When processing wood using power tools, the problem of accurate cutting often arises. Unfortunately, even modern disk models cannot boast of a perfectly executed job. This is due to the impossibility of proper control over the position of the cutting tool relative to the workpiece. To solve the problem of sawing accuracy, a plunge-cut circular saw was invented and put into production, which immediately gained popularity among woodworking craftsmen and became a sales leader.

Plunge circular saw device

These tools, designed for manual woodworking, have become available on the market in our country relatively recently. When the disk is inoperative, they are not visible, since they are hidden by a protective casing, located flush with the mounting base. This is required to accurately position the machine on the work surface.

In order to adjust the depth of cut , the design of the tool has a special mechanism. Using it, the specialist can release the rotating saw blade. The degree of overhang is set in advance, and the speed at which the disc lowers can be controlled manually. When the cut is formed, then, using the same mechanism, you can bring the cutting woodworking tool to its original state.

Plunge-type circular saws, depending on their design, may have the following features:

- spring loaded bottom base. Its presence makes it possible to adjust the degree of clamping of the saw part. If the workpiece contains foreign elements, such as nails, you can stop working in a timely manner;

- function of tilting the cutting part. It is necessary when it is necessary to produce wood products of complex configuration;

- number of disks (varies from 1 to 2). Using a tool with two disks, you can make boards of various widths, simultaneously making two cuts at once;

- additional devices. These include guide rulers, which can have different sizes and configurations.

To prevent clogging of wood dust and shavings that arise during processing with this tool during operation, most modern models have a socket to which you can connect a chip vacuum cleaner . When used in conjunction with a saw, this equipment makes it possible to quickly and forcefully remove cutting products that arise during operation.

A specialist can set the immersion depth using a mechanism that has precise adjustment and is equipped with an additional eccentric. The latter is required when there is a need to smoothly adjust the position of the disk within the selected working area.

This provides the opportunity to improve the quality of processing of wooden workpieces.

All about the plunge-cut saw FESTOOL TS 55 REBQ

One of the main operations in woodworking is sawing the workpiece into the necessary parts. In most cases, one or another type of saw is used for sawing. To trim bars, boards, skirting boards, platbands, layouts and other similar moldings, use a circular saw, miter saw or assembly circular saws, but to work with sheet materials such as laminated chipboard, fiberboard, plywood, a format-cutting machine or An alternative is a plunge-cut saw.

The difference lies in the design of the saw. The design of a classic circular saw has a permanently protruding saw blade covered by a spring-loaded pendulum housing. In the plunge-cut saw design, the saw blade is contained in a casing. When work starts, the saw blade unwinds and the user plunges the saw directly into the workpiece or in front of the workpiece (only possible when using a guide bar) for further insertion onto the workpiece. The German company that came up with this saw design named it based on the principle of the action being carried out - Tauchsäge - plunge-cut saw.

The design of a plunge-cut saw is much more convenient than the design of a classic circular saw when sawing sheet materials, when working with a saw on a guide rail on a workbench, for example MTF3.

However, do not try to cut anything suspended, such as a block or board, with a plunge-cut saw. Nothing will work out. This is the field of activity for the classic circular saw... not quite classic - the HK 55.

To identify which saw we are talking about, recently a plunge-cut saw (rarely a parquet) is used when we are talking about a plunge-cut saw and a circular saw, a circular saw, a hand-held circular saw, a saw with a pendulum casing when we are talking about a classic hand-held circular saw .

Plunge VS circular saw

Today there are more than two dozen manufacturers of plunge-cut saws. AEG, Batavia (T-Raxx), Black & Decker, Bosch, Builder, Einhell, Festool, Flex, Güde, Holzmann, Kawasaki, Mafell, Makita, Matrix, Metabo, LUX, Scheppach, Triton, Varo, Virutex, Walter, Westfalia . The list goes on.

Roughly they can be divided into two weight categories up to 250 Euro – DIY saws and over 250 Euro saws for professional use. Often in reviews of plunge-cut saws, saws from different categories are compared, because... the main technical characteristics of all saws are similar, which is not true. An important difference is the reliability of the mechanisms and the presence of special functions. Some DIY saws are made by the same manufacturer under different brands.

A little history. The first plunge-cut saws AXF 45 and AXF 55 were introduced by the German company FESTO in 1980. It was proposed to work with the saw in conjunction with a guide rail, which ensured cutting accuracy unattainable for hand tools at that time. The advantages of using a saw in combination with a guide rail quickly gained the trust of carpenters and joiners.

In 1989, the ATF 55 saw (ATF 55 E, ATF 55 EB) became the standard saw for cutting sheet materials for almost 15 years. The ideal plunge-cut saw design is patented, which is the reason for FESTOOL's long-term dominance in the plunge-cut saw market. The saw design uses three bearings on the shaft, instead of the usual and much less reliable design with two bearings. The saw is tilted around the protective edge on the guide rail, therefore, strictly perpendicular and at any angle from 0 to 45 degrees, the saw cuts along the same line (without displacement).

Read also: Renovator for metal cutting

The standard among plunge-cut saws for many years

Smooth speed control, soft start, electromagnetic brake, overload and overheat protection with LED indicator - the most advanced electronic components of that time. In addition to its main use - sawing sheet material - the saw was used for another operation popular at that time in Southern Germany - trimming a wooden ceiling with a uniform gap around the perimeter of the room.

A separate advantage was also the trimming of the door leaf instead of adjusting the end with a plane. The ATF 55 EB saw also had a more powerful version - AT 65 EB. Any FESTOOL tool is accompanied by a variety of different accessories; a large number of additional accessories are also offered for the saw, expanding the scope of its application, improving the result of the work and simplifying difficult tasks.

