A clamp, or in other words a clamp, is a must-have tool for every carpenter. The device has a simple design, but at the same time allows you to perform very important work. There are many types of clamps, each of which has a specific purpose. So that the novice master does not have difficulties, we will consider all types of clamps, their purpose and application, as well as the main criteria for choosing a quality tool.

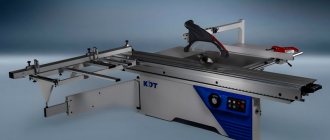

What is a clamp and its design?

Surely many people have such a kitchen tool as a manual meat grinder.

So this device is attached to the table using a clamp, which is a clamp. From this it is now clear that this device serves to fix parts in the corresponding preset position. The clamp is used mainly when carrying out carpentry and plumbing work, and is one of the mandatory tools for roofers and builders. A clamp is also called a second hand or an assistant, which is not surprising, because this device allows the master to independently work with long beams, boards and other building materials. The main task of the device is to temporarily secure parts in the appropriate position. And the tool copes with this function best, because in addition to reliability, it is worth highlighting such an advantage of its use as ease of operation.

This is interesting!

The name clamp comes from the German word schraubzwinge.

According to the design, the clamp is a vertical base with or without a thread, which is fixed on a metal frame with a mating part. The screw part serves not only for fixation, but also to increase or decrease pressure on the object being fixed. The devices are made primarily of metal, but wooden or plastic versions are also produced for specific purposes.

Band clamp - everything you need to know about the tool

One of the most little-known types of clamps is the band clamp. Very often, novice craftsmen wonder about the design of this tool and its operating principle. Let's look at this issue in more detail.

A tape clamp is a tool that is based on a nylon tape, belt or cable. Unlike classic models, these clamp options are designed to work with round, triangular and other geometric shapes. The devices have a simple design and operating principle. The tape acts as a clamp, and special plastic or metal corners are used as clamps.

This type of tool is used when working with furniture, and also allows you to glue aquariums, make window frames and picture frames. When choosing such a device, you should specify the length of the tape, since it determines what size parts can be compressed.

This is interesting! You can make a tape clamp with your own hands. To do this you will need a steel cable, angles and a housing with a clamping mechanism. Making a tool with your own hands is not difficult, so if you need it, then based on the video, you can realize your idea.

Detailed description of the clamp device

The tool is characterized by simplicity and reliability, and if you treat it with care and use it correctly, the likelihood of breakdown is reduced to zero. The principle of operation of the device is similar to that of a vice. Only, unlike heavy and large-sized devices, the clamp is lightweight, which makes it mobile, and has a lightweight design for effortless operation. The structural elements of such a device are:

- Frame - plays the role of a response element to which the part itself is directly attached. The frame part can have different types of design: G-shaped, C-shaped and T-shaped.

- Movable part - allows you to increase or decrease the distance from the working part to the frame

- Lever or screw - serves to secure the clamp in the appropriate position and makes it possible to adjust the compression force. Lever devices are equipped with a drive for quick fixation; therefore, the less force is applied, the more intense compression is obtained.

- Support heel - located on the inside of the U-shaped frame.

For more convenient movement of the threaded rod, a handle is used (can be of different types). At the end of the movable screw there is a heel, which rests against the workpiece being pressed, ensuring its reliable fixation. The pressing force depends on the physical strength that a person has.

The photo shows a clamp with the designation of its structural elements. However, such instruments are produced in different types, although their operating principle and purpose are the same. You can find out more about what a clamp is used for in the next section.

Instructions for making a wooden clamp: detailed description

With a minimal set of tools, you can make a wood clamp. For this you will need:

- two wooden blocks measuring 50x50 mm;

- several long bolts or studs with nuts and washers;

- The only tool you need is a drill.

Let's start creating a tool with our own hands. We cut out two blanks from bars 25 cm long. These will be the jaws of the future tool. Further actions are presented in the list:

- The bars must be pre-treated with sandpaper and varnished to give the instrument an aesthetic appearance.

- Take studs with a diameter of 8 mm and a length of 20 cm with nuts and washers, and drill holes for them in the blanks.

- Drill holes at a distance of 5-8 cm from each other, as shown in the photo.

- Assemble the tool using nuts and washers. The photo below shows a homemade wooden clamp, which took no more than 20 minutes to make.

The resulting tool is recommended to be used exclusively for working with wooden workpieces or sheet steel. The video below describes the process of making the tool and also demonstrates its effectiveness in use.

Below are photos of various options for making clamps with your own hands. Using them as a basis for your ideas, it will not be difficult to turn them into reality.

- This model is based on stainless steel. For manufacturing you will need semi-automatic welding.

- The clamp is made of steel. Its advantage is that the fixed foot can move, expanding the capabilities of the tool.

- If you have a steel profile and a welding machine, then making a simple clamp will not be difficult.

- This model is based on round tubes to which heels and wide nuts are welded.

- This tool is based on round metal pipes.

