Subtleties of choice

It is best to buy saw attachments for rip cutting in specialized stores - unlike small retail outlets, here the product comes with complete instructions and descriptions for users, and the sellers have the necessary knowledge and can give detailed advice.

Be sure to study the information on the disc itself. Typically, arrows are used here to indicate the cutting direction (crosswise or lengthwise), as well as the maximum cutting speed in revolutions and the angle of inclination of the teeth. Usually a negative angle is denoted as neg, and a positive angle as pos. These designations are usually preceded by a letter - it indicates the magnitude of the degrees. Be sure to examine the quality of sanding. If the saw blade is good, then clearly defined grinding circles will diverge from the center to the edges. They indicate that after stamping such a circle was necessarily calibrated, then ground and brought to the most efficient working condition.

If the wheels are cheap, then usually they are not subjected to additional refinement; at most, the entire sheet is sanded. Resin with shavings sticks to a poorly sanded surface, which significantly interferes with work.

See the next video for more details.

Types of saws

Which greenhouse is better to choose, 7 popular models

The following main types of hand saws can be distinguished:

The most common and affordable are wood hacksaws. They can saw wood pieces of any size. They, in turn, can be standard, narrow and obushkovy.

A standard or classic saw is designed for large wood materials. It comes in sizes: length 75 cm, width from six to one point six centimeters, thickness varies from one to six millimeters.

Note: There is a simple rule when choosing a saw - the size of the blade should be twice as long as the width of the log being cut. Otherwise, if the canvas is too long, it may be pulled to the side.

It is impossible to cut deep into the material with a back saw. It can be used to outline the future cut, and then cut along this groove with a regular saw. The whole point here is in the stiffening rib - the butt, which will not allow it to go deep into the tree.

A narrow saw is mainly used to perform tasks of a delicate nature, such as sawing thin material, cutting curved parts and a through hole. For a precise cut, such a hacksaw is only suitable if you work extremely carefully.

A two-handed hacksaw can be used by 2 people. She cuts logs, beams, and stacks of boards. With such a saw you can do work that not every machine can do.

Another popular type of hacksaw is for metal. These hacksaws are designed for sawing metal parts made of alloys. Depending on the type of frame, there are classic and folding types.

Saws for cutting blocks are considered the most budget option and are mainly used on construction sites. Perhaps the most convenient and easy to use.

The following types can also be distinguished:

- Garden saw. Used in gardening for crowning small fruit trees and shrubs, i.e., for sawing off thin branches;

- The joiner's saw is used in the production of wooden furniture;

- The award is somewhat similar to a plane. She has several arms. With its help, tenons, grooves are cut, and recesses of various sizes are made on any type of wood;

- Folding saws. This saw is good to take with you outdoors, thanks to its compactness and lightness. It has very sharp small teeth.

Saws: characteristics, types, types

— Chain brake. A device that ensures the saw stops during the so-called. reverse kick. In accordance with the name, it is used in chain saws (see “Device”). Kickback can occur, in particular, when the very tip (toe) of the tire comes into contact with the material being processed. The bar and chain are thrown towards the operator, which can lead to injury. To avoid this, a chain brake is provided: during a reverse strike, it stops the saw almost instantly. — Anti-vibration system. Various design solutions that reduce tool vibration during operation. Strong vibrations, especially long-term ones, negatively affect the quality of work and condition of the tool, and also lead to rapid fatigue of the operator; The anti-vibration system allows to eliminate these phenomena to a certain extent.

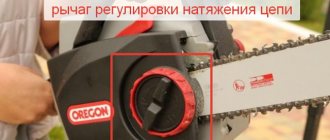

— Keyless chain tension. Possibility of adjusting chain tension in chain saws (see “Device”) without the use of special tools - wrenches, screwdrivers, etc. This function is especially convenient in light of the fact that during more or less long-term operation, the saw needs to be periodically checked and, if necessary, the chain must be tightened right on the spot - and this is more convenient to do without unnecessary devices.

— Oil-free saw set. Saws that do not require additional lubrication of sawing equipment. Such models are unsuitable for long, productive cuts and are suitable for minor work. But the absence of the need for lubrication greatly simplifies the maintenance of the device and “keeping it in shape.”

- Smooth start. A special control system used in electric saws (see “Power source”). Without a soft start, the electric motor “starts” very abruptly, which leads to jerking of the saw and creates the risk of letting go of it. In addition, when started in this way, the tool consumes high currents, creating a significant load on the electrical network. The soft start system allows you to avoid these phenomena: the electronics limit the starting currents of the electric motor, avoiding tool jerks and voltage surges in the network.

— Electronic engine protection. A protection system that turns off power to the saw motor in the event of a critical increase in load - for example, when the disk/chain jams. Such systems are used in electric saws (see “Power source”). They help avoid damage to the unit due to overload. At the same time, we note that the electronic protection is reusable; after it is triggered and the problem is eliminated, it is enough to turn on the power again - and the saw can be used again.

— Brushless motor. The presence of a brushless (brushless) motor in an electric saw (see “Power source”). Such electric motors have a number of advantages over traditional commutator motors: in particular, they are more economical in terms of energy consumption, less noisy, and do not spark, which can be important in conditions of increased fire danger. The disadvantages of brushless motors are complexity and high cost.

