Any owner of a living space who has encountered at least once in his life the services of plumbers and their prices knows that the ratio of the complexity of the work performed and payment is significantly skewed towards the latter. Therefore, many owners prefer to install plumbing equipment themselves, and one of the simple jobs that can save considerable money is connecting the toilet to the sewer.

Despite its apparent simplicity, connecting a toilet to a sewer pipe requires knowledge of the technology of work, which takes into account the design features of the equipment, the spatial arrangement of the pipeline, and the parameters of the inlet and outlet pipes. In addition to the classic models, wall-hung toilets have appeared on the plumbing equipment market, the installation and connection of which to the sewer system is much more complicated, but practically doable by any competent owner if he has the necessary power tools, the ability to read simple drawings and strictly follow the instructions.

Rice. 1 Toilet bowl shapes

Types and designs of toilets

Toilets sold in the retail chain differ from each other in a significant number of parameters; they are conventionally divided into the following groups according to:

- bowl shape: plate-shaped, funnel-shaped, and visor-shaped;

- type of flush: straight (horizontal, cascade), straight circular or swirling circular;

- placement: floor and suspended structures;

- location of the tank: together with the bowl or placed upward, behind the false wall (equipment with installation);

- water supply: right-handed or left-handed;

- materials of manufacture: porcelain, earthenware, stainless steel, glass, stone, plastic and exclusive options made of gold.

Rice. 2 Types of flush

Types of releases

The distinctive features listed above, with the exception of models with installation, do not affect how the toilets are connected to the pipeline, in contrast to the outlet designs given below.

Vertical

The outlet pipe in this modification is located at the base of the housing and goes into the floor - this arrangement after installation of the device differs from other designs in its aesthetic appearance and ease of use of the room (the floor can be washed under the tank).

Vertically located sewerage system under the toilet is popular in Western Europe and the USA; in ordinary city apartments, its implementation involves a large amount of work and is technically difficult due to relatively thin floor slabs, in which it is difficult to hide a thick sewer pipe with an outlet.

Theoretically, a vertical outlet can be made in any apartment building on the ground floor, where the pipeline will not damage the ceiling of the lower apartment, but in a private house such installation is much easier to implement due to the minimum number of restrictions.

Rice. 3 Types of toilets by release

Horizontal

Connecting a toilet with a horizontal outlet is convenient because it allows you to move the device close to a false wall in order to save free space in the toilet. The drain pipe for the toilet is located behind the wall and is directly connected to the riser.

During installation, a rigid pipe with an internal cuff comes out of the wall at the required height, and the device is moved back, pushing the toilet outlet into the pipe coming out of the wall.

Oblique

Bowls with an oblique pipe located at an angle of 140 - 145 degrees to the horizon are connected to the riser at floor level; the advantage of this design is the absence of stagnation of wastewater in a pipeline placed at an angle. The detailed connection of the toilet is universal thanks to the use of an external flexible corrugation, which can be connected to the sewer in different positions and distances from the plumbing fixture.

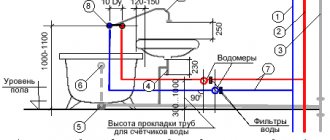

Rice. 4 Toilet connection diagram - example

Article on the topic:

Shut-off valves for a toilet with bottom supply - device, selection, installation . In the article you can learn about the design of a typical toilet cistern, the operating principle of the shut-off valves, and also how to install them.

How to connect a toilet to a sewer system using corrugated pipes

This method allows you to connect equipment in any place, even the most inaccessible, without any problems. It should be taken into account that to install the corrugated cuff you will need about 10-15 cm of free space, so you should not fix the device to the floor before it is connected to the sewer.

Another important nuance: the quality of the corrugation. It is best to buy reinforced models with thick walls and a stainless steel coating.

The connection procedure is as follows:

- Turn off the water supply.

- Lubricate the edge of the corrugated cuff with silicone and insert it into the sewer pipe.

- We connect the second part of the corrugation to the toilet and check the reliability of the resulting connection. To do this, fill a tank or just a bucket with water and pour it into a bowl. We look carefully to see if there are any leaks.

- We remove the corrugation and securely fasten the plumbing equipment.

