Such unique equipment as a magnetic drilling machine is increasingly used by specialists. The reasons for the popularity of such equipment lie in the functionality it has.

Compact magnetic machine KBB-30, used for drilling with core drills up to 30 mm in diameter

There is a wide variety of similar installations on the modern market, which differ in both design features and functionality. In order for the use of such machines to be as efficient as possible, they should be correctly selected to solve specific technological problems.

Why and where is drilling equipment with a magnetic sole used?

Conventional drill presses, although versatile, cannot be used in certain situations. Thus, due to its design features, this equipment is used only for drilling holes in oversized parts that are placed directly on the device’s desktop. Even the largest drilling machines have a limited maximum lift height of the drill bit above the workbench surface, which sets stringent requirements for the height of the workpiece.

Models of magnetic machines with a “flat” layout can work in limited height spaces

The use of such a machine also imposes restrictions on the location of the drilled holes relative to the edge of the part. This is due to the fact that the support post of the device is located at a small distance from the axis of the drill.

A magnetic drilling machine is free of all of the above limitations - a portable, compact device that allows you to effectively perform various technological operations. Due to the presence of a special magnetic pad in its design, such a machine can be securely fixed on any metal surfaces that need to be processed. Using such an installation, you can effectively perform a whole list of technological operations:

- drilling holes of various diameters;

- internal thread cutting;

- milling;

- deployment;

- countersinking.

Depending on the functionality of a particular model, a drilling machine with a magnetic sole can be used in conjunction with various types of tools. Thus, to form holes with a diameter of up to 32 mm in parts of small thickness, spiral drills and core cutters are used. And to create holes of significant diameter (up to 150 mm) in parts of large thickness, core drills and cutters of reinforced design are installed on a magnetic drilling machine.

HSS ring cutters

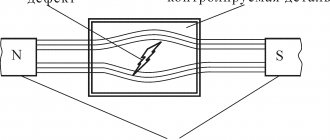

At the base of the stand of machines of this type, magnets with a power of up to 26 kN are placed, which makes it possible to reliably fix such installations on horizontal, inclined and even vertical metal surfaces. If the surface on which it is necessary to fasten the drilling unit on a magnetic base does not have the required flatness and stability, then the reliability of the machine is ensured by using vacuum or chain clamps.

Drilling machines equipped with a magnetic pad are most widespread in those industries where it is necessary to drill holes in large structures. This includes shipbuilding, construction of high-rise structures and bridges, construction of dams and other metal structures. The compact dimensions and light weight of the drilling machine on a magnetic base allow it to be used effectively in hard-to-reach places where the use of conventional equipment is simply impossible.

Drilling technological holes in metal beams of an overpass using a magnetic machine

Classifications of drilling machines

Dimensions of the machine

To determine the optimal type of drilling machine on a magnetic levitation, it is necessary to take into account its technical and operational qualities. Despite its relatively small size, this type of equipment can have wide functionality.

There is no generally accepted classification of magnetic base machines. Therefore, before purchasing, it is recommended to do a comparative analysis of the proposed models. The determining parameter is the operating conditions of the equipment. They must correspond to the characteristics of the magnetic machine.

Based on this condition, the following equipment parameters can be distinguished:

- drill feed – manual or automatic. The second option is used when it is impossible to manually carry out the drilling process. The parameters of the machine with a magnetic base are pre-set, and then, after installation on the metal structure, the program is launched;

- type of electric motor power supply – from batteries or by connecting to the mains;

- function of rotating the drilling head relative to the workpiece. This makes it possible to form complex through and blind holes.

In addition to these design features, it is necessary to take into account the actual technical characteristics of the model. They determine not only the list of operations performed, but also their quality.

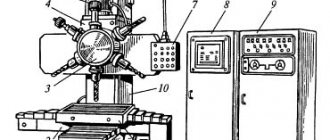

To reduce the size of the machine, a gear drive is often used instead of a traditional belt drive. Thanks to it, you can adjust the rotation speed of the drill.

Types of electromagnetic drills

The downforce, which depends on the volume of the electromagnet used, starts from 500 kg. The thicker the metal that needs to be processed, the higher the clamping force value the tool must have. Often in a metal structure it becomes necessary to drill a hole in the bottom. If you do this with a regular drill, you will need a lot of effort, time and new drills. Thanks to a magnetic drill, this operation can be completed in a matter of minutes, after first fixing the device on a metal base.

Don't miss: Should I buy a horizontal or vertical hammer drill?

This is interesting! An important parameter of a magnetic drill is the drilling diameter. Its minimum value for any similar device is 1 mm, and the maximum depends on the massiveness of the unit.

The maximum hole diameter that can be drilled with the tool in question is 150 mm. To obtain such a hole you will need core drills for a magnetic drill. For such an unusual tool, special drills are used, equipped with a magnetic grip on the tail part.

