Choosing the right tools

A hammer drill and an impact drill are bad assistants when working with finishing tiles. They are used later, when a hole has already been made in the tile itself, and then comes concrete or brick. For these purposes, it is better to use a hand drill. It regulates the rotation speed . The drill should enter smoothly: without jerking or vibration.

Tips for working with tiles are different from tips designed for other materials. Special drills for tiles or glass are required . Most of them have an abrasive coating, thanks to which, with the help of friction forces, the tiles are drilled. The speed and ease of drilling the material, and most importantly, the absence of chips and cracks on the tiles, depends on the correctly selected nozzle.

Diamond drills

These tips are spear-shaped and have a special feature: diamond coating covering the tip. This coating greatly increases the service life of the drill and the hardness of the working surface of the tip.

These tools are used by professionals in their field: work with them is done quickly and without overlaps. Diamond cutters are the most effective, but also the most expensive. For masters of various repair work, this is a quick-payback purchase.

However, there is an affordable manufacturer of diamond cutters and crowns -. An analogue of diamond-coated end switches are drills made from pobedite. They can also be purchased at a good price.

Tubular diamond bits

They, just like drills with tapered tips, make the master’s work quick and easy to use.

This set, of course, is not cheap, but the purchase will serve a professional repairman well, saving him time and ensuring the quality of his work.

These crowns are convenient for making holes for sockets; they are also used to make room for a pipe or faucet. They come in various diameters. Below are prices for different brands of diamond bits.

| Brand | Manufacturer country | Diameter (mm.) | Price in rubles | Notes |

| "Practice" 777-215 | Russia | 5 | 110 | Set contains 2 pieces. |

| "Santool" 031930-006 -070 | Russia | 6 | 123 | |

| "Dewalt" DT6039QZ | USA | 7 | 539 | |

| "Bosch" 2608550611 | Germany | 14 | 1269 | |

| "Practice" 777-246 | Russia | 10 | 170 | Set contains 2 pieces. |

| "Practice" 777-314 | Russia | 35 | 290 | |

| "Practice" 777-369 | Russia | 65 | 550 |

Working with such limit switches has a number of features:

- The drill must be immersed in water frequently to avoid overheating. Otherwise, it will quickly fail;

- A screwdriver or drill must operate at low speed.

These conditions will extend the life of the tool. The new diamond bur can drill through tiles in 2-5 minutes.

Spear-shaped cutters and specially sharpened

Some tile drill bits have spear-shaped tips like diamond bits, while others have a flat tip with sharp edges. They are made from heavy-duty materials. Using such cutters, small holes up to 12 mm are made. They are used to hang wall furniture, mirrors, etc.

Lance-shaped pobedite cutters are more affordable than diamond drills. Of course, they are significantly inferior in service life, but one tip is enough to drill holes in the bathroom and kitchen. The tile for this should be tile or ceramic. If you use a cutter when working with porcelain stoneware, it will make 4-5 holes and fail. The spear-shaped tip is very sharp , so the drill easily enters the tile and does not slip off.

- Don't forget to sharpen the tip.

- With such a cutter, it is necessary to operate the drill with speeds up to 500 rpm and not exceed this limit.

| "Skrab" 30282 | China | 12 | 680 | Hexagonal |

| "Practice" 038-456 | Russia | 5 | 70 | Hastate |

| "Stayer master" 2986-05 | Germany | 5 | 80 | Hastate |

| "Stayer profi" 2985-04 z01 | Germany | 4 | 140 | Hexagonal |

| "Course" 35455 | Russia | 8 | 253 | Hastate |

| "Graphite" 57H261 | Poland | 6 | 265 | Hastate |

| "AEG" 4932363866 | China | 6 | 350 | Hastate |

| "Zubr" 29845-10 "Expert" | Russia | 10 | 290 | Hexagonal |

Tungsten core bit with center drill

It is used mainly on laid tiles, but it is possible to drill tiles that have not yet been installed. This tungsten bit can be used to drill a hole without damaging the installed tile if you are careful. This type of crown is also used for drilling out places for pipes and sockets.

- Before work, the tiles are soaked in water to avoid possible damage.