- Lubricate the inside of the free end of the corrugated cuff with silicone sealant and connect it to the toilet outlet pipe.

- Check the tightness of the connection again.

Connection diagram of the toilet to the sewer pipe

The preparatory stage also includes cleaning the toilet outlet from contaminants after dismantling the old corrugation or pipe. These can be either particles of previous communications or remnants of cement or sealing composition.

The cleaned surface can even be degreased if this is in accordance with the instructions for use of the new sealant. Before installing the corrugation, a fan pipe should be placed on the outlet of the new toilet.

After this, you can begin to actually install the corrugation. First, the required amount of sealant is applied to the edge of the toilet outlet. To work with plumbing, it is recommended to use a special sanitary sealant based on acrylic or silicone.

Such compositions expand well and provide high tightness of the connection; they are specially designed for conditions of high humidity and prevent the penetration of fungus and mold on treated surfaces.

Before starting to work with sealant, you should carefully study the manufacturer's instructions and strictly follow them.

A corrugated pipe is placed on the edge of the outlet, treated with a sealing compound. It should be turned towards the toilet with the side on which the inner membrane is located. The corrugation should block the exit from the toilet by about five to six centimeters; these dimensions are considered optimal.

It is very important that the corrugation is put on very evenly, this will ensure maximum reliability of the connection. To ensure a reliable fit of the corrugation at the connection point, it is necessary to carefully press the pipe section to the toilet outlet surface.

After this, you should wait until the sealant is completely dry, the timing is indicated in the instructions. During this period, you should not displace the corrugated connector; it is best to leave the structure alone to prevent possible leaks.

After this, the new toilet can be installed in its intended place. The procedure for connecting the corrugation to the entrance to the sewer is approximately the same. Part of the pipe must be treated with sealant and connected in the right place. It should be noted that the installation of a corrugated connector can be performed without the use of sealant.

There are special internal membranes along the edges of the pipe that allow you to fix its position. But in practice, the lack of a sealing compound often leads to leaks and displacement of the corrugation.

The main work of installing the corrugation at this stage can be considered completed, however, the reliability of the connection should be checked to prevent possible leaks. First, of course, you should wait for the sealant that was applied to the part of the pipe connected to the sewer to dry.

After this, water is supplied to the system to fill the tank, and the flush is performed. If for some reason you cannot connect the water, just pour a few liters of water into the toilet.

Now you need to observe the joints. If water seeps or leaks through them, it means that the seal is broken and the defects need to be eliminated. To do this, you do not need to redo all the work; it is enough to apply one or two layers of sealant to problem areas.

If there are no leaks, it is not necessary to reseal the connections from the outside. After repairing leaks, you need to wait for the composition to dry and check the connections again for leaks.

Corrugation for connecting the toilet to the sewer

Corrugation (corrugated cuff, pipe) is a transitional element of the plumbing system, designed to connect the toilet to the sewer system. It is a fairly wide pipe with corrugated walls, made of modern thermoplastic.

The corrugated toilet connector allows you to connect plumbing to the sewer quickly and efficiently. The duration of its operation depends on correct installation.

The edge is decorated with a cuff, which facilitates the process of connecting to the pipes and the toilet outlet. The design of the walls, which gave the name to this product, allows you to increase the size of the adapter to certain limits. Typically the sleeve length varies between 23-50 cm.

The diameter of the cuff that is attached to the toilet is 13.4 cm on the outside and 7.5 cm on the inside. The end that is installed on the sewer pipe usually has a hole with a diameter of 11 cm.

The main advantages of corrugation designed for toilets are low price and easy installation. This element is often used in cases where the diameter of the toilet outlet and the sewer pipe do not match. The corrugation is very convenient if the position of the toilet needs to be changed, moving it relative to the entrance to the sewer.

It is also often used as a temporary element, when during repairs the toilet is not yet fixed, but it needs to be used. However, corrugation cannot be called an ideal choice; it is not the most durable element. For example, if a piece of ceramic tile or a sharp piece of glass accidentally falls into the toilet, the corrugated joint can easily be damaged.

