Today, individual water meters are installed in almost every house or apartment. This article describes in detail the design and operating principles of water meters.

Classification of water flow meters:

- mechanical water meter;

- electromagnetic flow sensor;

- ultrasonic flow meter;

- vortex water meter.

Mechanical (tachometer) meters have become widespread for measuring water flow in water supply systems of residential apartments. How the device works and the principle of its operation are described in detail in this article.

Operating principle and how a tachometer water meter works

Let's look at how a tachometer water meter works. The driving force in this flow meter is the tachometer - a mechanism that, when in contact with liquid, sets the rotating part of the measuring device in motion.

The principle of operation of such a water meter is extremely simple: the passing flow rotates the impeller, and through a magnetic coupling the rotation is transmitted to a system of plastic gears, which set the hands and numbers on the dial in motion.

The upper part of the flowmeter has no contact with the liquid, as it is protected by a sealed partition. This type of device is called a dry water meter.

Selection rules

When deciding which water meter is best to choose, you need to proceed from the following number of factors:

- Technical requirements.

The water meter must first of all meet a given set of operating parameters for a particular water supply system:

- Temperature.

- Pipe diameter.

- Body length.

- System pressure.

- Allowable flow limit.

- Error.

- Integrity of the package.

- Price.

One of the important selection criteria for most consumers. More expensive models, as a rule, have the same set of characteristics as cheaper ones. Therefore, there is no point in overpaying just for the prestige of the manufacturer.

A water meter quickly pays for itself Source stroyday.ru

- Reliability. The build quality must allow the device to be used for the entire service life declared by the manufacturer without unexpected accidents.

- Factory warranty.

- Period between checks.

- Compliance with operating conditions. The device must be designed for low water quality, the presence of particles in the water mass and other factors characteristic of domestic water supply systems.

Recommendation! A correct idea of how to choose a water meter comes from knowledge of its material. It is better not to deal with devices with a silumin body. Models made of brass or bronze are quite reliable. Water meters in constant contact with water exhibit maximum durability if made of stainless steel. Reliable electronic analogues are produced in a polymer shell.

What are the types of mechanical metering devices?

By design, mechanical liquid flow meters are:

- Single-jet - water passes through the impeller in one place. These meters are suitable for pipes with a diameter of up to 25 mm inclusive. Due to the turbulence that occurs with strong pressure, such a meter begins to show incorrect flow.

- Multi-jet - the water flow is divided into several parts to reduce turbulence.

According to the type of rotating mechanism, water meters are:

- The impact of water flow on the impeller causes the elements of the device to rotate. The devices are used in apartments on pipelines whose diameter is less than 25 mm.

- The mechanism of the water meter measuring device is to rotate the turbine by the movement of the liquid. The turbine design allows for more accurate measurements at high flow rates or pipeline diameters greater than 25 mm.

- Combined flow meter. If the pressure in the system is low, water passes through the impeller. If the pressure increases, the flow is transmitted to the turbine mechanism, at the same time the entrance to the impeller is closed by a special valve. Due to the complex design, the cost of such measuring devices is much higher, however, the accuracy of the readings is greater than that of the first and second devices equipped with the same mechanism.

Meters for hot and cold water supply

Hot and cold water flow meters differ from each other in the materials used in the manufacture of moving parts of the structure. Device parts are capable of operating at different temperatures. The cold water flow sensor can be used at temperatures not exceeding forty degrees. The hot water meter can operate at temperatures up to one hundred and fifty degrees.

Water meter design: principle of operation 2021

Today, a water meter is installed in almost every house or apartment. All devices are varied, but how can you choose the most economical, convenient and accurate from the numerous assortment? After all, the operating principle of each water meter is different. Mechanical water meters are considered the most reliable, easiest to operate and affordable. Let's consider how the devices differ from each other, their operating principle and scope of application?