— Engine brake. A device that additionally brakes the engine when the tool is turned off. The engine itself (and, accordingly, the working attachment) after switching off can still rotate for quite a long time by inertia; the brake stops this rotation almost immediately, so you don’t have to hold the tool suspended for extra time.

— Safety clutch. A device that protects the operator from sudden jerks, as well as the engine from damage due to a sharp increase in load. In such cases, the overload clutch disconnects the motor shaft, avoiding overload. Note that such devices can be either reusable or disposable - the latter are destroyed when triggered, and to continue operation you will need to install a new coupling.

— Laser marker. A kind of “target designator” that allows you to clearly determine where the cut will go. To do this, a clearly visible line is projected onto the workpiece, the location of which corresponds to the location of the future cut.

— Backlight. Lighting system built into the saw. This feature is definitely desirable when working in low light conditions. However, it can also be useful in bright external light: the place of work is often in the shadow (for example, from the tool itself), and without special lighting it can be difficult to work in such conditions.

— Speed regulator. The ability to limit the rotation speed of the saw motor (and, accordingly, the speed of the blade). This function is essentially a smooth speed control; it is especially useful in cases where full speed is not required - for example, when working with soft materials that require delicate processing.

— Maintaining speed. A function that ensures maintaining a constant engine speed (and, accordingly, a constant blade speed) regardless of the load on the tool. To do this, the tool’s automation regulates the output power depending on the current load: when the load increases, the power increases, when it decreases, it decreases. Constant operating speed has a positive effect on both the quality of the cut and the service life of the blade and the durability of the entire tool.

— Stationary installation. Possibility of installing a portable saw (see “Type”) in a stationary manner. Most often, this feature is provided in circular saws (see “Device”), and for a stationary installation such a saw is usually turned “upside down” and fixed on a workbench or other base - thus, the sole turns into an impromptu work table. In addition, there are reciprocating saws with a similar function. In them, a stationary installation means the ability to secure the saw directly to the workpiece using a clamp - this allows you to make an even cut without the need to hold the saw suspended and constantly control its position in your hands.

— Water cooling (coolant). The saw has a water cooling system. In this case, we are talking about cooling the workpiece and the blade: water is constantly supplied to the cutting site using a special pump. Thanks to this, the heating of the blade is reduced, its service life is increased, the quality of the cut is improved and the amount of dust generated during sawing is noticeably reduced. The method of collecting water supply may be different: some models need to be connected to a water supply, others are equipped with their own water tanks. Note that water cooling is not required for sawing wood; but when working on stone, concrete and other hard and dense materials, it can be very useful.

— Keyless blade replacement. Possibility of replacing the saw blade without using wrenches, screwdrivers or other special tools. In other words, to replace the blade, the user does not have to look for an additional tool - you can open the fasteners, change the blade and secure it manually.

— Pendulum stroke. The presence of a pendulum function in the reciprocating saw (see “Device”). With this stroke, the blade, making a reverse movement, deviates slightly from the cutting line in the direction opposite to the teeth. This increases the cutting speed, reduces the heating of the blade and makes it easier to remove sawdust from the working area. At the same time, the pendulum stroke somewhat reduces the quality of the cut and is not suitable for curved lines. Therefore, this function is usually made switchable, and in some models it is also adjustable: using the switch you can change the amplitude of the pendulum.

- Display. The display shows important information about the operating modes of the saw. This can be: current strength, cutting speed, number of passes, operating time, etc. The information displayed on the screen depends on the modification of the sawing tool.

Popular models

Attics. types of mansard roofs. Which design is better to choose?

The best new wood hacksaw models are presented below.

Gross Piranha 24106 450 mm

High-quality hacksaw at an affordable price. It can be purchased for 900 rubles. The model is equipped with a fixed handle. Features hardened teeth and Teflon coating.

Has the following advantages:

- 3D sharpening.

- Processes wood, laminate and polystyrene foam.

- Rubberized handle.

The length of the canvas is 450 mm, and the pitch is 11-12.

Gross Piranha 24106 450 mm

BLACK+DECKER BDHT0-20169 500 mm

One of the cheapest hacksaws for wood. Its cost is about 600 rubles. The teeth are hardened and their pitch is 11. Equipped with a fixed handle. Only wood is processed with a 500 mm long blade. The saw with hardened teeth received a longitudinal-transverse direction. There is also a 3D sharpening function.

BLACK+DECKER BDHT0-20169 500 mm

STANLEY JETCUT 2-15-595 450 mm

Fine teeth allow you to make the cut as accurately as possible. Also processes wood. Teeth pitch 11 points. The hardened teeth received a longitudinal-transverse direction. The fixed handle adds reliability during operation. The length of the blade is 450 mm. The price is within 1000 rubles.

STANLEY JETCUT 2-15-595 450 mm

BISON Professional 15154-250 250 mm

Great option for hiking. The length of the canvas is 250 mm. This is optimal for small jobs. Can process laminate, wood and plastic. It will cost only 450 rubles. Ideal option for tourists.

BISON Professional 15154-250 250 mm

Vira 800240 400 mm

A fixed handle and 3D sharpening function are typical characteristics of modern hacksaws. Suitable for smooth and precise operation. Designed for wood processing only. The 400 mm long blade is suitable for small and medium-sized jobs. The direction is transverse. Price 450 rubles.

Vira 800240 400 mm

STANLEY JETCUT 2-15-281 380 mm

Belongs to the category of new products. Cutting direction: longitudinal-transverse. Hardened teeth process the wood. The length of the canvas is 380 mm. The price is within 950 rubles. Teeth pitch 7 points.

