General issues

Argon arc welding is called welding with the formation of an electric arc in an argon environment. One of the electrodes is the surface of the part. The second electrode may be consumable or non-consumable. The non-consumable electrode is usually made of tungsten. In regulatory documents, argon arc welding can be designated by the following abbreviations:

- RAD – manual argon arc welding. In this case, a non-consumable electrode is used.

- AMA is argon arc welding, carried out with non-consumable electrodes, but in automatic mode.

- AADP – automatic welding with consumable electrodes.

In the international classification, this type of welding is defined as TIG - Tungsten Inert Gas or GTAW - Gas Tungsten Arc Welding, which translated means “welding in an inert gas environment”. Often this gas is argon.

An inert gas was chosen to create a protective environment due to the lack of chemical interaction with metal and other gases. Since argon is heavier than air, it displaces atmospheric oxygen and hydrogen from the weld formation zone, which eliminates the appearance of pores and cracks in the metal, and also prevents the formation of a layer of oxide film.

Welding technology boils down to the formation of an arc between a tungsten electrode and the surface. Gas enters the welding zone through a special torch nozzle. Unlike welding with a consumable electrode, here the additive is excluded from the electrical circuit, and is supplied to the bath area separately in the form of a rod. Manual welding differs from automatic welding in that in the first case the welder himself holds the torch and adds the additive, and in the second the process is automated. The technology also differs in the method of arc formation.

For a number of reasons, the arc cannot be formed by simply touching the electrode, so the installation provides for parallel operation of the oscillator. It is necessary to understand that welding can be carried out with both direct and alternating current. According to the method of connecting the electrode, direct and reverse polarity are distinguished. Before carrying out preparatory work, it is necessary to select the necessary parameters for each specific metal.

The main issues were discussed above, since many parameters are subject to standardization. GOST for argon arc welding is not limited to just one document. Standards have been determined for burners, processing and size of seams, working with aluminum, for filler wire, for equipment and electrodes. But, before presenting a list of these documents, let’s look at the issue of standardization.

Argon arc welding. Technology and equipment

Today, not a single construction site or production where it is necessary to connect metal parts can be done without such an operation as welding. This type of connection is considered one of the fastest and quite high-quality. There are several types of welding, but in this article we will talk specifically about argon arc welding. What is remarkable about it, its pros and cons, all this will be discussed below.

Technology

Argon arc welding is essentially the same as electric arc welding, but it uses an inert gas - argon, which is supplied to the place where the electric arc burns.

Argon arc welding has two international designations: TIG (welding with non-consumable tungsten electrodes in an argon gas environment) and MIG/MAG (welding with an electrode wire in an argon or carbon dioxide environment).

Thus, a gas environment is created in which the metal melts. Due to the fact that argon does not interact with the metal, it does not change its chemical composition and this is a big plus. The fact that this gas is 1/3 heavier than air helps to displace the latter from the arc environment and isolate the molten metal from the effects of the atmosphere.

This protects the weld from the formation of an oxide film and generally improves the quality of the metal connection. There are cases when oxygen is added to argon in an amount of 4%.

This is due to the fact that when the edges of the metal burn inside a gaseous environment, argon does not completely protect the seam from various types of contaminants and moisture. And oxygen burns these harmful impurities, eliminating the formation of porosity in the seam.

But this is done mainly where very high quality welding joints are required. Usually one argon is sufficient.

Principle of operation

Equipment for argon welding consists of: a welding machine - which includes an inverter converter for generating an electric arc, an oscillator, a torch, an argon cylinder, gas hoses and welding cables.

Argon arc welding (tig) with a non-consumable electrode

Before starting work, the device is turned on and argon is supplied. To form an electric arc, the welder brings the tungsten (when welding with a non-consumable electrode) electrode a short distance to the workpiece. There is one important nuance at this stage. An arc cannot be formed when the electrode is directly connected to the workpiece, as with electric welding.