Water meters differ in operating principles

When purchasing a water meter, you need to know the general characteristics of the device. This product is presented quite widely in stores, so purchasing may be difficult. Liquid metering devices can be mechanical, electromagnetic, ultrasonic and vortex. All of the listed meters can be volatile (operate from the network) or autonomous, where the work is performed by a built-in battery.

Water meter device

Meters for hot and cold water differ from each other in the materials used in the manufacture of certain parts of the structure. Spare parts that come into contact with warm and cold substances are capable of operating at different temperatures. When in contact with cold liquid, the water meter operates in a mode not exceeding forty degrees Celsius; with hot water, the indicative figures increase to one hundred and fifty degrees.

This design option is practical, reliable and popular among consumers. It is not connected to the power grid, is easy to maintain, and has different pricing options. Let's look at the water meter device in more detail. The main functional part of the device is the tachometer. Therefore, very often this type is called tachometer.

The tachometer is a mechanism that, when in contact with a liquid, influences the impeller or turbine.

It rotates and, using a gearbox, numerical data is transmitted to the screen device. It is in this way that the indicators of the water used are reflected on the dial.

The mechanical device can be single-jet, multi-jet or turbine. The operating principle of a single-jet and multi-jet element is that the water pressure is directed towards the impeller (perpendicular). Next, the lower part of the blade is affected. Despite the fact that the mechanical counter is the most popular, it has a number of disadvantages:

- the device shows perfect accuracy only with low water consumption in a narrow flow range;

- moving elements contribute to a short service life;

- the device is equipped with high hydraulic resistance;

- does not reflect current fluid consumption.

This water meter device is mostly used in private sectors where an emergency power supply system is equipped. This is due to the energy dependence of the device.

Electromagnetic water meter ensures accurate readings

The main advantage of an electromagnetic water meter is the accuracy of the readings, which are based on the overall speed and area of the substance flow. The operation of the device does not depend on the temperature, density and viscosity of water. The consumer chooses an electromagnetic installation in order to save money, without fear of inaccurate readings. How does an electromagnetic water meter work? The composition of the passed water includes various impurities that can change the performance of the device.

But there are also disadvantages to the operation of this unit, namely: the readings may be distorted due to the sediment contained in the liquid, but crystal clear liquid is not an ideal option. It can completely damage the structure.

These structures are installed in enterprises, industrial areas, large households, hotels, and sanatoriums. Installation of these devices in residential areas is absolutely unprofitable. Since the cost of meters is quite high. Let's consider the operating principle and characteristics of each water meter separately.

The ultrasonic design is equipped with four elements (flow metering zone, calculator and two pulse transmitters). They all generate and control ultrasound. The computational module part analyzes the received data. The device is capable of comparing the period of sound divergence along and against the flow of liquid. The consumption of the substance is measured with precise accuracy. But the pipe must be clean, free of scale and debris. Otherwise, errors in accuracy may be observed.

The service life ranges from ten to fifteen years.

How does a vortex counter work? The device is equipped with a special geometric element and a pressure sensor, which converts numbers using a computing module. The device operates on the principle of a vortex road. This type of meter functions stably. The only condition for excellent performance is clean water. There should be no impurities or abrasive particles in the liquid. The service life of the structure is no more than eight years.

Having understood the characteristics of each water meter individually, you can easily choose the device that is right for you!

The annual increase in prices for utilities forces residents of the country to save; for this purpose, meters are installed for heat, gas and water. Thanks to installed water meters, owners pay exclusively for the resource consumed.

Water meters are installed to measure the amount of water passing through a pipeline. There is also a flow meter that measures water consumption over a certain period of time.

After installation, a seal is installed on the water meter

Water meters can be installed in a private or multi-storey building, in a large enterprise or in a small office.

Mechanical water meters are non-volatile models and are divided into cold (up to 40 degrees) or hot (130 degrees) water meters.

