Safe work

Before you start welding, you need to take safety precautions. The welder must have protective equipment:

- gaiters made of spark-resistant materials;

- mask – “Chameleon” type or regular with a light filter;

- robe;

- shoes made of leather and felt;

- goggles to protect your eyes from metal particles when sanding.

“Chamelion” mask with automatic adjustment – darkens only when the arc is ignited. The degree of darkness can be adjusted independently.

When working, fire and electrical safety must be observed. It is necessary to install ventilation in the workroom, and work with open doors and windows in the garage or home workshop.

Sharpening electrodes

The main element in welding is the tungsten electrode. TIG welding electrodes require constant care. It consists of regularly sharpening its tip. This ensures a good weld.

There is a rule - when welding with direct current, the tip of the electrode is sharpened cone-shaped, and with alternating current - spherically. The length of the cone can be calculated by doubling the diameter of the electrode. For stability, the end of the cone should be slightly blunted.

Electrode sharpening angle values for TIG welding:

- at a small current value - 10-20°;

- average - 20-30°;

- for high current - 60-120°.

If the sharpening angle is less than 20°, then the capabilities of the electrode are reduced, and at an angle of more than 90°, arc burning may lose stability. It is also negatively affected by the risks that arise on the surface during sharpening.

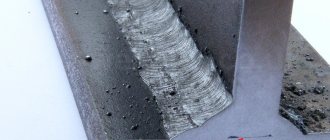

To make them minimal, TIG electrodes must be sharpened lengthwise. Turning occurs with the help of a grinder, a fine-grained abrasive wheel, emery, rotating the electrode in the hand. To make sharpening uniform, the rod is secured in a screwdriver or electric drill. In this case, it is necessary to set small rotation speed values. To protect against dust, you should wear a mask.

Necessary equipment and consumables

First of all, a beginner needs to learn what tig welding is.

This is the process of welding metals in a gas environment with a non-consumable electrode. It is a combination of arc and gas welding, because... Electric arc and gas are used.

First, it is important for beginners to familiarize themselves with the necessary equipment and consumables.

Tool selection

A reasonable selection of equipment and consumables that you intend to use helps you successfully obtain the desired connection.

Much depends on the composition of the additive, because it must “grow together” with the overall structure that you are welding. In an ideal situation, you know the elemental composition of the parts and select the wire based on it.

But such situations are rare, so study in detail the brands of filler material that are considered universal. It doesn't matter what metal you're welding, you can probably get the SV-08G2S.

For wire, the boiling point and its lightness are important. Beginners who have not worked with ferrous metal before often encounter unexpected boiling of this consumable.

To prevent this from happening, carefully examine the markings on the materials.

If you see the letters KP, such wire boils easily and is definitely not suitable for argon arc welding. Also look at the thickness and density of the additive.

The thicker your parts, the larger the diameter of the wire should be, and its density should be identical to the density of the metal you are welding.

What gas is used

In this technology, gas is needed to protect the welding zone from the harmful effects of air.

The best inert gases for this purpose are argon and helium. Argon is heavier than atmospheric oxygen and displaces it from the working area, and in practice welding is carried out in an argon environment, less often in a mixture of argon and helium. Pure helium is used extremely rarely.

Gas is supplied to the welding zone from a cylinder equipped with a pressure gauge and a reducer with a rotameter. The reducer is designed to regulate the gas pressure at the outlet and to automatically maintain a constant operating gas flow. The rotameter determines the exact amount of gas in a given unit of time. The pressure gauge shows the pressure in the cylinder.

Devices (devices) for welding

For tig welding, an inexperienced welder is best suited to an MMA inverter machine with a tig function equipped with an oscillator. With this inverter, a beginner will be able to learn tig welding on stainless steel, low-alloy steel, etc., which do not require much skill from beginners.

To work with aluminum, magnesium, etc., you need a more serious inverter that switches to alternating current.

Professional inverters are equipped with additional functions:

- arc stabilization;

- welding current modulation;

- accelerated ignition;

- crater filling.

Only qualified welders can use and adjust them correctly. It is useful to read about tig welding of aluminum in a kettle on the website mrmetall.ru.

Welding torch

When working with low currents - 50-150A, the burner has time to cool down naturally - gas cooling. The burner with water cooling built into the handle is designed for an operating current of 200-600A. Water circulates through the entire cable channel from the apparatus to the burner.