This is due to the fact that high ionization is required to create an arc in an argon environment. And since the tungsten electrode is refractory (melting point about 5000 °C) and practically does not burn, there is no formation of gases that promote ionization and ignition of the arc. Therefore, in such cases, an oscillator is used.

An oscillator is a device, usually installed in a TIG welding machine, that starts the electric arc in the case of a non-consumable electrode.

This happens as follows: by bringing a torch with a tungsten electrode a short distance to the part, the oscillator delivers a high-voltage, high-frequency pulse to the electrode, which electrically penetrates the distance to the part, forming ionization in a gaseous environment. Thanks to this, the arc is ignited and continues to burn.

When using direct current welding, a straight polarity connection is used. That is, “plus” is applied to the body of the product, and “minus” to the electrode. This is done because with such a connection, up to 70% of the heat is released on the part, that is, the “plus”, and only 30% on the electrode, the “minus”. As a result, the metal of the part melts, and the electrode is less susceptible to combustion.

The exception is aluminum welding. In this case, the best results are obtained by welding with alternating current, since this destroys the formation of the oxide film. As for the oscillator, when using alternating current, after ignition of the arc, it goes into stabilization mode, delivering breakdown pulses every time the polarity changes.

This ensures stable combustion of the electric arc.

Due to the fact that the tungsten electrode does not melt, to form a weld, a filler material is added to the place where the arc burns, which the welder holds with his left hand and, if necessary, applies.

Under the influence of temperature, a bath of molten metal is formed in the parts being joined. Since the burner has an inlet for connecting a gas hose, argon passes through a special cavity to the gas nozzle and escapes between it and the tungsten electrode. Thus, as if “enveloping” the electrode and the cooking bath.

In addition to the gas cavity, the burner also has inlet and outlet pipes for supplying cold liquid and removing heated liquid. This is necessary to cool the burner nozzle due to severe overheating.

TIG welding with consumable electrode

In this case, the role of the electrode is played by a metal rod coated with rutile. When the electrode directly touches the part, a short circuit occurs (as in conventional electric arc welding), as a result of which vapors of molten metal are formed, which give ionization in an argon gas environment.

The arc is ignited thanks to these vapors, so the use of an oscillator in this case is not necessary. The filler wire is fed manually or by a special automated mechanism, in the form of a drum with wire, rollers and an electric motor with a gearbox.

Typically this type of equipment is located at a specialized welding station.

Application area

Argon arc welding (tig and mig/mag) is successfully used when joining non-ferrous metals, alloy steels and aluminum. It is also good for welding aluminum and titanium alloys. For example, alloy wheels and other car components. If the thickness of the surfaces to be welded is small, argon welding can be carried out without additional additives.

Argon welding with a melting electrode is used to join stainless steel and aluminum.

Advantages of argon arc welding

The main advantages of argon arc welding are:

1) high quality of the resulting seam;

2) uniform penetration of the metal depth;

3) indispensable when welding products made of thin sheet aluminum;

4) wide scope of application, ranging from auto repair shops to aircraft manufacturing;

5) does not require frequent replacement of the electrode, which does not create defects when stopping and resuming work.

Disadvantages of argon welding

1) with manual welding - low productivity;

2) for high-quality welding, high qualifications and sufficient practice are required;

3) automatic option - not always convenient, as it is used for single-profile long seams. When welding short and differently oriented joints, it is not practical;

From what was discussed above, it is clear that this type of welding is much more effective and versatile than conventional electric arc welding. It is clear that for home purposes this can be an expensive pleasure, but when using this technology in business, the equipment will more than pay for itself in a minimum period of time.

Specifications and standards

Some types of work, goods and services are controlled by the state in terms of quality. The reason for such control was the inter-industry significance. State standards (GOST) contain a list of requirements for each product, for each result of activity that is subject to standardization. This is a document based on international standards and taking into account best practices, as well as all the achievements of science and technology. Standardization was introduced during the existence of the USSR. Standards cannot be static, so they change over time.