- During work, the tiles are also moistened with water - this will prevent the tiles from cracking from overheating. The crown is cooled in the same way.

- To prevent the centering drill from slipping, glue masking tape to the ceramic tile and mark the hole for the future hole.

- Be careful and work at low speed.

With low drill speeds and careful use of bits, they are capable of making up to fifty holes in such a hard material as porcelain stoneware over the entire period of their work. Their disadvantage is the inability to adjust the hole diameter. But on sale there are the most popular sizes for sockets, switches, etc. Crowns can be purchased in a set of 4 or 5 pieces.

| "KWB" 4994-03 | China | 33 | 230 | |

| "Hurricane" 902-2123-089 | China | 89 | 400 | |

| "KWB" 4994-05 | China | 53 | 621 | |

| "Santool" 031935-004 | Russia | 33/52/67/73 | 1528 | Set of 4 crowns |

| Vorel 3301 | Poland | 33/52/67/73 | 1730 | Set of 4 crowns |

| "FIT" 16510 "Profi" | Germany | 33-83 | 2654 | Set of 5 carbide bits and carbide file |

| Hurricane 902-2623-102 | China | 102 | 349 | |

| "KWB" 4994-04 | China | 43 | 579 |

Ballerina

Unlike tungsten crowns, the diameter of the “ballerina” crown can be changed. The distance from the central to the side cutter is adjustable. With this drill it is possible to make holes starting from 20 mm and ending with 130 mm. The operation of a drill is reminiscent of describing a circle using a compass.

This is a very capricious instrument. Beginners will have difficulty working with this drill, as its use requires skill. After drilling, the “ballerina” leaves uneven edges. If the hole is covered by decorative elements, then this drawback is insignificant. When drilling large holes, the drill bit is difficult to hold in place due to the rotating side cutter.

| "Course" 1628 | Russia | 30-100 | 408 | |

| "Hammer" 202-408 DR GG BN | Germany | 21-90 | 350 | |

| "Fit" 16532 | Germany | 40-130 | 510 | |

| "Biber" 55502 | Germany | 30-90 | 440 | |

| "Santool" 032511 | Russia | 20-94 | 893 | With protective grille |

| "Matrix" 88340 | Germany | 20-94 | 845 | With protective grille |

| Legionnaire 32342 | China | 20-94 | 750 | With protective grille |

| "Stayer master" 3230 _z01 | Germany | 20-90 | 235 |

Features of porcelain stoneware

Porcelain tiles are much stronger and harder than simple tiles. The general technology for drilling it is the same, but with some nuances. Thus, to work with it, diamond-coated drills or crowns are used, made by the diffusion-vacuum method. Such products are extremely durable and wear-resistant. Drilling occurs with a simple drill or hammer drill without a hammer function.

Related article: Insulating walls from the inside with foam plastic - all the pros and cons

Very large holes

If you need to make a very large hole in the tile, you will have to work a little. The drilled edges will be uneven.

- Mark the required size with a tile pencil or felt-tip pen.

- Drill holes around the entire perimeter of the intended circle.

- Use drills with small tip diameters.

- The holes should be drilled close together.

When this work is done, knock out the drilled circle from the tile with the handle of a hammer.

In order not to spoil the tiles, you must follow the following rules.

- Step back 15 mm or more from the edge of the tile, this way you will reduce the risk of splitting it.

- Dip the tiles in water for an hour before working, or simply moisten them with water.

- If conditions permit, drill a hole in the tile joints. The joints in the installed tiles are considered the safest for drilling. Place the mark exactly in the middle and do not move from the intended place.

- Low rotation speeds of the screwdriver will help avoid chips and cracks. Use a drill that has a minimum speed setting.

- Do not press on the surface, but hold the drill firmly: rest the tip firmly perpendicular to the tile so that the drill does not jump off.

- Use masking tape to prevent the tip from sliding on the tile surface.

- Turn off the impact mode on your drill or screwdriver.

- When the drill completely enters the mounted tiles and rests against the wall, change the nozzle to a smaller diameter.

- Sharpen the drill regularly - this will make the job much easier.