The burner is assembled as follows:

- Install the collet holder;

- insert a collet into it;

- screw the cap on (not to the edge) - to prevent short circuits to ground;

- insert a non-consumable electrode;

- screw a ceramic nozzle onto the collet;

- adjust the electrode extension to the minimum possible;

- tighten the cap tightly.

The electrode is inserted in the center of the nozzle, and argon is supplied around the circumference.

The torch handle is attached to the cable hose statically or by means of a flexible neck, which allows for fine and long-lasting work in any plane. The button on the handle activates the supply of current to the electrode and gas.

Collet holders are available with or without a lens. The gas lens is like a filter mesh that provides an even flow of gas and a wider area of protection. This is especially useful for working with stainless steel and active metals. Without a gas lens, you can work with aluminum and black steel. For beginners, it is better to learn on black steel and not use a gas lens.

Non-consumable electrodes

The melting point of tungsten is more than 3400 degrees, so the electrode does not burn or melt under high temperature. There are electrodes made of pure tungsten or with alloying additives. The tips are painted in different colors, depending on their purpose.

To obtain a reliable seam and stabilize the arc, the working tip of the electrode must be periodically sharpened. When working with alternating current it should be round, with direct current it should be cone-shaped.

The sharpening length is approximately 2-3 times the diameter of the electrode. For the stability of the arc, the marks from the sharpening tool should be located along the tip, and not across. It is unacceptable to overheat the electrode when sharpening, because tungsten becomes more brittle.

Electrodes are selected depending on the current welding modes.

| Electrode diameter, mm | Metal thickness, mm | Current strength, A |

| 1,5 | 1 | 45 – 55 |

| 2 | 2 | 80 – 90 |

| 3,5 | 3 | 120 – 150 |

| 5 | 4 | 170 – 190 |

Beginners most often work with electrodes of 1.6 and 2.4 mm in diameter.

Additive consumables

The additive is needed to create a weld when there is not enough melted metal from the edges of the part to fill the weld pool. The additive is rods of welding wire. In composition they must be similar or close to the metal being welded.

Oscillator

For non-contact ignition of the arc at the beginning of welding and its stability during operation, a high-voltage high-frequency generator is used - an oscillator. It can be either a separate device or integrated into a welding machine.

Using the device, the arc is ignited without the electrode coming into contact with the metal. This is very convenient for beginners. During the welding process, the arc is constant with respect to the changing gap between the electrode and the metal surface. As a result of the operation of the oscillator, a uniform seam is obtained.

What you need for TIG welding

TIG technology has also become widespread due to the fact that the generated arc generates high temperatures. Thanks to this, an experienced welder will not have a problem joining carbon steel workpieces. It is important to emphasize that this will ensure a high quality weld. In addition to steel, you can work with a large number of other metals: cast iron, titanium, aluminum and others. The seams obtained when welding stainless steel are of high quality. They don't even need subsequent cleaning.

To get started you will need:

- welding machine;

- gearbox;

- inert gas;

- filler wire.

Those who plan to engage in professional welding work need a machine with several TIG modes. You need to inquire about the type of burner. There are two of them: for welding thin sheets of metal and for all other types of work.

Preparation for welding

Bringing it into working condition consists of assembling all flexible connections into one unit with the device:

- We fix the reducer with a rotameter on the gas cylinder;

- connect the hose to the reducer;

- insert the bayonet connector of the burner into the negative socket;

- the control cable is connected to the corresponding socket on the front panel of the inverter;

- The ground cable is connected to the positive socket on the device.

Typically, a torch cable, gas hose and ground cable with all connecting parts are supplied with the welding machine.

Features of the package

It is quite simple: you need a device to connect the mass and the burner - durable hoses, a reducer that provides regulation of the shielding gas pressure and is installed on a gas cylinder. There are two types of burners used:

- No. 1 - metals with a thickness of no more than 3 mm.

- No. 2 - for thicker structures.

The current value in the first option is not so large, so the body quickly cools down naturally; the second option uses water cooling: a mixture of alcohol-ethanol and distilled water circulates from the device to the burner, cooling the hose and body, and also protecting them from hypothermia in sub-zero weather .

Proper use of the inverter

When doing argon welding from an inverter with your own hands, it is useful for beginners to learn some nuances: first set the machine to the required amperage, connect the hoses. What matters is the type of current being connected, after which you need to adjust the gas supply, checking the table below.

| Gas consumption, l/min | Metals |

| 15—20 | aluminum |

| 10—12 | copper |

| 6—8 | low alloy steel |

| 12—14 | magnesium alloys |

| 10—12 | Nickel alloys |

The arc can now be activated and welding can begin, adding filler wire to improve weld quality.