GOSTs in Russia are mandatory only for defense products, but in construction they are of great practical importance, because the main design indicators are safety and reliability. Some people confuse the state standard with technical specifications. In fact, specifications regulate the production of those goods that are not subject to standardization according to GOST. We can say that technical specifications are the result of the development of entrepreneurs who are producers. Although the TU is not a guest document, they do not contradict the state document, but, on the contrary, complement it.

In some sources, upon request, you can find only one document. However, it does not fully reflect all the standards relating to argon arc welding, its preparation and implementation. The list of all regulatory documents contains GOSTs adopted at different times. To date, there are 9 documents.

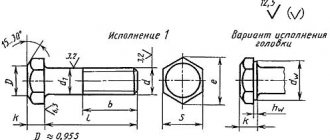

- GOST 5.917-71 defines the requirements for hand-held burners RGA-150 and RGA-400.

- GOST 14806-80 contains information on the parameters of argon arc welding of alloys containing aluminum.

- GOST 14771-76 is similar in structure to the previous document. Only here we are talking about gas-shielded arc welding as a generalized process.

- GOST 7871-75 defines the parameters of aluminum welding wire for TIG welding.

- GOST 2246-70 is a document that specifies the requirements for steel wire.

- GOST 23949-80 is a standard applied to tungsten electrodes for argon arc welding.

- GOST 18130-79 and GOST 13821-77 regulate the operation of equipment, including semi-automatic devices and rectifiers.

- GOST 10157-79 defines the standard for the most inert gas (argon).

Manual argon arc welding with non-consumable electrode

Welding in shielding gases has always been considered the highest quality. There are several technologies, of which manual argon arc welding with a non-consumable electrode stands out. Firstly, it is manual, which makes it possible to use it in non-industrial conditions. Secondly, the simplicity of the process makes it possible for non-specialists to use it.

After all, its technology is based on the process of heating the metal with an electrode, melting it and feeding filler material into the weld pool, with which the bath is filled. In this case, argon acts as a protection against chemical elements in the air that negatively affect the welding seam, thereby reducing the quality of the joint of the workpieces being joined.

Non-consumable electrodes for arc welding

This argon welding element has two types: carbon and tungsten. The first is rarely used; it is usually used to cook irresponsible structures. The second is used today everywhere and often. After all, tungsten is a refractory metal with very low thermal conductivity and evaporation. It interacts very actively with oxygen, so when welding, the tungsten rod must be protected, for which a protective gas mixture is used.

The diameter of the non-consumable electrodes used is 0.5-10 mm. In this case, the composition of the rod can be made of pure tungsten or with impurities of lanthanum, thorium or yttrium. Alloys have better characteristics, especially with regard to the erosive resistance of the metal, plus such electrodes can withstand current load well. The choice of rod diameter depends on the welding current used and the thickness of the metal workpieces being welded.

Typically, the welding process with a non-consumable electrode is carried out using direct current of straight polarity. It is this mode that allows maximum melting of the metal of the parts being connected. By the way, in this mode, almost 85% of the thermal energy is spent on melting the workpieces, and only 7% on heating the non-consumable electrode. The remaining percentages are radiation losses due to the radiation of the electric arc. Welding of aluminum with a non-consumable electrode is carried out with reverse polarity. In this mode, heat loss is almost 50%, so this mode is unacceptable when welding steel workpieces.

Welding with a non-consumable electrode can also be carried out with alternating current. To do this, the equipment will have to be equipped with a stabilizer, which will stabilize the electric arc, and a current compensator.

Equipment

Depending on the volume of welding work that will be performed and what structures will be assembled, two types of equipment can be used: universal or special. The first class of devices is most often used, because the second is intended for large volumes and most often mechanized. Universal manual and automated welding units are easy to use and maintain, so they are used in both small workshops and large industries.

The apparatus for arc welding with a non-consumable electrode in shielding gases consists of:

- a source of direct or alternating current (there are devices that produce both currents);

- burners of different sizes, designed for different current values;

- oscillator for igniting the primary arc;

- devices for argon gas supply;

- welding process controls.

