A novice welder needs to know what an electrode consists of and how to choose it correctly. In case of an error, even an experienced craftsman will not be able to complete the seam efficiently. More than 200 types of consumables are produced for different tasks.

A welding electrode is a metal rod made of electrically conductive materials.

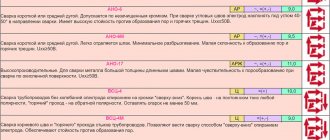

Explanation of the designations of the electrodes used for welding.

The markings on the electrode pack are very important. This determines whether the selected welding materials are suitable. Let's look at the decoding of the notation. Designations are applied in accordance with GOST 9466. The marking has the form of a simple fraction, with a numerator and denominator.

E50A - This is a type of electrodes used for manual arc welding. It is determined depending on the material that needs to be boiled. For ordinary ferrous, heat-resistant and structural steels, the type is taken from GOST 9467. The number in the index that follows “E” indicates the temporary resistance ( σпч ). For a weld seam welded with E50 type electrodes, the temporary resistance is 50 kgf/mm2 . Next comes the stamp - “UONII 13/55” . The brand carries information about the metal from which the electrode core is made. The brand is selected based on the metal being welded. You can familiarize yourself with the list of main brands and their areas of application.

Let's go back to the labeling. After the mark comes the diameter of the electrode, indicated in millimeters - “4.0”. After the diameter comes the letter “U” - this place indicates the purpose of the selected electrodes.

Brands of quality electrodes

Among the products of various manufacturers, there are companies that have become the most popular in the welding consumables market due to their quality, low cost and accessibility to consumers.

Among these manufacturers are:

- Russian brand UONI, whose products are also produced in neighboring countries. Works with all types of steel and cast iron. The resulting seams meet the requirements of domestic standards.

- The Japanese company Kobelco has certified the Lb-52U product line with reliable protection inside the joint, easy removal of slag, and a minimal amount of scale. The products are certified by NAKS.

- ESAB offers several types of electrodes. OK 94.25 work with cast iron, tin bronze, and non-ferrous metals. OK 96.20 for welding aluminum without the use of inert gases. OK 61.30 for processing stainless steel under thermal load.

In addition, products from factories such as KISWEL (South Korea) are widespread; Resanta; Lincoln Electric (USA), QUATTRO ELEMENTI (Italy).

What is the purpose of electrodes?

Differences in the coating and core material of the electrodes are determined by their purpose. Some are used for welding carbon, low-carbon, and low-alloy steels whose tensile strength does not exceed 600 MPa. This group is conventionally designated by the letter - U.

The second group are materials used for medium-alloy steels whose tensile strength exceeds 600 MPa. Symbol – L.

The third group includes welding materials used for welding work with high-alloy steels. The properties of which are aimed at solving certain problems. They are designated V.

The next group is used when welding heat-resistant alloy steels. Denoted by T.

And the group closes, which also includes highly specialized welding materials, namely those used for surfacing metal products with special characteristics. Designated - N.

The last designation is “D”.

The thickness of the coating is indicated here. They come in 4 types:

- “M” – with thin.

- "C" - with average.

- "D" - with thick.

- “G” – especially thick.

Each type includes electrodes in which the ratio of the diameters of the rod and coating corresponds to the following conditions:

- For thin – D/d ≤1.2

- For medium D/d ≤1.45

- For thick D/d ≤1.8

- For particularly thick D/d ≥1.8

Now let's go down. We see “E 43 2(5)” - this is the index of the weld metal (welded metal). Most often it is taken from GOST 9467, 10051 or 10052. According to the index in GOST, you can see what minimum properties the seam will have. Next we see the letter “B”. It indicates the type of electrode coating.

Types of coverage: how to determine which one to choose?

Coating of electrodes is possible in the following options:

- Acid coating - A

- Basic coating - B

- Rutile coating - R

- Cellulose coating - C

In this regard, it is impossible to say which one is better and which one is worse: they are all designed for different types of work, as well as conditions of use. Therefore, it is impossible to unambiguously answer the question which electrodes for welding will be better. As a rule, it is necessary to use them to form a strong weld seam in critical structures.

Next we see the number “1”.

This is a designation for the positions in which you can cook.