If the corrugation is located at too large an angle or incorrectly curved, blockages often occur in it, and an element that is too long sometimes sags under the influence of its contents. Corrugation should never be placed inside a wall; it is only suitable for open installation.

How to shorten a toilet corrugation

If necessary, the connecting cuff can be shortened.

It is not recommended to cut the corrugation; in this situation, it is better to buy one that is suitable in size. However, if there is no way out, then they do this procedure carefully, otherwise in the future it can lead to disastrous consequences.

Using a sharp knife with a thin blade, disconnect the corrugation from the pipe on the side of the pipe from the sewer. Then the pipe itself is shortened and glued back into the pipe.

Leave the product for several hours so that the material sticks securely. After this, insert the pipe back into the pipe from the sewer. Next, you need to check the connection for leaks. To do this, drain the drain tank several times and check for leaks.

Hanging models

Recently, hanging varieties with installation have become increasingly popular, the connection methods of which involve hanging the bowl on a false wall and placing a cistern behind it. To do this, a strong metal vertical frame is mounted behind the wall, threaded studs with nuts are removed from it to hold the bowl, and a plastic drain tank is placed inside the frame; a button is placed on top of the wall to turn on the flush.

The advantages of a hanging design are space saving in a small toilet, aesthetic appearance, ease of cleaning (the floor is easier to clean under a hanging bowl).

Connection tool

As noted above, installing a toilet in a sewer is not particularly difficult if you have the appropriate tools and components; for installation you will need:

- A wrench or adjustable wrench for screwing fastening hex bolts and flexible connections to a ball valve on a water supply system.

- Metal saw – needed for cutting polyvinyl chloride (PVC) pipes to the required size with rigid fasteners.

- A hammer drill with drills of a suitable diameter for tiles and concrete is necessary for attaching the bowl to the floor.

- Fittings, flexible connection to the toilet for supplying cold water.

- Dowels and hexagon screws, fasteners are usually included with the new device.

- Pipes, corrugations, eccentrics, cuffs, adapters and other shaped elements with which the toilet is connected.

What it is

An installation is a wall-hung type of toilet that is installed on its own supporting structure. It is a metal frame to which the flush cistern and toilet bowl are attached. After installation and finishing, only the toilet bowl with the cistern button become visible structural elements. All sewer or water pipes, connecting elements, and other parts remain under the layer of exterior finishing. This makes the room neat, devoid of technological details and elements.

The connection of the toilet installation to the sewer system is made through standard fittings, or using your own components. Most often, the structure can be connected without any problems, since its configuration is designed for a standard connection to the system.

Advantages and disadvantages

The advantages of the design are:

- all communications are connected in a hidden way, only the bowl with the tank button remains visible;

- hinged mounting allows you to change the floor covering and install a heating system without the need to turn off or partially dismantle the toilet;

- high degree of sound insulation. The sounds of draining water or a filling tank are practically inaudible;

- the quality of cleaning in the toilet improves, the floor under the toilet is free, it does not become a reservoir for bacteria and dirt;

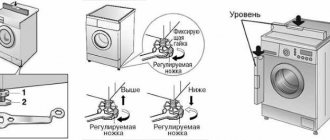

- the height of the toilet can be adjusted taking into account the physical characteristics of the owner or his family members;

- There is an opportunity to stylishly and neatly decorate the toilet. This is especially important for combined bathrooms.

Disadvantages of such kits:

- relatively high cost;

- complexity of installation, connection to the sewer;

- repair and maintenance of the kit is difficult.

It must be borne in mind that installation of the structure is not difficult in itself. It’s just that not all plumbers know how to connect the installation to the sewer, what subtleties or features of the process exist. It is important to provide in advance the possibility of access to all parts so that for repairs you do not have to sacrifice the finishing of the room.

Kinds

There are different types of such kits on sale. By installation type:

- with support on the floor (at 4 points);

- supported on the floor and wall (2 mounting points each);

- hinged (there is no contact between the structure and the floor);

- corner complexes.

According to the type of construction, they are distinguished:

- block. They are designed for wall-mounted installation only. Installation requires a solid solid wall of sufficient thickness, since you will have to make a niche for the tank. Such designs allow you to save about 15 cm in the length of the room by immersing the tank into the wall;

- framed These are kits for which the supporting structure is a frame made of square pipe. Such assemblies can be installed either separately or mounted on a wall. The load-bearing capacity reaches half a ton. The reliability and strength of frame structures are highly appreciated by experts, although it will not be possible to save the length of the room when installing a frame installation.