The advantage of the clamp is that it has a simple design. If you have an unnecessary manual meat grinder, then by cutting off the top part of it, you can get a finished tool. Due to their simplicity, clamps can be made from almost anything, the main thing is that the device has sufficient reliability, since human safety depends on its quality and serviceability.

Clamps for all occasions

In addition to screw and quick-release clamps, there are other models, some of which are good for every home craftsman to have. Ratchet clamps are indispensable in modeling and when working with small workpieces where strong compression is not required. Anyone who often stands at a workbench will benefit from clamps secured in the holes on the working surface of the workbench. Lever clamps are used in cases where very strong compression is required. They are significantly stronger than spring steel clamps, but require more space to install.

Pincer Clamps with Ratchet Mechanism 1. The ability to finely dose compression and low weight make these clamps indispensable for making small crafts.

2. Ratchet clamps are inexpensive. They can be used to join very thin materials with greater or lesser compression.

Spring steel clamps

Spring steel clamps (pictured with a grip for metal pipes) have a certain flexibility during compression and therefore will firmly hold the workpiece even when the structure is shaken

Lever clamps are professional tools that provide extreme compression.

Convenient clamps for workbenches are installed in 20 mm holes on the working surface.

Two or more clamps can be used to securely secure the workpieces being processed.

Gross 20706

Another representative of the Gross brand in our TOP of the best quick-release clamps is Gross 20706.

This is a pistol-type rack clamp that will allow its owners to securely fix 2 or more workpieces with a total width of 600 mm. The workpieces clamped with it are securely and quickly fixed and do not move due to vibrations. And thanks to the ergonomic handle, this tool is comfortable to use with one hand.

The clamp guide has a length of 820 mm, on which a support jaw is installed. It moves and is fixed along the entire length of the guide using a special clamp, and is also rearranged to the other end. Moreover, the jaws of this clamp have rubber linings that prevent damage to the objects being clamped.

Among the advantages of this model, many owners note the ratcheting mechanism, which is convenient to adjust with one hand and which provides reliable fixation. And installation into or out of the working position with such a tool takes a couple of seconds. In general, an excellent clamp for a carpentry workshop and construction work where it is necessary to clamp large workpieces.

- Type: F-shaped.

- Clamping width: 600 mm.

- Clamping depth: 90 mm.

- Ratchet clamp.

- Weight: 1100 g.

What are they used for?

The purpose of clamps is quite varied. This metalworking and carpentry device is quite successfully used in the construction industry.

There are stationary models with mounting for a workbench or for a table in a workshop, as well as mobile devices.

They are used in a wide variety of fields and activities.

- For sheet metal . The clamp here is used as a vertical grip; such equipment is used mainly in the warehouse sector and in production

- For assembling furniture . The same carpentry tool is used for frames and for wood in any of its configurations. Clamps are mainly used when gluing elements together. For furniture panels you also need a carpentry clamp.

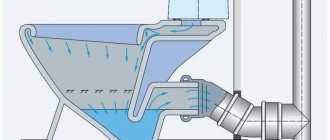

- For artificial stone. Vacuum clamps are used here to glue the sides and wall plinths and create an anti-overflow system.

- For doors. Here, clamps are used to install boxes into the opening with the ability to straighten crooked corners.

- For gluing parts. The clamp provides a more dense and uniform connection, as a result, the adhesion of materials occurs more effectively. End models allow you to glue decor to the front edges of furniture.

- For formwork. Here the clamp acts as a load-bearing element.

- For floors, for laying laminate. The clamping element used when tapping planks is also a clamp, although it looks more like a bracket.

- For drill . Here the clamp acts as an external accessory for a power or hand tool.

- For lighting devices. Clamp lamps are widely used as a necessary addition to the work of architects and other people working with drawings.

- For hairpins . The metal clamp provides easy fixation of threaded products to ceilings and other load-bearing metal structures.

- For the tire. Here clamps are used to make the saws easier to operate. For proper use of guide bars in power tools, the selection of F-shaped or quick-release models is recommended.

READ What is a caliper used for?

- For ventilation. This type of beam clamp is made of metal. Used when laying various utilities, it helps to fix fasteners on load-bearing structures without drilling holes or welding.

- For suspended ceilings. Here pincer-shaped crab clamps made of plastic with sizes of 100, 150, 200 mm are used. With the help of such a clamp, the canvas is hung in the corners of the room before heating; usually 6 products per room are enough.

The scope of application of clamps does not end there. Craftsmen even use them to secure sheet materials and large cargo on the trunk of a car. In any case, you can’t do without this in a home workshop.

A mounting clamp is used for turning products (rotating a part from one plane to another) and lifting them in a horizontal position. However, the main function of this device is still to hold the device in a so-called “vice” for repair and restoration work. It is worth noting that if you need to use this device for turning parts, you do not have to purchase any expensive devices. Even the cheapest device can cope with such work. If you need to use a clamp as a lifting element, you need to have universal devices for such purposes. Such tools (including clamps for fastening air ducts) are distinguished by the fact that they can be equipped with additional attachments.

