Band saws for cutting metals

Effective cutting of metal workpieces cannot be performed without the use of special technological equipment - a saw blade. Currently, the modern metalworking market offers band saws made of carbon steels, as well as bimetallic ones (spring base, teeth made of high-speed steel or carbide). Depending on the design features and the cutting modes used, the equipment in question makes it possible to achieve high productivity and a significant reduction in the cost of performing the required technological operations. The output is products with excellent cutting quality without any external defects.

Selecting a band saw blade by tooth pitch

A common problem among woodworking businesses is choosing blades for their saws. Whether they're working with a table saw or a band saw, most woodworkers seek the holy grail of saws that offer the straightest, smoothest, and best quality cuts. Workers soon learn that the number of teeth per inch ( TPI ) on a blade has a big impact on the quality of the cut. A general rule of thumb is, “The higher the TPI, the smoother the cut.” However, the true answer is a little more complicated, which you will discover once you understand how the teeth work.

How teeth are cut

Each tooth on a saw blade is a tiny, sharp chisel that knocks out wood fibers as it passes through the workpiece. As a general rule, the more teeth a saw has, the smoother the cut will be. This is true for almost any saw you use—a table saw, a table saw, a jigsaw, or a band saw. But even, smooth cuts come at a price, which affects speed, since blades with a large number of teeth cut perfectly, only at a limited speed. Saw blades with fewer teeth will cut faster and more aggressively, but tend to have a rougher cut. This is because on a saw with fewer teeth, the spaces between the teeth are deeper and the chisel is more aggressive.

At the same feed speed, a fine-tooth blade with more TPI increases the number of teeth on the cut, meaning each tooth is responsible for cutting less wood. On a rough blade with more teeth, each tooth cuts more wood. The obvious consequence is a rougher cut. For this reason, roughing saws with fewer teeth per inch are often kept for carpentry frames or for cutting workpieces that will not be visible. In delicate woodworking using hardwoods, smoothness of the cut is more important and fine tooth blades with a high amount of TPI are more often used.

There are trade-offs you pay for that smoother cut on a fine-tooth blade. Because cutting is naturally slower and less aggressive, there is a greater chance that the wood will burn due to friction as the blade passes through the workpiece. And because the grooves between the teeth are so small and don't clear out sawdust as quickly, there's a greater chance that the saw will jam when cutting.

Other Factors Affecting Cut Quality

There are other factors that affect the quality of the cut on a saw blade. Teeth setting angle. A blade with a more pronounced angle will cut more aggressively and faster, but it will also waste more wood because the kerf (the cut made by the blade) will be wider. This can be a problem if you are trying to save as much wood as possible on a very expensive piece of wood.

The sharpness of the saw teeth can greatly affect the quality of the cut. Dull saws are more likely to chisel and burn wood because the teeth do not cut the wood fibers effectively. A dirty blade can also affect the cut. As tree resin accumulates on the surface of your teeth, it is more likely to bind and burn the wood. Keep saw blades clean to ensure smooth cuts.

Manufacturers offer different types of blades for different types of cutting:

- Crosscuts typically have a higher amount of TPI and smaller teeth designed to cut wood smoothly, perpendicular to the wood surface. The teeth have ends with alternating chamfers - teeth with left-hand chamfers alternate with teeth with right-hand chamfers.

- Longitudinal ones have less TPI, larger teeth and deep chip removal grooves between the teeth. They are designed to cut in the same direction as wood fibers. The teeth have a flat top, which allows them to effectively separate wood fibers.

- Combination saws are designed to cut crosscuts and rips quite efficiently, but they won't get the job done because the blade has teeth specifically designed for that purpose. They are a good choice for general carpentry or for craftsmen who do not need much precision.

Recommendations

Typically, woodworking businesses will have several different saws for each machine they own. For example, for a table saw, it would be nice to have a 40-tooth general-purpose blade, an 80-tooth blade for plywood and veneer, and a specialty blade for making cuts. For a band saw, it is best to keep several blades of different widths depending on the sharpness of the curves being cut. For example, use a 6mm blade for fairly tight bends, a 10mm blade for general band saw cuts, and a 20-25mm blade for general wood cutting. 10mm, 20mm and 25mm bandsaw blades should preferably have 3-4 TPI (teeth per inch) pitch, while narrower blades should have a higher number of teeth per inch.

Types of band saws

Band saw blades made from high-quality, high-carbon tool steel enable economical cutting of a wide range of materials such as alloy and non-alloy steel (tensile strength up to 80 kPa/mm). It should be noted that in terms of certain operational characteristics, the band saw blades under consideration are somewhat inferior to bimetallic blades.

A bimetallic blade with a tooth made of high-speed steel is very popular and is often used as technological equipment in modern band saw machines. The cutting part of the teeth is made of M42 high-speed steel. This steel is characterized by significant hardness (up to 950 HV). To create the base of the saw blade, spring steel was specially selected, which is characterized by wear resistance (resistance even to significant operating loads). The base and cutting teeth are connected to each other through a high-strength electron beam welded joint. The saw can be used in difficult production conditions. The new design of the saw blade with a combined pitch makes it possible to cope with such technological operations as efficiently as possible, such as cutting pipes, profiles, as well as workpieces with variable cross-sections. Thanks to the variable pitch of the saw tooth, the vibration load on the equipment is significantly reduced, and the stability and efficiency of the process of cutting workpieces of variable cross-section increases.