STANLEY JETCUT 2-15-281 380 mm

Kraftool Katran Precision Cut 1-15194-18-22 185 mm

Performs cutting of wood, plastic and laminate. There is also a 3D sharpening function. The length of the canvas is 185 mm. The price starts from 720 rubles. The direction of the saw is longitudinal-transverse. Suitable for hiking or trimming small branches in the garden.

Kraftool Katran Precision Cut 1-15194-18-22 185 mm

JCB JSW002 550 mm

This model is equipped with the longest blade of the models presented in the rating. Its length is 550 mm. The fixed handle with a rubberized insert ensures comfortable work. Can process materials of sufficiently large diameter and thickness. Tool steel prevents possible spring actions. Such a tool will cost 600 rubles.

JCB JSW002 550 mm

Gross Piranha 24100 450 mm

Processes wood, plastic and laminate. The set includes one canvas. Its length is 450 mm. The longitudinal direction of the saw is provided by hardened teeth. The fixed handle and the possibility of 3D sharpening play an important role. The tooth pitch is 7-8 points. The cost of a copy is 1100 rubles.

Gross Piranha 24100 450 mm

STANLEY Fatmax 0-20-556

A miniature hacksaw will be indispensable in tourism and farming. The length of the entire tool is 302 mm. Outwardly it resembles an ordinary knife, but differs in the presence of teeth. The reliable rubberized handle prevents slipping in the hand. Best for cutting drywall or thin plywood. The price is in the average range for such a tool. It will cost 1200 rubles.

Bahco 2600-16-XT11-HP

Universal model for cross cutting. This is one of the best rating models. Many are amazed by the long-lasting sharpness of the teeth. Friction during operation is reduced by the low friction coating. This protective layer reduces the degree of heating of the canvas and also protects against corrosion. Unfortunately, the cut quickly begins to turn black. This model costs 1500 rubles.

*Review of the best according to the editors of expertology.ru. About the selection criteria. This material is subjective in nature, does not constitute advertising and does not serve as a purchase guide. Before purchasing, consultation with a specialist is required.

Despite the abundance of electric tools for cutting materials, traditional hacksaws are also used in human activities. With their help, you can quickly cut workpieces of various densities. In this case, there is no need to unwind the electrical wire, refuel the equipment with gasoline, and the tool does not take up much space in the trunk of the car. The low price allows not only professionals, but also home craftsmen to have hand tools. Today there are many different models; expert advice will help you make the right choice.

“Friendship-2” – where does the name come from?

“Friendship” - under this name in the USSR both processed cheese and chainsaws were produced. But it suits a two-handed cross saw perfectly! Why "Friendship-2"? Yes, because it takes two to cut, and their actions must be well coordinated, in a word, like friends. So the people who gave such an unofficial name to the instrument hit, as they say, not in the eyebrow, but in the eye.

If you inherited such a tool and are collecting dust in your workshop or garage, don’t even think about parting with it! Think for yourself - the saw is hand-held, which means it does not need electricity or other fuel. Without gasoline, a chainsaw is just a pile of metal, but Druzhba-2 will always help you out. So wipe the canvas with machine oil and place it in the far corner, fortunately, it does not take up much space.

Tape

Which hob is better to choose: glass-ceramic or induction

The band saw is a continuation of the jigsaw. Its canvas is represented by a belt with teeth, which is closed and driven by an electric motor. Compared to a jigsaw, it provides greater precision and cleanliness of the cut. The cutting depth can be 8-50 cm. Neither a circular saw nor a jigsaw can achieve the maximum cutting depth with a band saw.

The following types of band saws are distinguished:

- According to the material of manufacture - carbon and alloy saws. The latter are characterized by increased wear resistance.

- According to the manufacturing technology and hardening of the teeth, the tapes are classified into saw blades with cut unhardened teeth and cut hardened teeth.

The first saws are inexpensive and allow you to cut wood that has various inclusions. It is logical that low speeds and small amounts of work are used here. Second saws have a high cost, but also high wear resistance.

For shape cutting, 3/8" blades are used, for regular woodworking - 1/2" blades.

There are also band saws for cutting metal, similar in design to a woodworking band saw, but allowing only cross-cutting of rolled steel. This cut can be made at various angles.

What type of saw is needed

Circular saws are divided into two types: hand and table saws. Stationary or table saws are practically not used in everyday life, due to their complexity in operation. Therefore, hand-held circular saws are most often used in everyday life.

Special designs have been developed for them, thanks to the use of which it becomes possible to secure the saws upside down on the working surface.

As a result, you get a mini-machine, like a stationary circular saw. But the mounts are not universal; the platform must be selected individually for a specific model. Don't forget to take this into account when purchasing.