Types of clamps according to their design

An auxiliary tool is used to fix various parts and objects. Clamping can be performed temporarily or permanently, which the device also copes with quite effectively. The clamp allows you to fix the part in the required position with its preliminary alignment to ensure better fastening of the parts. Subsequent fixation of parts can be done using glue, self-tapping screws, bolts, or welding joints. Depending on the type of work performed, the following types of clamps are used:

- G-shaped (C-shaped) is a fastening tool whose main purpose is to work with metal workpieces. The design is called G-shaped due to its resemblance to the letter G. Tool steel is used to manufacture the product, which has a positive effect on the strength properties of the device. The shape of the tool plays an important role, since thanks to this design, the clamp is resistant to deformation. High-quality clamping of the workpiece is achieved due to the fine pitch of the thread on the screw. The only disadvantage of small threads is the time required to fix the workpiece. Clamps of this shape are suitable for working not only with metal, but also with wood. An analogue of G-shaped clamps are C-shaped ones, which are characterized by the absence of a protrusion on the fixed heel.

Examples of C-shaped and G-shaped clamps:Article: BE-VC2 C-clamp VC, stable BESSEY VC2

5,480 rubles

Article: BE-SC80 C-clamps SC BESSEY SC80

5,960 rubles

Article: Piher 55508 Clamp Piher GF 7.5 x 6.3 cm G-shaped copper screw 18000N М00016052

1,760 rubles

Article: Piher 20015 Screw clamp G-shaped Piher G 15x12.5cm 20000N М00006391

4,190 rubles

Article: Piher 07004 Clamp Piher GC30 G-shaped M00014024

410 rubles

Article: BE-CDF408C C-clamp CDF-C BESSEY CDF408C

10,590 rubles

- End clamps are the name given to clamps that are used to secure workpieces from the end side. The devices are a standard clamp, which is equipped with one fixed and two movable clamps, which are located perpendicular to each other. Such devices are especially popular in furniture manufacturing, since they are used to secure furniture overlays to the end side. Examples of end clamps (clamps):

Article: BE-EKT55 Edge clamp EKT for one-handed operation BESSEY EKT55

9,270 rubles

Article: VI-8100200 End clamp (3 in 1: end clamp, corner clamp, transport device) PC81U VIRUTEX

8,150 rubles

Article: Piher 57100 / Zim ZSF01 End clamp Piher Spannfix 65mm 57100 М00000801

9,980 rubles

Article: Piher 55400 End clamp Piher G-3 55400 M00017832

1,210 rubles

Article: Piher 57102 / Zim ZK02 End clamp for furniture assembly Piher Kantenfix, 45 mm M00000803

5,770 rubles

Article: Piher 19000 RED End stop for Piher clamps 90 mm M00006573

1,670 rubles

- T-shaped and I-shaped - they consist of a base with guides for the movable jaws of the tool. One jaw is rigidly fixed to the base with a metal stopper, and the second is moved using a threaded screw. This type of tool is used for installing window frames, as well as for fixing workpieces with their subsequent processing. The length of such devices can reach up to 2.5 meters, so they can easily replace a conventional vice.

Examples of T-shaped and I-shaped clamps:Article: BE-TB120 Door clamp TB with T-profile 40x40x5 mm BESSEY TB120

16,230 rubles

Article: BE-TAN250 Vime clamp for clamping when gluing TAN with I-shaped profile 80x42x3.9 mm BESSEY TAN250

42,110 rubles

Article: BE-TL180 Clamp for gluing panels TL light with I-shaped profile 37x11x4.5 mm BESSEY TL180

12,780 rubles

Article: Di 707691 Clamp-clamp DUBUQUE 37 900 mm Dictum М00016149

4,780 rubles

Article: York DU 2200 Clamp York DU 2200 М00008615

21,350 rubles

- F-shaped - a simplified version of T-shaped models. The main advantages of such devices are a wide range of adjustments and tool mobility. However, this type of tool has a drawback, which manifests itself in the form of reduced reliability, which is due to a large range of adjustments. The components of F-shaped clamps are: a metal strip with a fixed and also a movable jaw. The latter moves along the guide, which allows you to work with workpieces of different sizes. With their help you can fix a large number of workpieces.