When it is necessary to cut metal in difficult conditions, it would be advisable to use band saw blades with carbide teeth. This technological equipment is typical for the use of rigid double-column band saw machines and with its help, cutting materials such as cast iron, non-ferromagnetic alloys, rare earth metals is a simple and convenient task that does not require much time and effort. The cost of separation cutting is significantly reduced. Structurally, the socket for fixing the carbide plate is designed in such a way that it ensures high strength of its connection with the band saw blade. The saw teeth have the appropriate setting, which is able to provide the required clearance when sawing and removing metal shavings. These saws are only used for cutting solid sections with a diameter of more than 60 mm.

Wood Band Saw Dimensions

We equip your home workshop. We install a wood band saw

wood band saw differs in alloy, width, as well as size, shape and frequency of teeth. Poor quality cuts are often not due to poor fabric, but to poor blade selection. In this case, there are many characteristics that you need to focus on when purchasing. Therefore, it is necessary to understand how to choose a band saw .

The most important criteria for choosing a saw are:

- Amount of work and frequency of their behavior;

- Characteristics of wood (thickness, species, humidity);

- Shape, size, frequency of teeth;

- Blade width;

- Quality of sharpening;

- Manufacturing company.

All these parameters affect the main characteristics of the saw:

- Its uniformity;

- Thickness;

- Presence of cracks and chips;

- Vibrations in progress.

Content

Scope of work

The simplest criterion. This is the amount of material to be cut. For one-time use, it is better to choose a cheap canvas with standard hardness. For permanent use, you need to purchase the highest quality wood tape. Tools made from durable steel will last much longer, so the investment will pay off.

Blade width

The width should be selected based on the working conditions. First of all, you need to focus on the type of machine, recommendations for choosing a saw should be discussed in the operating instructions.

The width of the blade varies in the range of 14-80 mm, the standard value is 38-41 mm.

In addition, when purchasing, consider the following nuances:

- Thin fabrics bend quickly when working with rough wood;

- Wide blades give a smoother cut;

- Thick saws easily deform thin and plastic rods due to high heat;

- Sometimes it is necessary to make a cut at an angle, and this greatly affects the depth of the cut.

READ How to start a Husqvarna 236 chainsaw

What teeth are needed?

Before choosing a band saw

you need to determine the type of teeth that will be optimal for the job.

First you need to determine the density of the dentition:

- The more frequent the teeth, the better the quality of the drink; this is especially important when performing decorative work;

- The rarer, the higher the pressure on each individual tooth, this is suitable for hardwood;

- The more frequent the teeth, the more uniform the stress is distributed in the network, the less deformed it is;

- The more common the teeth, the lower the pressure on each and the longer they last.

Next parameter. Teeth size:

- Larger sizes

are needed for rough cutting, such as sawing large logs; - Small sizes

are suitable for thin plywood and decorative work.

Selection of saw blades for band saws

The tape is torn into a small bordered

Saw? This is a known issue. I shared my experience as with.

Saw blade strip

We received a parcel with new blades for our band saws

Seller's contact details:.

Remember to take into account the pitch of the teeth, there are 2 recommendations:

- Thin plywood requires a wide rhythmic step;

- Thick rods require a narrow pitch.

To prevent the blade from clogging, you can choose a variable pitch blade for sawing soft rocks.

In a band saw on wood, the teeth are not kept straight, but at an angle to each other. This design is called routing and is necessary to reduce vibration levels, which is beneficial to the wear resistance and life of the tool.

READ Hiller for Walk-behind tractor with your own hands Dimensions

Standard layout. A three with alternately slanted left and right teeth and another straight tooth that stands between them. This type is used for most jobs and can be used for contour cutting. The group layout is distinguished by the fact that straight lines and teeth, inclined to the left or right, stand in pairs. This shape makes sawing more efficient, but the fabric is also more expensive.

Also consider the shape of the teeth. It is better to choose a profile for the type of wood that needs to be sawed:

Sharpening level

A complex but very important parameter to evaluate. It is necessary to check the sharpness of the teeth, to do this manually, experience is required. It is also necessary to ensure the uniformity of the material; it can be assessed by the uniformity of color and metal count. If possible, buy blades that provide services to re-rotate the canvas. If you want to sharpen your DIY wood band saw, be sure to specify how many cycles the blade is allowed to operate.

Saw manufacturers

Mostly high-quality instruments are produced by European and American companies. When choosing a saw, special attention should be paid to the manufacturer:

- Arntz (Germany). The largest company that supplies saws to all European countries. It is distinguished by high quality and also an appropriate price. The range includes high-strength carbide wheels.

- Lenox (USA). The company is interesting in that all its cutting discs use a special armor coating of their own design (aluminium-titanium nitride). The tool is characterized by high strength and long service life.

- Wikus (Germany). The company's product range includes a wide range of tools. In terms of the number of different models, it is a leader among sawmills.

- Forezienne (France). The company produces high-quality discs that are re-baked. The tools are distinguished by exceptional cutting ability and high strength.

- Lennartz (Germany). One of the largest companies, but it concentrates on the production of band saws. The selection of disk tools is sufficient, but not that large.

- Dollar (USA). A small company that produces high-quality equipment. The saws last for a long time and have excellent performance. The company has successfully established itself in the market.

READ How to Use a Chainsaw in Rasta

Make your own saw

If you have the skills and special tools, you can make a blade with your own hands. The mechanism of the machine itself is extremely simple, it looks like a bicycle with a wheel and pedals, but between them there is not a chain, but a saw blade. The first wheel is attached to any rotating motor (you can use a drill). The second wheel is only needed to secure the saw.