Qualification by purpose

Of course, it is very difficult to perform cutting work on a variety of materials with one tool. Therefore, experienced craftsmen in their arsenal have various hacksaws that can quickly and efficiently perform the task. According to their intended purpose, hand sawing tools are divided into the following types:

A classic hacksaw should be in the household of almost every person, even those far from carpentry and construction work. This tool can have different blade lengths and cutters of different heights. The ideal option is to have a tool with replaceable blades that can process materials of any hardness and porosity. A circular hacksaw (narrow) allows you to clearly and accurately cut lines of various shapes, up to through square and round holes. Frequent teeth can be located on both sides of a narrow blade. Working with such a device requires special care so that the blade does not turn in the other direction when moving uncertainly. The bow saw differs from its counterparts in its rather complex design. Its supporting part is made in the form of a large arc, to which a narrow blade with teeth is attached. This design solution allows you to cut out various shapes from wood materials and plywood. Despite the fragility of the bow saw, it is very effective when cutting branches and tree trunks. The backed hacksaw is equipped with a special stiffening rib, which completely eliminates the possibility of bending the blade during operation. A feature of this tool is its inability to make a cut below the width of the working part of the blade. A tenon saw has two handles and is very similar in appearance to a plane. Working with this tool requires special skill and experience from the carpenter. It is mainly used for cutting tenons or grooves in wooden materials of any hardness. Mechanical folding hacksaw is convenient for use on a hike or on vacation

Its compactness and safety when folded attract the attention of tourists.

Classification and use of hand tools

Hand saw - bow

In the most general form, hand saws are divided into bow (tension) structures and hacksaws.

In the beam design, the tension of the blade is achieved by the movement of the movable cheeks of the machine, equipped with lugs for fastening.

A classic hacksaw does not have a tension mechanism. The strength and weight of the blade attached to the handle are sufficient for normal operation.

Hand saw - hacksaw

A variation of the large hacksaw is the two-handed saw, which is pulled by physical force when pulled.

A compromise between the two designs was a tension hacksaw on a metal machine and a jigsaw of the same design.

In such saws, the blade is tensioned with special wing nuts.

The main differences that determine the use of a saw depend on the length of the cutting blade, the size and shape of the teeth, and their setting.

Hacksaws for cross-cutting wooden beams and boards are equipped with triangular-shaped teeth.

Loppers and saws for cutting down bushes and trees are equipped with the same blade.

Hand saw - lopper

For longitudinal cutting of wood (along the grain lines), blades with inclined (oblique) teeth are used.

The sawing speed, applied force, and cutting thickness depend on the height of the teeth, their shape, frequency, sharpening and setting of the cutting edge.

An undone wood saw becomes clogged with sawdust; an incorrectly sharpened tooth edge requires extra effort when cutting.

Various degrees of tension on the bow saw blade are used for straight, oblique, and shaped cuts. The tighter the canvas is, the more difficult it is to turn.

Straight cutting requires the use of a wide hacksaw blade; for figured sawing, narrow blades with fine teeth are used.

Jigsaw blades are distinguished by the smallest and most frequent teeth, which are used to make fine artistic cuts on soft wood or plywood.

When working with soft wood, high teeth are sharpened at 40 - 50°; for hard wood, small teeth require sharpening at an angle of 70°.

Hand saw - jigsaw with replaceable blades

Jigsaw blades do not need to be sharpened; they are easier to replace.

Hacksaws and loppers, in the blade of which the teeth are grouped into 7-8 pieces and separated by a deep cut, are intended for wet (living) wood.

For home use and garden work, universal hacksaws with a single handle and replaceable blades (with different blade and tooth configurations) are convenient.

Special hacksaws with a back, veneer saws, cutters, circular, and tenon hacksaws are rarely used in household work.

Features of the instrument

The design of the saw is formed by the same basic components - a cutting metal blade and a handle. The fundamental feature of the device can be called the presence of that same pad. This is an overhead part on the top of the canvas that acts as a stiffener. What is this add-on for? A traditional hacksaw produces slight vibrations in the blade during the sawing process, which slow down the work and can affect the quality of the result. In order to minimize “hanging”, manufacturers increase the rigidity of the canvas by increasing its thickness. The negative effect of such a change in parameters will be the expansion of the cutting area, which is unacceptable in the delicate processing of small structures and parts. In turn, the back saw, precisely due to the additional device with increased rigidity, eliminates the effect of vibration, while maintaining a moderate thickness of the blade. This tool is also distinguished by a small, hardened tooth, which allows it to perform precise and neat cuts.

How to use?

To cleanly saw sheet materials and various boards, it is worth installing a cutting block with 50-60 teeth instead of a standard disk. If the quality bar is not very high, you can limit yourself to a disc with 40 teeth. If possible, place the material face down. If this is not possible, they resort to preliminary trimming or install an overlay that prevents splitting, or use a guide rail.

Almost all circular saws are equipped with thumbscrews or special levers. These items help loosen the bolt that holds the blade. Having set its new desired angle, you need to tighten the bolt again.

The best hacksaws for wood

Such instruments differ in the size and shape of the blade, which determines the purpose of the instrument. Different cutters are used for longitudinal, transverse and mixed cuts. The universal saw blade is 450-500 mm, and its teeth are of medium size. It is more comfortable to cut branches in the garden with a short hacksaw, but it is better to cut logs with a long one.

FatMax 300 mm 11TPI Stanley 2-17-205

5

★★★★★ editorial assessment

100% of buyers recommend this product

See review

This is a circular hacksaw for precise and straight cuts. It can also be used to make holes in wood. Three cutting edges on each induction-hardened tooth ensure fast and efficient cutting. The two-component handle fits securely in your hand, allowing you to fully control the process. The length of the canvas is 300 mm.

Advantages:

- High-quality manufacturing materials;

- Long service life;

- Light weight;

- Wear resistance;

- Easy and fast cutting.

Flaws:

Price.