How to drill in the right place?

If you think about this question a little, the answer should come to your mind even without a hint. Well, at least it seems so to me. But if you don’t want to think, then read.

For this case you will need a core. This is a tool made of durable steel, having a cylindrical shape and a point at the end.

We place the tip at the desired drilling location and hit the roll on the other side with a hammer several times.

Now that you have finished drilling, place a drill on the surface of the roughness and start drilling - the tip will not run away anywhere.

What to consider when drilling into ceramics

If you need to carry out drilling work on tiles, you should choose the right model of electric drill. Suitable models are those that can operate at low speeds and in which the impact drilling mode is absent or can be turned off. Thus, in order to drill a hole in ceramic tiles with high quality, the following devices are optimally suited:

- electric drills that can operate at a minimum rotation speed of the cutting tool;

- cordless screwdrivers, the maximum rotation speed of which does not exceed 800–1000 rpm;

- low-speed screwdrivers operating from the central electrical network.

A drill for tiles or ceramic tiles differs in its design from a tool used for drilling any other material. Processing of tiles using a special drill is carried out due to the friction forces created by the abrasive material applied to the working surface of the tool. The working part of a drill for ceramics or any other similar materials can have an arrow-shaped or crown-shaped configuration. In such situations, a tool with an adjustable processing diameter, which is commonly called a ballerina, is also often used.

When performing drilling work on ceramic tiles, it is important to adhere to certain rules that will allow you to obtain a high-quality result:

- It is necessary to constantly monitor the temperature of the drill and the ceramic tile being processed, since overheating can lead to failure of the tool and the appearance of cracks on the surface of the product. To prevent overheating, the processing area and drill must be periodically watered.

- The pressure exerted on the drill when working on ceramics should not be too weak (in which case it will not be possible to drill through the tiles) and too strong (this may lead to breakage of the workpiece).

- The drill should rotate slowly and only clockwise; reverse mode cannot be used, as this can lead to cracking of the tiles.

- In the event that it is necessary to drill not in the tile itself, but in the gap between two adjacent products, the drill should be placed strictly in the middle of the seam between the tiles. You should drill holes very carefully if they are located in close proximity to such a seam. In this case, the drill can easily slip into the seam, and it will not be possible to get a hole in the required place. It should also be taken into account that at the edges of the tile the thickness of the protective layer applied to it is minimal (or there is none at all), so when drilling in such places, pieces of material may break off from the tile.

Very often you can find advice on preliminary punching the surface of the tile in the place where it is necessary to drill a hole. The design of modern drills used for tile work is designed in such a way that there is no need to perform this procedure, which can easily lead to breakage of the product.

One of the main rules: no matter what drill you use, it should always be sharp.

How to avoid dulling drills?

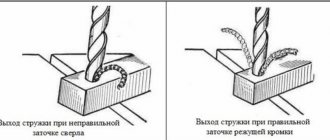

Metal drills become dull if they get too hot during operation, causing them to lose their strength. Heating occurs due to friction. Moreover, the faster it spins, the more it heats up.

Hence the obvious rule - you need to drill at low drill speeds. They should be no more than 1000 per minute. But who will measure this during work? So just don't press the start button all the way. The correct speed can be assessed as follows: the eye should see the rotation of the drill. That is, the grooves on it should not merge into one for vision.

When working with thick workpieces, additional cooling is necessary. It is provided by special lubricants or pastes that are added to the drilling site, or the drill is dipped into them. In addition, they not only cool, but also lubricate the tip, resulting in less friction.

In domestic conditions there is no need to have special lubricants and pastes. You can get by with regular machine oil.

So, use a core, drill low and add some lube or oil and this job will be a cakewalk.

Well, a few more tips on this topic.

How to make a small hole in a tile

Very often, in order to fix shelves or any other objects on the wall surface, a hole must be drilled in the already glued tile. A dowel is then inserted into such a hole, which should have a sufficiently deep depth, and a self-tapping screw is screwed in. Drills for ceramic tiles in such cases are used in conjunction with an electric drill, and after the tool drills through the tile and enters the wall, the hole can be modified using a hammer drill. Just as in all other cases, drilling tiles fixed to the wall must be performed at low speeds.