A band saw is made on wood with your own hands in accordance with several rules:

- Particular attention should be paid to the machine frame and wheel mounting. The design must withstand strong vibration, and the wheels must turn easily and sit on the machine.

- The saw must be securely fastened; it must not fly and injure anyone during operation. This is a basic safety requirement.

- The blade must be purchased from a store because it is made of special steel and it is very difficult to make teeth yourself.

Technical specifications

Depending on the shape of the workpieces and groups of materials, it is necessary to select the parameters of the band saw blade in exact accordance. Pay attention to the pitch, tooth shape and setting, as well as the operating modes of the band saw.

Teeth Per Inch (TPI) The number of teeth per inch determines the tooth pitch of the blade and can vary from 1 to 32 for constant pitch saws and from 10/14 to 0.75/1.25 for variable pitch saws.

| Constant tooth pitch (Industrial cutting volumes of solid workpieces) |

| Variable tooth pitch (minimal vibration, improved cut cleanliness and versatility) |

Classification of band saw blades

Carbon steel is used in the manufacture of band saws; it is highly wear-resistant. On sale there are blades made of bimetallic material, and band saws with a blade where carbide tips are used in the manufacture of teeth.

The dimensions of band saws in width (these saws are delivered to the customer mainly in the form of a coil or in the state of several bands connected to each other) vary from 13 to 80 mm. For machines where vertical cutting is used, band saws of smaller width (up to 6 mm) are manufactured.

Based on the variety of areas of use, the following classification of paintings has been compiled:

- M42. This bimetallic blade is used for cutting material made from carbon steel.

- M51. It is used for sawing material made from high-carbon steel, as well as its alloy.

- SP. This blade is preferred for cutting rare and heat-resistant alloys.

- TST. Manufacturing companies produce them for processing materials made of hard alloys or those that have a non-uniform structure.

When choosing products, pay attention to the TPI indicator, which reflects the number of teeth per 1 inch. It is worth finding out what material the workpiece is made of. This affects the thickness and accuracy of the cut.

The higher the TPI parameter, the lower the speed of work and the cut will be. Thanks to this, the cut is more accurate

If you are going to cut wood, it is better to choose a tape with a characteristic of 3 TPI or more. When working with metal, it is recommended to use tape with a TPI rating of 4 to 20.

The teeth in the belt differ not only in their distance from each other, but also in their shape. There are 2 types of teeth. One of them is called skip. It is most often found on belts with small pitches (from 3 to 6), which contributes to a larger area of sawdust ejection.

The second type is called regular. It has a triangular shape and, unlike skip teeth, does not have additional space for sawdust. For this reason, such products are used when sawing objects of large thickness or hard materials.

There are many types of canvases, the most popular are presented below:

- 3 TPI skip. This is a good choice if you need to cut thick materials quickly. The product is used for sawing wood lengthwise.

- 4 TPI skip. This type of tape is suitable for general sawing.

- 6 TPI skip. Blades are needed when the machine operates at medium speed; they can be used for longitudinal sawing of wood up to 50 mm thick and cross-cutting up to 150 mm.

- 10 TPI regular is required when you need to saw artificial materials - plywood, plastic, etc. When feeding at low speed, it is suitable for sawing wood 50 mm thick.

- 14 TPI regular. At a low feed rate, it can be used for sawing various materials up to 25 mm thick. Used when working with light metals.

The service life of the paintings depends on which company produced them.

Teeth setting

A parameter such as tooth set indicates the inclination or angle of rotation of the tooth to the plane of the saw blade. Allows for free movement of the blade and tooth edge. The main types of wiring will be presented below.

| Standard (left, right, straight), for all types of steel |

| Variable (left, right + sweep), reduced noise and vibration |

| Wave, for thin materials |

| Form NORMAL (N). The tooth has a rake angle of 0°. Saws with this tooth shape are designed for cutting alloys with a high carbon content (such as cast iron), for materials with a small cross-section and for thin-walled profiles and pipes. |

| HOOK (H) shape. The tooth has a rake angle of 10°. Saws with this tooth shape are designed for cutting solid bars and thick-walled pipes made of alloy steel. |

| Form RP. The tooth has a rake angle of 16°. Saws with this tooth shape are designed for aggressive cutting of solid bars made of high-alloy steels, difficult-to-cut metals and non-ferrous alloys. |

| MASTER form. The tooth is manufactured in two versions at a rake angle of 10° and 16°. It has a longitudinally ground chamfer, which improves the roughness of the treated surface. Saws with this tooth shape are designed for cutting solid bars made of high-alloy steels. |

Tooth shape

Band saw blades are equipped with teeth of several standardized shapes:

NORMAL (N)

HOOK (H)

R.P.

MASTER

- The NORMAL tooth (N) does not have a chamfer slope in front. The working edge is directed vertically upward. Used for cutting high-carbon materials, thin-walled pipes and rolled products.

- HOOK (H) has a front angle of 100. Its purpose is to cut thick-walled pipes and solid rods of any cross-section made of alloy steel.

- For non-ferrous alloys, high-alloy steels, and difficult-to-cut metals, a band saw blade equipped with an RP tooth with a working edge angle of 160 is used.

- The band blade with the MASTER is highly versatile; in addition to the working front edge with an angle of 10 or 160, a longitudinal chamfer is ground, as a result of which the cut roughness is significantly reduced. Such saw blades are used on all types of metal machines.

The thickness of the material that it can process depends on the pitch of the saw. When cutting solid metal, choose a band saw blade with one step, and pipes with another. Approximate parameters are given below in the tables.