The letters and numbers in the name ATF 55 EB are deciphered as follows:

A – (the first, main, basic) tool in the manufacturer’s line, T – (tauchen (German) – plunge, submersible type of saw, F – Fuge (Schattenfuge) – uniform gap around the perimeter of the ceiling, 55 or 65 – depth of cut of the saw, mm, E – presence of electronics, B – electromagnetic brake.

The design of the saw turned out to be so successful that to this day (06.2018) a specialized router for facade composite panels PF 1200 E is produced based on the ATF 55 E saw.

2003-2012. Nine years of leadership in its segment

In 2003, the ATF 55 was replaced by the TS 55 EBQ saw (the new TS 75 EBQ replaced the AT 65 EB). And again, many revolutionary solutions: a cast, more stable base body, a special mechanism for quickly changing the saw blade, an anti-splinter insert for the counter side of the workpiece, tool-free removal of play when installing on a guide rail, a quick-release cable. A color code appears - almost all controls are green.

In 2011, Bosch launches its first version of the plunge-cut saw, the GKT 55 GCE, on the market.

In 2012, with the advertising slogan: “Even more precise. Even slimmer. The best plunge-cut saw we have ever created” – the fourth generation of plunge-cut saws from FESTOOL arrives: the TS 55 REBQ. Instead of developing a completely new tool, TTS Tooltechnic Systems engineers rightly decided that in many respects the TS 55 EBQ did not need improvement, so the parts proven over many years of practice - the motor, gearbox and other surrounding components remained unchanged. Also, the electronic functions: soft start, speed control, overheating and overload protection remain the same.

Advantages of the TS 55 REBQ saw

- Double scale for reading readings when working together with and without a guide rail.

- Tool-free fine adjustment of sawing depth.

- An inspection window or an anti-splinter liner is your choice, depending on the type of work.

- The main distinguishing feature is the ultra-thin body, with a fully integrated suction pipe, without a “belly”. Thus, it is possible, for example, to cut a parquet board at a distance of 12 mm from the wall!

- The second important feature is the riving knife. When immersed, it lowers before the saw blade, which is a safety measure and also allows you to accurately hit the previously made cut. When sawing wood along the grain, where the saw blade may become pinched, the riving knife prevents the risk of kickback.

Along with the TS 55 REBQ version, many consumers nevertheless demand the TS 55 RQ model, which lacks electronics and, accordingly, a saw blade brake. In addition to lower cost, the saw has an increased idle speed of up to 6500 and lower power consumption, which in some cases can be decisive when choosing.

| Feature/Model | TS 55 RQ | TS 55 REBQ |

| Power, W | 1.050 | 1.200 |

| Speed, rpm | 6.500 | 2.000 — 5.200 |

| Weight, kg | 4,4 | 4,5 |

Advantages and disadvantages of operation

This tool has a fairly wide range of applications. It can be used from wood crafts to furniture making to home workshop work. However, in order to understand how relevant the purchase of such a tool is, it is necessary to establish what advantages and disadvantages this equipment has during operation.

The versatility of hand saws can be considered as its main advantage. With this tool in their arsenal, specialists and home craftsmen have the opportunity to perform high-quality precision cuts to form workpieces. Using it, you can easily trim the edges of furniture panels made of fiberboard or chipboard. If, in addition to the main tool , additional devices are available , then the specialist has the opportunity to form a figured cut.

Advantages

Additional positive qualities of this equipment include the following:

- performing all types of cuts - longitudinal and transverse. The only exception is shaped processing performed with a small radius of curvature.

- uniform weight distribution in the structure. This ensures a reduction in the labor intensity of the work performed, and in addition, has a positive effect on their quality;

- processing accuracy. This is ensured due to the design features of these saws, as well as the precise positioning of the saw blade in the area of the future cut;

Flaws

The relative disadvantages that hand saws have include the high price tag for this tool compared to conventional models. The high cost of the tool is due to the fact that the design of the system for adjusting the position of the cutting device of the equipment relative to the wooden workpieces has its own difficulties. In addition, when using plunge-cut saws , certain problems may arise when cutting the width of workpieces for which this parameter is insignificant. Its minimum size for workpieces is limited by the dimensions of the supporting part of the saw.

The design of the plunge-cut saw contains a mechanism for regulating the speed of the electric motor. This makes it possible to select the most suitable operating mode for the tool, focusing on the configuration of the part, and also taking into account the type of wood. The adjustment mechanism should be located in the most convenient part of the tool, so that the specialist can easily change the rotation speed of the cutting part of the tool while working.

Specifications

If you have realized the need to purchase this equipment, then you should carefully familiarize yourself with the main technical characteristics of plunge-cut saws. They may differ slightly in their design and performance properties.

When choosing a saw to solve your problems , the main attention, first of all, needs to be paid to the power of the installed electric motor. In most models that are available on the market, the power unit present in the design of plunge-cut saws is designed to operate on a 220 V network. This makes it possible for even a home craftsman to use this tool. When choosing equipment, you should also take into account the fact that the speed at which the workpieces will be processed depends on the power of the electric motor with which the saw is equipped. Additionally, the hardness of the parts, relative humidity, and the depth of cut should be taken into account.

Read also: Making labels for clothes

The main technical characteristics present in the saws are the following:

- maximum depth of cut. This parameter largely depends on the feed unit, the diameter of the saw blade, as well as the angle of inclination of the cut. For plunge-cut saws it can vary from 45 to 90 degrees;

- power of the installed electric motor;

- distance from the blade to the edge of the support pad;

- saw parameters. The maximum and minimum diameters should be taken into account, taking into account the seat size and thickness;

- drive shaft rotation speed. In order to reduce weight, manufacturers use gear transmissions of torque from the engine to the cutting tool in the design of such tools;

- diameter of the pipe for connecting the chip vacuum cleaner;

- weight of the structure.

