Drilling into concrete walls occurs in every home from time to time, for example when you need to hang a lightweight object. The work is usually done with a conventional drill, but in order to use it correctly, you need to know the technique and certain rules. How to drill through a concrete wall with a regular drill? This is discussed in detail below.

A conventional drill allows you to drill a hole of the required length and diameter

Features of working with concrete pavement

First of all, it is important to choose the right drill. A pobedit nozzle is suitable for working with concrete. However, it is not suitable for drilling other surfaces; for example, it tears wood, resulting in sloppy holes.

When drilling, a lot of dust is generated, so you should prepare a vacuum cleaner to collect small particles. Of course, this technique will not ensure perfect cleanliness after repair work, however, it can reduce the amount of dust.

After completing the preparatory activities, you can begin to work. So, how to drill a hole in concrete with a drill correctly? First you need to determine the place where the future recess will be. The mark is made with a pencil.

You need to start using the device at low speed, gradually increasing it. This rule will improve the accuracy of the procedure. To make the hole the right size, the drill must enter the concrete wall at one angle, without wobbling.

Important! If you are making a hole for a cornice or TV, then you should use reliable fasteners, for example, an anchor, since it can withstand heavy loads.

During the drilling process, concrete crumbles, so you need to use the device at low speeds

How to make a hole in a reinforced concrete slab if the drill hits the reinforcement

If you hit reinforcement while drilling, the first thing you should do is not get excited. When drilling a concrete slab, the hammer drill or drill bit hits an obstacle - you should stop drilling. Stop and make sure that the obstacle the drill has encountered is not an electrical cable. Take the indicator screwdriver and bring it to the obstacle in the hole. If the indicator lights up, then this is a sign that you need to be careful. You most likely encountered an electrical conductor.

This is interesting!

If you are convinced that you have hit an electrical cable in the drilled hole, you should pause work to repair the damage.

If you hit reinforcement during the drilling process, do not rush to drill through it. The first thing you should do is try to move the drill to the side. Be careful when doing this, as the drill may jam. If this happens, below are methods for removing a jammed nozzle.

This option is appropriate for those cases where it is not so important that the hole is smooth. Try to get around the reinforcement by pointing the drill to the side, and thereby eliminate the need to drill into the metal. If you need to get an even hole, then it is better to step back a few centimeters from the original place and make a new opening.

How to drill concrete walls

It is quite difficult to make a hole in concrete, since when drilling you come across crushed stone, which interferes with the operation of the tool. You can drill through a concrete wall using several devices:

- perforator;

- electric drill;

- powerful screwdriver;

- ordinary drill.

The selection of tools largely depends on the purpose of the area. For home use, a regular drill is best suited. It is recommended to choose an impact tool, since a non-impact tool will deteriorate with prolonged use.

Before drilling into a concrete wall with a drill, the worker should choose a reliable attachment, since the whole process depends on it.

Choosing the right tool attachment makes your job much easier

Diamond drills and other devices

Diamond core bits are suitable for hammerless drilling in concrete. When using them, you can drill a hole of the desired diameter without applying additional effort.

The drills have shaped cutouts and an abrasive structure on the edge. The worker just has to choose the correct length of the nozzle. So, for small household work, drills with a maximum diameter of 120 mm are used.

Using crowns for drilling concrete walls using a drill

The most popular are diamond and carbide crowns, the diameter of which is 68 mm. When starting work, you should consider the following features:

- use the unit only in the place where it is required by the Electrical Installation Rules;

- After finishing the work, it is necessary to remove the concrete dust that remains inside the hole using a chisel and a hammer or a hammer drill.

If carbide products are used for drilling, then you need to take short breaks so that the device has time to cool down. Otherwise, it will quickly lose its functions.

If crowns with a large diameter (more than 100 mm) are used, the following should be considered:

- it is strictly forbidden to put excessive pressure on the tool, as this will cause breakage or overheating;

- When working on reinforced concrete, wet cooling cannot be used;

- Before turning on the device, you need to check the reliability of fixation of the product in the unit socket.

Important! Before drilling into concrete with a conventional drill, the worker must wear protective equipment to avoid injury.

For drilling, it is best to choose diamond drills

Features of drilling

When using a drill, it is important to select equipment and a drill with the necessary technical parameters. It is recommended to use an electrical device with a speed controller and an additional shock mode.

The use of a side handle speeds up drilling and reduces the load on the operator; a drilling depth regulator will not be superfluous.

Drill device and drill installation

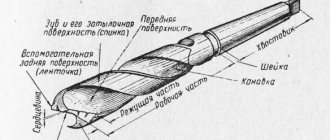

The design of the drill uses a commutator electric motor of alternating current. The design of the motor includes a speed controller located on the power button. To reduce the rotation speed and increase the torque, a gearbox is used; there is a tool with a 2-speed gearbox.