In order for the workpieces to be welded to effectively melt under the action of a non-consumable electrode and argon, it is necessary to strictly observe some features of argon arc welding. This is how you can achieve maximum quality of the final result.

- The non-consumable tungsten rod should penetrate as deeply as possible into the gap between the workpieces. The welding arc should be as short as possible. In this way, melting can be carried out deeper, which will affect the size of the weld. It will be smaller and the quality will be higher.

- The movement of the electrode must be carried out strictly in the center of the gap, and in the middle. Deviations reduce the quality of the seam and its appearance.

- The filler wire should not extend beyond the welded area and should always be in the argon zone. This is how the bath is protected from the negative effects of oxygen and nitrogen in the air. Their impact will lead to increased brittleness of the weld. The same requirements apply to the infusible electrode.

- Do not suddenly apply the additive into the welded zone. This will lead to a lot of metal spattering and waste.

- Wire feeding during manual welding should be done at an angle. No lateral deviations.

- At the end of welding, it is impossible to cut off the seam by removing the electrode from the welding zone. You just need to extinguish the arc using a rheostat.

- It is possible to supply shielding gas and turn it off after welding is completed only after 10 seconds. In this way, the still uncooled melting metal is protected, which, upon contact with air, will immediately become covered with an oxide film.

- Before starting welding work, it is imperative to prepare the metal workpieces to be joined. This applies to steel, aluminum and other metals. It is necessary to clean the joining surfaces from dirt, rust and other materials using an iron brush or an angle grinder with a metal brush attachment. It must be cleaned to a metallic shine. If there is a need (greasy and oil stains), then the surfaces to be joined will have to be degreased with a solvent or alcohol.

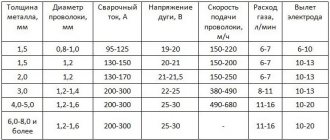

- The welding modes must be compared with the thickness of the workpieces being joined, taking into account the diameter of the non-consumable electrode.

Pros and cons of argon arc welding

As for the advantages of welding with a non-consumable electrode in shielding gases, this technology is the best option if thin parts are connected together, as well as workpieces made of non-ferrous metals (aluminum, copper, and so on). Welding also performed excellently when joining alloyed materials.

Here you can also add an almost jewel-like weld, if you correctly deepen the infusible electrode and additive into the bath. Very thin workpieces can be welded without filler wire. Increasingly, argon arc welding is used to connect pipes, which is called orbital welding.

If we talk about the disadvantages of manual argon welding, it is its low productivity. It is possible to mechanize the process, thereby increasing the welding speed. But in this mode it will be almost impossible to connect differently oriented and short joints.

5.917-71

This document was published on May 13, 1971 in accordance with the decree of the State Committee of Standards of the USSR. The given limits apply only to burners of the RGA-150 and RGA-400 types. They are used in argon arc welding with a tungsten electrode of aluminum, its alloys and stainless steel. Products that comply with GOST received a quality mark.

Expert opinion

Bagrov Viktor Sergeevich

Welder of the highest 6th category. He is considered a master of his craft, knows the intricacies and nuances of the profession.

Today, manufacturers of welding inverters operating in TIG mode do not adhere to these standards, however, thanks to modern technologies, the quality of the devices remains high.

14806-80 and 14771-76

Standardization of direct welding technology for aluminum and aluminum products is reflected in the corresponding regulatory document. This includes connections of parts with edge thicknesses from 0.8 to 60 mm. Pipeline welding has slightly different requirements, so this standard does not apply to them.

GOST 14771-76, as stated earlier, has the same structure. The only difference is that the first document is defined specifically for aluminum-containing materials, and the second - for steels and alloys based on nickel and iron-nickel.

GOST 14771-76 – semi-automatic welding, work technique

During work, shielding gas displaces air from the place where the connecting work is performed. Using special rollers, the wire is fed to the junction of the parts. The rollers are rotated by a special motor, which is located in the inside of the welding machine. Since the melting of the wire occurs under the influence of current, it must be delivered to the welding site.

This happens using a special bent contact. Gas is supplied to the site from a cylinder. Feed rate and dosage are performed automatically. In addition, in some cases, gas supply and adjustment can be done manually.

The molten metal of the electrode and wire is fed to the junction through a nozzle. The liquid substance is supplied in the form of drops and steam.

7871-75 and 2246-70

The introduced GOST concerns wire made of aluminum or alloys. Manufacturers use it, since the document regulates the possible values of wire diameter. Among all other requirements, standards for the chemical composition of consumables have been determined.

There are several types of wire, differing from each other in the quantitative content of elements (magnesium, manganese, aluminum, iron, silicon, titanium, beryllium, zirconium). Most popular brands:

- SvA99;

- SvA97;

- SvA85T;

- SvA5;

- SvAMts;

- SwAMg3;

- SvAK5.

The presence of impurities is allowed. The manufactured wire is tested, including for strength. The table shows the values of the maximum loads at which rupture occurs. Acceptance of materials is carried out in batches. One batch must contain wire with the same parameters. The appendix to the document specifies the conditions for storing and transporting the wire. Since it is supplied in coils, the dimensions of the coils are also subject to normalization.

Steel wire must meet the requirements of GOST 2246-70. Popular types:

- Sv-08;

- Sv-08A;

- Sv-10GA;

- Sv-08GSMT.

This is not a complete list of wire brands. They are divided not only by characteristics, but also by applicability. There are materials for the manufacture of electrodes, wires for welding copper-plated surfaces, and wires for surfacing.

Semi-automatic welding technologies

Butt. This is a continuous spot weld.

Overlapping. In this case, a small piece of metal is placed on the seam and scalded in two ways. These are: continuous seam or spot welding.

Welding on prepared holes.

Thus, the reinforcement can be welded using a semi-automatic welding machine. In this case, it is necessary to take into account the peculiarities of the production of the work. The welding process is influenced by the materials used. First of all, it is gas. For each type of welding work, it is necessary to use a certain type of gas, which is supplied to the place where the parts are connected.

During the entire process, gas and electricity interact. This forces the welder to pay special attention to the safety system.

Welding GOST 14771-76 is the main quality standard for this type of welding work. GOST includes a list of various gases, materials and work techniques. If all technical characteristics meet established standards, then the work will be performed at the proper level.

More on this topic on our website:

- Designation of a weld seam on a drawing according to GOST - welding drawings There are legally established GOST standards, which spell out all the designations for weld seams. Knowing all the features and recording the designations will allow you to quickly and efficiently complete all the work on…

- Diagram of a DC welding machine for assembly A homemade welding machine can be perfect for performing everyday tasks of average complexity. Naturally, it is difficult to compare it with a full-fledged welding inverter, but small homework is so...

- Semi-automatic welding – operating principle, semi-automatic welding technology, welding modes There are several types of welding machines. In order to choose a suitable device, you need to know the principle of its operation. The welding machine helps to obtain a high-quality and even seam. Modes…

- What is a welding log - an example filled out by a welder This type of log refers to technical documentation. This document reflects the full scope of all work performed by the welder. In addition, the quality and time of completion of the task are reflected here...

Share a link to this material with your friends on social networks (click on the icons):

18130-79 and 13821-77

Currently, GOST standards adopted back in 1977 remain relevant. They prescribe the functional features of welding equipment, in particular, semi-automatic machines for argon arc welding. The list of requirements includes such as functionality, resistance to external factors, welding current values, availability of measuring and control instruments.

Such a variety of requirements does not allow us to formulate all the standards in one document, therefore this GOST refers to a number of minor regulatory documents. Thus, standardization of the argon arc welding process has a comprehensive approach. The total number of major and minor standards amounts to several dozen approved and adopted documents that are still in force at the present time, with the exception of some minor changes.