«1» – for any provisions;

«2» -for any, with the exception of top-down;

«3» — vertical from top to bottom, horizontal, bottom;

«4» - lower position and boat position.

And the number “0” ends.

This is the type of current and polarity. This figure is taken from the table below. Indicates “0” that welding must be performed on direct current with reverse polarity connected. Having analyzed the transcript, we will dwell in more detail on each point.

What are welding electrodes coated with? What is this coating?

Coating is a special coating that is designed to protect molten metal from the negative effects of oxygen. It creates a gas shell while the core melts.

Coatings are divided according to the functions they perform: gas-forming and slag-forming

functions.

Gas-forming

components create protective gases and an ionizing atmosphere.

Slag-forming

include elements that promote deoxidation, refining, alloying of the seam and the base metal, increasing the bonding and plastic properties of the seam. During welding, a layer of slag is formed in the weld pool for protection.

Types of coverage: how to determine which one to choose?

There are 4 main types of electrode coatings used in manual arc welding. Let's deal with each of them one by one.

Let's talk about the main component. Rutile

- a natural mineral that, by forming a protective gas shell, creates a weld pool. Welding with materials such as rutile is characterized by high stability.

Ignition of the arc occurs without problems even for beginners. That is why they are often used in installation. The seam is obtained with small scales, with a uniform casting structure over the cross-section.

The following advantages of working with this coating can be highlighted:

- It is permissible to use both alternating current (AC) and direct current (DC);

- Easy to ignite using both new and secondary arc ignition;

- Not demanding on the cleanliness of the product surface. Can be used on rust, undried edges of the product, scale and even paint;

- The metal practically does not splash.

The disadvantages include:

- There is not a large range of materials that can be used with;

- In the weld pool there is active mixing of slag and metal, which makes it difficult to distinguish where the slag is and where the metal is. This leads to slag inclusions;

- The presence of moisture in the coating leads to a defect in the form of pores. This is an important point that is worth paying attention to. Proper storage and calcination before welding is necessary.

Acid coating: application features

Good to use, but in an open space, otherwise it will not be safe for the welder. The advantage is definitely that the slag is easily separated.

Acid coating requires low idle voltage. Currently they are rarely used.

Basic coating

They have become very widespread, one might even say ubiquitous, due to their versatility. Their coating contains fluorine and calcium. During welding, the coating elements evaporate, protecting the molten metal. The bath's gas shield actually consists of carbon dioxide.

They are used when using direct current; as a rule, the polarity is reversed.

When melted, the coating removes harmful impurities from the weld such as sulfur (S), phosphorus (P) into the slag. This helps to increase strength, increase ductility, and reduce fragility. As a result, there are no cracks.

Arc ignition is worse than that of rutile ones, but their range of application is wider. The arc burns less stably compared to rutile. This is due to the content of fluoride compounds that reduce ionization.

Welding should be carried out only on a well-prepared surface. There should be no moisture or dirt. Otherwise, we will get a large number of pores in the weld metal. Another reason for pores is an increase in the length of the arc. The protection dissipates and gas from the atmosphere enters the weld pool.

Cellulose coated electrodes

The use of welding materials with this type of protection is less and less. This is due to the fact that welding with them hydrogenates the weld seam. The strength of the connection decreases and pores appear.

More than half of the coating consists of organic substances and during welding provides strong gas formation. They cook in all positions; it is even possible to carry out the process from top to bottom.

The surfaces may not be well prepared; this will not actually affect the quality of welding. This has something in common with rutile coating.

Main characteristics

Electrode diameter

Each electrode has its own diameter. In this case, two diameters are separated: the diameter of the coated electrode itself, and the diameter of the welding wire from which the rod is made. The first diameter is used most often.

The most popular are 3 mm welding electrodes. 3 millimeters is equal to the diameter of the rod. 1 mm electrodes and 2 mm electrodes are used less frequently. Welding electrodes with a diameter of 1 mm are generally used only for welding thin metal parts. For example, steel sheets. There are also thick electrodes, for example 5 mm electrodes. They are also used infrequently, since they are used to weld thick metals. In addition, to use thick electrodes, a very powerful welding machine is required.

The diameter is selected based on the thickness of the metal. Usually these are the same values. For example, to weld metal 2 mm thick, electrodes with a diameter of 2 mm are often used.