Table of ratio of saw teeth to metal thickness

The pitch of the band saw teeth in relation to the pipe diameter

Band saw blade feed speed

Each tooth of the band saw blade must cut metal shavings of a given thickness. With this approach, you can achieve optimal cut quality. The selection of the blade feed speed is carried out depending on the recommendations of the equipment manufacturers, as well as taking into account the type of chips that will be obtained during cutting. When the chips are thin or even dusty, it is recommended to increase the blade feed speed or reduce a parameter such as cutting speed. If the chips curl weakly, then the sawing mode has been selected accurately and correctly. Thick chips indicate that the saw blade feed speed is too high.

Durability of band saws

| Material | Productivity, cm/min | Number of blanks, pcs. |

| Steel 20-45 | 40 | 820 |

| 50 | 780 | |

| 60 | 660 | |

| Steel 40Х | 35 | 700 |

| 45 | 630 | |

| 50 | 510 | |

| 20Х13, Р6М5 12Х18Н9Т | 15 | 380 |

| 20 | 300 | |

| 25 | 210 |

When carrying out movement in the belt transport mechanism of a machine, cyclic alternating loads inevitably arise, so it is important that both the saw tooth and the blade itself are resistant to such effects (are wear-resistant).

For the vast majority of band saw blades, the service life varies from 140-160 hours. In order to slightly increase the operating time of this equipment, during breaks in the operation of the equipment, you should remove the saw for relaxation.

The durability of the tooth directly depends on how correctly you select the tooth pitch of the band saw. Below is a table showing the dependence of the saw pitch on the diameter of the material being cut.

Band saw care

A band saw blade, like any other tool, requires proper storage and care.

To extend the life of the belt during breaks in work, it should be removed from the machine and stored in a relaxed state. On the machine, the blade tension should not exceed 300 N/m; exceeding this indicator threatens metal rupture or deformation.

When working, coolant supply modes must be observed. Without lubrication and cooling, the life of the belt is significantly reduced. When installing a new blade, you should “roll” it in idle mode for 10-15 minutes and only then perform several cuts in a mode with a load of up to 50% of the nominal.

Proper operation and durability of the band saw depends on sharpening and setting. Special machines with different setting modes are designed for these operations. When sharpening, in addition to actually restoring the sharpness of the teeth, microcracks and defects that occur in the sinuses are eliminated. Adjusting the height of the seam allowance is also very important to maintain the strength of the fabric.

Sharpening is carried out without pressing the sharpening disk, in order to avoid annealing of the belt, which can occur even with the correct settings for the type of tooth and its pitch.

Saw pitch size for cutting solid steel

| Constant step | Variable pitch | ||

| Diameter, mm | Teeth per inch | Diameter, mm | Teeth per inch |

| to 10 | 14 | up to 25 | 10/14 |

| 10 -30 | 10 | 15 — 40 | 8/12 |

| 30 – 50 | 8 | 25 — 40 | 6/10 |

| 50 — 80 | 6 | 35 — 70 | 5/8 |

| 80 — 120 | 4 | 40 — 90 | 5/6 |

| 120 — 200 | 3 | 50 — 120 | 4/6 |

| 200 — 400 | 2 | 80 — 150 | 3/4 |

| 300 — 700 | 1,25 | 130 — 350 | 2/3 |

| > 600 | 0,75 | 150 — 450 | 1,5/2 |

| 200 — 600 | 1,1/1,6 | ||

| > 500 | 0,75/1,25 | ||

Saw pitch size for cutting profiles and pipes

| Wall S, mm | Outer diameter D, mm | ||||||||||

| 20 | 40 | 60 | 80 | 100 | 120 | 150 | 200 | 300 | 500 | ||

| 2 | 14 | 14 | 14 | 14 | 14 | 14 | 10/14 | 10/14 | 8/12 | 6/10 | |

| 3 | 14 | 14 | 14 | 10/14 | 10/14 | 10/14 | 8/12 | 8/12 | 6/10 | 5/8 | |

| 4 | 10/14 | 10/14 | 10/14 | 8/12 | 8/12 | 8/12 | 6/10 | 6/10 | 5/8 | 4/6 | |

| 5 | 10/14 | 8/ 12 | 8/ 12 | 8/ 12 | 6/10 | 6/10 | 5/8 | 5/8 | 4/6 | 4/6 | |

| 6 | 8/12 | 8/ 12 | 6/ 10 | 6/10 | 5/8 | 5/8 | 5/8 | 5/8 | 4/6 | 3/4 | |

| 8 | 8/12 | 6/10 | 6/ 10 | 6/ 10 | 5/8 | 5/8 | 5/8 | 5/8 | 4/6 | 3/4 | |

| 10 | 6/10 | 5/8 | 5/8 | 5/8 | 5/8 | 4/6 | 4/6 | 3/4 | 3/4 | ||

| 12 | 5/8 | 5/8 | 5/8 | 4/6 | 4/6 | 4/6 | 3/4 | 3/4 | 3/4 | ||

| 15 | 5/8 | 5/8 | 4/6 | 4/6 | 4/6 | 4/6 | 3/4 | 2/3 | 2/3 | ||

| 20 | 4/6 | 4/6 | 4/6 | 3/4 | 3/4 | 2/3 | 2/3 | 2/3 | |||

| 30 | 3/4 | 3/4 | 3/4 | 3/4 | 2/3 | 2/3 | 2/3 | ||||

| 50 | 2/3 | 2/3 | 2/3 | 2/3 | |||||||

If you need to cut pipes that are located nearby, then values with double the wall thickness should be used.

