During the construction of any building, in the process of installing utilities, special wells are most often designed. Such designs make it possible to quickly and easily maintain systems as needed, and also ensure the safety of their operation and reduce the risk of emergency situations. When designing such systems today, polymer hatches for manholes are most often used, which are a relatively new development, but immediately became in demand due to a number of advantages.

Functions and purpose

Its main task is to protect against the entry of debris, dirt, foreign objects, drains and other contaminants into the collector. Otherwise, the sewer system will quickly become clogged and will not perform its main function. Among other things, its presence allows for scheduled maintenance of the utility network or to eliminate the problem in the event of a blockage.

According to their purpose they are divided into:

- Lightweight , with a permissible load of up to 3 tons. Mainly for pedestrian areas.

- Heavy , with a permissible pressure of up to 20 tons. Used for highways.

- Super heavy , with a maximum pressure of up to 60 tons. Scope of application: airfields.

Why are polymer hatches better than cast iron ones, and why are polymer sand wells better than reinforced concrete ones?

Odes to this material are often sung. Products made from it are increasingly being seen, much more often than its name – polymer-sand composite. Of course, this product of modern technology turned out to be in demand from different sides. Firstly, it is used as a material for construction (sidings, paving slabs, roofing tiles, bricks, etc.). And secondly, and no less important, it solves the problem of recycling plastic waste, which is becoming more and more every day. As a building material, it was taken for use in sewers. First of all, these are polymer sand tanks and polymer manhole covers.

Kinds

The lid is made of different materials:

- Cast iron.

- Polymer (combined).

- Plastic.

- Concrete.

Cast iron

This is a classic solution when arranging a sewer system.

The cast iron lid has a large mass. Because of this, difficulties arise during installation, as well as during their maintenance. However, their excellent performance characteristics completely cover their disadvantages. On average, it will last up to 100 years with a maximum load of up to 100 tons. It is characterized by its low price and is used in the construction of highways and areas where the movement of lifting equipment is expected.

Polymer

Well sewer manhole, also known as polymer sand manhole.

In its production, a composite material from polymer and sand raw materials is used.

Mainly used in the construction of underground communications:

- Heating network.

- Telephone networks.

- Gas pipelines.

- Cable networks.

Due to its light weight, the polymer-sand cover is convenient to transport, install and lift when servicing certain communications. The material used copes well with thermal, acid-chemical and atmospheric loads.

Plastic

They have minimal weight.

Due to this, it is easy to work with during installation. Mainly used for gardening or landscaping local areas. May be green or some other color.

Due to this, it will not be conspicuous, but will be successfully camouflaged. The PVC cover has a low cost compared to analogues. At the same time, the plastic hatch can cope with a load of up to 1.5 tons. Also allowed for installation in stadiums, squares and parks.

What does installation work involve?

If you need to install a well on a house plot, then the choice of cover depends on the financial capabilities of the owners. Since there will not be a lot of stress on it, there is simply no need to make it thick. The cost depends on the thickness. If it is a cast iron structure, then it can easily be purchased for two thousand or a little more. The price of sewer manholes made of polymer materials is even cheaper.

There will not be much difficulty in installing the product. The manhole cover is simply placed on the created support rings. They are made of concrete to be reliable and durable. In addition, an important task is to prevent water from getting inside, which means that a slight elevation is created above the lawn. There is an important point: the structure must not be allowed to fall below the required level.

Forms

Manhole hatches can take various forms:

- Square.

- Round.

- Rectangular.

The most common ones are round. The reason is that a large number of mines have this shape. The diameter of the hatch is selected individually, although there are standards. As a rule, the guideline is based on GOST 3634 99. This standard provides for a standard diameter, as well as weight and other characteristics.

The shape of a square and a rectangle is a rare occurrence. Although the specified GOSTs mention a hatch of this shape. It can be used when arranging a personal garden. This shape may be the most convenient for lowering into a well shaft. If a rectangular product is used, one of the sides may have a minimum edge of 300 mm and a maximum width of 800 mm.

Rules for choosing sewer manholes

Round or square

Manufacturers of manholes for sewer wells produce several types of manholes. Different types of sewer manholes may have:

- round shape;

- square shape;

- rectangular shape.

Round sewer manholes are considered the most common. The main advantages of this form are:

- minimal consumption of materials for manufacturing, which is reflected in the price of the product;

- complete absence of the possibility of deformation and failure of the product;

- better load distribution.

An example of using a round hatch

Square manhole covers, as well as rectangular-shaped products, are installed in places where a specific design is required, such as a tiled sidewalk path.

Example of using a square hatch

There is no difference in the shape of the installed hatch. The choice of form is based solely on consumer preferences.

How to choose a product

When choosing a hatch, experts recommend paying attention to the following factors:

- dimensions of the sewer hatch. The internal diameter of the sewer hatch must correspond to the outer diameter of the well. The gap between the cover and the body of a quality product should not be more than 3mm;

- hatch weight. The lighter the product, the easier it will be to install it yourself. However, lightweight hatches are not always able to withstand the required load. Thus, you cannot rely only on the weight of the sewer hatch. This indicator should be considered in comparison with the load withstand;

- the hatch must be cast without visible defects or large cracks. A quality product allows for potholes with a diameter of no more than 10mm and a depth of no more than 3mm.

Each storm drain or sewer manhole must be accompanied by a product passport, which contains information about:

- date of technical control;

- release date;

- warranty period.

The simplest rules listed will help you choose not only the right size product, but also one of sufficient quality.

Specifications

| Marking |

|

| Dimensions | There are no restrictions. Dimensions may vary depending on the application. However, there are restrictions on the minimum and maximum diameter from 300 to 800 mm |

| Weight |

|

| Load |

|

With lock

Considering the theft of hatches, it is necessary to take care of their safety.