Coverage type

We wrote above that the electrodes may have a coating or coating that protects the seam from oxidation and stabilizes the arc. There are several types of coating: acidic (denoted by the letter A), basic (letter B), cellulose (letter C), rutile (P), mixed coating (when several types of coating are used simultaneously).

The most common coatings are basic and rutile. For beginners, we recommend choosing electrodes with rutile coating, since it is much easier to weld with such rods.

Spatial position

At first you will most likely only weld horizontal seams. But over time, you will learn to cook in other spatial positions. For example, in vertical or ceiling. To perform such work, special electrodes designed for this are required. Before purchasing, make sure that the electrodes you choose are suitable for your application.

Purpose of electrodes

Also, many electrodes are designed only for welding certain metals. It is advisable to know in advance what you will be cooking. If it is steel, then buy electrodes designed for steel. You should not take rods for another metal.

Marking

All the information we described above is usually described in a short set of numbers and letters. This set is called a marking or brand of electrodes. We talked about this in detail here. Be sure to read it to learn how to read the labels.

What should you keep in mind when you are about to start welding?

Before you begin, you should carefully inspect your home welding electrodes and determine:

Is there any mechanical damage? If they exist, then this is an obstacle to further actions, the welding arc will not be stable, and the protection of the molten metal of the bath will not be of high quality.

Humidity: Should be minimal. The electrodes will only be dry if they have been stored correctly. Don’t worry if this point has become an obstacle to further action – it can still be fixed. To do this, you need to dry them in a special oven or, if you are at home, in a regular oven.

Another option , which will require more time, is to leave them in a warm, not humid place. So, dry welding materials will provide you with a strong weld and reduce the risk of such a defect as gas pores.

The shelf life of electrodes used for manual arc welding is determined by the manufacturer, but as a rule it is without restrictions. The main thing is the storage conditions, which are also given by the manufacturer. In a closed package sealed in plastic film, the electrodes will be nothing even after 10 years.

Storage

Storing electrodes is a topic that for some reason many people avoid. And in vain. After all, a beginner can follow the welding technology and generally weld correctly, but the weld will be of poor quality due to the fact that the storage conditions have been violated. And the welder, due to his inexperience, will blame everything on a bad welding machine, inconvenient working conditions, or any other reasons.

Yes, if stored incorrectly, electrodes can indeed significantly deteriorate the quality of the finished welded joint. And all because of the moisture that the electrodes actively absorb. For this reason, it is not recommended to store electrodes in damp, stuffy areas, such as basements. Also, do not store electrodes on the ground, even if they are in a box. And don't use storage boxes at all. Replace them with a special case. You don’t have to buy it; you can make it yourself from a section of HDPE pipe.

After all, the box is just a package of electrodes; it is not intended for long-term storage in a garage or on mezzanines. Try to ensure that there are no strong temperature changes in the room. This is obvious, but many people leave electrodes in an unheated garage all winter and then wonder why the rods crumble or why the arc doesn't strike.

Types of electrodes and how to choose them for welding at first?

Among the most popular and available for welding are the following brands of electrodes:

- OK-46

- MR-3

- SSSI 13/55

- TsL-11

Let's consider each type in detail.

TsL-11

Electrodes of this brand are used for stainless steel, the so-called stainless steel. They are used in products that will operate at temperatures not exceeding 250 °C.

In everyday situations, they help the welder to achieve a seam with fine flakes, and to obtain a transition without fractures between the edges of the product and the seam. The slag itself has a small volume, so it will not be difficult to remove it. Please note that they have basic coverage.

Rutile MP-3 and OK -46

These electrode brands are rutile. It should be chosen if you work with carbon and low-alloy steels. The undoubted advantage of the chosen model is that it can be used with both direct and alternating current. The most widely used welding electrodes are the MP-3 brand, especially in everyday life. At the dacha or in the garage, they are best used for welding.

The arc is stable despite the quality of preparation of the product and the cleanliness of the metal surface. Another plus is that the metal practically does not splash. They have absorbed all the advantages of their coverage while at the same time reducing the negative factors.