Examples of F-shaped clamps:Article: BE-GSM50 High-performance clamp ClassiX GSM BESSEY GSM50

13,940 rubles

Article: BE-GK15 Clamp with gear GearKlamp BESSEY GK15

3,790 rubles

Article: BE-TGK40-2K Ductile iron clamp TGK with Best-Comfort system BESSEY TGK40-2K

8,330 rubles

Article: Piher 04120 Clamp Piher F 120 x 12 cm 9000N M00014022

5,250 rubles

Article: Piher 30901 Quick-release extra-strong clamp with ratcheting mechanism Piher Pal Light 16x8cm, force up to 1200N 30901 M00016048

1,430 rubles

Article: Piher 30703 Clamp Piher Pal R 30 x 14 cm 5000N M00014027

6,790 rubles

Article: Piher 60120 Screw clamp F-shaped Piher Maxi-F 120x12cm, 9000N M00012038

5,870 rubles

Article: Wo 3605000 Screw clamp (extension/gap when clamping 50 / 200 mm) Wolfcraft 3605000

760 rubles

Article: Wo 3621000 Screw clamp SZ (reach/gap when clamping 120 / 450 mm) Wolfcraft 3621000

2,950 rubles

- Corner - they are used to combine parts at different angles. Devices are classified into magnetic and screw. If the first type is used primarily for working with metal workpieces, then various wood workpieces are connected with screws. Such devices consist of a body with two pressure heels located relative to each other at a right angle of 90 degrees. Examples of corner clamps

Article: BE-WS1 Corner clamp WS BESSEY WS1 HIT!

1,280 rubles

Article: BE-WSM9 Corner clamp (Metal corner clamp, vice) Bessey 2×90/60 WSM9

28,640 rubles

Article: Wo 3051000-4-AM SET: Angle clamp set 8 pcs. ES 22 for fixing boards from 10 to 22 mm thick Wolfcraft

3,595 rubles 3,720 rubles

Article: Piher 30001 Power vice (clamp) for corner joints (Angle clamp for welding) Piher A-10 М00006354

9,210 rubles

Article: Piher 30003 Vice for corner joints (angular clamp) Piher A-30 30003 M00005922

4,240 rubles

Article: Piher 30002 Vice for corner joints (angular clamp) Piher A-20 M00005921 HIT!

3,120 rubles

Article: Di 705769 Clamp for corner connections with rotating base Dictum 705769 M00013940

8,610 rubles

Article: Piher 30000 Clamp for assembling corner joints Piher A-40 M00013362

1,660 rubles

- Band clamps - carpenters actively use band clamps, which consist of wooden or metal clamps placed on a belt. Clamps in an amount of 4 pieces are pre-installed on the structure, and they are pressed and secured with a belt. Such devices are used in the assembly and manufacture of furniture, facilitating the work process. The length of the tape can reach 8 m. Examples of band clamps:

Article: BE-BAN700 Band clamp (band clamp) BESSEY BAN 700 with 7m tape

6,480 rubles

Article: BE-BAN400 Band clamp (Tape clamp) BESSEY BAN 400 with 4 m tape HIT!

4,320 rubles

Article: Piher 24002 Band clamp Piher A, 5m*12mm, for quadrangular structures M00005926

7,380 rubles

Article: Piher 24005 Band clamp Piher B, 6.5m*20mm, arched (aros) M00006566

8,430 rubles

Article: Wo 3681000 Clamping device for gluing frames, furniture, one-handed Wolfcraft 3681000 HIT!

4,560 rubles

Article: Wo 3416000 Clamping device for gluing frames, furniture Wolfcraft 3416000 HIT!

2,720 rubles

Article: PRM 4-8-05N1401-AM Convenient SET: Frame clamp Plano NOBEX PRM 4-8 PLUS Veritas Poly-Gauge template

4,960 rubles

Article: Di 705870 Multi Clip clamp (pulling together wooden blanks when gluing, tying pipes, rods and wires) Dictum M00000789

430 rubles

- Pipe - they are called so not because of the purpose of working with pipes, but because the basis of their design is a pipe. They look like a classic clamp, only a tube is used as the base. One heel is fixed, and the second is adjusted by moving along the pipe, and is clamped using a screw clamp. The main area of application of such devices is in the furniture industry for gluing panels in the manufacture of countertops and doors. The main advantage is the ability to work with large-sized workpieces. These devices are based on pipes, since they are the ones that make it possible to achieve such high reliability and durability of the tool.

Examples of pipe clamps:Article: BE-BPC-H34 Pipe clamp 3/4 inch BESSEY BPC-H34 HIT!

4,490 rubles

Article: TC-0899 Pipe clamp for professional use 3/4 inches with rotary handle force 600 kg EHOMA TC-0899

2,985 rubles

Article: BE-BPC-H12 Pipe clamp 1/2 inch BESSEY BPC-H12

4,070 rubles

- Spring pliers are pliers with handles, with the help of which the clamping jaws are driven. One jaw has a rigid fastening, and the second can be adjusted depending on the size of the workpiece being clamped. Examples of spring clamps (clamps):

Article: Wo 3431000 Spring clamp with sharp ends, jaw width 60 mm microtip 60 2 pcs Wolfcraft 3431000

450 rubles

Article: Wo 3616000 Spring clamp with ratchet mechanism (jaw width 60mm) Wolfcraft 3616000

1,170 rubles

Article: Wo 3420000 Set of mini spring clamps, gap width 20 mm 6 pcs Wolfcraft 3420000

470 rubles

Article: Piher 30910 Spring clamp with force adjustment 30mm Piher 30910 M00016050

390 rubles

Article: Piher 52201 Spring clamp with Piher fixation 50 mm M00006926

750 rubles

Article: Piher 57050 Piher metal spring clip (clothespin) 5 x 5 cm M00006360

220 rubles

Article: BE-XCL2 Spring clamp Clippix XCL 55 mm BESSEY XCL2

480 rubles

Article: BE-XC5 Quick-release clamp 50x50 mm Clippix (Spring clamp) XC BESSEY XC5

650 rubles

Article: BE-XV5-100 Spring clamp VarioClippix XV BESSEY XV5-100

1,220 rubles

Having an idea of the types of clamps, it will not be difficult to choose them depending on the planned work.