A cam chuck is attached to the output shaft of the gearbox; a chuck with a latch is used in rotary hammers. The hammer drill gearbox is equipped with a separate unit that ensures the formation of translational and rotational movement of the drill.

Before drilling into a concrete surface, the drill must be secured. The tool is placed in the chuck, the cams ensure the alignment of the drill and the axis of the chuck. The drill is placed inside the chuck for the entire length of the shank; lengthening the working part of the tool by pulling the shank out of the chuck is prohibited. To tighten the chuck, use a wrench (included with the drill).

Power selection

To make holes in concrete surfaces, a tool with a power of at least 600 W is required. The rotation speed is selected depending on the diameter of the drill and the characteristics of the material being processed. The worker independently selects the speed, reducing the emission of dust into the air and reducing the likelihood of wall fragments breaking off when drilling a hole.

Errors when working with a drill

Main mistakes when operating an electric drill:

- Do not hold the equipment by the chuck when working. Protective gloves and clothing should not sag or have loose parts, as there is a risk of material wrapping around the rotating drill.

- Do not point the tool at an angle or apply excessive force as the worker may fall from the stepladder or ladder and be injured.

Surface preparation

Before operating the device, you need to check whether there are any communications on the area of the selected surface. If you neglect this rule, you can damage the electrical wiring or the place where the pipe passes. A metal detector will help the worker cope with this task, since when it detects non-ferrous metals, iron or steel, it gives a specific signal.

If the selected section of the concrete wall meets all the requirements, then you need to mark a point and then begin operating the device.

Important! The surface of the wall is looser than subsequent layers.

The intended drilling location should be marked with a pencil.

Drill selection

The decisive step is the choice of drill, since the quality and integrity of the nozzle depends on it. Construction stores offer a wide range of drills that are suitable for a specific type of material.

Concrete drills have a triangular tip shape and are made of carbide. Experienced repairmen recommend using a pobedit drill as it does not tear the material.

If the drill becomes stuck, you will need to use a punch. After installing the device in the hole, you need to hit it with a hammer several times so that the impassable area softens.

Also, many people who carry out minor repairs are interested in the question of whether it is possible to drill concrete with an impact drill. So, if difficulties arise at the drilling stage, then holes can be drilled using impact mode or a hammer drill. However, the latter has a significant drawback - it forms holes with a diameter of at least 13 mm.

To make several holes, soldering on the nozzle is used:

- pobedite tip;

- universal drills - they need to be cooled regularly;

- Diamond drills are a very expensive material, but they can last for several years.

During operation, it is important to ensure that there is no sound of contact with metal. If the drill hits a reinforced concrete block, you need to complete the procedure before the bit becomes dull.

Correctly drilling a concrete wall with reinforcement can be done in several stages:

- Make a hole up to the metal layer with a pobedit tip.

- Place a metal drill and continue operating the device.

If it was not possible to make a hole in concrete with a conventional drill, you should use a hammer drill

How to drill through a concrete wall with a regular drill

A hammer drill is intended for drilling concrete, but if one is not available, in many cases a hand-held electric drill will do the job. You can achieve success if you choose the right drill or crown. To figure out how to drill a concrete wall with a conventional drill, you need to know a clear algorithm of actions and take into account a number of important drilling nuances.

Additional tool for drilling concrete

It is wise to start drilling concrete if the electric drill is equipped with a hammer function. Using a drill with a hammerless tool is pointless. The drill will simply overheat, which will result in the motor burning out. Using a non-impact tool, you can drill a large hole with a diamond core, if the power of the electric motor allows.

For simple hammer drilling of small holes, you will need an additional tool:

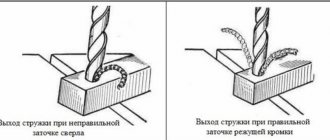

- A set of concrete drills of different diameters. They can be distinguished by special soldering on the carbide end. The element is a small plate with sharpened edges at an angle of 60°. The screw part and cylindrical shank are made of ordinary tool steel.

- Punch. The tool is made in the form of a rod with a sharpened end. A punch helps to destroy concrete by hitting it with a hammer.

Concrete drills have one weak point. Upon contact with the fittings, the solder breaks off. If the immersion of the drill into the concrete has stopped and a characteristic whistle appears, the hole is tapped with a punch. If there is reinforcement, move the drilling site to the side.

When it is necessary to cut a large hole for a socket box with a drill, a crown is used instead of a drill. When choosing a nozzle, look at the shank. Its shape must be suitable for clamping in the chuck. The drill will fit a hex or SDS shank.

Drilling concrete is carried out by three types of crowns:

- Carbide bits have a serrated cutting edge. Crowns are used only for impact drilling. If the drill does not have a hammer function, the soldering tips overheat and fall off the bowl. The crowns are afraid of contact with the reinforcement. To preserve the cutters, before drilling, try to drill through the wall with a drill. Additional action will help determine whether there is reinforcement in this area.