Magnetic drills are divided into types depending on their mass indicators. The following types are distinguished:

- Ultramobile. The mass of such tools is 10 kg, and are used exclusively in cases where access for installing a stationary device is limited

- Mobile. Their weight ranges from 10 to 14 kg. Popular models that are in demand when working at heights. Their advantage is their relatively low weight and high downforce performance.

- Medium mobile. Their weight is up to 20 kg, and they are used when the metal structure is thick

- Heavy. The weight of such units reaches 25 kg. They are very inconvenient to transport, but at the same time they have a huge range of possibilities. The use of such tools is resorted to when all of the above modifications do not cope with the assigned tasks.

This is interesting! The need for a tool such as a magnetic drill at home is extremely low, unless your type of activity is related to metal structures. You can drill a hole in metal up to 5 mm thick using an ordinary electric drill with a high-quality steel drill bit.

A magnetic drill is somewhat reminiscent of a drilling machine, but the only difference is that the machines are stationary, unlike the units in question. Using a magnetic unit, you can process other materials, but the main condition is reliable fixation of the tool on a metal base.

Design and types of drilling rigs on a magnetic base

Drilling machines equipped with a stand with a magnetic base, depending on the type of main movement drive used, are divided into several categories:

- electrical;

- pneumatic;

- hydraulic.

Electric machines with a magnetic base are among the most common. Such installations are used in places where there is access to the electrical network and there is no explosive atmosphere. The drive of such a machine, which ensures the rotation of the cutting tool, is an electric motor, the power of which directly determines the functionality of the equipment. Among machines of this type, the most popular are compact models, the weight of which does not exceed 16 kg, and the engine power is 0.75–1.4 kW.

Magnetic drilling machine EBM-360 powered by built-in battery

A pneumatic magnetic plate drilling machine is equipment in which the cutting tool rotates using the energy of compressed air. They work with such installations in places where there is no access to electricity, as well as in cases where the use of the latter is simply unacceptable due to safety requirements (for example, in an explosive environment).

The structural elements of such machines can be made of special alloys that do not produce a spark, which significantly increases the safety of this equipment.

The drive of hydraulic magnetic machines is a hydraulic motor, which is driven by the pressure of a special oil. Such machines, the structural elements of which are made of alloys that are not subject to corrosion, are used when performing work in conditions of high humidity or under water.

Since machines on a magnetic base are used primarily for drilling holes in large parts of considerable thickness, the working tool becomes very hot during operation. To neutralize the effects of strong heating, which can lead to tool breakage, almost all models of magnetic machines are equipped with an effective cooling system. The working fluid in such cooling systems is most often water, which is poured into a special container. Water is supplied to the processing zone automatically, for which the design of the machine includes a special tube and a compact pump.

The device of a drilling machine on a magnetic base

To protect the tool from damage in emergency situations, as well as to ensure the safety of the installation operator, modern models of magnetic machines are equipped with safety mechanisms. Many manufacturers use slipping clutches as such a mechanism, which are installed on the equipment gearbox. At the moment when a drill or core cutter gets stuck in the workpiece, the installation drive and the unit in which the tool is fixed are disconnected.

Magnetic drilling machine (drill) Vector MS-36 – availability

A lightweight and inexpensive domestic model of a drill with a magnetic sole. The MFSC system has been introduced, which ensures reliable fixation of the machine to uneven metal surfaces. Built-in gravity control mechanism.

The overall height of the machine has been reduced for work in places with limited space. A design is provided for supplying cooling and lubricating fluid to the cutting zone. Reliable operation is ensured by special winding of the rotor and an overload protection mechanism.

Pros:

- Compact size, light weight.

- Easy to control, cooling of the processing area and drill.

- Mobility, complete with case.

Minuses:

- One speed without adjustment.

What to consider when choosing a magnetic drilling machine

Since drilling machines equipped with a magnetic base must be extremely mobile, the main characteristic of such equipment is its weight. That is why modern manufacturers equip these machines with lightweight commutator-type electric motors.

The power of the electric motor, which is installed on a magnetic drilling machine as a drive, can vary between 0.6–3 kW. Most models of such machines have electric motors whose shaft rotation speed does not exceed 1100 rpm. This is explained by the fact that at higher tool speeds it is almost impossible to ensure effective cooling. The only exceptions are Japanese-made machines, in which conical drills made of carbide steel are used as cutting tools.

Budget models of drilling machines with a magnetic base are equipped with motors that provide a rotation speed of 250–600 rpm. Such revolutions are quite enough to effectively drill holes with a diameter of 18–38 mm.

Magnetic drilling machine BDS MABasic 200 – simplicity and reliability

Simplicity of design, ease of use, moderately powerful and high-speed motor, along with low weight allow a magnetic drill to perform production operations in hard-to-reach places. It is possible to work with spiral or annular drills.

The machine is equipped with a standard chuck for reliable fixation of the cutting tool and quick change to another size. The attractive force of the electromagnet allows you to install the machine in any position.

Pros:

- A good unit for the money, it fully performs its functions.