As an additional characteristic when choosing equipment, cutting speed should be taken into account. This parameter depends mainly on the density of the workpiece, as well as the parameters inherent to the saw blade.

In order for the processing of wooden workpieces using a plunge-cut saw to occur quickly, and the final result to be of high quality, it is necessary to choose the right tool. To do this, you should know the main types of tools, as well as be able to understand the symbols on the saw blade.

Criterias of choice

There are usually no problems with choosing the right saw model for a home craftsman or specialist. This is due to the fact that in specialized stores this equipment is offered in a large assortment, so everyone can choose the appropriate solution to solve their problems. In the selection process, it is necessary to comprehensively consider the technical and operational characteristics of this tool. Additionally, the requirements set by manufacturers for the safety of work performed should be taken into account.

When selecting a saw, one of the important parameters is ease of use of the tool. Therefore, before you pay money for your favorite saw model, you need to hold it in your hands. If possible, make a few test cuts. This way you will have an idea of how comfortable you will be using the tool. Already in the selection process, this will allow you to draw a conclusion about which models are comfortable to use.

In addition, when choosing a tool, experts advise taking into account other factors:

- availability of specialized services and spare parts. If all this is easily accessible, then when a malfunction occurs, a high speed of repair work is ensured;

- the complexity of reconfiguring parameters. Basically, when using the tool, adjustment of the sawing depth is required;

- power and number of revolutions made by the cutting part of the machine;

- cost and completeness of a specific model.

In order to eliminate the risk of electric motor overload when using the tool, it is necessary that the saw design includes an emergency shutdown mechanism. Experts advise choosing a model that has a smooth start. In this case, jerking when the cut is formed is completely eliminated.

When performing bevel sawing operations, specialists may encounter a phenomenon where the processing depth does not completely correspond to the readings given on the adjustable scale. In such a situation, it is necessary to correct the value, for which you should use the recommendations contained in the instructions for using the tool.

Conventional circular saws have been used for cutting workpieces for many years. With all the advantages of this tool, it had one significant drawback - poor cutting quality. To improve this, woodworking equipment manufacturers have created plunge-cut saws. When used in industrial conditions and at home, good cutting quality is ensured.

Today, every home master can use them to solve the problems facing him. Modern models produced by well-known manufacturers are distinguished by high quality and ease of use. They are quite easy to use. When using a plunge-cut circular saw, high cutting speed is ensured. This is achieved due to a powerful electric motor, which complements the design of most modern saw models from well-known manufacturers.

When you decide to buy such a tool, you must choose it correctly. Manufacturers offer a large selection of models that vary in design, price and capabilities. Based on your needs, as well as the functionality that such a saw should have, you should make a choice. They are absolutely safe to use. To eliminate the risk of injury during work, you just need to follow all the manufacturer’s recommendations specified in the instructions when using the tool. In this case, operations using this equipment will be performed quickly and safely.

The circular saw is one of the top ten most popular power tools. It speeds up carpentry and joinery work significantly. The “circular saw” is designed for working with wood, but can also be used for cutting plastic.

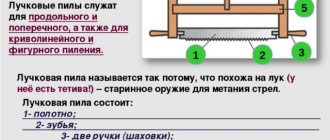

Circular saw device

The design of a circular saw is simple: a toothed disk is mounted on an electric motor shaft. The unit is housed in a housing with two handles so that you can hold the tool with both hands. The operator moves the tool along the workpiece (or vice versa if the saw is a table saw); The teeth of the rotating disc cut the material. For safety, the blade is covered with a casing that opens automatically while sawing.

To figure out which circular saw is better, you need to understand how they differ and what additional functions the tool may have depending on the type and model.

Circular saw or miter saw - which one to choose?

Do you want to make a cute table to go with your couch, but can't decide between a miter saw or a circular saw?

Don't worry, read our comparison guide to find out all the differences between these two saws and decide which one is the best option for your application.

Some people think that one of them is better than the other, others that there is not much difference between them, and you can replace one saw with another. However, each of them has its own characteristics and it is better to use the saw for its intended purpose.

So, let's first take a quick look at the advantages and disadvantages of both types of saws.

Classification of circular saws

Household and professional

A professional tool differs from a household one primarily in its resource and the possibility of long-term continuous use. Household models overheat in this mode of operation and require regular breaks in operation to cool down.

Also, professional power tools are supplemented with some special functions that are not useful to an amateur craftsman.

In addition, professional models are much more expensive than household ones.

The division into professional and household (amateur) is conditional. Some models may have professional functionality, but their design is not up to the mark in terms of durability. Don't put too much emphasis on classification. Be guided solely by practical considerations.

Read also: Precision seeding vegetable seeder

Hand and stationary saws

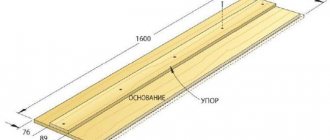

These tools differ significantly. The hand-held circular saw is compact; the operator holds it in his hands and moves it along the workpiece along the cutting line. This is a portable tool, it is easy to move it to the place of work. Stationary machines are a different matter. This tool is ideal for work on the shop floor or in the workshop. The electric motor is mounted under a large working platform. Its length can exceed one meter; The machine is installed on legs. During operation, the operator moves the workpiece along the platform and feeds it onto the cutting disk.

A stationary machine or table circular saw is convenient for performing voluminous work of the same type. For example, if you need to cut narrow bars of the same size from a wide board.