Types of counters:

- Single jet. Such dry-run meters measure the number of revolutions of the impeller, which rotates under the influence of water flow. Using magnetic couplings, the rotation data of the device blades is transmitted to the reading device. The design of the mechanical counter is protected from external magnetic fields. Water meters can be equipped with a pulse output, which allows readings to be read remotely.

- Multi-jet. The main difference from single-jet ones is that the water flow is divided into jets before being fed to the impeller. Thus, the reading error is reduced. Installing a water meter is quite simple, and to check it you only need to remove the top part of the device. For remote data transmission, the meters can also be equipped with a pulse output.

- Valve. The principle of operation of this water meter is no different from those described above, but the design of the device provides for the installation of a special valve that can turn off the water. The upper part of the water flow meter with the reading panel can be rotated around its axis for easy reading of water consumption.

- Turbine. Meters for measuring the flow of hot or cold water, which are installed on a pipe of 5 cm in diameter. They are mounted at the entrances of water supply systems of industrial companies, high-rise buildings and for water supply systems.

You can also highlight electromagnetic water meters, which are used primarily to measure the amount of water in the food and chemical industries; they are not used to account for water in an apartment. Ultrasonic meters are installed in industrial enterprises.

This is interesting: Passport for a water meter: how to restore if lost 2021

The principle of operation of water meters is based on counting the number of rotations of the impeller under the pressure of water, which is located inside the structure. The element of mechanical meters, which is responsible for counting the flow of cold or hot water, is isolated from the flow in the pipeline.

Depending on the location of use of the device and the power of the water supply system, meters can be divided into individual and industrial.

In apartment buildings and country houses, as a rule, dry-running water meters are used, the mechanism of which does not come into direct contact with water. Wet water meters have a simpler design, but are short-lived - the mechanism is not protected from various impurities and contaminants contained in tap water.

Hot water is metered using similar devices, but made from more durable materials that are resistant to temperature changes.

According to GOST, the minimum service life of water meters is 12 years of continuous use.

To understand the principle of operation of a water meter, you need to know how it works. The design of mechanical water meters resembles a water mill - the flow of water drives the impeller, which, in turn, starts the gearbox mechanism. The mechanism itself acts on the rollers of the mechanical scoreboard with indicator numbers.

The indicator board displays the flow of water passing through the scaling mechanical gearbox in cubic meter units.

The red rollers display the percentage of cubic meters used in the water supply system.

From time to time, the meter should be given to specialists from the relevant authorities for verification.

The connection between the impeller and the data reading mechanism is carried out through magnetic contact through a sealed film.

To ensure that the measuring device is reliable and durable, the supporting elements of the impeller and reading mechanism are equipped with solid axes.

Some models are equipped with turbines instead of impellers, which makes it possible to obtain more accurate measurements of strong water flow. In turn, turbine devices do not work well at low flow rates.

Turbine water meters are installed on water supply pipes from DN 50 and above, while for vane devices a diameter of up to 50 DN is suitable.

The service life of water meters largely depends on the quality of the water in the pipeline, so they periodically break down. Buying a new device means additional expenses, so to save your budget, you can do the repair yourself.

All water meters - hot or cold - are registered with the water supply organization, so each device is sealed with a special chip, which must be removed with the permission of the organization before disassembling the meter.

Before dismantling the meter, you need to study its structure and consider the problems that may arise.

What problems you may encounter:

- The body of the water meter cracked and began to leak;

- The reading mechanism does not work correctly - during normal use of water, the readings do not correspond to the flow rate;

- The readings on the scoreboard with a counting mechanism do not change or decrease;

It is forbidden to remove the meter yourself

To repair the meter, you do not need to take the device for repair; it can be done at home yourself. Disassembly of the device is possible after shutting off the water that enters the apartment. Then you need to open the water tap so that the remaining water in the system goes down the drain. By unscrewing the union nuts, you can remove the device.

If the cause of the breakdown is a clogged mechanism, sometimes it is enough to blow the device through the inlet. If the water meter does not start working, you need to rinse it under a strong stream of water, which will remove the blockage from the impeller.