- Drilling a concrete wall with a hammerless drill is carried out with a diamond core bit. The nozzles are not afraid of contact with the fittings. Air-cooled crowns are produced for domestic use. They are recognized by the presence of holes on the cutting edge. Drill bits are not used for wet cutting. Diamond coating can be hard, soft or medium hard, which is reflected by the marking of the nozzle with the letters “T”, “M”, “C”. “KS” bits are usually used with a drill. The design of the nozzle provides slots for air cooling. The cutting edge is made of medium-hard diamond chips.

For drills, bits made of carbide materials are sold, where instead of soldering there is a coating of tungsten carbide chips. The nozzle can be used to carefully drill into a tiled wall. It is reasonable to use crowns if the drill power exceeds 1 kW.

Drilling a wall with a drill

The drilling process with a hammer drill requires maximum effort. It will take more time than when working with a hammer drill due to the lower power of the tool. Drills periodically give time to rest. The entire procedure for making a hole with a drill consists of the following steps:

- The location of the future hole is marked on the wall. Place a punch on the mark and hit it sharply 2-3 times with a hammer.

- After impacts, a small crater is formed in the concrete. A tapped drill is inserted into the recess, the hammer mode is turned on on the drill, and they begin to drill. When the hand feels overheating of the electric motor, the tool is given time to rest.

- The drill may stop going deep for two reasons: solid fractions of concrete or reinforcement have entered. Drilling is stopped. A punch is inserted inside the funnel and sharp blows are applied with a hammer. When the solid fractions are destroyed, continue drilling. If reinforcement gets in, it is better to move the hole to the side. If this option is not suitable, the rods can be cut with a diamond core bit or a metal drill.

Actions continue until the desired hole depth is reached.

The nuances of proper concrete drilling

In order for concrete drilling to be successful, a number of important nuances are taken into account:

- Making a hole with a diameter of more than 12 mm and a depth of 100 mm is best done with a hybrid power tool, a hammer drill.

- For plastic dowels, the depth of the hole is 7 mm greater than the length of the fastening element. The stock will become clogged with concrete dust when inserting the dowel.

- Work begins at medium speed of the drill without impact mode. The speed is increased when the drill reaches 4 mm deep. At the same time, the drummer mode is turned on. This measure is necessary to prevent the drill from moving along the wall due to strong vibrations.

- The drilling process is accompanied by a large amount of dust. If you turn on the vacuum cleaner, flying concrete particles will be immediately sucked up and will not clog the room.

- When clamping the drill in the chuck, check that the shank is inserted all the way.

- Operate with a low-power drill for a maximum of 15 minutes. 10 minutes is enough to rest. Before starting work, the drill is dipped in water. A little trick can reduce wear on the cutting tip.

- When making a through hole at high speeds, a piece of concrete may break off from the back side of the wall. Reducing the speed helps avoid damage.

Practical advice from experts

To ensure that the drilling process goes without incident, you should take on board some useful tips from experienced craftsmen:

- For a hole for a dowel, you need to make a recess larger than its length.

- You need to start the process with low speeds so that the nozzle fits clearly into the hole and does not wobble, causing unnecessary inconvenience to the worker. When the hole is of sufficient length, the number of revolutions can be increased or the drill can be put into impact mode.

- With prolonged use, the chuck begins to hold drills worse, so it should be changed regularly. If you do not replace it in a timely manner, it will be very difficult to drill through concrete.

- It is necessary to moisten the drill with cold water to avoid destruction of the nozzle.

- Since concrete dust is generated during drilling, the work can only be carried out using glasses.

- To reduce the amount of dust, place a plastic cup on the drill.

- If you need to drill a hole through a ceramic material, which is often used for wall decoration, then the movements should be performed smoothly so as not to split it.

Compliance with safety precautions is the main condition when using the tool.

The need to drill a concrete wall arises when carrying out cosmetic repairs, for example, if a curtain, shelf or picture is installed. If you choose a site in a concrete wall wisely and follow safety precautions, both a woman and a man will be able to drill a hole, even without experience.

Tool selection criteria

| Name | Characteristic |

| Drilling speed switch | Ensures accurate drill operation |

| The working surface is not damaged | |

| Presence of a function for creating strikes | Used in difficult areas |

| The material softens | |

| Provision of work depth regulator | Fixes the length of the resulting recess |

| Can be held with two hands | Heavy tool is securely fixed during operation |

| Product power | Must ensure the required work is completed |

The device must be kept parallel to the floor during operation.

After purchasing a tool, you should learn how to hold it. To do this, the device is taken in the hand like a pistol, and with the other hand is held by the side auxiliary handle. If the model of the unit is not equipped with such an element, then with the second hand they fix it by the area near the cartridge. Hold the object only horizontally to ensure that the hole is laid without distortion and at the correct angle. Before use, it is necessary that the tool reaches the temperature of the environment where it is used. Temperature changes provoke the formation of condensation inside the equipment.

When stopping repair work, the electric drill should be disconnected from the power supply.