Recommended cutting conditions for band saw equipment

| Workpiece material | Material designation | Cutting speed, m/min | Cooling | ||||

| DIN | GOST | Special | Bi-metal | Emulsion | Oil | ||

| Yes | No | ||||||

| Structural steels | St 35-St 42 | St 35-55 | 40-55 | 60-80 | 1:10 | X | |

| St 50-St 70 | 30-45 | 50-70 | 1:20 | X | |||

| Hardenable steels | C10-C15 | 45-65 | 60-90 | 1:10 | X | ||

| 14NiCr14 | 30-40 | 40-50 | 1:10 | X | |||

| 21 NiCrMo 2 | 30-45 | 45-55 | 1:10 | X | |||

| 16MnCr5 | 30-45 | 50-65 | 1:10 | X | |||

| Nitrided steels | 34 CrAI 6 | 20-35 | 1:20 | X | |||

| 34 CrAI Ni 7 | 20-35 | 1:20 | X | ||||

| Chrome steels | C 35-C 45 | 35-55 | 55-75 | 1:20 | X | ||

| 41 Cr4 | 40X | 25-35 | 40-60 | 1:20 | X | ||

| 40Mn4 | 40G | 35-45 | 50-65 | 1:20 | X | ||

| 42 CrMo 4 | 40 XM | 30-40 | 35-50 | 1:20 | X | ||

| 36 NiCr 6 | 40 HN | 30-40 | 50-60 | 1:20 | X | ||

| 24NiCr14 | 25-35 | 40-60 | 1:20 | X | |||

| Bearing steels | 100 Cr 6 | 25-35 | 50-65 | 1:30 | X | ||

| 105 Cr4 | ШХ 15 | 25-35 | 50-65 | 1:30 | X | ||

| 100 CrMo 6 | 20-30 | 40-50 | 1:30 | X | |||

| Spring steels | 65Si7 | 65 G | 30-40 | -100 | 1:30 | X | |

| 50 CrV 4 | 50HFA | 30-40 | 40-60 | 1:30 | X | ||

| High carbon tool steels | C80W1 | U8A | 25-35 | 40-55 | 1:30 | X | |

| C125W1 | 20-30 | 35-45 | 1:30 | X | |||

| C 105 W 2 | U10A | 25-35 | 40-50 | 1:30 | X | ||

| Alloyed | 105 Cr 5 | 30-40 | 50-60 | 1:30 | X | ||

| x210Cr12 | X12 | 20-35 | X | ||||

| x 40 CrMoV 51 | 4Х5МФС | 20-30 | 30-40 | 1:30 | X | ||

| x210CrW12 | HVG | 20-30 | X | ||||

| x 165 CrMoV 12 | XM12 | 20-35 | 1:30 | X | |||

| 56 NiCrMoV 7 | 5ХНМ | 25-3 | 20-40 | 1:30 | X | ||

| 100 CrMo 5 | 20-30 | 35-45 | 1:30 | X | |||

| x 32 CrMoV 33 | 20-30 | 30-45 | 1:20 | ||||

| High speed steels | S 6-5-2 | R6M5 | 25-40 | 1:30 | X | ||

| S 6-5-2-5 | R6M5K5 | 25-40 | 1:30 | X | |||

| S 18-0-1 | P18 | 25-40 | 1:30 | X | |||

| S 18-1-2-10 | Р18К10 | 25-40 | 1:30 | X | |||

| Valve steels | x 45 CrSi 93 | 30-40 | 1:20 | X | |||

| x45CrNiW189 | 30-40 | 1:20 | X | ||||

| High temperature steels | CrNi 2520 | 25-40 | 1:10 | X | |||

| x 20 CrMoV 211 | 25-40 | 1:10 | X | ||||

| x5NiCrTi2615 | 25-40 | 1:10 | X | ||||

| Heat-resistant steels | x 10 CrAI 7 | 20-30 | 1:10 | X | |||

| x15CrNiSi25/20 | 20-30 | 1:10 | X | ||||

| x 10 CrSi 6 | 20-30 | 1:10 | X | ||||

| Stainless and Scale-resistant steels | x 5 CrNi 189 | 25-35 | 1:10 | X | |||

| x 10CrNiMoT1810 | 25-35 | 1:10 | X | ||||

| x 10 Cr 13 | 12Х13 | 25-35 | 1:10 | X | |||

| x5CrNiMo 1810 | 25-35 | 1:10 | X | ||||

| Steel casting | GS-38 | 30-40 | 50-60 | 1:50 | X | ||

| GS-60 | 30-40 | 50-60 | 1:50 | X | |||

| Iron casting | GG-15 | Sch 15-32 | 30-40 | 40-50 | X | ||

| GG-30 | Sch21-40 | 30-40 | 40-50 | X | |||

| GTW-40 | 30-40 | 40-50 | X | ||||

| GTS - 65 | 30-40 | 40-50 | X | ||||

| High temperature nickel alloys | NiMoNic | Nimonic | 15-25 | 1:10 | X | ||

| Hastelloy | Hastelloy | 15-25 | 1:10 | X | |||

| Inconel | Inconel | 15-25 | 1:10 | X | |||

| Aluminum alloys | Al 99.5 | A1 | 80-300 | 100-700 | 1:10 | X | |

| AIMg3 | AL13 | 80-300 | 100-700 | 1:10 | X | ||

| Bronze | CuSn6 | Br. Mts 5 | 50-70 | 70-100 | 1:50 | X | |

| CuAI8 | Br.AYU | 30-45 | 50-70 | 1:50 | X | ||

| Brass | CuZn 10 | 80-200 | 100-300 | 1:50 | X | ||

| CuZn 31 Si | 80-200 | 100-300 | 1:50 | X | |||

Selection and operation of the belt web

The information presented in the tables below is a guideline only and please be aware that some values may vary. Manufacturing companies of band saw blades indicate their own designations for blade materials, as well as types of setting and tooth shapes. Provide detailed instructions for selection and use. Below are only general ISO symbols.