UANNI 13/55

This is an extremely commonly used and very popular electrode. Unlike the previous type, the main coating is used. They are used in the same way as the previous grades for low-carbon, low-alloy steels. This option is also good because it is used for elements of critical products and structures. This is due to the characteristics of the weld seam formed:

- It is distinguished by its special plasticity;

- The seam is durable and can withstand heavy loads;

- When applied, it is not afraid of cold;

- Voltage drops are not critical.

When working with UONII 13/55, special rules must be observed

These rules apply to the preliminary preparation of materials: they must be clean from rust, soil, oily contaminants, and moisture. If the workpiece has oil, water, rust stains or drops, pores will appear.

Features of electrode coating

Coating is a solid porous substance. It covers the entire rod with the exception of the outermost section 20-30 mm long, intended for fixation in the electrode holder.

The entire electrode rod is coated with coating.

What is the role of the coating?

As a result of combustion of the mixture, the following occurs:

- A cloud of carbon dioxide and other gases forms. They are needed to protect the melt from oxidation by atmospheric air.

- Free ions are formed that support the arc. Particles act as charge carriers.

- Oxygen is removed from the steel (deoxidation occurs).

- The melt is saturated with alloying elements. They improve the properties of the material.

- The fresh seam is covered with slag. It protects the metal from oxidation by atmospheric air and slows down its cooling. As a result, gases and impurities have time to leave the seam before crystallization, and the appearance of cracks is prevented.

We recommend reading Where OZL-6 electrodes are used

The listed effects manifest themselves to varying degrees depending on the type of coating.

Properties of coating components

To stabilize the arc, substances with low ionization potential are used:

- Potash, ammonium nitrate, potassium chromate.

- Silicate glue with sodium or potassium (liquid glass). At the same time it plays the role of a binder.

- Barium carbonate.

- Titanium concentrate.

- Calcium carbonate (chalk).

The coating consists of silicate glue and titanium concentrate.

The cloud of protective gases is formed by the following components:

- Cellulose.

- Dextrin.

- Food and wood flour.

- Starch.

- Marble.

Slag is formed due to the following elements:

- Marble.

- Potassium, feldspar and fluorspar.

- Chalk.

- Titanium concentrate.

- Quartz sand.

- Manganese ore.

- Rutile, ilmenite.

Alloying Additives:

- Titanium.

- Silicon.

- Manganese.

- Chromium.

- Vanadium.

- Graphite.

- Molybdenum.

Slag is formed due to marble and potassium.

For deoxidation, the following substances are introduced in the form of ferrites:

- Aluminum.

- Titanium.

- Molybdenum.

- Chromium.

- Manganese.

- Graphite.

These elements react more actively than iron with oxygen, binding it.

In addition to the listed components, others are also used.

To impart plasticity, the so-called. forming additives – bentonite and kaolin.

Some grades contain iron powder, which increases the deposition rate.

Electrode color

The coatings have the following colors:

- The main ones are beige or white.

- Sour - gray.

- Cellulose – light gray with a brown tint.

- Rutile - gray, blue, green or brown.

The color of the electrodes may be gray.

The above list corresponds to most products, but there are also green basic consumables, white sour consumables, etc.

How is electrode coating produced?

The shell is made in the following order:

- The ingredients are ground into flour.

- They are sifted through a system of sieves and mixed with precise proportions.

- Liquid glass (binder) is added to the dry mixture.

- The coating is thoroughly mixed.

There are 2 methods of applying coating to the wire:

- crimping;

- dipping.

Coating is applied to the wire by crimping or dipping.

It is necessary to strictly observe the quantity of components and distribute them evenly. Therefore, special equipment is required to produce the coating.

How does moisture affect materials?

All types of electrode coatings absorb water well due to their high porosity. As a result, they lose their protective and other properties, which leads to deterioration in the quality of the seam.

You need to do the following:

- Store products from an open package in a special sealed container with heat-insulated walls that prevent moisture condensation.

- Before work, dry consumables in special ovens, observing the duration and temperature indicated on the packaging.

If the product has not been used for 2-3 hours, it will have to be calcined again.

The number of procedures is limited to 3-4 (indicated on the package). Repeated heating leads to shedding of the coating.

The working properties of the rutile shell are fully manifested in the presence of a small amount of moisture. Therefore, such products are dried at a temperature no higher than +200°C, and work begins only after a day.