With such a specialized tool, you can make both straight and curved cuts.

Bahco 2600-16-XT11-HP

5

★★★★★ editorial assessment

98% of buyers recommend this product

See review

The Swedish tool can cope with various wooden bases. The hacksaw is designed for cross cutting, although if you have experience, you can also perform longitudinal cutting with it. Thanks to its unusual design and long-lasting tooth sharpness, Bahco is very popular. The presence of a low-friction coating significantly reduces friction during work, which means that the hacksaw blade heats up less, and the work itself is not so tiring.

Advantages:

- Corrosion protection;

- High quality;

- Light weight – 450 grams;

- Convenient design;

- Perfect cut.

Flaws:

Quite a high price.

The handle of the hacksaw is securely attached to the blade, ensuring safety and comfort of use.

Gross Piranha 24109

4.9

★★★★★ editorial assessment

80% of buyers recommend this product

See review

The tool is made of high quality steel. It is marked 52 HRc, but thanks to repeated hardening, the strength indicator has been increased to 66 HRc units. Classically shaped teeth with triangular sharpening make work easier. The length of the canvas is 400 mm, and it is coated with a Teflon layer. The plastic handle has a rubber insert that prevents the tool from slipping in your hand.

Advantages:

- Effortless work;

- The sharpness of the teeth is maintained for 2-3 years;

- Good glide on wet wood;

- Withstands intensive use;

- Ergonomics.

Flaws:

Not intended for cutting large diameter parts.

This hacksaw will provide an even cut that is indistinguishable from a circular saw.

Stanley Jetcut 2-15-283

4.7

★★★★★ editorial assessment

86% of buyers recommend this product

See review

The hacksaw was made by a popular Chinese brand known for the high quality of its products. Jetcut cannot be called a cheap tool, but the model has a number of advantages. Three-way sharpening of the teeth allows you to cut wood moving in both directions. The length of the blade is 450 mm, so the hacksaw can be used to process any piece of wood.

Advantages:

- Comfortable hard plastic handle with rubber insert;

- Possibility of long-term work without fatigue;

- Blade made of hardened steel;

- Long lasting sharpening;

- Reliable design.

Flaws:

Not the neatest cut.

The ergonomic handle will allow you to confidently operate the tool, but this hacksaw is not suitable for fine work.

Fiskars 124810

4.5

★★★★★ editorial assessment

84% of buyers recommend this product

See review

The bow saw has a collapsible design, which allows you to replace the blade without the use of additional tools. The worker can help himself with his second hand by grasping the arch, which has grooves for a comfortable grip. The blade length is 700 mm, making it possible to work with large diameter workpieces.

Advantages:

- The paint coating protects against corrosion;

- High quality product;

- Compactness;

- Sharp blade;

- Reasonable price.

Flaws:

It is tiring to work at arm's length due to the heavy weight of 0.77 kg.

The model is designed for pruning and sawing garden trees, but it is difficult to work with such a heavy hacksaw for a long time.

Choosing a saw for the job

In construction stores and on the market there are many different types of hacksaws for wood, and they all differ from each other in several ways:

- Size and shape of teeth.

- Canvas size.

- The grade of steel used, from which the blade is made.

- Handle shape.

If one of the described parameters changes, then the hacksaw will greatly change its original characteristics. All of these factors should be taken into account when purchasing a tool to perform various tasks. You should also make sure that the saw fits perfectly in the hand of the master, because this is what makes the work much easier. You should not buy tools with a small handle if the craftsman has large hands, because it will be inconvenient for him to use such a hacksaw, which means the quality of the cut will suffer.

Teeth size

This parameter greatly affects the speed of work, as well as quality. To make it convenient to determine the size and number of teeth, the designation TPI was specially introduced, which indicates how many teeth there are in one inch. A similar parameter can be found at any time in the description card of the hacksaw blade, and in addition, this value is often indicated directly on the hacksaw blade.

- A wood saw with large teeth is capable of providing a rough cut and even greater speed of work. This parameter will be required in order to cut firewood, large boards and branches. The TPI of such an instrument is from 3 to 6.

- If you want to make a neat and even cut, you will need to buy a saw with small teeth, namely with TPI from 7 to 8. Such a hacksaw will be ideal for cutting fiberboard, chipboard, and laminate. But it’s immediately worth noting the fact that the productivity will be much less than that of the first version of the hacksaw blade.

Carpentry saws are selected according to the size of the teeth. To process the simplest wood, you can buy either a small or large hacksaw, and for delicate material, for example, fiberboard, it is best to buy a fine-toothed saw. There are several types of markings in stores - for wood, for drywall, and so on. The difference will be the same size of the cloves. For each material, you should choose its own optimal parameter.

The teeth may also differ in shape, and this will also affect the purpose and scope of the tool:

- For longitudinal sawing, the teeth are made in the form of a triangle with oblique angles. Their external characteristics resemble hooks that are sharpened on both sides. Such a saw will slide along the wood fibers and make the cut very smoothly, without leaving any nicks.

- For cross cutting, teeth are used, which are identical in shape to an isosceles triangle. This type of hacksaw cuts as it goes back and forth, but it is best to use it only for dry wood.

- Sometimes it is necessary to use a mixed type of cutting, and for this option, a hacksaw with teeth of all types, which are located one after another, is best suited. Curved and long teeth will cut the material forward, and triangles, when moving backward, will help make the channel wider and catch shavings and sawdust.