- High-quality performance, price.

- A combination of lightness and power.

Minuses:

- Single speed, sometimes lacks power in cold weather.

Fixing equipment on the surface of a part

Drilling machines that are equipped with a stand with a magnetic base will only be securely fixed to the surface of the workpiece if all the necessary requirements are met.

The most important of these requirements is the sufficient massiveness of the part (its thickness should not be less than 6 mm). When drilling and milling (especially using core-type tools), significant vibration loads are created that can move the machine from the surface of an oversized part.

Swivel magnetic base makes it easy to accurately position the machine

You should also take into account the surface area of the part on which the machine will be installed. In order for the drilling rig to be reliably magnetized to the surface of the part, the area of the latter must be no less than the area of the magnet installed at the base. The magnetization force is also reduced by a layer of paint on the surface of the part.

If you are not sure that the drilling machine with a magnetic base is securely fixed to the part, it is better to strengthen the fastening using special belts that come with the equipment. Additional fastening devices are also necessary when a machine with a magnetic base is used for drilling holes in pipelines. In this case, a chain fixing platform is used. Its upper part, on which the magnetic drilling unit is attached, is a flat metal surface, securely fixed to the pipe using two chains.

Special clamping device for drilling large diameter pipes

On the modern market you can purchase mobile drilling machines that are installed on the surface of non-metallic structures. Fixation of such equipment on the surface of the workpiece is ensured not by a magnet, but by a vacuum created by means of a pump supplied with the machine. The use of such machines, which actually stick to the part with their base, is possible only if the surface being processed is exceptionally flat.

Magnetic electric drilling machine ELEMENT 30 “Rotabroach” – a workhorse

Mobile, moderately lightweight tool with a magnetic base. Equipped with a high-power electric motor. An increased rotation speed and an improved gearbox have increased the reliability and service life of the machine. The force on the magnetic sole reaches 800 kgf.

Power supply from a stationary power supply voltage of 220V. Compact dimensions are maintained, allowing you to reach the most inaccessible places. An effective system has been used - Cutsmart Technology - overload protection during peak loads.

Pros:

- Build quality, reliability.

- Good for auto repair shop operations.

- Reliable, easy to operate, adjustable pressure on the drill.

Minuses:

- The drilling diameter is too small.

Popular Brands of Magnetic Base Drilling Machines

The leaders in the production of drilling equipment equipped with a magnetic base are the companies BDS, ALFRA, Eibenstock, DeWalt, RUKO, Magrtron, Metabo, Nitto Kohki. The machines of the listed brands are distinguished by high functionality and exceptional operational reliability, which, naturally, is reflected in their cost, which is significantly higher than the prices of analogues of Chinese and domestic production.

If we talk about budget models of magnetic drilling machines, we can highlight Russian machines produced under the Vityaz and Hi-Tech brands. The equipment of these brands optimally combines decent performance characteristics and reliability with an affordable price for consumers.

How to choose a budget magnetic drilling machine

If you consider the option of purchasing a budget drilling machine equipped with a magnetic base, then you should pay attention to two models presented on the domestic market: Mab 100 from the BDS company and Vityaz 40P. Both of these machines are in the same price category, have decent functionality, reliability and are easy to use.

Two popular models of magnetic drilling machines

The engine equipped with the Mab 100 machine has a power of 0.8 kW, and it transmits rotation to the tool through a single-stage gearbox. The machine spindle can make a working stroke to a depth of up to 80 mm. The magnetic base of the installation has dimensions of 80x160 cm. Spiral and crown type tools can be installed on the machine, the shanks of which are made in the common size of ¾ inches.

Technical parameters of drilling machine BDS MAB 100

Due to the use of a gearbox with reverse speed in the Vityaz 40P machine, the functionality of this model is slightly higher than that of the Mab 100. The use of such a gearbox allows this equipment to be used for cutting threads in holes with a diameter of up to 16 mm.

The reverse gearbox is not the only advantage of such a machine; it has a more powerful motor (1.05 kW), and its spindle can make a working stroke to a depth of up to 150 mm. When using a tool with crowns on this machine, you can drill holes with a diameter of 12–40 mm, and when using twist drills – 1–16 mm.

Technical characteristics of the magnetic drilling machine “Vityaz-40R”

Magnetic drilling machine ECO.30 – the lightest in its class

The lightest magnetic drill among analogues. It has small overall dimensions, which allows processing in “narrow” places. This is facilitated by the design of the gearbox. The magnetic attraction force reaches 1.2 tons.

The powerful motor allows you to increase the diameter of the holes produced by a classic twist drill. The cutting zone and cutting tool are lubricated and cooled by coolant. Durable and comfortable handles provide the necessary pressing force and drill feed speed.

Pros:

- An unexpectedly light and, at the same time, powerful magnetic drill.

- Great force of attraction to the treated base.

- Power in a compact size.

Minuses:

- Consumers did not identify any negative characteristics.