And now more about polarity

If work is carried out on direct current (which most often happens), then the question may arise: what polarity should be connected - reverse or direct? How to do it?

We partially paid attention to the first question when we considered the types of coatings and types of electrodes. So be sure to check this when you get started.

Direct polarity connection diagram: ground is connected to the “plus” of the inverter, and the electrode holder is connected to the “minus”.

When the connection is made according to the reverse polarity scheme, as you understand, everything is the other way around: the ground cable is connected to the “minus” of the device, the “plus” is connected to the holder.

The question arises, what is the difference between these two connection schemes?

The difference when connecting is that with reverse polarity, more heat goes into the electrode metal. This reduces the heat input into the base metal and the structure is less deformed. When using direct polarity, on the contrary, heat input increases in the metal of the product.

It is often used for welding thick metal or TIG welding. You can read more in this article.

Purpose and classification

Such products are popular both at large enterprises and among private individuals. In addition, popular varieties and existing brands of electrodes are used for the same purposes.

Therefore, before you start welding, you need to know what consumables will be required in a particular type of activity:

- during repairs;

- connecting parts;

- eliminating cracks;

- metal deposition;

- for cutting.

In each individual case, a special substance will be required, which is introduced into the composition of the electrode or its coating.

Therefore, the purpose and price of each variety are different. The diversity of products has led to the appearance of many non-standardized names whose range of application is narrow. Therefore, the main classifier became the material of the rod from which the product is made.

From non-metallic options you can choose:

- graphite for soldering copper;

- carbon for cutting melting holes in various grades of steel;

Metal ones are non-melting and melting. The first includes a group of products that are not directly involved in the creation of the weld:

- tungsten for work in an argon environment;

- lanthanum with a highly stable arc and low melting point;

- thoriated with increased corrosion resistance;

- yttriated with increased stability.

Melting electrodes directly melt the edges of the parts to be joined.

Among them:

- 5 grades of carbon, 23 alloy and 28 high alloy steel;

- cast iron;

- from non-ferrous metals - copper, bronze, aluminum.

One of the main classifiers was the chemical component.

Based on this, the following varieties can be distinguished:

- Ore acids with an increased melting rate. They are used for inverter and transformer devices, which makes them the most common among other brands. Welding produces a lot of acrid smoke, which is harmful to the health of operators and requires increased occupational safety measures.

- Rutile with the addition of titanium dioxide. More secure than previous ones. They are characterized by low scale spread and form a neat seam.

- Mixed rutile-cellulose.

- Calcium fluoride for operation with constant reverse current.

- Organic with cellulose coating. It is convenient for the welder to work with them in any position, with direct and alternating current.

- Ilmenite with a smooth and stable arc.

We recommend reading Technical characteristics of MP-3 electrodes

What electrode diameter should I choose?

This is another question you may encounter. Everything here is quite simple: the diameter will be selected according to the thickness of your welded metal.

Moreover, if the metal is very thin (less than one and a half millimeters), then manual welding (RMW) is most often unacceptable (here we use tungsten electrode welding, semi-automatic or automatic).

In other situations, you can select an electrode. You can see the ratio in the following table:

Distribution by purpose

Purpose is the characteristic according to which absolutely all known electrodes are distributed. The types and use of rods are indicated by one letter (GOST 9466-75):

- structural steels, including low-alloy steels with a strength of 60 kgf/mm2 (600 MPa) are marked in the markings with the letter “U” - carbon;

- alloyed structural steels having a strength of 600 MPa - “L”;

- high-alloy structural steels – “B”;

- heat-resistant alloy steels – “T”;

- alloys with special properties, which are characterized by surfacing - “N”.

The purpose is indicated on the unfolded stamp.

How to determine the current value?

This is another important question you may have. In general, it should be noted that the current value is always given approximately, in a fairly wide range. This is due to the fact that with different spatial positions, different thicknesses of the product, and the number of passes, it will vary. And it is determined by the welder himself (we can say that this comes with experience).

The main thing is that you feel confident, focus on the controllability of the bathroom and adjust the current so that it is convenient for you to control the welding seam. Indicative figures are shown in the table below:

Read about how to properly adjust the current strength here.

Now you have become acquainted with the main aspects that a beginner should take into account when starting to work on welding seams. Read more information on our information portal mrmetall.ru.