STEP 1 Selecting fabric material

| Material | Section, profile | Machine type | Canvas material |

| Non-alloy steel | Thin-walled pipes and profiles, small diameter rods | easy | Carbon steel |

| Low alloy steel up to 22 HRC | Carbon steel | ||

| Unalloyed and low alloy steel | Bimetal Matrix II |

STEP 2 Selecting the blade tooth pitch

| CONTINUOUS SECTION | PROFILE SECTION | ||||||||||||||||||

| Constant step | Variable pitch | D mm | 20 | 40 | 60 | 80 | 100 | 150 | 200 | 300 | |||||||||

| Diameter, mm | Teeth per inch | Diameter, mm | Teeth per inch | S mm | Tooth pitch, Z | ||||||||||||||

| to 10 | 14 | up to 25 | 10/14 | 2 | 14 | 14 | 14 | 14 | 10/14 | 10/14 | 10/14 | 10/14 | |||||||

| 10 – 30 | 10 | 15 — 40 | 8/12 | 3 | 14 | 10/14 | 10/14 | 8/12 | 8/12 | 8/12 | 6/10 | 6/10 | |||||||

| 30 – 50 | 8 | 25 — 40 | 6/10 | 4 | 14 | 10/14 | 10/14 | 8/12 | 8/12 | 6/10 | 6/10 | 5/8 | |||||||

| 50 – 80 | 6 | 35 — 70 | 5/8 | 5 | 14 | 10/14 | 10/14 | 8/12 | 6/10 | 6/10 | 5/8 | 4/6 | |||||||

| 80 – 120 | 4 | 40 — 90 | 5/6 | 6 | 14 | 10/14 | 8/12 | 8/12 | 6/10 | 5/8 | 5/8 | 4/6 | |||||||

| 120 – 200 | 3 | 50 — 120 | 4/6 | 8 | 14 | 8/12 | 6/10 | 6/10 | 6/10 | 5/8 | 5/8 | 4/6 | |||||||

| 200 – 400 | 2 | 80 — 150 | 3/4 | 10 | 6/10 | 6/10 | 5/8 | 5/8 | 4/6 | 4/6 | 4/6 | ||||||||

| D - cross section S - profile wall thickness Z - blade pitch, number of teeth per inch | 12 | 6/10 | 5/8 | 4/6 | 4/6 | 4/6 | 4/6 | 3/4 | |||||||||||

| 15 | 4/6 | 4/6 | 3/4 | 3/4 | 3/4 | ||||||||||||||

| 20 | 4/6 | 4/6 | 3/4 | 3/4 | 3/4 | ||||||||||||||

| 30 | 3/4 | 3/4 | 3/4 | 2/3 | 2/3 | ||||||||||||||

| 50 | 2/3 | 2/3 | 2/3 | ||||||||||||||||

Blade tooth profile

| The rake angle of the tooth is 0°. For cutting high carbon alloys, materials with small cross-sections, thin-walled profiles and pipes. |

| The rake angle of the tooth is 10°. For cutting solid bars, thick-walled pipes made of alloy steels. |

| The rake angle of the tooth is 16°. For cutting solid bars made of high-alloy steels, difficult-to-cut metals and non-ferrous alloys. |

| The front angle of the tooth has two points 10° and 16° and a longitudinally ground chamfer, which improves the roughness of the machined surface. For cutting solid bars made of high-alloy steels. |

How to choose the right band saw

Home \ MASTER Tips \ How to choose the right band saw

How to choose the right band saw

One of the main stages in band sawing is the correct selection of the pitch of the teeth on the band saw (the number of teeth per inch).

The fundamental points when choosing saw sizes, tooth shapes and pitches are as follows: - it is necessary to use saws only of the length and width specified in the technical data sheet of the band saw machine. — when cutting soft materials, you should use saws with large pitches and the volume of chip flutes. — cutting hard materials requires the use of saws with a large number of teeth to better distribute the load on the tooth.

As general recommendations, you can adhere to the following requirements for the simultaneous operation of teeth (see table):

| Number of teeth simultaneously located in the metal | Normal machinability materials | High hardness materials |

| Minimum | 3 | 6 |

| Maximum | 24 | 36 |

| Optimal | 6-12 | 12-24 |

These recommendations are based on the characteristics of the band saw cutting mechanism. If there are too few teeth along the length of the cut, the load on each tooth may be excessive and cause it to break. If the number of teeth is greater than the permissible limit, the load on each tooth is small, but the overall cutting force increases, which can lead to a tear in the overloaded saw blade.

The volume of the chip flutes should also be taken into account, since When too many chips are generated and they cannot fit into the tooth cavities, cutting conditions deteriorate sharply, the saw teeth are pressed away from the workpiece, which leads to rapid wear and breakage of the saw.

Other factors influencing the choice of pitch and tooth shape are the chemical composition and mechanical properties of the workpiece material, as well as the shape of its cross-section.

The pitch of the teeth is defined as the number of cutting edges of the teeth per inch (25.4 mm) and is designated - tpi (teeth per inch - teeth per inch). There are constant and variable tooth pitches.

With a constant pitch, the teeth are located at equal distances from each other. Saws with this pitch are recommended for cutting solid-section workpieces.

With variable pitch, teeth with different pitches are formed into groups. Saws with variable pitch are more resistant to vibration, so they are recommended for cutting a wide range of solid-section workpieces, as well as profile materials and packages of workpieces.

Choosing a saw pitch when sawing solid workpieces

Sawing solid pieces

The diagram will help you choose the correct tooth pitch for sawing solid workpieces. The ideal step choice is determined by the top of each individual diagram.

Example 1: If you are sawing a soft material such as plastic, aluminum or wood, use a step 2 grades coarser than the chart recommends. For example, when cutting an aluminum workpiece 16 mm wide, use a blade with a pitch of 6 TPI or 5/8 TPI.

Example: To cut a 150mm diameter bar with a uniform tooth pitch blade, use a 2 TPI pitch. For uneven spacing, use 2/3 TPI or 1/2 TPI spacing.

Choosing a saw pitch when cutting pipes and profiles depending on overall dimensions and wall thickness

It is especially important to choose the correct geometric parameters of saws when cutting pipes and profiles. The variable cross-sections of these workpieces suggest the presence of several walls or ribs, into which the teeth are cut in an impact manner. Due to the uneven load, vibration increases and micro-chipping of the sharp cutting edges of the saw teeth occurs. In many cases, there is a decrease in expected tool life (by 40-50%) and a decrease in cutting performance (by 20-30%). This necessitates the use of saws with small, strong teeth of a special profile, the number of which must be at least three at a time in the cutting zone of any section of the workpiece.

The dependence of the tooth pitch on the dimensions of the workpiece when cutting pipes is more complex, since both the diameter and thickness of the pipe wall should be taken into account - see figure:

Operation of the belt web

An example of a strip design:

| M42 20x0.9x2360 4/6 N | M42 | bimetallic blade M42, high-speed steel teeth |

| 20x0.9x2360 | width x thickness x length of the blade, mm | |

| 4/6 | blade tooth pitch, 4 – 6 teeth per inch, variable pitch | |

| N | tooth shape, rake angle 10 |

| Very fine dusty chips | Thick, heavy shavings with a blue tint - the blade is overloaded | Loosely wound (twisted) chips - ideal cutting conditions |

The tension value of the belt web should be approximately 300 N/mm. If the blade tension is not sufficient, it is possible to make a non-perpendicular cut. When the tension of the fabric is excessive, rupture is possible. In two cases, the service life of the belt web will be significantly reduced. The tension force is monitored using special devices - strain gauges.

Let's look at how the canvas is rolled in:

- Set the required speed;

- Start cutting at 70% of the power recommended for the blade and 50% feed speed;

- If vibration occurs, you should quite carefully reduce the feed speed until it comes to a complete stop. It is necessary to monitor chip formation and determine from the resulting chip shape whether the blade is overloaded.

After making a cut of 400-600 cm or at least 15 minutes of actual sawing time, you should gradually increase the blade speed to the required speed and gradually the feed speed.

Cooling and lubrication are mandatory in the vast majority of metalworking operations. When processing aluminum and aluminum alloys, coolant allows you to maintain a better surface finish. Remember that the service life of the saw blade directly depends on the selection of coolant. The main task is to prevent the canvas from being overheated.

Let's consider the main reasons for premature failure of the belt web

- Chipping of teeth:

- Blade pitch too small

- Blade pitch too large

- Workpieces are not securely fastened

- Blade speed too low resulting in excessive penetration

- Poor quality welding

- Feed pressure is too high, resulting in excessive cutting of the blade into the material

- Weak web tension causes it to slip

- Slipping (stopping) of the saw under load, leading to excessive penetration of the blade into the material

- The web cleaning brush is missing, does not work or is worn out

- Cracks in tooth cavities:

- Difficult movement of the saw in the guides and pulleys due to contamination of the pulleys or reduced clearance in the guides

- The gap between the guides is too large

- The guides are too far from the workpiece

- Side guides clamp the saw in the tooth gullet area

- Weak side guides cause the saw to tilt

- Incorrect saw tension

- Wear of the upper support bearing in the guides

- High supply pressure

- Wear of side guides

- The blade is pressed against the pulley collar

- Crooked weld

- Blade pitch too large

- Missing teeth (broken)

- Supply pressure too low or high

- The saw speed is too high for the material.

- Saw pitch too small or too large

- Saw blade not parallel to feed direction

- Defects on the side guides

- Guides are loose or worn

- Saw blade not parallel to feed direction

- Large gap in guides

- The table surface is not perpendicular to the canvas

- The vice is not perpendicular to the saw

- Weak web tension

- The roller table at the feed is not perpendicular to the web

- The side guides are poorly secured

- Big feed

- The cleaning brush does not work

- Dull blade

- No cooling

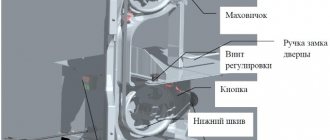

Step-by-step instructions for replacing a band saw blade

Let's look at the process of replacing a band saw on a manual machine for cutting metal workpieces.

Important. Before starting work, you need to make sure that the equipment is completely de-energized. You must not only press the control button, but also turn off the power to the circuit breaker.

A sudden turn on of the power is sure to cause severe injuries, many of them life-threatening. Never violate safety rules, they are written based on someone else's mistakes and injuries.

| Step, No. | Description |

| Open the protective cover of the band saw drive mechanism. It is secured with several latches and has mounting loops at the bottom. |

| Loosen the tension on the saw as much as possible. To do this, you need to turn a special lever located at the end of the machine body counterclockwise. When the screw rotates, the tension wheel moves towards the drive wheel and thus weakens the tension of the band saw. |

| Remove the saw from the tension pulley, then remove it from the guide mechanism and only then from the drive pulley. Wear thick gloves to avoid damaging your hands. Do not bend the saw blade too much; it may injure the worker when leveling. The saw is held in the guide mechanism by bearings; they level the cut and dampen vibrations. For effective operation, the bearing races press the blade tightly; it should be removed from there with a sharp blow of the hand. Do not use hammers; they may damage machine parts. |

| Get a new saw, clean it of technical oil, and make a visual inspection. If manufacturing defects are detected, use of the saw is strictly prohibited. Start inserting the blade into the guide, it should fit tightly into the bearings. If everything falls into place, then you should feel the moment the blade comes into contact with the clips - the force will increase, the upper edge of the blade will rest against the metal surface. |

| Carefully slide the saw onto the drive pulley and then onto the driven pulley. Place it exactly in the previous position. Tension the fabric slightly by rotating the tension wheel. Once again correct the position of the saw in the rollers and tighten the saw again. At this stage, the saw is not tensioned to working values, but is only tightened for proper installation. Pulling the saw with the casing open is strictly prohibited by the instructions for using the equipment. |

| Close the saw guard with the latches. The cutting tool has been replaced, but it is still impossible to work on the machine - the saw needs to be adjusted. The algorithm of actions changes slightly taking into account the technical data of the machines, but the principle is the same. |

Video - Replacing the blade on the saw

Operation of belts

Cutting metal blanks on band saws is currently the most cost-effective way to perform metal processing in blank production. Thanks to its design features, the band saw machine allows you to process even fairly large products, while the area occupied by the equipment can be insignificant. When assessing a technological process such as band sawing, it should be noted that its efficiency is several times higher than other traditional processing methods, including a mechanical hacksaw, disk cutting, and cutting on lathes.

With traditional methods, parameters such as material consumption, cut thickness and non-perpendicularity are significantly higher than when cutting on a band saw. The cost of band saw blades is not the cheapest, but this can be successfully offset by high speed, productivity, and good durability. You just need to carefully select this technological equipment and pay attention to the type of material being processed and the overall dimensions of the workpieces being cut.

Below are the basic requirements that should be taken into account when using tapes. Compliance with these rules will significantly increase the service life of the paintings, as well as avoid their premature wear.

Preparing the canvas for work

If the pencil is sharpened enough, there is a very high probability that it will break almost immediately. But at the same time, a slightly dull pencil can last much longer. The same principle can be applied to band saw blades. Therefore, initially you should let the blade run in to the machine pulleys by running it idle through the air for about 5-10 minutes. Then, at a lower speed than that recommended and with half the feed, carry out sawing for another 15-30 minutes, followed by reaching the recommended mode.

Web tension

This parameter will be indicated in the equipment operating instructions. The presence of built-in strain gauges allows you to control the degree of tension. Remember that it is important not to overtighten the fabric, as this can lead to a significant reduction in the durability period or even lead to tearing of the fabric along the seam or cracks forming.

Below are the basic requirements that should be taken into account when using tapes. Compliance with these rules will significantly increase the service life of the paintings, as well as avoid their premature wear.

Operation of the canvas

The main indicators that the cutting mode has been chosen correctly include the absence of strong vibrations during cutting, as well as the type of chips. When the cutting process is carried out optimally, each saw tooth produces chips of a certain thickness. The selection of feed is carried out taking into account the recommendations of the manufacturer, as well as the type of chips that are obtained during cutting.

Rest of canvas

During operation, fatigue stresses inevitably arise, and when the blade rests, they are redistributed. If there is a significant operating load throughout the entire working day, it is better to cut with 2 blades (one is used before lunch, and the other after). At the end of the working day, it is necessary to loosen the tension of the canvas. Or remove the canvas from the machine and hang it on a hook, having first turned it inside out.

Lapping in the strip by cutting

Just like a new car requires running-in, a new bandsaw blade requires grinding in by cutting. It is necessary if the standard mode of movement of the web is 30 meters per minute or higher. The blade must work about 1000 square centimeters at a lower load than with standard cutting conditions.

If grinding by cutting has not been carried out or has not been carried out sufficiently, then the cutting edges of the teeth are not yet aligned. In this case, problems such as vibration, tooth chipping, and uneven wear may occur. The resource of the canvas and its quality can be significantly deteriorated.

To perform proper grinding by cutting you must:

1. Set the blade speed on the band saw to 30 meters per minute and calculate the cutting time according to the graph below. For example, for a section width of 200 mm. cutting time will be 16 minutes. The cutting speed is set so that the required cutting time is achieved. Installation is carried out using the “+,-” buttons of the speed controller. Keep the cutting force at a fixed level, which is set in the standard cutting mode.

2. Increase blade speed and cutting speed step by step until standard cutting conditions are achieved. In this case, the number of cuts that will be required for grinding in by cutting is found as follows: the required running-in area must be divided by the cross-sectional area of the material being cut.

3. Cutting lapping is completed when the lapping area defined for the blade and material is reached.

The specified cutting grinding mode should be taken into account as a recommendation. It may be necessary to individually select a cutting mode that eliminates chatter or vibration during the initial cutting period.