Kinds

The classification of clamping mechanisms is quite extensive. Here you can find furniture clamps and “pistols”, pliers and double-sided models. All of them deserve the closest attention. It is worth considering the classification and types of clamps in more detail.

By size

Depending on their purpose, clamps can be small or large, long or short. Mini versions are commonly used in jewelry making and other small projects. The average parameters will be as follows:

- length – from 150 to 900 mm;

- width – 120-350 mm;

- size of the working area (at maximum opening) – 10-600 mm.

The corner clamps have the smallest grip - no more than 10-100 mm, since contact occurs at an angle of 90 degrees.

Among standard clamps, the F-shaped models have the largest working range - from 15 to 350 mm with a tool length of up to 400 mm. G-clamps are considered medium clamps. Their grip reaches 70-170 mm, which is quite enough to perform most types of work.

According to the material of manufacture

The base from which the tool is made also matters. The main materials used for the manufacture of clamping mechanisms are ferrous and non-ferrous metals, but wooden or plastic elements are also found . It is worth considering all the options in more detail.

- Forged. The most durable and durable, considered the most reliable. Classic F-shaped clamps with a screw clamp are made from ductile cast iron. Staples in this design provide maximum stability.

- Plastic . They are used mainly when installing suspended ceilings. Made from polymers that are resistant to operational loads.

- Metal stamped . This category includes mass market steel products and heavy-duty industrial products. For installation of metal frames and supporting structures, clamps with anti-corrosion galvanized or galvanic coating are used. Forged steel clamps are more reliable, but more expensive.

- Wooden. Designed for gluing parts made of soft and brittle materials. Made from hardwood.

- Cast aluminum. Lightweight and corrosion resistant, but not intended for heavy use.

These are the main materials available on the market.

To save money, Chinese manufacturers can use more brittle metal alloys. That is why it is better not to choose products from unknown brands.

Device and principle of operation

The design of the universal clamp resembles the mechanism with which an ordinary manual meat grinder is attached to the table. The materials used to create this type of clamp are wood and metal, and in more modern versions – durable plastic.

The clamp frame has the shape of a monolithic frame in the shape of the letter “P”. Clamps are attached to it on one side. In the Soviet version, this is a screw for fastening, on the reverse side of which there is a flat and large-diameter coin.

Reliable fastening is ensured by the fact that when turning it, additional pressure is created. If you place several objects or spare parts between it and the frame, and then tighten the screw tightly, the parts will lock together. Depending on the angle of the frame and other design features, the following types of clamps are distinguished:

- Corpus. The parts are pressed by the housing elements. It consists of iron bars, the connection of which is ensured by a strong strip.

- Screw. The tool, which is presented in the form of two options - case and in the form of the letter G. Products made of forged tool steel are widespread.

- Magnetic. Used for welding work.

- Equipped with a ratchet. In appearance they look like large clothespins; the main clamping occurs with the help of human effort. The ratcheting mechanism prevents the jaws from opening.

- Trigger. They are shaped like the letter F.

- Hydraulic. Instead of the classic screw mechanism, a device vaguely reminiscent of a jack is used as a clamping mechanism. A nickel is also installed on the rod.

- Vacuum. They consist of a frame and two suction cups, which are installed next to each other in parallel. Clamping is carried out using built-in hand pumps.

Each type of clamp is used in separate cases - when the parts are very small in size or they need to be securely fastened in one plane next to each other.

Design Features

The mounting clamp consists of three main parts: a body, a screw and a special support pad. Moreover, the body of this device has a G-shaped design and is made of high-strength carbon steel. A screw drive or simply a screw provides a significant contact load, which is necessary for reliable fixation of the tool in the clamp. All work and actions for clamping parts are carried out manually, that is, using human physical strength. Due to the fact that this tool does not have an electric motor in its design, it is one of the most reliable and durable.

Selection of clamps

The choice of a high-quality clamp and its variety directly depends on what tasks it will solve. You should pay attention to such parameters as:

- weight;

- clamping force;

- functionality;

- material of manufacture;

- the presence of corrosion protection;

- additional accessories.

In addition to devices that can be used to firmly compress parts, there are often models on sale that can also work as a spacer. To “switch” the tool, you need to rotate the jaws 180 degrees.

The clamping force is affected by the clamping mechanism. To fix steel, a more powerful clamp is required, while for wood, a lighter version is suitable. Additional accessories include a T-handle that helps you adjust the clamping force.