Frame sold separately. This is a universal design that is suitable for all models of wall-mounted toilets. When purchasing a frame, you need to clarify its purpose, since there are varieties for toilets, sinks or bidets.

Assembly is not particularly difficult. The delivery set always includes instructions, which contain an exact drawing of the supporting structure, as well as a diagram of the points of connection to the walls or floor. The problem area is the sewerage system for installing the toilet. The location of the riser and horizontal pipes sometimes turn out to be incompatible with the frame designs, dimensions or shape of the toilet outlet. This greatly complicates installation work. The kit must be connected by experienced professionals who do not make mistakes.

Also read: Jet rupture in the sewer, what is it: air gap, funnel, where necessary

Flush control panel

The cistern control button is located above the toilet, at a height of 1 m above the floor level. It is located on a plastic panel, which simultaneously serves as an inspection hatch. Through it you can carry out some repair work. There are simpler designs with a single button. There are also advanced models with several flush options:

- single;

- double (regular or economical);

- stop flush (water flow can be stopped by pressing the button again).

There are modern models with touch or contactless water start. They are equipped with a sensor system that can independently determine the moment the flush starts. These kits are very expensive so use is limited. Typically, they are installed in the toilets of restaurants, cafes, bars or public buildings.

Methods for connecting a toilet to a sewer system

Any user who independently installs plumbing equipment has to choose the appropriate connection of the toilet to the riser from a variety of options, while the determining factors during the work are the type of outlet, dimensional parameters and spatial location of the sewer inlet pipe.

Rice. 7 Connecting a toilet to a sewer with corrugated plastic - examples

Using corrugation

Connecting a toilet to a sewer with corrugated pipes is one of the most common options due to its low cost, the absence of problems with the alignment of the joined pipes, and the ability to stretch and bend. Most often, corrugations are used to connect a toilet with an oblique outlet to the sewer system, this is due to the fact that waste is less retained on inclined walls and blockages occur less frequently.

To connect the toilet to the sewer system with corrugated pipes, carry out the following operations:

- Insert the corrugation into the sewer outlet, covering the cuff with silicone grease, and then place the assembled toilet in the toilet in the intended place.

- Connect the corrugated pipe to the plumbing in such a way that there are no strong transverse distortions, then fill the tank with water and monitor the drainage. In case of leaks, adjust the position of the bowl and corrugation until there are no drops from below.

- Slightly lift the bowl and stick pieces of masking tape under the mounting holes, return it to its place, once again check the accuracy of the location, and use a construction pencil to mark the mounting points on the paint.

Rice. 8 Types of connecting shaped products

- They sit on the bowl and check its stability; if the tiles are uneven, draw a marker around the base around the perimeter and then look for a suitable waterproof lining material underneath. They can be strips of linoleum, a backing for laminate flooring, a rubber mat; plumbers often use sealing silicone during the installation process (they coat the bottom of an inverted bowl with it).

- The toilet bowl is removed, placed on the substrate and cut along its contour, the marked holes in the tile are first drilled with a feather drill, and after passing through the tile layer, they are deepened with a Pobedit concrete drill in perforation mode.

- Drive in the dowels, place the toilet on the workplace (if using a backing, place the device in the oval previously described with a marker) and screw it with hex bolts using a wrench, and put decorative caps over the caps.

- The second end of the corrugation is inserted into the outlet, a flexible water supply is connected to the tank, the functionality and presence of leaks are checked, and the position of the corrugated pipe is adjusted if necessary.

Rice. 9 Installing a toilet in the sewer using polymer elbows

Related article:

How to connect a kitchen faucet to a water supply using different types of pipes . If you don’t know how and how to connect a sink in the kitchen, be sure to read a separate article on our website. It explains all the details in great detail. tools, types of connections for different pipes and mixers.

Plastic knees

If there is no alignment of the joined horizontal holes, the work becomes more complicated and requires higher plumbing knowledge and skills in the use of rigid corner elements or rubber eccentrics.

Connecting a toilet to a sewer system made of plastic pipes using rigid polymer elbows is optimal in terms of channel permeability, preventing blockages and reducing hydraulic losses.

To connect a toilet to the sewer with your own hands, which has a horizontal outlet, using polyvinyl chloride elbows, proceed as follows:

- Purchase two standard corner elbows with outer diameters of 110 mm and sockets with an internal elastic ring.

- Connect the inlet parts to each other in the shape of the letter Z and insert the assembly into the outlet socket of the sewer pipe, move the bowl towards the assembled elbow and place its outlet into the socket with an internal rubber ring.

- Typically, standard bowls have an outlet with an outer diameter of 102 mm - 105 mm, and the elbow socket is designed to connect to a pipe with an outer diameter of 110 mm. To seal this gap to approximately 7 mm, an intermediate cuff is placed on the outlet. Its internal diameter should be about 100 mm with a wall thickness of at least 5 mm.

- The connecting unit is assembled using a soap solution or silicone grease to lubricate the rubber rings.

Types of bends

Today, to connect toilets to sewers, there are the following types of connecting elements:

- Corrugated;

- Eccentric pipes;

- Hard plastic.

Below we will take a closer look at the highlights of all these products and consider in what cases they are used.

Corrugated

A corrugated bend is a flexible adapter with a folded texture. Essentially, this is a corrugation with a pipe. Like each type of connecting element, this part provides a connection between the outlet of a plumbing fixture and the socket of a sewer pipe.

It must be stated that the corrugations contain a smooth pipe, the usual diameter of which is 75 mm. The length of the product may vary, in most cases it ranges from 231-500 mm. As mentioned above, the length is selected personally and depends on the placement of the plumbing fixture and other connection conditions.

Corrugation is used when it is not possible to make a solid connection from the selected position.

Much more often this is not uncommon in the following cases:

- In case it is necessary to make a connection with a small axial displacement relative to the sewer pipe . This often happens when laying tiles on the floor, which leads to lifting of the equipment. Accordingly, it will not be possible to perform hard installation in this case.

- During a small transfer of a plumbing fixture to a more ergonomic location.

- If the socket is made under an oblique projection, and the equipment is intended for an even connection.

Note!

When choosing a corrugated bend, keep in mind that corrugations are often reinforced or non-reinforced. The price of reinforced products is higher, but they are stronger and more durable.

It must be stated that corrugated pipes are often used when connecting plumbing fixtures, since they have the following advantages:

- The connection can be made to a sewer pipe made of any material.

- Allows you to install any type of toilet.

- Easy to install, making it possible to do the work yourself.

But keep in mind that this product is not always a suitable option, since it has many disadvantages:

- Low strength and sensitivity to mechanical action.

- Can only be used in open areas.

- At enormous turning angles, sagging occurs, which leads to frequent blockages in this area.

Thus, the use of corrugation is justified only in those cases at a time when it is really needed.

Eccentric adapter

This connecting element is a cuff made of two cylinders, which are hermetically connected to each other, but their longitudinal axes are moved relative to each other.

Eccentricity is needed in cases where the toilet outlet does not coincide in height with the riser pipe.

There are two types of such products on sale:

- For a long connection;

- For a small connection.

Unlike corrugations, rigid eccentric adapters have the following advantages:

- Able to withstand mechanical load. That is why, in case of blockages, the sewer can be cleaned with a plumbing cable without fear.

- They are less susceptible to high temperatures, making it possible to flush the system with boiling water to prevent blockages.

Hard plastic pipe

A solid toilet pipe is a hard plastic pipe, which has rubber cuffs around the edges that ensure the tightness of the connection. The product can be either straight or curved.

Angled adapters are available for sale:

- 45 degrees;

- 90 degrees.

The plastic product provides firm fixation. Its main advantage, in addition to mechanical strength, is the absence of a tendency to cause blockages (in the absence of extended sections with a horizontal plane). But, they can only be used in cases where the placement parameters of the plumbing fixture and sewer pipe fully correspond to the bend angle of the pipe.

Here, in fact, are all the main types of outlet adapters that are used when connecting toilets.