In the case where washing does not help, you will have to disassemble the meter into parts. To do this, you first need to remove the transparent plastic case, then dismantle the parts that make it up: the display with numbers, the counting mechanism and the impeller. Having found out the cause of the breakdown, you can replace the worn parts with new ones.

Upon completion of the repair, the water meter must be assembled and installed in place. After checking the device for functionality, you can call an employee of the water supply organization to seal the meter.

Human water consumption differs from the generally accepted standards that the organization sets when paying for utilities. To save the family budget, it is advisable to install water meters. Household water meters are easy to install and use, and if necessary, they can be easily disassembled for self-repair.

Modern amenities of civilization, including water supply, greatly simplify life and make it more comfortable. But you have to pay for all the pleasures, and the services of public utilities are becoming more and more expensive, so sooner or later the thought of installing a water meter comes to mind. Of course, only if water consumption is below the standard standards by which payments in housing and communal services are calculated. But before you buy a water meter, you need to know the design of a water meter - the information will be useful not only when selecting a device, but also in determining its necessity for a house, a country mansion, or even a cottage, if the buildings are connected to a central water supply.

A water meter is a design that measures the volume of flow passing through a water pipe per unit of time. Measurements are calculated in m3. Using the device, the user can see exactly how much cold or hot water is consumed within an hour, day or month and, accordingly, pay only for the volume consumed. As a rule, such savings are at least 40%.

You can install a water meter yourself or seek professional help. But even if you do the work yourself, calling a sealing inspector is necessary, and even if the installation was carried out by specialists, there will be someone to file a claim if the meter does not work.

As for the advantages, they become obvious immediately after installation:

- No extra charges to pay;

- Ability to control water consumption.

- Purchasing a device of poor quality risks adding extra cubic meters;

- A broken seal is the reason for replacing the meter, and this means additional costs for installing a new one, as well as payment at the average tariff for the entire period of absence of the meter.

Despite the cost involved in purchasing and installing a water meter, the period of use will significantly recoup the financial investment. It is only important to remember that in addition to the water meter, filter units are needed - they extend the service life, as well as working taps.

The first meters for cold and hot water were used in Germany already in 1958. It was a vane water meter, the operating principle of which was based on the movement of a counting gear mechanism, reproducing the number of revolutions of the impeller on the dial. Modern water meters are divided into:

- Tachometer - the operating principle of which is based on counting the number of rotations of the wing element. The impeller is contained inside and rotates from the flow of water, while in the part protected from flows there is a device responsible for the accuracy of the readings.

- Vortex - a design whose functionality lies in the fact that the water supply system creates vortices, the frequency of which is proportional to the speed of fluid flow. This is what equipment calculations are based on.

- Magnetic, where the magnetic field is induced at a speed proportional to the strength of the incoming flux.

- Ultrasonic. The device measures water flow by analyzing the acoustic effect of ultrasonic vibrations that occur as liquid flows through the water meter.

This is interesting: Is it worth installing water meters: advice and opinions 2021

Thus, there is one or another difference in the operating principle of each water meter. In addition to functional features, there are differences in classification.

The classification according to the principle of operation is known, then the devices are divided according to the number of pipelines that can serve:

- Single channel;

- Two-channel;

- Multichannel.

The design for metering the flow of hot and cold water can be separate and compact, powered from an external power supply or be non-volatile. In some cases, there are meters whose power is supplied by devices in the form of conventional batteries. There are mechanical devices for metering cold (up to +40) and hot (+40+150) water. However, the differences lie in the use of materials for the manufacture of the impeller and bearings. Mechanical water meters operate only from the flow of incoming water, and the accuracy of the readings is very high. The devices have one drawback - in the case of low pressure, the operation of the equipment may be slow or completely stopped.