It is not possible to glue and process some parts without clamps. Therefore, it is recommended to have several types of clamps in your arsenal.

What are there

Clamps are classified into several types according to their design features.

F-shaped clamp TOPEX 12A102

F-shaped

The tool consists of an axial plate on which jaws are mounted. One of them is stationary, the other is capable of moving along the tire. A clamping screw with a handle is installed on the movable element. The handle can be made of wood, plastic or metal.

Advantages of the design: versatility, strong fixation, ability to fix parts of different thicknesses.

Cons: working with this type of clamp is not always convenient; both hands are involved in the process.

G-clamp Wilton 540A series 50 mm 22001EU

G-shaped

The axial plate, lower and upper jaws form a one-piece structure. The pressure screw is installed on the lower jaw. Externally, the design resembles a bracket.

Pros: no backlash, ease of use, light weight.

Cons: limited range of thickness of processed workpieces.

Corner quick-release clamp CALIBR 96403

Best G Clamps

They got their name due to their similar shape, which is optimal for grasping volumetric parts made of metal and wood. One part is constantly stationary, and the second moves along the threads on the shaft.

Used in carpentry and plumbing. When choosing, pay attention to the strength of the frame and the width of the jaws.

MASTER MATRIX 20604 100x100x190 mm - for thick beams

This is the best clamp in carpentry for grasping thick beams, because the clamp has a frame depth of up to 100 mm, and the clamping screw is retracted to the same depth.

The end of both jaws is equipped with plastic pads that are gentle on the wood and leave virtually no marks on it.

Pros:

- the large thread on the screw prevents the clamping element from slipping;

- powder coating of frame;

- weight 900 grams is convenient for transporting the tool with you to the place of work;

- limiters at the end of the drive;

- casting with reinforcement ribs at the corners of the structure;

- all steel body;

- long service life.

Minuses:

- cost from 520 rubles;

- plastic linings are often lost because they hold weakly.

FIT 59201 G 25 mm - for small metal work

This is the best G-shaped clamp for clamping small metal plates before drilling or welding.

The clamp width is 25 mm, and the compact dimensions of 65x35x8 mm will allow you to carry the device even in your pocket and always have it at hand. The body is powder coated, which will protect against corrosion for a long time.

READ How to choose a wood lathe

Pros:

- cost from 97 rubles;

- Light weight 60 grams, convenient to carry in your pocket;

- along the entire length of the body, stiffening ribs are poured along the edges, increasing the strength of the frame;

- tool steel construction;

- fine threads provide ample opportunity to adjust the clamping force.

Minuses:

- the rotation handle is very thin and can bend;

- At the end of the clamping screw there is no nickel with an independent axis, which leads to displacement of the clamp at the last stage of tightening, and also leaves marks on the workpiece.

Corner

The design ensures clamping of the workpiece at a strictly right angle. The components of the device are: body, screw clamps (1 or 2), clamping heels.

Pros: simple device, compact, can be attached to a workbench.

Cons: not suitable for processing large parts.

Edge (end) clamp COBALT 248-863

End clamp

Clamping device: forged/cast element equipped with three heel screws. Distinctive features:

- Field of application: furniture manufacturing (gluing overlays, finishing edges).

- Tight fastening of wooden products.

- The downside is that holding the base and tightening all the screws at the same time is inconvenient when working alone.

- The mounting clamp consists of a steel body with a screw. It is used to secure pipes and forming modules when lifting to a height. It completely depends on the manual strength of the master.

T-clamp

The clamping device is a supporting “T” shaped body (approximately 1 m in length). It has movable lips. The fixation force is created by a screw connected to one lip. Distinctive features:

- Scope of application: installation of window openings, furniture assembly, fastening of sectional parts, products of any thickness.

- Used as a press, which requires additional rigidity with increased force.

- Well suited for processing simple and complex elements.

- Wood clamps hold parts of any thickness.

Band clamp

Clamping device: leather or nylon belt and locking mechanism. Distinctive features:

- The pressure is distributed equally over the entire area of the parts.

- Careful fixation of corners without distortion.

- When wrapping massive devices, a clamp helps to tighten all of their parts.

- Lowest risk of product deformation.

- The tool reliably fixes wood blanks and their derivatives for further processing (wooden tables and chairs, frames, barrels).

- A furniture clamp helps to clamp the elements so that they can be drilled at once.

Pipe clamp

Clamping device: pipe and two lips. One lip moves along the guide, and the second is stationary. Pipe clamps on both sides are used for alignment and fixation. Distinctive features:

- The strong thread of the tightening screw with a large pitch facilitates fast clamping of the workpiece.

- This clamp helps glue panels together and secure large items while providing strong compression.

- At any time, the pipe can be disassembled or connected to a product of a different size.

- A pipe clamp is a must-have tool for any type of welding.

Spring clamps

Design features. Clamps with unregulated clamping force, working on the principle of clothespins. A popular variation of the classic spring clamp are designs with variable clamping width.