Now let's look at the types of hand saws based on the material they are made of.

Steel

No one wants a recently purchased saw to break down after only a couple of uses, and for this reason it is advisable to opt for the highest grades of steel. The teeth can be hardened or regular, and the latter are sharpened themselves. Blades with hardened teeth are disposable, and this is not a joke, because when they wear out, you can’t do anything with them yourself.

This species can be easily recognized by its dark color. Ideally, you should choose saws that are made of stainless steel, because the garage is often damp and wet, which means the saw begins to corrode. And there are often situations when work is carried out outdoors, but after using the saw, it is forgotten on the site, it rains, and then the tool inevitably becomes covered with a layer of rust.

Length of metal sheet

This parameter is determined by the pitch of the teeth and the size of the saw.

- Small hacksaws are equipped with frequent and small teeth, and the blade length is no more than 35 cm.

- Universal type hacksaws are made with medium-sized teeth, and the blade length is no more than 55 cm.

- Wide hacksaw blades have large teeth and an increased pitch, and the length of the tool is no more than 60 cm.

By the way, the hacksaw blade itself can differ not only in length, but also in shape. Traditional saws are usually tapered at the end (on one side). This will indicate that you bought a universal tool that can be used to cut all kinds of objects. A rounded blade is usually used for cutting branches or other objects at a distance. Such hacksaws are usually very light and glide efficiently over the surface of the wood, and do not cause much trouble to the owner.

Handle

The handle makes it convenient to carry out any type of work. The saw should fit perfectly in the hand, and also be quite comfortable. To make a handle, different plastics are usually used, which are quite pleasant to the touch. When choosing, you should make sure that the material will not slip under any circumstances if your hand gets sweaty while working. It is for this purpose that special grooves and indentations are made in the handle, as well as rubberized linings. Such parameters are often taken into account by manufacturers themselves, so they try to produce products that are distinguished by an incredible variety of handles.

Criterias of choice

Which saw do you use most often?

LuchkovaHacksaw

When selecting a tool, you need to proceed from the following considerations:

- Purpose of the saw.

- What kind of workpieces need to be sawed?

The length of the saw is also worth considering; it can be 300 mm or more than 700. The smaller this value, the smaller the diameter (or width) of parts (or branches) can be cut.

A blade is often included with the saw, but often it is not of very high quality and is only needed to demonstrate the features of the tool. It is recommended to immediately purchase new blades of the required type and length.

The width of the saw also limits the possibilities when processing thick workpieces; for ease of work, the front part is sometimes made narrower than the back part - near the handle. This makes it easier to cut shapes.

It is recommended to buy bow saws with rubberized handles - they will allow you to work for a long time without rubbing your palms and allowing you to hold the tool securely.

How the tool works

An electric circular saw for wood consists of several elements. The electric motor is its main part. The blade for cutting is attached to the shaft of this element. Experts say that the synchronous commutator motor is most often used.

It has special brushes that wear out after some time. If these parts are not replaced in time, the electric motor will fail. Because of this, when choosing circulation equipment, it is better to give preference to a mechanism where the motor turns off automatically.

The performance of the device is determined by the engine power. The larger it is, the thicker the boards can be. Power also affects the following parameters:

- diameter of knives used in the tool;

- weight of the device;

- cost of equipment.

All this must be taken into account when purchasing.

Characteristics

The main characteristic that needs to be taken into account when choosing an electric circular saw for wood is the number of revolutions. The best option would be a device where this characteristic can be controlled. This will make it possible to perform high-quality sawing with optimal load on the device.

The circular saw must have protective electronic functions so that in the event of an accident both the device and the master are protected. Blocking accidental activation must also be mandatory.

The appearance of the product also matters. An additional handle will provide convenience when working. The product must be made of strong material to withstand load and mechanical stress. Balancing should be comfortable, hands should not slip, so that the equipment can be firmly held by a person.

Varieties depending on the functions performed

There are several types of circular saws with a disk:

- The mini saw is a portable device with an electric motor, which is convenient for small and medium-sized work.

- The fixed device is equipped with a support, under which there is a motor, started by a cord from a fixed network.

- Equipment with a battery (the most popular type of device).

- A miter saw that has a simple design and has a handle with a power button, a working unit, and a saw blade.

Operating rules and safety precautions when working with power tools

Electric circular saw

A hand saw for wood does not require special storage and care measures. It is enough to store it in a dry place, in a special box.

For occasional use, the canvas is protected from rust by lubricating it with grease.

To protect yourself from injury, it is better to work with hand tools wearing canvas gloves.

Self-sharpening of teeth can only be recommended for experienced users.

Black coloring of the cutting edge is used for hardened or ceramic teeth. These wood saws are sharp and durable, but cannot be sharpened.

The rules for operating power tools are more complicated.

The chainsaw must be run in, lubricated regularly, and all requirements of the manufacturer’s instructions must be followed.

It is necessary to drain the fuel after work and occasionally sharpen the saw chain, which is best left to specialists.

The same requirements apply to the mechanical part of electric saws.

When operating an electric saw, you must constantly monitor the condition of the cable insulation, the electric motor contacts, and the integrity of the plug.

Safety rules for working with power tools prohibit their use when tired or drunk.

You cannot work without a protective casing, or move the tool to another place with it turned on.

Inexperienced users are not recommended to work with power tools above shoulder level, from awkward (unstable) positions.