But a hand-held circular saw makes it possible to work “on site”, as well as with large-sized workpieces that cannot be cut on a stationary machine. A typical use for this is cutting plywood sheets. Some models of hand-held circular saws can be secured to a work table using special clamps. In this position, workpieces are cut in the same way as on a stationary circular saw. This expands the capabilities of the tool, but due to the small dimensions of the platform, it does not fully replace a stationary saw.

If portability and versatility are important, choose a hand-held circular saw. If you have a workshop and require high productivity, a stationary “circular machine” is your option.

How to choose a hand-held circular saw for wood at home

A hand saw seems like a simpler tool than a stationary circular saw. However, it must be chosen very carefully, otherwise the instrument may disappoint.

Power

The average figure for a hand-held circular saw is 1.2 kW. If you need to equip a home workshop, and there are increased demands on performance, you can choose a model with 1.6 kW or higher.

Power type

Manual circular saws can be powered either by mains or by battery. As a rule, models with a built-in battery are less powerful and require regular recharging, but they can be used anywhere in the garden. Corded saws are always limited by the length of the cord; they must be plugged in close to an outlet or extended to the required location.

Disk rotation speed

For hand saws, this figure is usually 3000-6000 rpm. The higher the speed of the tool, the smoother and better the cut will be, even in very dense wood.

Attention! When comparing hand-held circular saws, the best models are those that can maintain a constant speed. They maintain the quality of the cut even in areas with hard knots.

The constant speed of rotation of the circular saw helps to achieve the highest quality cut

Angle adjustment

Some models of circular saws can only cut at right angles. But most devices support a tilt of 45 °, and they should be preferred.

Smooth start

If the circular saw is started immediately at full speed, this leads to an unpleasant jerking of the device in the hands. In addition, the engine in this case wears out faster. A soft start is responsible for ensuring that the tool starts working and accelerates gradually. This feature improves ease of use and extends the life of the saw.

Spindle lock

When changing a blade on a circular saw, the spindle must be locked. This can be done either using special keys or using a button on the device body. Push-button hand saws make changing attachments very quick and easy.

Overload protection

The circular saw may become very hot during operation. The built-in protection system will turn off the tool automatically if its temperature reaches the limit values.

Protection against accidental start

Some models of circular saws are equipped with an additional button to prevent accidental activation. To start the tool, you must first press this key, and then the normal start, which is quite difficult to do accidentally.

Main technical characteristics

The passport for the device indicates many characteristics, but not all of them are equally important for the correct choice.

Disc diameter

The larger the diameter of the saw blade, the thicker the timber or other part that it can cut. However, it would be a big mistake to try at all costs to buy a tool with the largest disc of 210 mm. A large disc requires a powerful motor. And this increases the weight of the device and its dimensions. Working with such a tool requires a lot of physical strength and quickly tires. Models with a disk diameter of 160-190 mm are much more convenient to use.

Select the diameter of the circular saw blade based on the size of the workpieces that you have to process. Here, “big” does not mean “good.”

Power

All other things being equal, a more powerful electric motor will allow you to cut faster.

However, power is an indirect characteristic of a power tool. Firstly, the actual power of a particular device may differ from that stated in the passport. Secondly, sawing speed depends not only on power, but also on the number and shape of teeth sharpening, wood moisture and other factors.

When choosing a tool, do not consider power as the main criterion. Functionality is more important.

Miter saw

What is a miter saw? A crosscutter is a tool for precise, mainly transverse, cutting of a workpiece. Most miter saws are small and portable. Unlike stationary cross-cut saws, you can pull it out and set it on a temporary base by placing the drop mechanism (sometimes called a drip) over your workpiece. The blade sizes most commonly used for miter saws range from 8 to 12 inches (20-30 cm).

What is a miter saw used for? You can use it to create cross cuts on a workpiece in one quick motion. But more importantly, you can do it at the angle you choose. This is the best choice if you need to cut trim and moldings.

Pros A miter saw is useful when you require precise cross cuts on your workpieces. This saw is also a great option for miter cuts. This is one of the main competitive advantages of this saw over other types of saws. What’s important is that the miter saw is one of the safest.

Cons Despite all the advantages, a miter saw is not useful when you are going to cut large pieces. While it is the best choice for cross sections, miter cutting may not be effective for long cuts (over 15 centimeters). Miter saws are more of a luxury than a necessity.

Functionality

Some functions are present in each model, but there are also specific options.

Adjustment of cutting depth and blade tilt

In most cases, during operation, the disk is adjusted to its maximum depth and set at an angle of 90° to the plane of the part. However, there are times when you need to limit the cutting depth or cut at a different angle. For example, for some carpentry, it may be necessary to saw a board exactly half its thickness.

These adjustments are available in all models of circular saws. Just pay attention to how convenient it is to use them: do they require special keys or handles, or are there graduated scales for accurate readings?

Rip fence

All tools are supplied with this device. It makes it very easy to cut the part straight parallel to the edge. In this way, you can reduce the width of the workpiece or cut several identical slats from a wide board.

Smooth start

As a rule, only professional models have this option. It solves two important problems.

Firstly, it limits the starting current of the electric motor. In the first milliseconds after starting, while the motor is gaining speed, it consumes current several times the rated value. This overloads the power grid and can trip circuit breakers, especially if the motor is powerful. The soft starter reduces the starting current to a safe level.

Secondly, the engine speed increases smoothly when starting. For stationary instruments this is not a big deal, but for hand-held instruments it may be useful. The rapid acceleration of the motor causes kickback: when turned on, the tool jerks sharply in the hands, which has a detrimental effect on the cutting accuracy. A soft start significantly reduces recoil. If you have to power the tool from a low-power electrical network (for example, in a holiday village), pay attention to the soft start function.