Advantages . The clamps are lightweight and convenient; all manipulations when working with them are performed with one hand. They provide a stable, powerful clamping force. Optimal for delicate fixation of glued parts.

Flaws . Small grip depth.

Application area . A universal device for gluing and fixing oversized parts.

Quick-release (automatic) clamps

Design features . The typical design of a quick-release clamp consists of a metal tire and two plastic jaws (movable and fixed). The moving part is pressed using a special lever mechanism. The lightweight and durable body of quick-release clamps is made of glass fiber reinforced plastic composites. This allows automatic clamping to be used in almost any environment.

Advantages. One-handed options are perhaps the most convenient and ergonomic type of clamps. How to use such clamps is intuitive: all manipulations are performed with one hand, while the other holds the part. Even the smallest quick-release clamps have enormous clamping force.

Most lever models have a transformable design that expands the capabilities of the tool. For example, on some models you can turn the jaws in opposite directions to work sideways, which is very convenient when disassembling tenon joints. Two quick-release clamps can be easily re-arranged into one long one by interlocking the protrusions on the fixed jaws.

Flaws . High-quality automatic clamps are quite expensive, and almost all budget analogues are not highly reliable.

Application area .

Quick-release clamps are used for all types of carpentry work: from fixing small parts to gluing large panels.

Gross 20717

The model is the best clamp among compact quick-clamping analogues. The best option for those who need to get into places that cannot be reached with a large tool. Despite its compact dimensions, it is capable of grasping up to 100 mm of clamping width.

Clamp Gross 20717 from the middle price range Source onlinetrade.ru

To manufacture the guide bar, the manufacturer used cold-drawn steel, which makes it particularly accurate in size. The pressing function is assigned to the Vibrafix locking mechanism. Thanks to it, the clamp provides a clamping force of 1,200 N. Fast clamping is achieved due to competent ergonomics and the layout of the handle.

Protection of the surface of the pressed workpieces is achieved thanks to rubber pads on the jaws. They can be removed to work with metal products.

Price range for the model in construction stores: 1,750 – 1,950 rubles.

Carpentry clamps - general description

Carpentry clamps are made from wood and metal.

Having installed such a device on the surface, you can work with both hands. The simplest manual clamp consists of a main frame and moving elements , which are equipped with clamps in the form of screws or levers. They not only fix the moving part, but also regulate the compression force.

There are lever devices that are based on both axle and lever systems. They are most often called clamps or clamps. With their help you can quickly fix the workpiece. All you need to do is apply a little force to move the handle, and a decent clamping force will be created instantly.

Types of metalwork and carpentry clamps

Clamp models differ in mechanisms, therefore they are divided into the following classes:

- corner;

- installation;

- screw;

- manual;

- quick-clamping

When choosing such a device, you need to pay attention to the distance to which the clamps are moved apart and to the working stroke. The most practical are the clamps that have the highest indicators listed above. With their help you can work with large-sized products (from 20 to 350 mm).

What does it consist of and why is a carpentry clamp needed?

A carpenter's clamp is an auxiliary tool that provides reliable fixation of workpieces when processing them.

The standard design consists of a frame and a clamping mechanism. As you move the clamp, the spacing between frames increases or decreases. The fixing force is adjusted using a screw or lever.

Modern models are made of durable material. The tool must meet the following requirements: convenience, reliability, durability.

Lever devices operate under the influence of the handle. When it moves, a decent clamping force is created. Having immobilized the workpiece, they begin to process the part.

Scope of application:

- welding work;

- joinery;

- sharpening of blanks;

- grinding the surface of parts;

- making holes or notches, etc.

Hull modifications

They are also called beam clamps. The force of the device can be used to fasten the elements being processed at parallel and oblique levels. The name of the instrument comes from the fact that the main action is performed by parts of the body (beams). The device is a pair of rectangular bars, which are connected to each other using a reinforced strip at one end. This is a very useful tool.

The working element is statically attached to the bar, the second is equipped with a tightening screw and moves freely. The reverse part of the bars is the pressing jaws. To hold the part, you should bring the metal beams all the way to the part, and then tighten the screw element using the provided handle. This variety is the most popular.

The principle of operation of the clamp

For high-quality processing of products made from various materials, all parts must be tightly secured. In such a situation, a clamp helps out; it’s worth finding out how the device works. The components are attached to the base, clamped with screws and the required actions are performed with them. Modern models allow you to work, freeing the master’s hands and fixing the workpieces in any convenient position. The screw clamp helps to set the required clamping force without damaging the workpiece and protects against spontaneous release.

READ Where is a file used?

Manufacturers of clamps

One of the important criteria for choosing tools is the reputation of the manufacturer. We have selected brands whose products you can trust:

- Gross is a manufacturer that is part of the Russian concern “World of Instrument”. Offers high-tech products made at a professional level. The company's catalog has a large selection of carpentry, plumbing, measuring and other tools.

- Zubr is a company that appeared only in 2005, but has already established itself thanks to its high-quality, reliable products. The brand's equipment can be trusted with the most complex tasks.

- Kraftool is a German manufacturer of professional construction tools for various tasks. The company's products are famous for their ergonomics, stylish design, and durability.

- Fit or Finch Industrial Tools is a Canadian company that produces hand and power tools for professional or home use. The brand was born in 1996, today it is one of the largest players in the global market.

- Stanley is a brand known since 1843. The American manufacturer quickly gained recognition due to the high quality of its products. This logo sells reliable manual or electric construction equipment made from durable materials, which are distinguished by well-thought-out ergonomics and high performance.

- Cobalt is a Russian brand that makes assembly and plumbing equipment. The company follows three main principles: reliability, ergonomics, optimal price.

- Matrix is a German manufacturer whose product range includes more than 3,000 items. Here you can find everything from fasteners to plumbing equipment or automotive tools.

- Sparta - produces accessories for home or car repairs. They are known for their low prices and are in demand among thrifty buyers who do not often resort to construction work.

- Santool is a company that has been selling hand-held construction tools since 2004. The main advantage of its products is a reasonable combination of price and quality. The brand's products are intended for personal use, but are also in demand in small workshops.

- Sibrtech is a brand that makes a simple, reliable, inexpensive tool. The name combines two words – Siberia and Technology. Laconic design and the absence of unnecessary bells and whistles are the main differences between the brand’s products. Sibrtech products are designed to help with home or car repairs.

Methods of fastening clamps

This type of fastener is used in the installation of engineering systems, air ducts, exhaust and climate control systems. When it is not possible to secure a separate part of an engineering structure to load-bearing walls or ceilings, steel beams or metal corners are used. For fastening to such structures, mounting clamps are used. This type of fastener allows you to secure various parts of air ducts or other engineering systems without the use of welding. Also, clamps reduce installation time by 40%, compared to installation in which brackets are used. Clamps are installed directly on steel structures, and installing brackets requires time spent drilling holes.

How to use?

The use of clamps does not raise any special questions. Regardless of the type of structure, they are used to clamp parts or objects, materials in a given position. It is enough to place the object between the jaws and then fix it.

Quick-release clamps operate similar to a pistol with a trigger. It is enough to use the lever, and the jaws will close with the required force. Their convenience lies in the fact that you can do all the work with one hand. Pincer clamps have the same lever principle, but the compression force is regulated by a spring element. Working with them is reminiscent of using pruning shears - this is not the easiest or most comfortable tool.

End clamps are distinguished by the fact that they have a spacer not only on the sides, but also in the center; the clamping force is created at 3 points. First you need to clamp the material itself between the jaws, and then use the third pad. This tool is mainly used for gluing decorative end edges.

matrix 20562

Our TOP clamp continues with matrix 20562, which has a quick-release trigger design and is designed for a width of up to 200 mm.

The clamp tire is made of steel, and the jaws and handle are made of impact-resistant plastic, which ensures high reliability.

The support jaw moves and is fixed along the entire length of the guide. And the ergonomic handle ensures comfortable use of the tool with one hand. In addition, the clamp jaws have rubber linings, which will protect the pressed workpieces from damage. Also, it is worth noting that one of the jaws can be moved to the other end of the guide, which allows you to use the clamp “unclamping”.

Most buyers like this clamp for its affordable price. At the same time, many note that she does not have the most reliable grip. Otherwise, for carpentry work at home or in the country, where you need to clamp several slats or boards, it will do. Well, for fixing metal workpieces, I would consider another model.

- Type: F-shaped.

- Clamp width: 200 mm.

- Clamping depth: 45 mm.

- Weight: 200 g.

Buying tips

To buy a carpenter's clamp, in general, you do not need a lot of knowledge or buying secrets. It is enough just to carefully inspect the tool, make sure that their pressing surfaces are in close contact with each other, and also that these surfaces have a smooth and even structure. Rotary screws, threads and handles must be of high quality and free from any defects - chips or cracks.

In order to avoid dents that may remain on the workpieces after work, it is necessary to use special plastic or rubber gaskets. Therefore, when purchasing, make sure that they are included in the kit.

The main thing is that the gaskets are made of a material that is softer than the part being clamped. And, of course, when purchasing, pay attention to the working stroke of the clamps, which can range from 20 to 250 mm. It is selected depending on how and where you will use the additional tool.

Thus, now you know what types of carpentry clamps exist and what to look for when purchasing them.

Purpose

A clamp is a lightweight auxiliary tool that helps secure several parts both to each other and to another surface. During work, it is often necessary that workpieces and other parts be securely fastened in one position. This device is widely used in welding and carpentry.

The design of the clamp is very simple; it consists of only two parts - a frame and a clamp. A high level of rigidity is achieved precisely due to the strength of the frame, and the clamping mechanism carries the main functionality and secures the parts.

Locksmith machines have a similar principle of operation, which can also be used to perform gluing. But it is more correct according to GOST and more convenient to do this with clamps.