices with a built-in microlift are available on the market. This guarantees quiet and comfortable operation.

In order not to get confused among the variety of plumbing equipment, it is important to carefully study each of the listed items, consult with specialists and only then make a purchase.

What is needed for connection and some installation nuances

Self-installation of a toilet to a sewer, in addition to the connection diagram, requires the availability of tools, including:

- a set of keys (needed to install the drain and connect the device itself);

- Screwdrivers of different types;

- Metal saw for removing unusable plumbing fixtures;

- Hammer, sandpaper, knife and three-meter tape measure;

- A small amount of tow, cement, and sealant;

- Hammer, pobedit drills, dowels.

The installation of a toilet with an oblique outlet to a cast iron sewer must be carried out using a rubber cuff. When putting the equipment on the outlet, the specified part must be turned out. This way you can completely seal the joint. To increase the density of the joint, you can additionally use sealant.

You may also like - Slope of sewer pipes according to SNiP

Connecting a toilet using an adapter

You can connect the toilet to a centralized sewerage system using special pipes, which are called adapters or fan pipes. With this connection method, the shape of the toilet outlet plays an important role.

If the outlet has an oblique shape, then the toilet is installed “on the floor”. Devices with a vertical outlet form are mounted “into the wall”, maintaining a straight 90-degree angle of the nozzle. Toilets with an oblique outlet are also installed “into the wall,” but the connecting pipe is already inserted at an acute angle of approximately 30-40 degrees.

When replacing plumbing fixtures, as a rule, a new toilet model with the same release form is selected. If, when purchasing a new device, you ignore such a criterion as the release form, you will have to modify the connection method using corrugation or eccentric cuffs.

According to the existing classification, all toilet models by type of release can be schematically divided into three large groups, presented in this picture

Installation of a toilet with vertical outlet

Models of toilets with a vertical release form are installed in cottages and old houses. The siphon and pipe are an integral part of the device, and therefore it is impossible to see these parts after installation is completed.

The product can be installed at a close distance from the wall, since there is no need to leave space for placing pipeline fittings. The installation of a plumbing fixture begins after dismantling the old product and cleaning the surface of the area allocated for the new toilet.

Installation of a toilet with a vertical outlet is distinguished by the presence of a special flange connection, which ensures reliable sealing of the interface between the device and the sewage system

Having made markings for the fasteners, they begin to install a screw-type flange into the floor, which has a lock and a hole intended for connecting the device to the sewer system.

All flanges are the same size. Manufacturers producing vertical toilets equip them with special elements necessary for a sealed connection with the flanges.

Having put the toilet in place, and making sure that all the existing holes and joints match, the entire structure is slightly rotated.

In this case, two elements are connected, the tightness of which is guaranteed by the presence of an O-ring placed between the parts.

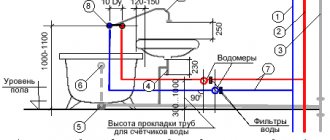

A method of connecting a toilet with a horizontal outlet to a plastic sewer pipe located in the floor of the bathroom of a private house using corrugated pipes

Installation of a toilet with horizontal outlet

It is convenient and easy to connect a toilet with a horizontal outlet to a vertically standing sewer riser. The device is installed at a short distance from the socket of the sewer pipe.

This requirement is taken into account when planning the bathroom area. In multi-storey buildings, it is not advisable to design and create a sewer line with a horizontal outlet, since in this case a 110 mm pipe must be built into the floor or hidden in a decorative box.

A toilet with a horizontal outlet is connected to the vertical riser of the central sewer system, using a sealing collar or corrugation as a connecting element. It is recommended to seal the connections with silicone sealants to prevent leaks and unpleasant odors.

When the center of the horizontal outlet is shifted relative to the socket of the sewerage system, a corrugation or angle paired with a short pipe is used to connect the elements. The toilet is connected to the pipe through a rubber collar.

Installation and connection of a toilet with a horizontal outlet to the sewer system using a rigid drain pipe

Installation of a toilet with an oblique outlet

This form of sewerage discharge is typical for houses built in the second half of the twentieth century. At that time, cast iron fittings were used to equip the sewage system at the facility.

Now we have to connect the oblique outlets of toilet bowls with cast iron sockets, carefully covering the resulting connection with cement mortar. During the work, carefully ensure that the solution does not fall into the sewer riser.

Before opening the toilet bowl into the socket, a mixture of red lead and drying oil is applied to its surface. Then the resin strand is wound tightly, leaving its end free. Once again coat the outlet with the wound strand with red lead, after which it is inserted into the sewer socket, firmly fixing its position.

A toilet with an oblique outlet and a diagram of its connection to the sewer riser by a plumber, indicating the height of the location of the main structural elements of the device

There is another way to connect a toilet with an oblique outlet to the sewerage system, which does not involve carrying out “dirty” work.

We are talking about using a rubber cuff, which is put on the outlet pipe and then connected to the sewer pipe. To ensure reliable tightness of the connection, the old dried mortar is carefully cleaned from the cast iron socket. When the toilet is forced to move relative to the location of the hole in the sewer pipe, corrugation is used.

If the sewerage system in an apartment building is made of plastic pipes, then the toilet connection is made using the methods described above with one difference: there is no need to use cement mortar to seal the connections.

Corrugated connection

Often, plumbing connections are made using corrugations. This connecting part is distinguished by its plasticity, the ability to bend and stretch to the required size. The use of corrugation allows the master to gain freedom of movement and facilitate the process of connecting the toilet. However, it is important to remember that the corrugation must be installed at a certain angle to ensure good drainage. In addition, when choosing this connection option, you should be concerned about the material of the corrugation walls. It must be durable and ensure reliable operation.

Corrugated connection

Connection steps

The use of corrugation should be used when it is not possible to take other fittings for work. Connecting a toilet to a sewer system made of plastic pipes consists of the following sequence of actions:

- The compressed pipe is connected to the sewer hole, and the connecting point must be coated with silicone.

- The plumbing fixture is connected to the opposite end of the corrugation. The reliability of the connection is checked by simply pouring a small amount of water into a container and then draining it. This will allow you to check that there are no leaks.

- The location of future holes is marked for subsequent fastening of the equipment. The procedure is quite simple and involves installing plumbing fixtures at a permanent location and marking future holes using a simple pencil or felt-tip pen.

- The toilet is removed, and holes are drilled at the marks and dowels are inserted.

- Next comes the stage of connecting the toilet and flushing system. Be sure to coat the area where the parts come into contact with sealant. At this stage of work, it is necessary to check the reliability of the fastening for leaks. When the water drains without problems, you can continue installing the equipment. If the situation is different, then you will have to re-check the calculations for the height of the corrugation.

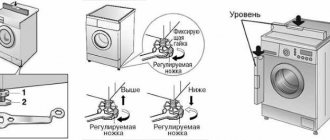

Checking stability

After installation and fastening, the toilet must be checked for stability. If there is play, it is necessary to remove the plumbing and screed with cement under the floor to level it.

At the last stage, it is important to seal the joints between the toilet and the floor covering.

The process is complete. All you have to do is wait until the sealant has completely dried and you can use the new toilet for its intended purpose.

How to connect without corrugation

To understand how to connect a toilet to a sewer without a compressed pipe, you must adhere to a list of specific rules:

- Use a pipe called a fan pipe ;

- When obliquely , place the equipment strictly on the floor;

- With a vertical outlet, plumbing fixtures should be installed into the wall at 90 degrees ;

- When the outlet is placed in a horizontal direction, the device is placed into the wall at an angle, the value of which is in the range of 30−40.

Plumbing equipment should be selected based on the existing connection diagram to the system.