The welder holds the torch at a certain angle, which allows him to visually correctly perform the metal connection.

We make the device at home

A simple way is to use a regular MMA inverter with parameters suitable for welding, but you need to modify and reconfigure it. As a result, you get an inverter unit that allows you to weld metal with any type of current connected. You will need a set of hoses to connect a factory-made burner, an oscillator and a current delay unit.

The second option involves making all the components of the circuit yourself - this reduces financial costs, but the performer requires knowledge and high skills in assembly, manufacturing complex circuit boards and parts, as well as a lot of free time.

How to work with a burner correctly

In tig welding, it is very important for a beginner to get used to holding the torch and filler rod. The hand should rest on the work surface to stabilize the movement.

The hose coming from the burner is looped around your hand. The burner is placed between the thumb and index finger and rests on the ring and little fingers. Very similar to the position of the pen when writing.

The left hand holds the rod and regularly moves it in small steps into the weld pool in front of the torch. The direction of movement of the burner is from right to left.

The side angle should be 90°. The inclination of the torch to the working surface is 70° – 80°, and the tilt of the rod is 15° – 30°. A constant right angle must be maintained between the torch and the rod, i.e. if the burner changes position, then the rod follows it, maintaining the tilt.

The torch moves at an angle forward in an inclined position towards the weld. Guide the electrode along the axis of the seam without deviating. It is important to ensure that the end of the rod is always in the gas protection zone, otherwise it will oxidize and contaminate the weld pool.

There are many videos of tig welding for beginners on the Internet, which clearly show how to work with a torch.

Application

The advantages of TIG welding of metals find its application in the following industries:

- mechanical and instrument engineering;

- food production;

- oil industry;

- chemical industry;

- drilling rigs;

- construction of metal structures for high-rise buildings;

- steel frame structures;

- pipelines;

- aviation;

- astronautics;

- aircraft manufacturing;

- shipbuilding.

Argon TIG welding is also used for less global solutions. It is often used in domestic conditions. An example is installing an air conditioner in a car or repairing cracks in a car radiator. In all homes there are kitchen utensils and metal towel rails made using this method.

TIG argon welding has become so widespread due to the fact that it can be used to weld both carbon steel and non-ferrous metals, while maintaining excellent weld quality.

The essence of the welding process

The current strength determines the quality of the weld and productivity, being the main and most important welding parameter.

The heat necessary for a reliable connection comes from the electric arc. It forms between the electrode and the metal being welded. To form and burn an electric arc, there is a device - a generator, which supplies the required amount of current. There are two types of these devices.

Alternating current generator – transformer.

The current leaving the device takes the form of a square wave, which changes its polarity with frequency depending on the generator. In this case, the rectifier converts the mains current into alternating current suitable for welding.

DC generator - inverter or rectifier.

Both methods are for beginners, but you need to start with direct current. The current output from the device has the form of a constant wave. In this case, the alternating current of the network is converted into direct current. There are two options for connecting the inverter poles to the material being welded:

with straight polarity - the electrode is connected to the negative pole of the inverter, and the part is connected to the positive pole;

with reverse polarity – the electrode is connected to “+”, the part – to “–”

Features of welding with straight polarity: increase in the amount of heat in the product and decrease in the electrode; the metal melting zone is narrow but deep. This is the main tig welding mode for all types of complex metals and alloys.

With reverse polarity : heat input into the product is reduced, and heat input into the electrode is increased. The weld pool is wide, but not deep. In addition, there is the effect of cathodic cleaning of the metal surface, when the oxide film is destroyed. This improves edge fusion and seam formation.

Aluminum and magnesium, as well as their alloys, can and should be welded using alternating current.

There are also generators that produce pulsed direct current - pulse inverters. Such generators have devices that change the amplitude of the welding current by superimposing square waves on the base direct current. The result is a periodic pulsation of the arc. In pulse mode, a seam is formed by continuously superimposing welding points on top of each other.

Mainly used on thin products, when it is necessary to maintain the required temperature to avoid burning through the metal and, at the same time, not to disturb the penetration depth.

Adjusting process parameters on a welding machine

Before starting work, you need to adjust the indicator values so that the seam is the right size and of good quality. The device is adjusted depending on the type of metal, its thickness and working gas.