When working for a long time, be sure to wear safety glasses, special earplugs or headphones, and gloves.

When pruning or cutting down garden trees, a safety helmet will not hurt.

Hand-held circular saws

An indispensable tool at a construction site is a hand-held circular saw for wood. It is capable of cutting sheet material (plywood, various wood-based boards, metal), and with its help it is easy to cut boards of small thickness.

The circular saw is universal. It copes equally well with the transverse cutting of wood; it can be used to make precise longitudinal cuts. For any material and method of work, it is easy to choose a disc with suitable parameters. Thanks to a properly selected saw blade, the saw will provide a thin, even cut with clean, smooth edges.

When choosing this power tool, you need to take into account its main characteristics.

Engine power. The more power, the more “omnivorous” the saw, but also the higher its cost.

Rotation speed (rpm). The higher this indicator, the harder the material is on the saw teeth and the cleaner the resulting cut.

Depth of cut. Maximum disk output. In household devices this indicator is at the level of 50-65 mm, in professional models – up to 130 mm.

Among other things, when choosing a circular saw, you should pay attention to its weight. The mini-tool is highly maneuverable; when working with it, you do not need to exert excessive effort, but the low weight will certainly affect the power indicators

Varieties of hand saw

To obtain maximum results, you need to make 40-50 saw movements per minute. When it moves forward, pressure is applied; when moving backward, it is absent. The pressure force is determined by the properties of the material on which the work is being carried out. For example, the pressure force when working with soft metals should be significantly less than when cutting hard metal.

When working with a hand hacksaw, so that the tool blade does not injure your hands by cracking, it is necessary to avoid sudden movements accompanied by great pressure. In addition to hand saws, electric ones are also used. When using such a hacksaw, from time to time it is necessary to moisten the tool blade with a watery emulsion in order to avoid overheating.

Hand saws are divided into several types according to their intended purpose:

- transverse;

- archery;

- round (for cutting holes);

- classic hacksaws (longitudinal or transverse cutting);

- tenon hacksaws (for cutting connecting tenons).

Crosscut saws are designed for carpentry work and crosscutting. The saw teeth have an oblique sharpening and look like isosceles triangles. The angle at the top of the teeth is almost always 42-45 degrees. The blades of the cutting blade itself can be 1.1 or 1.4 mm thick.

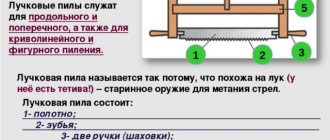

Bow saws are made from:

- from wood pulp of onion hardwoods,

- blades 785-800 mm long,

- bowstring, which is made of linen or twisted hemp cord having a thickness of 3-4 mm.

They can be transverse and longitudinal. For bow and cross saws, the width of the blade is 22-25 mm, the sharpening angle is within 70-79 degrees, the distance between the teeth is 4.5-5 mm. For bow rip saws, the cutting blade is 50-55 mm wide, 0.5-0.7 mm thick, the distance between their teeth is 5 mm, and the sharpening angle is 45-50 degrees.

Circular saws are used for sawing material along a curved path. The cutting part of these saws is 500 mm long, 5-15 mm wide, the distance between its teeth reaches 5 mm, and the sharpening degree is 55-60. Their sharpening is usually straight.

When selecting a hand hacksaw, not only the shape, but also the volume of the teeth plays a significant role.

There are 3 types of incisors:

- fine tooth - 2.0−2.5 mm (for cutting small products and high-precision sawing);

- medium tooth - 3.0−3.5 mm (for processing medium-sized parts);

- large tooth - 4.0−6.0 mm (for hard cutting of logs and beams).

There is also an international classification, it also classifies hacksaws, but not by the height of the teeth, but by their number, which falls on 1 inch of the cutting layer. This standard has also taken root among domestic manufacturers, so you should not be surprised if the instrument label contains foreign designations PPI or TPI. The number indicated behind these letters will indicate the number of teeth per 1 inch of length. The higher the number, the smaller the tooth (for example, PPI 8 or TPI 14).

Circular saw classes

When using a household saw, to avoid overheating, it is necessary to take breaks of about 15 minutes. Almost all tools are divided into professional and household, and circular saws are no exception.

When performing work using a household sample, breaks are taken every 20 minutes. Their total production per month will not exceed 30 hours.

If these indicators do not suit you and you require more intensive operation of the tool, then you need to purchase professional samples.

Professional saws will increase the time of continuous operation and have a significantly longer service life. But professional equipment also has its downside - the price.

Two-handed cross saw - a harsh tool

The crosscut saw is the largest of the hand saws, its length can reach almost two meters! There are four standard sizes in total, starting with 1 meter and ending with a canvas of 1750 mm, that is, each size is increased by 250 mm. The characteristic shape of the blades is rounded, and the tooth height usually does not exceed 20 mm. Even the smallest size of such a saw is a rather heavy tool that you cannot use alone for a long time...

The first two sizes were once produced for the needs of the population - their tooth shape is classic, triangular, with a sharpening angle of about 70°. However, everyone adapts the sharpening angle for themselves, because for soft wood in the summer it is better to reduce it to 35°, but for sawing in winter or for dry wood it is better to stick to 50° when sharpening. The longest saws (1500 mm and 1750 mm) were produced for sawing lumber. The teeth in such tools have a complex shape - between two M-shaped (Kremlin) cleaning teeth there are several simple ones, characteristic of cross-cut saws. They are sharpened and bred accordingly. Such teeth cut the fibers in the cut, and M-shaped cleaning teeth remove pieces of wood from the cut.