Construction of a sanitary unit

Connection node

The sanitary unit consists of:

- toilet bowls,

- platforms for installing a cistern,

- toilet siphon,

- siphon holes,

- toilet outlet (ceramic branch from its body),

- toilet drain pipe.

This list includes the connecting elbow, sewer riser and connection elements.

The installation method of the unit is based on the nature of the drainage of wastewater into the sewer pipe. Taking into account the features of the equipment, taking into account the design standards of sewer systems from Western and Chinese manufacturers, the choice more often falls on horizontal and vertical discharge. Domestic manufacturers have increasingly begun to resort to the same schemes for arranging a bathroom, along with the oblique outlet that is still available for connection to a vertical common riser, which leads to the need, when repairing such a toilet, to look for a rarely found outdated model of a bathroom and its elements.

Vertical release

Plumbing fixtures installed with the outlet placed in a vertical position are distinguished by the presence of a siphon and a pipe directed upward. This design is easy to install. The sequence of work will be as follows:

- The location of the plumbing is marked, a screw flange is installed along with a lock;

- A riser is inserted exactly into the middle of the flange;

- The equipment is placed directly on the flange and rotated until it is firmly secured. In the meantime, the pipe will automatically be fixed at the end of the pipe.

Advantages and disadvantages

The main advantage of this type of connection is the aesthetics of the room after installing the toilet. The plumbing fixture will fit as tightly as possible to the wall, which will hide the wiring. However, the disadvantage of the method lies in the fact that the pipes will be located under the floor. If the system leaks, you will have to break the tiles or other floor covering to fix it.

It is best to install plumbing fixtures with a vertical outlet in your own home. This will help solve the problem while saving space, since it will be easy to connect the toilet to the sewer, and the pipe can be hidden in the interior ceiling.

Horizontal release

Since this type of connection implies the direction of the outlet towards the wall, a sealing collar should be used to connect the plumbing to the system. The installation should begin by securing the toilet to the floor covering. It is important to carry out the subsequent connection of the toilet with the sewer pipe with the utmost care, because mechanical damage to the installed device can be caused.

The main advantage of the horizontal outlet lies in the ease of installation of plumbing fixtures. However, this type can only be used if there is a vertical riser in the building.

Popular models

Toilet Roca Victoria Nord 342ND7000

Buying a toilet for a toilet where the sewer pipe is located along the wall requires a thorough approach to choosing a model. Size, shape, design features, and appearance are important. Manufacturers who make direct-entry toilets offer traditional and wall-hung models.

The most popular, according to consumers, are toilets of a classic design:

- Roca Victoria Nord 342ND7000;

- VitrA S20 9800B003-7205;

- Jika Era 824532000;

- Cersanit Nature Clean On KO-NTR011-3/5-COn-DL-w;

- Cersanit Street Fusion Clean On KO-SFU011-3/5-COn-S-DL;

- Della Boston OAK.

The price range is from 5 to 18 thousand rubles. Most of them are characterized by the presence of dual flush, a spacious tank, high-quality sanitary porcelain, a comfortable seat, a microlift and an anti-splash system.

Among the suspended models, the leaders are:

- LAUFEN Pro 8.2096.6.000.000.1;

- AM.PM Sense L C741738SC;

- Gustavsberg Hygienic Flush WWC 5G84HR01;

- Cersanit Delfi MZ-DELFI.

The cost of models is from 4 to 15 thousand rubles. Most products do not include a tank, but they do have a microlift and an anti-splash system.

Oblique release

Connecting a toilet with an oblique outlet to the sewer requires compliance with special rules and sequence of actions:

- First, the outlet is coated with a drying oil mixture with the addition of red lead;

- A resin strand is wound on top . In this case, one end should not be wrapped;

- The strand is coated with red lead ;

- Installation is carried out with fixation of the outlet in the opening of the sewer pipe.

Oblique release

The main advantage of installation is the uniqueness of the method. The negative side is that you get a long distance from the wall to the toilet. However, it is necessary to connect the plumbing to the sewerage system.