Therefore, it is quite logical to install a lock on it. Plus, it allows you to organize protection for the inspection well.

Advice! If its installation is carried out in a fenced local area, then a lock is not needed. If it is outside the fence, then it must be present.

To install the lock, you need to make a reliable frame. For sewer covers there are the following types:

- Spacer devices.

- Threaded connections.

- Flag.

DIY installation

Installation instructions for a polymer-composite, cast-iron and plastic hatch.

Tools

The following tool is required:

- Concrete mixer.

- Shovel.

- Master OK.

- Container for mixing the solution.

- Lifting equipment in case of installation of a heavy hatch.

Polymeric

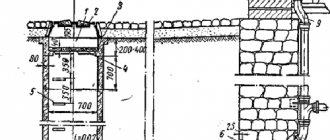

- The first step is to install the hatch ring. To do this, you need a reliable foundation, for example, reinforced concrete or concrete. This overlap must be durable and of high quality.

- A correctly mounted support ring (OK) will allow the entire intended load to be evenly distributed. As a result, the possibility of destruction is completely eliminated.

- To fix the OK, a concrete solution is used.

- After installing the ring, you need to wait until the concrete is completely dry.

- After this, the OK covers are mounted. At the same time, it is not recommended to lay the polymer hatch itself directly on a concrete slab. It is also unacceptable to use lining elements, such as bricks and mortar.

- During the installation process, it is necessary to ensure that the laid hatch does not protrude from the ground, but is at the same level.

- For fixation, a blind area is constructed. It should have a slope in one direction to remove moisture and precipitation.

- To prevent the corrosion process, it is recommended to lubricate the upper working part with lithol.

Important! Do not use support rings made of low-quality material.

Cast iron

- First, install OK. It is important that it perfectly coincides with the opening of the sewer shaft.

- OK is filled with concrete on all sides.

- The installation of the casing must be carried out accurately so that it does not wobble from side to side, and the cover installed later is flush with the ground or asphalt.

- After pouring the concrete, immediately put the hatch in its place. While the concrete is drying, moving the lid or lifting it is unacceptable.

Plastic

- Mounted OK. It must have technological holes, thanks to which it is possible to perform fixation using anchors.

- OK (support ring) is filled with concrete.

- The ring fits the cover into the corresponding grooves.

- It is extremely important that it is level with the ground. Although in some cases the hatch may protrude slightly from the ground level.

- If there are certain irregularities, then formwork is installed at a distance of 400 mm on each side.

- OK is secured with anchors.

- The formwork is poured with concrete and is expected to dry completely.

Advantages of polymer products

The well hatch must ensure the safety of engineering systems, preventing them from being affected by precipitation and other external factors. On the other hand, it must prevent injuries to pedestrians and animals and ensure the safe movement of vehicles. To do this, it must be durable, withstand severe mechanical loads and environmental influences.

Open well

Therefore, until recently, hatches were made from materials such as cast iron and reinforced concrete, which fully met the specified requirements. But the advent of modern polymer materials has made it possible to replace them with more practical and convenient plastic hatches for wells .

What are their advantages?

- First of all, this is a much lower weight of the product compared to cast iron counterparts. A plastic hatch of the same size and volume as a cast iron hatch weighs 4-6 times less. And this ensures simplicity not only of its installation, but also of transportation.

- In the production of polymer products, components are used that are not subject to corrosion and are resistant to the influence of aggressive substances - reagents used for treating roads, gasoline, motor oils, etc.

- Long service life. The well cover will last at least half a century without requiring repair or replacement.

- High degree of interchangeability. A new polymer hatch can be installed not only in place of the same lost one, but also in a ring designed for a cast iron cover.

For reference. To prevent theft, deliberate damage to the hatch or unauthorized access to equipment located in the well, it is recommended to install products with a special lock.

Hatch with lock

- Possibility of installation and operation in any climatic conditions from the Far North to the southern regions of the country - the polymer material from which the hatches are made is intended for use in the temperature range from -50 to +70 degrees Celsius.

- Operational safety. Plastic components do not contain toxic or carcinogenic substances hazardous to human or animal health.

Note. When opening or closing a heavy metal hatch, there is a high risk of accidental sparking. This can lead to an explosion of gases, which often accumulate in deep underground wells. With plastic covers for wells there is no need to worry about this.

- Plastic is not a material that might interest those who want to make money at someone else’s expense. A hatch made from it, unlike a cast iron one, cannot be sold for scrap metal and received money for it. Therefore, even products not equipped with locks are usually not stolen.

- Low price is another advantage of this material. Moreover, you will need to pay less for the products themselves, for installation, and for their transportation. And one or two hatches can be delivered to the site yourself, using a personal vehicle or simply putting it in a large bag.

- Wide range and high decorative characteristics. The range of color solutions for plastic hatches is so wide that it allows you to match them to any surface - green lawn grass, gray asphalt, colored paving slabs or paving stones.

The cover on the well can be chosen in the desired color

- At the same time, colored plastic is produced using heat-resistant pigments that do not fade under the influence of ultraviolet rays. Therefore, products, which are mostly installed in open areas, do not lose their original color brightness throughout their entire service life.

- A large selection of sizes - from inspection hatches with a diameter of 315 mm to large ones with a diameter of 1000 mm or more, allowing you to go down into the well shaft.

Note. If you want to make the hatch not only less noticeable, but also not visible at all and not spoil the impression of the landscape design of the area, you can install a decorative cover in the form of a stone or a special box for organizing a flower bed with fresh flowers.

Decorative cover-boulder