There is also a difference in placement:

- Dry meters are devices where the counting mechanism is separated from the flow by a partition, which extends the service life and allows you to hope for the accuracy of the readings. In this case, the design can have either a wing or vortex operating principle. The service life of water meters is quite long, the price is affordable. Equipment of this type is popular and the range includes devices for hot and cold water.

- Wet water meters are devices where the counting mechanism is not separated from the flows, and therefore often fails when water enters with inclusions and contaminants. Ease of installation and affordable price are advantages, but possible errors in readings are disadvantages. The operating principle of such a device is mechanical, when the impeller rotates from incoming water.

Important! To extend the life of a wet water meter, it is necessary to install a filter mesh, preferably two: for coarse and fine cleaning. Streams cleared of inclusions will not have a destructive effect on the counting mechanism, and it will last much longer.

Single-jet water meters are indicated for installation on pipelines with a cross-section of no more than 25 mm; they are available for both hot and cold water and operate from the influence of a single flow on the impeller mechanism.

Now that the functionality of water meters, as well as their varieties, is known, all that remains is to choose the necessary equipment for installation on a hot or cold water pipeline or buy a universal device, choosing the best manufacturer and an affordable price.

Water meters have become as familiar to us as electric meters. But if the task of accounting for electricity does not present any particular difficulty, then with water everything is completely different.

This explains such a wide variety of instruments for measuring it: trying to come up with the most accurate method of measurement, engineers are coming up with new designs.

In this article we will study the design of a water meter and evaluate the advantages and disadvantages of each type of these devices.

The vast majority of water meters are purchased today by subscribers of centralized water supply networks.

The devices used to measure water - cold and hot - differ from each other.

The first ones are designed for an ambient temperature of no higher than +40 degrees, are cheaper and are marked in blue.

The latter operate at temperatures up to +150 degrees and are more expensive due to the use of special heat-resistant materials. Marking color is red. Today, models are produced in which both types of meters are combined in one housing. This device costs less than two separate ones.

Today, a system for remote control of water consumption is being actively implemented. Its operation requires meters equipped with a transmitting module, a kind of analogue of a computer network card. After connecting such a device to the network, data from it is sent to the settlement center automatically. Pulse and digital modules transmit data over a cable network, while radio frequency modules operate wirelessly.

Hot water meters with a pulse module are used not only as independent equipment, but also as a component of meters for heat supply systems.

About meters equipped with a transmitting module, it is customary to say: a meter with such and such an output.

For example, a meter with a radio output. These meters can also be called flow sensors or flow converters.

An integral component of any water meter - a section of pipe through which the medium flows - is usually called the flow meter section.

You can study the history of physics using water meters. As soon as a new discovery is made in this science, engineers immediately try to adapt it to calculate water consumption. Let us list the types of water meters that exist today.

Many people buy water meters without thinking about the characteristics of the device. However, flow meters are different. Water meters: we’ll tell you in this article how to choose the optimal model.

See the comparative characteristics of acrylic and steel bathtubs here.

And in this topic https://aquacomm.ru/cancliz/mnogokvartirnyie-doma/santehnika/oplombirovat-schetchiki-na-vodu.html we will explain how and where you need to seal water meters and whether you need to pay for this service.

The second name is mechanical. The design of these devices is extremely simple and resembles a water mill.

Here, too, there is a semblance of a rotating wheel - an impeller, only it drives not the millstones, but the gear mechanism, and that, in turn, drives the rollers of a mechanical display with printed numbers.

For significant water flows, the impeller does not provide the required accuracy, so a turbine is used instead.

Turbine water meters have a diameter of DN50 and above, and vane water meters have a diameter of less than DN50. The nuance is that the turbine also does not always give sufficiently accurate readings - its error becomes excessive precisely at low flow rates. What should users do if their water consumption varies widely? We came up with a solution: a combined meter, essentially consisting of two – a vane and a turbine. The water flow is redirected to one or the other automatically, depending on the speed.

This is interesting: Gas meter G6: features of a gas flow meter 2021

The accuracy of measurements is also affected by the nature of the flow of the medium: in the presence of turbulence, the error increases. This phenomenon is minimized in the so-called. multi-jet meters equipped with a flow separator. They are slightly larger than conventional ones (single-jet), but are more accurate.

Mechanical flow meters also differ in the design of the counting mechanism, which can be wet or dry. In the first case, the gearbox and display rollers are washed with water, and the impeller is directly attached to the gear or worm shaft. In the second, all the “filling”, except for the impeller, is located in a hermetically sealed box, and a magnetic coupling is used to transmit rotation. “Wet” meters are cheaper, but with a significant amount of mechanical impurities in the water they quickly fail. “Dry” solid contaminants are less afraid and allow you to dismantle the counting mechanism without turning off the water, but are somewhat more expensive.

Mechanical meters have a number of disadvantages:

- Acceptable accuracy is observed only over a narrow range of flow rates.

- They have a relatively short service life due to the presence of moving elements.

- High hydraulic resistance.

- The current water consumption is not displayed.

- A strainer must be installed in front of the device.

Nevertheless, it is these devices that have become the most in demand, at least in everyday life. There are several reasons:

- mechanical meters do not require an electrical connection;

- simple maintenance;

- low cost.

All other types of meters, which will be described below, are volatile, that is, they require a source of electricity to operate. In addition, they are more expensive than mechanical ones. But they have important advantages:

- demonstrate high accuracy, both at low and high flow rates;

- due to the absence of moving elements, they are more reliable and durable than mechanical ones;

- characterized by low hydraulic resistance;

- can show current water consumption and store data archive.

Why can’t we limit ourselves to just one type of electronic meters? The fact is that each of them, as we will see later, has its own weaknesses.

In the flow-measuring section of such a device, two or four elements are installed that are capable of generating and capturing ultrasound.

The computing module analyzes the received data.

The disadvantage of an ultrasonic counter is the following: if there are a significant number of bubbles in the water, its accuracy drops significantly.

Such a device also has a computing unit, and the working part consists of inductive coils and a voltmeter. The pipe through which the medium flows is made of a dielectric material, usually polyethylene or fluoroplastic. The weakness of these meters is the high error during turbulence. In addition, they can quickly become clogged with metal particles held by the magnetic field.

A prerequisite for the operation of an electromagnetic meter is the electrical conductivity of the transported medium, therefore they cannot be used to calculate the consumption of substances such as alcohol or petroleum products.

These devices are also called superstatic. This time, a piezoelectric frequency sensor is responsible for counting liters and cubic meters, and the pipe is divided into three channels and equipped with a flow shaper. The device is afraid of solid impurities, so it is advisable to install a mesh filter in front of it.

Inside the pipe of this flow meter there is an element with a special geometry and a pressure sensor.

The latter's readings are converted into digital data by the computing module.

Due to the susceptibility of the streamlined element to abrasive wear, they have the same short service life as mechanical ones - from 8 to 12 years (other types can last up to 25 years).

If everything is clear with mechanical counters, then the operating principle of other types should be explained:

- Ultrasonic: sensors installed at the beginning and end of the flow-measuring section operate alternately in generator and receiver modes, “driving” ultrasound either in the direction of the associated water flow or in the opposite direction. The water flow is determined by the computing module based on the difference in time required for the oscillations to overcome the area between the sensors in the forward and reverse directions.

- Electromagnetic: the operating principle of devices of this type is based on the phenomenon of electromagnetic induction. In a conductor moving in a constant magnetic field, a force (electromotive) arises, the magnitude of which depends on the speed of movement of the conductor. In this case, the role of a conductor is played by the flow of water, and the magnetic field is generated by inductance coils.

- Resonant: the meter is designed so that part of the flow returns to the beginning of the flow meter section, either through one or another additional channel. The frequency of channel changes (it is recorded by a piezoelectric sensor) depends on the flow rate, and therefore on the flow rate.

- Vortex: due to the special shape of the element located inside the meter, the flow of water around it forms vortices, accompanied by pressure drops.

Based on the frequency of these changes, the computing module determines the flow rate and flow rate.

When purchasing a water meter, the following parameters should be taken into account:

- Connecting diameter or nominal diameter (DN or DN).

- Maximum permissible pressure in the system (PN or PN). Specified in atmospheres or bars (both units are identical).

- Maximum flow (Qmax): the maximum permissible supply of medium that the meter can withstand for a short time (no more than an hour per day and 200 hours per year), maintaining the accuracy of readings within the required limits.

- Nominal flow Qn: the maximum flow with which the meter is capable of operating in continuous mode.

- Transition flow Qt: the limit after which the accuracy of the device readings changes.

The minimum flow rate Qmin is also important - the smallest flow at which the meter readings remain fairly accurate.

Installing a water meter is a fairly simple procedure, so it is not necessary to call a specialist when you can save a little. Installing water meters yourself - determining the installation location and putting the device into operation.

You will find everything about arranging a summer water supply at your dacha in this material.

»

Counters

Gas meter with thermal corrector: features of choosing a meter in 2021

Read more

Counters

Two-tariff meter: profitable or not? 2021

Read more

Counters

Until what date should water meter readings be reported in 2021?

Read more

Counters

How to check an electric meter for correct readings 2021

Read more

Counters

Which electricity meter is better to install in a private house? 2021

Read more

Great article 0

Mechanical meters of wet and dry type

Wet-type water meters are simpler in design, since the parts in them are not in any way isolated from the liquid flow. Such flow meters are inexpensive, but they cannot be used if the water is heavily polluted, since dirt particles can get into the moving mechanisms of the device and block them.

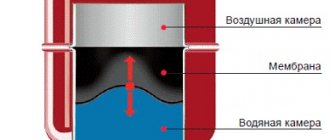

In dry meters, a system of plastic gears is hermetically protected from the measured liquid flow by a non-magnetic separating membrane. The transmission of rotation from the impeller or turbine to the dial is carried out through a magnetic coupling consisting of two magnets.

Doppler method

Counters operating using this method measure the difference in wavelength reflected from a moving stream relative to the wavelength of the emitted signal. Measuring the received and transmitted signals to determine the difference between them is done using wedge-shaped or pipe speed sensors installed at the bottom of the channel or pipe.

Water meters operating on the Doppler effect are used in pressure and gravity systems, fully and partially filled pipes, and open channels. They work in streams of varying degrees of pollution (except clean water). Doppler flow meters are used for commercial metering in pipelines and gravity canals, for measuring flows in rivers and canals of irrigation systems, in storm sewers, at pumping stations, water intake pipelines and discharge of wastewater into reservoirs.

Disassembling a mechanical device

Let's look at how to disassemble a water meter using the example of a dry flow meter. To disassemble the water meter, it must be disconnected from the pipeline and the seal removed. Next, disconnect the ring plastic housing holder.

After which you can remove the cover of the counting mechanism, which belongs to the “dry part” of the flow meter, which consists of plastic gears and a dial. If desired, this part of the measuring device can also be disassembled using a screwdriver.

To get to the impeller we need to unscrew the plastic or metal locking washer and remove the sealing gasket that separates the dry and wet parts of the measuring device. Under the cover we will see the impeller itself, which, if necessary, can be easily removed from the metal body of the meter.

Installation rules

So, let's move on to the main question - how to properly install a water meter. You need to start by contacting the water utility. There are certain laws that must be followed. As for private houses, today the meter must be installed outside the house. The reason is free access to it by representatives of the water supply organization. That is, so that they simply do not enter the house. And if the owners are absent, the inspector himself can take readings.

There are two situations related to the installation of a water meter:

- The house is just under construction.

- The house is in use and needs to be connected to an existing water supply.