Each welding machine is supplied with a table for setting welding parameters. Based on the table, on the front panel we set the tig mode and the main indicators:

- current strength;

- gas purging time before the start – 0.5, and at the end – 1.5 seconds;

- the current value for igniting the arc is 25% of the operating current;

- the rise period to the operating current value is 0.2–1.0 sec;

- The current decay time and its value for crater filling are selected depending on the thickness of the metal.

According to the table, we initially set the gas flow rate under normal conditions to 8-10 l/min.

You need to start cooking on a similar test piece. If the arc is not stable and goes out, then the current must be increased. If the metal burns or deposits form, reduce the current.

We increase the gas supply if the arc is unstable and the seam is crooked. After finishing, when the arc has been extinguished, we blow on the welding zone for some time to avoid oxidation of the seam and electrode. Modern devices are equipped with many functions and, if not, for example, purge time or something else, then the welder controls the process independently.

Preparing parts

Unlike other types of welding, tig is very sensitive to contamination. This should be taken into account by all beginners. Therefore, parts should be cleaned especially carefully: degrease with solvent and sand the surface to be welded until shiny.

Before welding, sand the rod if necessary, and be sure to wipe it with alcohol.

Thick parts are cut by chamfering at an angle of 45°. This will ensure good penetration. Fix the position of the parts relative to each other using tacks or clamps.

Advantages and disadvantages of the method

The main advantages include:

- Displacement of air by argon from the area where welding occurs. Thanks to this, the seam is obtained without defects.

- Possibility of welding different metals.

- High quality seam.

- Low heating of parts, which eliminates their deformation.

- Working with metals that are difficult to weld.

- Ability to work with structures of different sizes.

- Fire safety.

- No waste.

- Isolation from the influence of the external environment.

- Electric arc stability.

- Versatility.

- Ability to work with thin metal sheets.

- Small heating zone of the product.

- Learning what TIG welding is is not difficult.

- Protecting the surface from oxide film.

- No need for additional processing after welding.

- Good control over the condition of the weld pool.

- Possibility of surfacing during restoration and restoration work.

- Possibility of using direct and reverse polarities.

- The compactness of the inverter with this function.

- Various TIG welding modes.

Disadvantages of the method:

- Low performance.

- Slow process speed.

- High cost of the equipment used.

- Availability of professional skills.

- Ineffective work in drafts or strong winds. It is necessary to install special shields and increase the supply of argon, which leads to its overconsumption.

- The need for preliminary surface preparation.

- Difficulty working in hard-to-reach places.

Provided that the shortcomings are not too significant, the use of this method is justified.

Training sessions for beginners

Exercise 1

After studying the theory of tig welding, a beginner can begin to practice. The main thing is to get used to holding the torch and filler wire, to “get your hand.”

Initially, a novice welder should train on a sheet of black steel. Use a grinder or other tool to mark small straight lines on it so that you can weld along them. You need to start cooking without additives. Carefully and smoothly move the torch straight along the line without igniting the arc. After this, we light the arc and move the torch from one edge of the line to the other. We make an even thread seam, teaching the hand to hold the bathtub correctly and not burn through the metal.

Exercise 2

After mastering the welding process, we move on to working with filler wire. First we practice welding the rod itself. We ignite the arc and, when the sheet metal has melted, we feed the rod into the weld pool. We stop the process, wait for the metal to harden a little and tear off the rod. We repeat the exercise several times. Once we have gained confidence, we begin training to perform a weld with an additive.

Tig welding is a widely used method of joining metals. It is quite possible for a novice welder to master it. With practice and consistency will come experience and mastery.

Safety precautions

Any craftsman, no matter whether he is a professional welder or a novice, needs to know the safety rules inside and out. By following them, you, first of all, preserve your health and life.

- Do not work in an area containing flammable materials. Even with the most careful work, a spark can get on them, becoming a source of fire. It is advisable that the surface on which you work is free of everything unnecessary;

- If you are not working outdoors, ensure the room is thoroughly ventilated. If the built-in ventilation ducts are weak, install a system that will remove combustion products;

- Before welding, make sure that the device is in full working order: it does not make unnecessary sounds, does not spark, and so on. Observe the gas supply characteristics from the cylinder and check for leaks from the tank or tube itself. If you notice damage to the tube, it is better to replace it;

- You should not connect several burners at once through a tee or reducer. This may lead to a malfunction in the electrical network and equipment operation;

- Wear protective suits and masks. It is advisable that the special suit completely covers all parts of the body and face, so that accidental splashing of metal does not cause burns. Hands should be wearing thick gloves and eyes protected with goggles. Even if you managed without it in previous times, don't risk it.