The best circular saws: top 5 review

5. PATRIOT CS 210

The electric circular has proven itself to be one of the best for both domestic and professional purposes. Suitable for working with wood and plastic. Has a powerful 2 kW electric motor. Connects to a 220 V network. The angle is easily adjustable, smooth start is provided, and there is a protective cover for increased safety. Cutting depth – 70 mm. Rotation speed – 4,500 rpm.

4. Whirlwind DP-235/2200

The parquet allows you to work with laminate, wood, plywood, sheet and polymer metal. The tilt is adjustable. The power of the electric motor is 2.2 kW. The use of an upper casing for removal of sawdust is provided. The cutting depth at right angles is 85 mm. Rotation speed – 4,500 rpm.

3. Hitachi C10RE

Circular saw on a die-cast aluminum frame with storage compartment for accessories. There is a dust extractor and wheels for easy transportation. The power of the electric motor is 1.6 kW. The depth of the cut at a right angle is 73 mm, you can choose a tilt angle of 45 degrees. Rotation speed – 4,800 rpm. Features high performance.

2. Bosch GKS 65

Tool from a German manufacturer. Suitable for cutting wood. It is distinguished by high cutting accuracy, as well as a powerful 1.6 kW motor and lightness - the weight of the circular saw is only 4.8 kg. Rotation speed – 5,900 rpm. The depth of the cut at a right angle is 65 mm, the angle of inclination and smoothness of the cut are adjustable. The switch is interlocked.

1. Evolution RAGE 1B

The leader of our rating is a multifunctional circular saw with patented Rage technology, which is responsible for the evenness and accuracy of the cut. The model allows you to work with aluminum, wood, steel, brick, concrete, stone, providing high accuracy and cutting speed regardless of the material. Resistant to shock and vibration. The angle of inclination and cutting depth are adjustable. Rotation speed – 3,700 rpm. The power of the electric motor is 1.2 kW, the cutting depth at right angles is 60 mm. The weight of the tool is only 5.5 kg. Connection for a vacuum cleaner is provided. During operation, no additional heat is generated and no sparks are formed. The model is notable for its excellent combination of features, quality and price.

How to choose a circular saw blade

When choosing a circular saw blade, pay attention to:

- Diameter: must exactly match the design of the tool, otherwise the work will be unsafe and ineffective. With a smaller blade size, your fingers may get caught under the protective cover; with a larger blade, the disk simply will not fit on the saw.

- Frequency of teeth: for soft materials, a disk with frequent teeth is suitable, this will ensure an even and accurate cut. The fewer teeth, the harder the material will be cut. Average quantity – 40–80 pcs.

- The inclination of the teeth: for cutting wood - in the direction of rotation, for cutting metal - in the opposite direction.

- Tooth sharpening angle: positive (15 to 20 degrees) for wood, negative (0 to -5 degrees) for metal.

- Tooth configuration: determined depending on the task. Combined cutter (Combi) is a universal option. The trapezoidal cutter (TCG) is suitable for processing non-ferrous and soft metals, wood and plastic materials. Replaceable with increased side slope (HiATB) – for easily splintering materials. Replaceable without tilting (ATB) - for processing composite boards, plywood, longitudinal cuts of wood. Flat (FT) – for soft and hard wood.

- Circular saw spindle speed: this parameter determines the permissible blade diameter for efficient operation of the tool.

- Purpose: Manufacturers offer special discs for cutting various materials; as a rule, they have all the necessary characteristics. All that remains to be determined independently is the outer and inner diameter. This greatly simplifies the choice.

Recommendations for choosing a circular saw

In order not to drown in the variety of characteristics and options, we present several ready-made solutions for typical cases.

Choosing a saw for the home

As a rule, a circular saw is needed on the farm only for repairs. This is occasional use. It makes no sense to purchase expensive powerful models for this. It is better to choose a medium-sized circular saw. A suitcase for storing it is very useful.

Choosing a saw for the garden

At a summer cottage there is always a need to repair or build something: a shed for household equipment, a gazebo, a doghouse, a playhouse for children, a fence. For these purposes, you will need a good-quality hand saw with a large blade. If funds allow and there is a workshop, its capabilities will be complemented by an inexpensive stationary household-grade circular saw.

What to choose for a professional

Let's clarify. A professional is someone who makes money using a tool. The tool must pay for itself. Professional craftsmen have two approaches.

Those who specialize in one type of service (for example, installing doors or assembling furniture) need durable, productive and high-precision tools.

There are generalists and construction teams. They provide a range of services and solve turnkey construction problems. Purchasing complex and expensive models is not practical for them. Often tools are purchased “for one object.” I bought an inexpensive circular saw, built a country house with it, used up all the resources and threw it away.

Read also: Jigsaw work on wood drawings

Combined "trimming"

You can cut parts in much the same way using a compound miter saw. There are not very many such “two-in-one” models on the market, but they deserve close attention.

The peculiarity of their design is that the saw blade works on two sides: the lower part is used for facing and sawing at an angle, the upper part is used for sawing workpieces lengthwise. For this purpose, a special platform is provided above the electric motor, like a stationary circular saw. The guide stop allows you to set the width of the sawn part.

Of course, in terms of their characteristics, such models are somewhat inferior to their highly specialized counterparts in terms of accuracy of operation, but their strength lies in their versatility.

If for some reason you are limited in choice and need to settle on one tool, a combination miter saw will be the best choice due to its versatility.

Professional craftsmen love tools like these. For example, when installing doors, a “trimming” will help connect the frame parts and platbands “on the mustache”, and on the upper platform you can quickly saw off the extensions to the required width.