Drill selection

There are many drill bits on the market today that can be successfully used for tile work. It should be borne in mind that the correct choice of tool directly affects the processing result. In order to decide which drill to use to drill ceramic tiles, you should understand the types of cutting tools.

- The greatest efficiency when performing drilling work on ceramics is demonstrated by a tool with a diamond coating applied to the working part. It should be borne in mind that it is quite expensive, so it makes no sense to purchase it for one-time tile work. Such drills for ceramic work are usually used by specialists who often have to drill into tiles.

- For drilling tiles, spear-shaped drills are also used, the working tip of which is made of a carbide plate sharpened in the shape of a spear. Their use minimizes the risk of tiles splitting. The design of these drills is specially designed for such hard and brittle materials as ceramics. The cutting edges of drills of this type are located at a fairly sharp angle, due to which the area of contact between the tool and the material being processed is reduced, so minimal pressure can be applied to the drill when using spear-shaped drills.

- The simplest tool option that can be used for drilling work on tiles in cases where nothing else is at hand are concrete drills equipped with a carbide tip. When working with such drills, the design of which is not intended for drilling tiles, you should exercise maximum caution, since the risk of breaking the workpiece is very high.

Practical recommendations

Drilling small diameter holes in tiles is performed in the following sequence:

- A piece of adhesive tape or paper tape is glued to the place on the surface of the tile where it is necessary to drill a hole. In this case, the center of the future hole is indicated using a marker.

- At the initial stage of drilling, the drill is set to the minimum number of revolutions. They can be increased after the tool cuts into the tile at least to a small depth. In this case, as mentioned above, under no circumstances should you use the impact mode of the drill.

- After the tile has been drilled through and the cutting part of the tool has reached the surface of the concrete or brick wall, the ceramic drill must be replaced with a more suitable one. To form a hole in the wall on which the already drilled tile is fixed, you can use the impact mode of a drill or hammer drill.

Drill types

For drilling, use only metal drills (not wood, for example). They have their own sharpening and are made from certain types of steel. The most common ones are marked P6M5 - this is high-speed steel, which foreign manufacturers label as HSS.

To provide additional strength, the above drill bits are coated with titanium nitride. That's why they are yellow.

There are also stronger P18, which are used respectively for hard steels.

Also, to increase strength, cobalt can be added, and then the marking P6M5K5 is obtained.

Well, the most durable ones are drills with carbide tips. They are used for drilling alloy steels. It will also take ordinary steel, but buying it just for this will be somewhat savvy, since the price for them is quite high, and although it is hard, it still dulls. But it will be difficult to sharpen it later, since this requires a diamond blade, which is also not very cheap, and you can’t buy it everywhere.

Read also: How to make a tire changing machine with your own hands

How to drill a large hole in tiles

The need to drill a large diameter hole in tiles arises in cases where it is necessary to install pipes or other plumbing communications, as well as prepare a place for installing an electrical outlet.

Basic Tools

For the above purposes, two main types of tools can be used:

- core drills;

- an instrument with adjustable cutters, better known as a ballerina.

- The most effective, but also the most expensive tool for drilling large-diameter holes in ceramic tiles is a core drill, the working part of which is coated with diamond. They work with a tool that needs to be cooled with water during the drilling process, also at low drill speeds, since drills of this type are very critical of overheating.

- A more inexpensive option is a core drill, the working part of which is equipped with carbide teeth. With this tool you can drill a limited number of holes, after which the drill becomes unusable. Using a tool of this type, you can drill holes with a diameter of up to 15 cm. This is quite enough to, for example, install a sewer pipe. However, even if you take the utmost care, the edges of the holes made with such a drill will be chipped and uneven.

- An even simpler tool that can be used to drill large diameter holes in tiles is a ballerina. Its design includes a central spear-type drill, a bracket on which there is a clamping device for the cutter. By changing the position of the cutter, moving it along the bracket relative to the central drill, you can create holes of different diameters in the tile. This inexpensive tool is most often used to do tile work at home.

Expert advice

To drill a large diameter hole in ceramic tiles, you can use the following recommendations:

- The contours of the hole that needs to be drilled must first be marked, and a plaster or paper tape must be applied to the corresponding section of the tile. To solve this problem, you can use a stencil cut from a sheet of plywood or fiberboard.

- If a large diameter hole needs to be made in a tile that is not yet fixed on the wall, the product is laid on a flat and hard surface and fixed.

- Drilling of tiles begins at low speeds of the tool, making sure that its cutting part is parallel to the surface of the workpiece.

- When drilling with either a diamond-coated crown or any other tool, it is advisable to use water, which will not only cool the drill and prevent it from overheating, but also prevent the formation of dust during the processing process.

- When drilling a hole in a tile using a ballerina, keep in mind that the distance from the central drill to the working cutter is the radius of the hole, not its diameter.

Drilling tiles, no matter what it is done, is associated with the formation of fragments of the material being processed, so you should definitely wear safety glasses. To get a high-quality result, you need to perform drilling as carefully and slowly as possible, use the appropriate tool for this and strictly follow all technological recommendations. In addition, do not forget that the tool used for drilling tiles must be constantly cooled with water.

In conclusion, a short training video on how to drill a large diameter hole in ceramic tiles.

If you need a large hole

Sometimes you need to carefully drill a large opening for a pipe, outlet or other purpose in the tile. In this case, ballerinas or crowns are used.

The ballerina consists of several components, the main one being the cutting drill. When the centering part is fixed to the drill, the cutting part is driven in a circular motion and breaks the working surface. This product is best used when you do not need non-standard openings or grooves. The drill should only be used without impact function and at low speed to avoid damaging the tiles. Also, when operating the device at high speeds, the ballerina may be damaged. The disadvantage of the product is that it cannot be used to create an opening with a smooth edge.

Related article: Choosing siding colors for cladding a house

But with the help of crowns you can get a surface with almost perfectly smooth edges. The device device may consist of a centering part or without it. If one is available, then drilling a hole is quite easy, since it fits into the surface to be treated and prevents the crown from moving along the surface. Using crowns, you can drill both simple tiles and porcelain tiles, stone, and marble.

How to work with a “ballerina”?

Let's see how to drill ceramic tiles with this tool. An electric drill without impact function is required for operation. The drilling process is carried out strictly at low speeds. Also, during the work, do not press too hard, pressing the tool against the surface of the tile.

It is most convenient to make holes in ceramics when they have not yet been laid. If you drill from both sides, you can get the best result.

But even with the correct use of drills of this type, the walls of the hole made will never be perfectly smooth. If the tile is located in an open area, the hole will definitely require modification. Well, if it is under the bathtub or under the sink, then uneven edges do not have such a serious significance.

Drilling technology

The first step is to determine the number of holes and the places where they will be made. Next, future holes are marked with a marker. The areas are sealed with tape so that the mark is clearly visible through it. Masking tape will prevent the drill from slipping. It won't be possible to do without it.

The drill must turn off the impact mode and set the minimum speed. After the top layer has been passed, the speed is increased. But you need to periodically cool the drill and drill. If the drill becomes dull, you should sharpen it. If damaged, replace it.

When the tiles have been completely drilled, you can change the drill according to the type of wall material. Now you can switch to impact mode and carefully, at medium speed, drill the hole to the desired depth. And finally, you can peel off the tape, insert the dowels into the holes - the fastening is completed.

It is better for beginners to first try their strengths and capabilities on broken tiles. In fact, the process of drilling tiles is much more complicated than working with any other materials. You can take a small drill for ceramic tiles (6 mm) and try to work with it.

Tool types

The following tools are suitable for making holes in tiles:

- hand drill . Its strengths are full control of rotation speed and lack of vibration. These advantages make a hand drill the most suitable tool for drilling ceramic tiles;

- electric drill . It is used in most cases, since hand drills are extremely rare on sale. A model with continuously adjustable chuck rotation speed is preferable: it is desirable that when drilling ceramics this parameter does not exceed 1000 rpm;

- screwdriver _ The power of this device is quite sufficient, because significant effort is not required to drill tiles. Compared to a drill, a screwdriver has an important advantage: there are models with batteries that allow you to work on sites without power supply;

- jigsaw _ Used to make large holes if there is no more suitable tool.