What is it and what is it for?

A bow saw can easily be defined as an outdated device. But even if you have the entire necessary set of power tools stored at home, there may be many situations when you cannot do without a hand-held bow saw. If we consider the main purpose of this tool, it is worth noting that this kind of device is intended for accurate sawing of metal parts, as well as for working with wooden surfaces.

A bow saw can be used to make various parting cuts with any type of wood. We must not forget that for a product intended for cutting wood, the method of cutting it – lengthwise or crosswise – does not matter. There is also the ability to work with only one hand. This tool can be easily selected for cutting wood: in the longitudinal direction, as well as in the transverse and figured, even in the angular direction. True, for thick logs it is better to choose a more serious tool.

If we compare a standard saw with two handles with a bow saw, we should highlight the following positive features over the classic product:

- a bow tool will allow you to make a much more beautiful cut;

- you will spend much less effort - sometimes you can work with a bow and a pair, which will not work when working with a hacksaw saw;

- easy care.

Recommendations for selection

It is very difficult to master the information and choose exactly the saw that is suitable for certain situations.

It is for this reason that it is advisable to study several recommendations at once that will help you choose the right hacksaw.

- First, decide on the material you plan to saw. Carpenters who work on small projects usually choose small saws with a short blade. Carpenters usually use large blades and teeth, because high precision of work is not important, but speed. A folding hacksaw is perfect for summer residents who need to process trees and shrubs.

- Frequency of use . Consider how often you need the tool. If it is rare, then it is better to buy a saw with hardened teeth, and if there is a lot of work, then a saw made of ordinary steel would be ideal.

The quality of steel should always be good. The higher the class, the better the product. Before purchasing, take the tool and bend it carefully. High-quality metal will be elastic and, when released, will quickly restore its shape, and if there is any deviation, then you should not buy such a tool. If the seller does not allow such a check, then he himself probably knows that the product is not of the best quality, which means it is not worth buying.

- When purchasing a saw, you should look at the cost. Not every tool’s price will correspond to its quality, because the price increase is often due to the well-known brand of the manufacturer. But here the situation is different - the higher the cost, the better the saw. Naturally, this is the case when the owner is honest and does not offer a fake, and the high quality product is not cheap. It is best to choose the average cost range, and if possible, buy an expensive saw.

- Always pick up a hacksaw before purchasing so that it is convenient for you.

There are no specific types of hacksaws that are better than others—there is a tool for every situation. Follow simple rules and you can easily choose the tool you need.

Circular saw with carriage

Such a device is intended for longitudinal and transverse cutting of boards, bars, wood, slabs and sheet materials. Angle cutting is also possible.

The main features of this machine include:

- you can set the minimum cut from 0 mm for cutting laminate, cutting grooves, cutting quarters

- instead of a saw, you can install groove cutters to create folding

- the table is made of steel, reinforced with profile pipes. Even with such a low weight, it is characterized by high rigidity, because ground steel has half the friction resistance, resulting in improved operation of the machine with an automatic feeder

- the working unit consists of a cast iron body on a cast iron bracket

- The dimensions of the machine make it possible to use the machine on a construction site and even move it through doorways

- If the client wishes, the dimensions of the table can be increased, a large carriage with a telescopic leg can be installed, and a metal-concrete frame can be made.

In order to accurately cut the workpiece across the grain and at an angle, a cross-cutting carriage with an increased stroke is required. The dimensions of the carriage make it possible to mount and trim long workpieces. The carriage must be equipped with a guide ruler.

Top 5 in terms of price and reliability

The range of “bows” is undoubtedly large, but there are brands and types that occupy leading positions. Let's look at the best of the best, which have a high rating among customer reviews.

BAHCO 10-30-51

Bow saw with one handle. The characteristics are simply amazing. With a light weight of 900 grams, it can be used for a variety of jobs. But its main purpose is the processing of dry wood. The saw blade reaches 76 cm in length and has triangular teeth. The tool has a comfortable handle, thanks to which the master’s hand will not slip, the work goes quickly, without delays.

Fiskars 1000615 (124810)

The Finnish company Fiskars produces saws of exceptional quality. The saw is made in the shape of a circular trapezoid, because quite long (70 cm). This device is necessary for the home because, firstly, it is light in weight (770 grams), and secondly, there are “Kremlin” teeth that alternate with regular ones, so you can cut both forward and backward. The device also has a very comfortable handle, thanks to which the master does not get tired of work. The main purpose is to cut thick branches and small tree trunks.

Stanley Pro 760

760 mm - bow saw blade, thanks to which you can trim branches of bushes and small trees. The weight of the device is 250 grams (very light, so it is a pleasure to use). The teeth alternate, and the main thing is the presence of double teeth, which allows you to work better and faster. Such teeth do not even require sharpening. The handle is comfortable, so there will be no problems with sawing.

TOPEX 530 mm 10A905

The unit has a low cost, so the characteristics are not at a very high level. Among the advantages: the size of the tool blade is 530 mm (this is the standard length), the teeth alternate (there are double ones), the weight is 500 grams, you can work with both dry and wet wood. The main and most serious drawback is the lack of a comfortable handle, which makes the work more difficult and time-consuming.