Let's sum it up

A circular saw is not as specialized a tool as it seems at first glance. If you need to work with more than just wood, you can choose a circular saw for wood, and then purchase replacement blades for cutting plastic or sheet aluminum.

In conclusion, let us remind you once again: any tool should be chosen based on the tasks that you intend to solve with its help. Fast and pleasant work will mean that the right choice has been made.

Table of contents:

It is not enough to purchase a reliable circular saw. Without good equipment, she will not be able to cope with the assigned tasks. Only the installation of high-quality saw blades will allow you to achieve high productivity when working on wood.

Purpose of the tool

The circular saw is designed for sawing wood raw materials, particle boards and plastics, when installed with the appropriate equipment. This tool is also called a wood circular saw. The cutting device is a saw with sharp teeth, the rotation range of which is from 4500 rpm.

A circular saw is capable of quickly and efficiently cutting wood both along and across the grain. When longitudinal sawing occurs, the material is cut according to width or thickness. And when cross-cutting, when the working body of the circular saw is located perpendicular to the wood fibers, the removal of wane areas and defects is carried out. After such processing, a joiner's jointer is used to level the surface of the product.

Despite the versatility of a circular saw, cutting metals, steel or other alloys without special saw blades is prohibited.

Therefore, it is most often used in the construction of wooden construction projects, for example, frame houses and bathhouses. And also in the process of repair or for small household needs.

It is not advisable to use a circular saw in large timber processing industries, except in cases where narrowly targeted rough processing of wood is required, associated with cutting or finishing the end joints of large products.

Classification of saw blades

Depending on the design features, the equipment is divided into 2 types:

Monolithic . The entire disc is made of tool steel. Its main advantages include low cost , the possibility of self-sharpening and maintainability - a large margin of safety.

Carbide . The base is made of tool steel, and the teeth are made of hard alloys with the addition of tungsten carbide. The main advantages are high saw edge hardness , clean cuts and long intervals between sharpenings .

Carbide-tipped discs allow you to perform woodworking with maximum speed and productivity , but they have a serious drawback - maintenance requires special tools and above-average skills.

Important Features

So that readers do not get lost in the wilds of the modern market for accessories for circular saws, we have prepared 5 main criteria that will help you make your choice. Let's consider them in order of importance.

External diameter

The outer or outer diameter of the disk should not exceed the dimensions of the circular saw casing, otherwise it will not be possible to install it in the seat. Increasing the parameter leads to an increase in the depth of cut. The characteristics vary from 65 to 500 mm.

Landing diameter

Landing, or internal diameter - the size of the hole in the center of the equipment. Determines whether the saw blade will fit on the spindle. The most popular sizes: 16 , 20 , 22 , 30 and 32 mm. But the full range is much wider - from 11 to 50 mm.

Manufacturers may install pins on the saw seat for additional fixation . In this case, you need to choose a disk with appropriate holes .

Number of teeth

As the number of teeth increases the processing speed decreases , but the cleanliness of the cut improves . And vice versa: the fewer teeth, the faster the work goes , but the cut becomes less and less accurate . The characteristic has its own classification, presented in the table:

| № | Name | Number of teeth, pcs |

| 1 | Big | 80-90 |

| 2 | Average | 40-80 |

| 3 | Small | 10-40 |

Tooth sharpening angle

Sharpening inclination is the angle of deviation of the cutting edge of the tooth from the radius of the saw blade. The picture clearly shows how a characteristic can influence the work process. The angles are:

Standard : 5-15 °. Universal sharpening. Suitable for all types of cuts.

Positive : 15-20 °. Ideal for rip sawing due to its gripping effect.

Negative : from to – 5 °. Used for cross cutting, does not form chips.

Disc thickness

The standard parameter is 3.2 mm. The thinner the disk, the more it heats up and the faster it fails. The large thickness guarantees a long service life of the equipment, but slows down the work. In this case, the excess consumption of material increases due to the wide cut.

HAND CIRCULAR (CIRCULAR) SAW. Part 3 (selection of saw blade)

The working tool of a hand-held circular saw is a saw blade. It is he who directly cuts the material and its parameters largely determine the quality and speed of sawing, as well as ease of use. Quite often, a tool is sold complete with accessories that are suitable for the most common tasks.

However, the sawing process often requires different characteristics of the disk, and the ideal complete consumable will require replacement over time. Today there is a wide range of choices available, so a beginner should be guided in advance by the main selection criteria: landing and outer diameters, cutting width, number and configuration of teeth, etc.

PURPOSE and DIMENSIONS

Let's start with the fact that truly universal equipment simply does not exist. Well, there is no such disk that would cut both dry wood and laminated chipboard with the same quality lengthwise and crosswise. Therefore, it is better to purchase a couple of medium-priced disks optimized for a specific job than one expensive “universal” one that performs many tasks at an average level.

Also not a criterion when choosing a consumable for Makita, Hitachi or Bosch. These corporations order equipment marked with their brands from third-party manufacturers. Moreover, its price is often unreasonably higher than that of the direct manufacturer (for example, SMT). A compromise is possible when an expensive consumable is purchased for important delicate work (Mafell, Hilti, Leitz, Festool, etc.), and if the material quickly destroys it and the quality of the cut is not important, a cheap one is purchased (for example, for cutting chipboard or plywood).

A modern saw blade is a high-tech product that reflects the latest research and engineering achievements. As a result, there is a wide range of equipment not only for different hardnesses of wood, but also non-ferrous metals, tin, raw and laminated chipboards, MDF, OSB, plastic, as well as ceramics, cement-bonded and cement-fiber boards, foam concrete blocks, etc. .

So the choice should begin with matching the type of material and the method of sawing it. Then move on to the outer and landing diameters so that the flow bar can, in principle, be installed on the tool. Each saw model has an engine, drive and other structural elements that are designed for equipment of a certain size, the maximum and minimum values of which are indicated in the instructions.