Varieties

There are several types of ceramic drills. Here is their comparative characteristics.

Spear-shaped

They have the following advantages:

- low cost: from 60 to 120 rubles;

- long service life.

These qualities make the spear-shaped drill one of the most popular when drilling holes in tiles with a diameter of up to 12 mm (the maximum for this drill).

The service life is greatly reduced when drilling porcelain stoneware - only enough for 4-5 holes. But taking into account the high cost of special drills for this material (300-500 rubles), drilling a small number of holes with two or three spear-shaped drills seems more profitable.

The profile and sharpening angle of the tool is designed exclusively for glass and ceramics. When you try to drill into brick or concrete, it quickly fails.

Pobeditovye

The winner is an alloy of tungsten and cobalt developed in the USSR, characterized by high hardness and at the same time affordable cost. Pobedite drills are quite popular as they have the optimal combination of price and durability.

Drill with pobedite tip

Carbide

A characteristic feature of this drill is the one-sided sharpening of the cutting part at an acute angle. Thanks to this, penetration into fragile materials such as ceramic tiles and natural stone occurs easily and without cracking. Carbide drills are produced with a diameter of no more than 12 mm.

Diamond coated

This variety is more suitable for professionals who need to drill tiles constantly and in large quantities, it is expensive, but:

- easily copes with even very hard materials: diamond is stronger than any other material in nature;

- has an increased resource;

- makes holes with very smooth edges, since the material is not cut, but crushed by sputtering crystals.

According to the method of fixing diamond coating, drills are divided into three types:

- with diamond chips attached to solder . This is the most affordable variety, but it loses its coating relatively quickly, especially when overheated (the solder softens);

- with mechanical fixation . Diamond chips are fused into the edge of the drill, heated by high-frequency currents to a state of plasticity. The tool is resistant to overheating and loses its coating much more easily, so it lasts longer. At the same time, its cost, although higher than the previous variety, is quite affordable;

- with laser soldering. The most expensive and durable drills. Typically used in industry.

Circular "ballerina"

The tool is similar to a compass: one “leg” is a centering drill, the second is set aside and equipped with a cutter.

There are models with two cutting “legs”. The distance between the legs, that is, the radius of the hole being made, is adjusted with a hex key.

The minimum value is 15 mm, the maximum is 45 mm. Accordingly, the “ballerina” allows you to drill holes with a diameter of 30 to 90 mm.

This type of drill is convenient if holes have to be made from time to time and of different diameters. For permanent work, it is better to purchase a set of crowns (cylindrical drills): they leave a smooth edge. After the “ballerina”, the edge of the hole has to be leveled with sandpaper or a file.

Feather

A characteristic feature of a feather drill is a pointed cone protruding in the center of the cutting edge. It allows you to accurately position the drill and at the same time “catch” on the slippery glazed surface.

There is no need to pre-core the tiles. The maximum diameter of the pen drill is 30 mm.

Universal

Manufactured from high carbon steel. They are sharpened in a special way, allowing them to process a wide range of materials.

How to work correctly?

Let's look at safe ways to drill ceramic tiles. There are two methods - manual and using a drilling machine.

When choosing the manual method, it is necessary to reduce the clamping force to a minimum. This will help maintain the integrity of the tile. Work should only be carried out at low speeds. The smaller they are, the less backlash and vibration.

Do not overheat the area where the hole will be. This can cause the ceramic tiles to crack. Experts recommend cooling drill bits for glass and ceramic tiles, and also pouring water on the surface of the material.

The main difficulty in making holes lies in the topmost layer, which is covered with glaze. Due to the strong smoothness, the drill moves away from the intended place. Several methods can be used to accurately position the drill at the desired point. So, you should scratch out the conical recess with a hardened self-tapping screw or the sharp edge of a file. You can achieve the same result by sticking masking tape or adhesive tape on the surface of the tile.

This will prevent the Victory bit from slipping during operation. You can mark the required point with a stationery proofreader.