Installing a larger diameter disc will require removing the protective covers, which can result in injury or worse. That is, this is an option for those who know how to grow new organs. If you take a smaller diameter, the cut depth scale will be lost.

If a riving knife is installed on the saw, then with a blade with a diameter less than the minimum it will be possible to make only through cuts. In other cases, the knife rests on the bottom of the cut and interferes with your work. It also imposes a limitation on the thickness of the equipment (blade thickness, knife thickness, cutting width).

Thin disks put less load on the engine, but they are more sensitive to loads and overheating. Such a parameter as the width (thickness) of the cut is indicated on almost all discs, but the thickness of the blade is mainly on premium ones. So, if necessary, you will have to resort to a caliper.

VARIABILITY OF FITTING DIAMETER

Unlike angle grinders, hand-held circular saws do not have a standard mounting hole. There is a range of sizes even for discs with the same outer diameter. To some extent, a couple of tricks can help resolve this confusion and use a wider selection of equipment.

So, in a number of Makita models, the internal flange on the shaft, which serves as a landing place for replaceable nozzles, is double-sided. By turning it over, you can change the mounting diameter (for example, alternate 30 mm and 20 mm or 16 mm and 30 mm).

Another option is to use replaceable adapter washers (also known as adapter rings). Often a couple of such rings are included with the disc, but there is no question of buying them separately.

You just need to keep in mind that in this way the mounting hole can only be enlarged, but not vice versa. That is, installing a disc with a 30 mm fit on a 20 mm shaft is not a problem, but with a 5/8” hole it will no longer be possible.

You should also pay attention to the thickness ratio. The adapter ring only positions the cutting tool on the axis of rotation. And it is held in place by the outer flange (clamping washer). And for reliable clamping, the ring should be slightly thinner than the disk. However, in most new models of saws the flange has grooves and presses with its outer edge, so in this case a couple of extra fractions of a mm in the thickness of the adapter washer is not a problem.

Speaking of sizes. Manufacturers of circular saws themselves and removable attachments for them supply their products to the markets of both the Old and New Worlds. Accordingly, inches with their fractions and centimeters with millimeters are used to indicate sizes. So, when converting inches to the metric system, there are variations in free rounding from both manufacturers and sellers.

Most often, discrepancies concern the 5/8” (15.875 mm) mounting hole, which is marked as 16 mm, 15.8 mm and even 15 mm. The millimeter also “walks” at the outer diameter (for example, 184 mm and 185 mm are actually the same thing).

STRUCTURE OF THE SAW BLADE

The basis of the disk is the body, also called the canvas or body. With rare exceptions (for example, abrasive), hardened high-quality steel is used for its manufacture. The lowest-cost and simplest production method is stamping. This is how they make inexpensive consumables.

The cutting of the canvas with first-class equipment is carried out using laser cutting. This technology allows you to quickly and accurately produce products of complex shapes with excellent edge quality. Each workpiece is then ground, calibrated and balanced.

If traces of grinding are visible on the surface of the blade, radiating in circles from the mounting hole, then it was processed individually, and not cut from a pre-polished sheet of steel. Also, markings are applied with a laser on a good canvas.

Rotating at enormous speed, the body heats up due to friction against the edges of the cut and experiences centrifugal forces. To prevent the disc from “driving”, that is, to level out such factors causing stress and deformation, special slits are created on its body.

To compensate for thermal expansion, they are cut 15-20 mm radially from the interdental cavity. Straight gaps end in a round relief hole, into which a copper rivet with a higher heat capacity is sometimes inserted. Today, such technology is considered obsolete - more advanced equipment has expansion slots that are more complex in shape and at the same time dampen vibrations.

In addition, to relieve internal stresses, a high-quality consumable is subjected to rolling by rolling on both sides of the web with hard rollers. Visually, this is a sort of “densed” strip located approximately in the middle along the circumference of the body, in which stresses are specially created to compensate for thermal expansion.

We also recommend: MANUAL SNOW Blower – OPTIMAL CHOICE. Part 1 (types, augers and rotor, bucket and skis)

The cool equipment also has intricately shaped slots to reduce shaking, and therefore sound vibrations, during operation. Such noise-reducing gaps are also filled with inserts with a special material (for example, Stabilteq technology in Bosch consumables).

The most important part of the saw blade is its edge, which actually cuts the workpiece. It can be solid or segmented with diamond coating, which allows you to cut ceramics, brick or concrete. However, much more common is the toothy expense.

Such discs can be monolithic - cut from a sheet of high-carbon or high-speed steel (HSS). They are cheaper, but quickly become dull and require frequent sharpening and setting of the teeth. The latter determines the width of the cut.

However, so-called carbide wheels have gained great popularity. They have specially shaped soldering tips attached to their teeth, made of tungsten carbide composite alloys, called victorious in the post-Soviet space, and carbide in other countries.

Equipment with carbide tips is more expensive, but with its help you can cut many more varieties of materials with high quality and it is more reliable. The width of the cut in this case is determined by soldering.

By the way, the consumption of a Chinese or Western manufacturer can be easily determined by how carefully the soldering is done. However, according to the tests carried out, this does not affect the reliability of fastening.

DIFFERENT TEETH ARE NEEDED

As mentioned, toothed discs are the most common. The convenience and quality of sawing with them is largely determined by the number and configuration of the teeth. When working, there are two speeds - cutting and feeding. The first characterizes the speed of separation of a part from the workpiece. The second determines the rate at which the cut length increases.

All other things being equal (that is, with teeth of the same shape and equal outer diameter), as the number of teeth increases, the feed rate should be reduced. If this is not done, then you can destroy not only the equipment, but also the tool itself, since the load on the engine seriously increases. So it’s easier to quickly make long cuts with a small-toothed blade, although the cleanliness of the cut gets worse.

That is, for rough sawing along relatively hard, massive wood pieces, you need a saw blade with 10-24 teeth. In this case, modern high-quality discs allow you to saw even raw wood with a tool with a relatively weak engine. But for finishing cross cuts or small thickness boards (plywood, chipboard, MDF, laminate, etc.), equipment from 40 teeth is optimal.

Now let's move on to such a fundamental issue as the configuration of the teeth. Monolithic disks have two profiles - either sharp, like a hacksaw, or curved with a wide back. The first is designed for finishing both longitudinal and transverse cuts in hard and soft wood, as well as cutting plywood, OSB, plastic and non-ferrous metals. The second is for quick sawing, also in both directions, but on soft wood.

Carbide-tipped equipment has a significantly larger variety of types, specially designed for high-quality sawing of various materials.

An important geometric parameter is the angle of inclination of the tooth (also known as the angle of sharpening or attack) - this is the angle between the radius and the front surface (front edge) of the soldering.

Its positive value (+, P) is measured from the radius line along the direction of rotation. The washer, as it were, grabs the material, speeding up sawing. The larger the value, the more aggressive the cut and feed rate.

Negative angle (-, N) is measured against the direction of rotation. The cutting speed decreases, but the quality improves. A value ranging from -2° to -10° is optimal for melanin, plywood, chipboard, laminate, OSB or MDF. The angle can also be zero, that is, without tilting the tooth.

The recess in front of the tooth (interdental cavity or sinus) ensures removal of chips. When longitudinal sawing, the sawdust size is larger and the feed speed is higher, therefore the cavity is deeper and wider than that of cross-cut equipment.

Also, some discs may have teeth with a pronounced back, designed to protect them from breaking and limiting the feed speed.

The geometry of the cutting edges of the faces plays an important role. There are many options for types of equipment with solid-state soldering for different purposes. Let's look at the most popular ones.

FTG or FT (Flat Top Grind) teeth with a flat top - this shape removes chips from the cut most effectively and is relatively impact resistant. The best option for quick rough cutting of wood or non-ferrous metals.

Alternate Top Bevel Teeth (ATB) – This combination provides a knife-like cutting edge on both sides of the blade and produces a smoother, clean cut than FTG.

The HiATB (High Alternate Top Bevel) option with a strong bevel is designed for ultra-clean cutting of plywood or chipboards with a decorative coating of melamine, veneer, etc.

The TCG or TC (Triple-Chip Grind) configuration of alternating straight and taller trapezoidal teeth excels at cutting MDF, OSB, laminates and plastics. Also used for cutting non-ferrous metals.

The combination of different tooth shapes is also used in the so-called universal blades for longitudinal and cross cuts (Combo or ATB/R). They have 4 ATB and 1 FTG arranged in groups with a large interdental cavity between them. It helps to effectively dispose of chips during longitudinal sawing. Smaller depressions in groups reduce the feed rate during transverse.

Since the materials being sawn can have similar characteristics, the equipment in some cases becomes multifunctional. Although such similarity does not always guarantee a good choice.

So it is better to cut a profile for drywall not with a disk for metal, but either with equipment specifically for tin, or with a negative angle for laminate.

Being composite materials, chipboard and MDF have a strong temperature and abrasive effect on the cutting edges, so the equipment for working with them is soldered with particularly hard alloys. They are wear-resistant, but fragile and are afraid of impacts from foreign inclusions.

And other consumables do not tolerate frequent encounters with nails very well. Therefore, if you need to disassemble or cut some old structure into firewood, it is best to use a special dismantling disk (for example, Makita B-09363).

Share information - don't leave your friends in the dark: Facebook

VK

Tumblr

StumbleUpon

Buffer

Marking

As you can see in the picture, the disc markings can tell you about many technical characteristics. But there is a dependence that should not be neglected: the shape of the teeth directly affects the ability to work with a specific material.

The classification developed by representatives of the GASS divides discs into the following categories based on tooth shape :

GK and GS:p alternately beveled . Suitable for processing all types of wood and “clean” chipboards , without plywood and plastic coatings.

GM : direct . They can only cope with cutting soft wood.

GT : trapezoidal . They are useful in cases where you need to cut MDF or chipboard with lamination.

GR : conical . Cuts multi-layer coatings with double lamination.

GA : trapezoidal and straight . Same features as GT .

laser markings to high-quality saw blades . If the parameters are “written” with ordinary paint , it means that we are looking at an economy-class product that will quickly become unusable.

Popular manufacturers

The modern market is full of offers from manufacturers. But there are companies that are time-tested. It is their products that are preferred by owners of circular saws. A short list of popular brands is as follows:

CMT . The company appeared in Italy back in 1962 . Production was moved to China, and only the head office remained in Europe.

"Makita" . The year the company was founded was 1915 . Much time has passed since then, but Japanese products are still popular all over the world.

"Bosch" . This name has long been a symbol of unsurpassed quality. Saw blades under the Bosh brand are welcome guests in every home workshop.

"Attack" . The organization appeared in 1998 in Russia. It can rightfully be called the oldest supplier of consumables on the domestic market.

Metabo . The name comes from the German name for a hand drill. The assembly of the first products began in Germany after 1924 .

Dewalt . The company's victorious march around the planet started in the USA . Since 1922 , the brand has produced accessories for power tools.

Advanced technologies are not easy to understand. Tooling manufacturers are constantly improving their production. We invite you to watch a video that will help you make the right choice and learn a lot of useful information: