Wells and wells are the main sources for water intake in individual households; in the vast majority of domestic wells, unlike concrete wells, plastic products are used to construct a water intake channel. But technological progress has not left well sources aside, and increasingly a plastic well is used to lift water from shallow depths.

The construction market offers a wide range of plastic prefabricated wells and pipes that can be effectively installed in shallow water sources. To verify the advantage of constructing a water intake unit from synthetic plastic materials, you should consider existing types of products, their technical and physical parameters, and compare the cost of purchase and work.

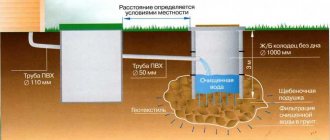

Fig.1 Well water supply for a private house

Plastic rings for wells: types and characteristics

New technologies in human life can only be considered successful when they have more efficient, energy-saving and environmentally friendly qualities than previous ones. Today, plastic sewer wells have practically proven their right to exist. They are replacing heavy reinforced concrete structures, the installation of which is labor-intensive and very expensive. The products simplified the process of arranging wells, and made operation reliable and affordable.

Purchasing containers for sewerage is an important condition when arranging a summer cottage.

In this article we will look in detail at what a plastic sewer well , what types of plastic rings and storage tanks there are, their features and main varieties, technical parameters, including dimensions. The text contains all the necessary information that allows you to get a brief overview of the existing product range on the market, prices for products and the rules for their selection, as well as further maintenance after installation.

The well made of polymer rings is a seamless structure with a maximum level of tightness.

Advantages and disadvantages

As mentioned above, plastic sewer wells are rapidly replacing their concrete counterparts. This is due to the large number of advantages that they have. Here are just some of the advantages:

- high strength characteristics;

- resistance of the tray part to wear;

- the smooth surface inside and outside ensures high tightness of the insertion of pipes;

- tightness of connections made in the factory;

- its low weight allows it to be installed without the use of special equipment and tools;

- service life of at least 40 years;

- resistance to temperature changes;

- minimum maintenance.

Of course, it is not without its drawbacks. The main disadvantages include:

- height limitation to 15 m;

- risk of tank deformation;

- quite high cost.

General information about storage tanks for sewerage

Construction of a house in a country village or on a summer cottage is accompanied by additional costs for the installation of water supply and sewerage, since there are no centralized systems in such an area. The easiest way in this case is to buy a sewer barrel or another type of storage structure where all wastewater will be discharged.

Plastic sewage containers are completely sealed and durable.

Such containers are environmentally friendly and completely sealed, but they do require regular maintenance, which includes cleaning the tank from sediment. Installing an internal sewer system in a private house is no different from installing a similar system in an apartment in a multi-story building. The only thing the owner of a suburban area will have to think about is the process of waste disposal.

Most often, the storage tank is a cylindrical tank. It is equipped with a pipe designed to collect liquid and a well, which is used for wastewater treatment. The supply pipe leading out of the house at an angle is connected to the pipe. When the tank is filled, it is cleaned through the well neck.

Note! To save money and avoid excavation work, you can install a storage structure on the surface. But in this case, the appearance of the site will be spoiled, so for aesthetic reasons it is better to hide the septic tank underground.

Sewage tanks are best installed underground.

Plastic sewer well: variety of types and scope of their application

Polymer rings for plastic sewer manholes have firmly and reliably entered various spheres of human life. The wells assembled from them provide production and consumer needs. Based on the characteristics of their intended purpose, wells can be divided into the following types:

- classical. It is a source of drinking water. Traditionally, water is supplied using a pump or pumping station;

Types and design of a drainage well.

- sewer well. Installed in the absence of sewerage. Kinetes are installed at the bottom, through which wastewater flows into the soil;

- drainage (absorption). This is a type of sewer well, only without the chute. A layer of gravel or sand is poured onto the bottom;

- cumulative. Serves to collect water, often rain, which can be used for irrigation or other needs;

- telecommunications. Designed for placing couplings and laying stock of fiber-optic and energy cables. Installed in both pedestrian and transport areas;

- viewing room Designed for monitoring and repair of sewer systems. Stairs, handrails and other devices are installed in it, allowing you to descend to perform repair and maintenance work;

- septic tank A special treatment facility where wastewater is processed in a settling tank. The underground filtration system produces decomposition without oxygen.

Note! To quickly and correctly select the desired option for a plastic well, it is better to use a ready-made configuration.

Types of sewer wells

According to their purpose, polymer sewer wells are divided into three types: inspection, absorption and water intake.

Viewing models with kinets

Inspection models are mounted on potentially dangerous sections of the pipeline. Their main purpose is to provide access for monitoring the condition of the system, placement of special equipment and the need for maintenance of the structure. Not a single sewer pipeline can do without them.

They must be installed in the following places:

- turning the highway;

- branch connections;

- changing the slope and diameter of pipes.

One inspection well can combine up to three or four traffic flows.

The main element of the inspection well is a small shaft, the upper part of which is equipped with a hatch, and the bottom is equipped with a tray part with special grooves (+)

When installing a sewer system, plastic inspection wells are placed at a distance from each other, regulated by regulatory documentation. The larger the diameters of the installed hydraulic structures, the greater the normatively permissible distance between them.

Additional information on different types of sewer inspection wells is presented in this article.

Absorption drainage structures

Structures of this type are installed where it is not possible to easily drain wastewater. They are cylindrical plastic shafts two meters deep and one and a half meters in diameter.

Unlike inspection wells, absorption-type models do not require the installation of showers. Instead, the bottom of the tanks is equipped with a mesh or lined with materials that have a drainage effect: gravel, crushed stone or crushed brick.

The same material is also used as coating for the outer walls of the well.

Wastewater, entering the absorption tank, is filtered through a drainage layer lined at the bottom and, in a purified form, gradually seeps into the ground

The minimum height for inserting drainage pipes into the walls of a plastic well is 40 cm. Thanks to this solution, the bottom of the tank, in addition to its main task, acts as a sand trap, which catches settling sand particles and other inclusions present in the water.

You can build a simple drainage well with your own hands, for more details, see the article - How to make a drainage well with your own hands and connect pipes to it

Water receiving storage tanks

The main function of water intake wells is to accumulate wastewater until it is pumped out, removed and transferred to treatment facilities. The “final destination” option depends on the degree of water contamination.

Since storage tanks are designed to hold tons of liquid, they are quite impressive in size.

The dimensional parameters of the plastic structure are determined by the daily productivity of the sewer system and the volume of incoming water

Water receiving plastic tanks have completely sealed walls and bottom. One of the prerequisites for installing water intake wells is that the lid is sealed.

This is necessary in order to prevent sewer overflow after heavy rainfall.

Plastic sewer well: features of the polymers used

Rings for wells (sewage, switching, drinking water and septic tanks) are usually called in one word - “plastic”. Since wells made from this material are used for various industrial purposes, in everyday life, to create drainage systems, since they function in different soils and under different mechanical and thermal influences, they are made from different polymers.

For the manufacture of plastic well rings use:

- polyvinyl chloride;

- polyethylene;

- polypropylene;

- polymer-sand mixture.

Despite the overall high performance indicators, the materials still differ in a number of features. Wells made of polyvinyl chloride are fire-resistant. This material is resistant to various chemical influences. Polyethylene products withstand temperature changes best; freezing and thawing water does not deform the rings.

Polypropylene is used for installation in places where there is constant mechanical or vibration impact on the structure. The material is plastic and most wear-resistant. The polymer-sand well is characterized by almost absolute tightness.

The complete tightness that polyvinyl chloride rings have prevents waste from seeping into the ground.

Note! When choosing rings for a plastic well, be sure to pay attention to the material of manufacture and compare its qualities with the conditions of use and purpose of the well.

For a drinking well, in the absence of problematic soil, you can buy polyethylene rings. They are inexpensive and quite suitable in terms of functional features. If the soil is unfavorable, you should buy a polymer sand well.

For a commutation well that is subject to constant mechanical stress (for example, when a car drives in, drives out, or is parked), it is better to purchase polyvinyl chloride rings. Their price is the highest, but only this material can withstand constant loads without consequences.

You can buy inexpensive rings for a septic tank, made of polyethylene. The accumulation of gases does not deform or negatively affect the condition of this polymer. The costs of purchasing more wear-resistant material are unnecessary.

Well rings made of polymer-sand composite.

The constantly growing demand is ensured by the choice of offers. Today, plastic rings for wells can be purchased at any store that sells plumbing equipment and plastic products. Selecting a pipe from the desired material is not difficult.

Restrictions

Plastic wells cannot be installed everywhere. For example, in earthquake-prone areas with points above 7, it is better not to use plastic. The same applies to areas in the North with permafrost and air temperatures below -50 degrees.

If the well is old

When the need arises to revive wells or buildings that are unsuitable for drinking for technical needs, then large-diameter pipes made of polymer parts will help to cope with the task.

Most of all, buildings made of wood, brick, and concrete need restoration, which, under the influence of the temporary factor, are destroyed, covered with mold, and rot. Concrete structures in the connecting parts of the segments shift and leak. In addition, silt often appears at the bottom, and the water loses its suitability.

Thanks to polypropylene and polyethylene rings of a different diameter towards reduction, it is possible to sanitize and deepen the well, thus returning life to it.

The working process is as follows:

The water needs to be pumped out.- The bottom filter, consisting of crushed stone or stones, must be removed down to the sand.

- Rings with a diameter of 850-950 mm are connected using waterproof sealant.

- A plastic shaft is lowered into an old shaft.

- The excess space should be filled with a mixture of sand and gravel, not forgetting about compaction.

- A filter layer is formed at the bottom.

With this method of resuscitating an old well, you can significantly save not only labor costs, but also money costs.

Well size

The height of well rings can vary from 50 to 150 cm. The higher the indicator, the more weight the structure has. This becomes the main reason for choosing plastic rings with a minimum height, which of course allows for installation alone.

It is recommended to buy small structures so as not to overpay and look for the so-called “golden mean”, especially for the country.

One of the important parameters is the diameter of the ring. A pipe is considered large if its diameter exceeds 50 mm. The standard diameters of the ECOSIS-850/95 model are 800 and 850 mm on the inner and outer sides, respectively. ECOSIS-950 has 900 and 950 mm, ECOSIS 730 has 690 and 730 mm. The cross-sectional size is almost always 25 mm.

There are also differences in rigidity:

- SN2 is suitable for depths up to 2 m and diameters 600/900/1500 mm;

- SN4 – from 2 to 4 m with diameters of 680/970/1600 mm;

- SN6 – 4-6 m and 700/1000/1800 mm;

- SN8 – 6-8 m, diameter same as SN6;

- SN12 – 8-12 m, with a diameter of 800/1200/2200 mm;

- SN14 – 12-16 m, 850/1300/2400 mm.

It is important to correctly calculate the size of the well, which should not be adjacent to the rings. The minimum width margin is 50 mm, which is subsequently filled in.

Plastic sewer well: plastic rings, sizes and connection methods

Well ring sizes vary. The main indicators are diameter, height and thickness. The diameter of the rings varies from 400 to 1500 mm. It must be taken into account that it should be 10 - 15 cm smaller than the diameter of the prepared shaft.

Height is the second indicator by which you should choose rings. This value must be calculated based on the depth of the future well. Typical ring height sizes are 500, 1000, 1500 mm.

The wall thickness is on average 55 mm (certain types of polyethylene rings have sizes of 6, 8, 22 mm). The outer diameter of the rings ranges from 455 to 1555 mm. It is the dimensions that make the loading capacity and installation of plastic products accessible.

The diameter and wall thickness of the pipe required for a well depend on the size of the well opening and the type of soil in which it is located.

To install a drinking well, it is recommended to choose rings with a diameter of 680, 800 and 900 mm. For sewer, commutation wells and drainage systems - 800, 900, 1500 mm.

Note! The deeper the shaft of the future well, the thicker the rings should be.

Assembling the rings into a single structure is not difficult. This process does not take much time and does not require significant preparation or a large number of participants. The connection of rings is carried out in three main ways:

- by threading;

- falling into the groove and snapping into place;

- welding

When installed correctly, all types of connections provide a high degree of tightness. The first two methods are recommended to be performed using silicone seals. Welding requires additional equipment.

Well rings, the height of which does not exceed half a meter, can be installed without outside help due to their low weight.

One-piece plastic rings are also used when creating sewer wells. They are actively used for the restoration of old concrete wells that cannot be dismantled.

Such products are also used for constructing septic tanks. The advantages of non-separable rings are:

- thickness from 6 mm (you can order the required one);

- height can reach 5 m (this greatly simplifies installation);

- diameter starts from 95 mm (allows you to equip a well).

Note! When purchasing plastic rings for a well, you must inspect their outer and inner surfaces. The uneven color of individual areas may indicate a violation of density or the presence of deformations.

The length of one-piece plastic rings can reach 5 meters, which greatly simplifies their installation.

Design features and dimensions

Regardless of whether the plastic well is a seamless or prefabricated structure, it consists of the following elements and parts:

- well bodies;

- bottom, which can be solid - in seamless models and tray (kinet), characterized by the presence of guides for the flow of water, as well as through;

- neck, but this element may be missing. It is mandatory only for products intended for the construction of inspection wells;

- hatch - this structural element is also optional. At the same time, design features may differ on products of different types and from different manufacturers. By type, hatches or covers are ordinary, blind (sealed) and lattice (used in wells intended for storm drains or drainage wells).

Dimensions of plastic products for constructing wells

Seamless products can be represented by products with different heights, which are not changeable.

Prefabricated structures are offered by manufacturers in the form of sections up to several meters long (this parameter differs for products of different brands) and additional elements (inserts).

Their height can vary from 200 to 1,000 mm and with the help of which you can easily assemble structures of the desired size.

To ensure the tightness of the well, prefabricated products are assembled using the tongue-and-groove principle, and the use of a special rubber gasket is mandatory.

In addition, prefabricated structures can also be presented in sections in the form of rings, the height of which also varies from 200 to 1,000 mm. In this case, assembly is carried out using threaded connections.

Also, models on the market may differ from each other in the presence or absence of a bottom, hatches, etc.

In addition, if necessary, you can select models with transition bends designed for constructing wells with the ability to change its diameter.

This situation may arise due to the characteristics of the design itself for which a plastic well is used, as well as due to the need to install, for example, pumping equipment.

When choosing a plastic well, an important parameter that you must pay attention to is its diameter.

Wells with diameters of 600, 800 and 1,000 mm are considered standard sizes, however, if a product with other parameters is required, it should be ordered individually.

Requirements for the placement of a plastic well for water supply

The construction of a plastic sewer well, like any other project, should begin with planning. If the well is going to be drinking, you definitely need to know at what depth the water layer is located and in what place it is closest to the surface. This will save physical and material costs on the device and make it more convenient to use the well in the future.

Only hydrogeodes of the site can provide such information. There are enough organizations licensed to carry out such work. The order is completed within three days (taking into account the preparation of the report).

In addition to information about the immediate depth of the water layer, such work will also provide information about the quality of the soil. Depending on the results, it will be possible to choose the location of the shaft preparation and the installation method.

Before you build a well, you need to plan everything carefully.

Note! When choosing a location for installing a well, you must avoid nearby trees. Roots can damage the walls of the device.

The dimensions of large diameter plastic pipes for a well with drinking water are selected taking into account the fact that they must be at least 50 cm above the surface of the site. This will prevent rain and melt water from entering the well. For devices of other types, this condition is not necessary, since their design includes a closing hatch.

Comprehensive restoration of drinking wells

Drinking wells fail for various reasons. Most often, the walls of a structure lose their former tightness, after which surface runoff begins to flow into it like a river. Sometimes the opposite happens: the well dries up hopelessly and water appears in it only under very rare circumstances.

If there is an old abandoned well on your site, it can be turned into a sealed tank with a capacity of 1.2 m³, designed to store drinking, rain or melt water. This will again be helped by plastic inserts of the “ROTOLINE” series with a height of 2000 mm, additional elements for them, as well as special adapters that provide a hermetically sealed insertion of pipes with a diameter of 25 to 160 mm.

Installing them in an abandoned well is not so difficult, but why not give an empty source of water a full second life...

Requirements for the placement of a plastic sewer well

When determining a location for a sewer well, you need to know whether other communications are laid close so as not to damage them during the preparation of the mine. It is necessary to remove the well from growing trees at least two meters. Elements of the sewerage system must be laid at a distance of 1.5 m from the water supply pipes.

The plastic sewer well must be located no further than 10 meters from the sewage outlet and at least 3 meters away from the building. It is better to buy plastic rings for a sewer well with a diameter of at least 900 mm. This size will make it accessible for repair and revision work.

Regardless of the purpose, private or public use, the construction of sewer wells must be carried out according to certain rules and requirements.

What is the price?

Having considered the advantages of plastic wells, the question arises: Why are they not used everywhere? The main problem is the high price of plastic rings. If you look at the prices of domestic producers, the picture is as follows:

Drinking well

— diameter 900/800 mm, height 1500 mm costs 10,000 rubles;- — diameter 600/680 mm, height 1500 mm will cost 9,000 rubles.

Drinking well with bottom

- — diameter 900/800 mm, height 1500 mm can be purchased for 15,000 rubles;

- — diameter 600/680 mm, height 1500 mm, price — 14,000 rubles.

On average, the cost of a concrete well ring with a diameter of 1000 mm and a height of 900 mm is 2,000 rubles.

Prices from companies involved in the installation of wells are significantly higher compared to manufacturers. As a rule, turnkey installation work costs several times more than the cost of the material itself.

However, it is worth noting that one cannot talk about the cost-effectiveness of a well made of precast reinforced concrete. Here you should compare not only the material, but also the costs of transportation and operation of special heavy equipment. For example, a finished reinforced concrete well 10 m deep will cost about 30 thousand rubles. For the same amount you can install a well made of polymer materials.

It is important to take into account the more economical operation of a plastic barrel, which does not require repair due to temperature deformation and cleaning from organic deposits.

Purchase of materials and methods of laying plastic rings

Only after studying the technical conditions and preparing the design component can you begin purchasing materials. You need to purchase components based on the required depth of the well, taking into account the possible or desired diameter. When determining dimensions, subsequent use must be taken into account.

Note! If there is uncertainty about the correctness of the preparatory stage, it is better to contact an organization involved in the installation of plastic wells to draw up a plan and estimate. Even minor errors can make it impossible to operate the device normally in the future.

It is not necessary to choose expensive plastic rings for a septic tank. Polyethylene (they are the cheapest) of medium thickness (20-30 mm) will be sufficient. It is better to buy a plastic drainage well from a more resistant material - polypropylene, since it will most likely be located in a place where external loads are inevitable.

Depending on the composition and mobility of the soil layers, rings can be laid in an open or closed way.

You need to dig a shaft for a well in an open way, giving the hole a round shape.

The open method is used if the soil is not loose or mobile. A shaft of the required depth is dug, having a size 10-15 cm larger than the diameter of the rings. If the well is drinking, a filter of sand, pebbles or geotextile is placed at the bottom. An appropriate tray is installed in a sewer system or well for other purposes:

- solid;

- with profiling in the form of grooves;

- distribution;

- passable.

A pipe is assembled from individual plastic rings and lowered into the well shaft. The pipe is leveled, and the space between the plastic and the soil is filled with small pebbles, sand or a mixture of both. The neck is mounted, the hatch is installed.

Note! There is no need to fill the space with cement mortar. This will make it much more difficult to repair or reconstruct the well in the future.

Plastic does not release harmful substances into the water, so concrete and metal pipes of old wells are replaced with polymer ones.

The closed method of installing a plastic sewer well is advisable where the soil is loose. The shaft is dug to the depth of one ring, which is subsequently installed. Then the soil is selected so that the ring lowers under its own weight. To use this method, it is important that the method of connecting the rings is simple - threaded or grooved. After laying the entire pipe, the necessary bottom is poured from sand, pebbles or cement mortar. Next, the space between the soil and the walls of the shaft is filled, and a hatch is installed.

Setting up a well for drinking water

Types of structures

The design can be of three types.

Team

- prefabricated, when the elements are assembled on site and are small in weight, which allows you to solve the problem with water supply alone. Such wells are assembled with a groove connection without the use of sealants and other adhesives. Ideal option for a limited budget. The rings are not expensive, and installation is very easy and does not require the use of special equipment;

Welded

- welded, requires certain knowledge, installation skills, and the ability to use special tools and equipment. But you can do it easier and turn to specialists. The cost of such a design is small, but installation will cost many times more. The well elements are delivered to the site separately and connected by welding inside the well. This option provides excellent sealing and eliminates the infiltration of rainwater;

Seamless

- seamless, that is, a ready-made assembled structure is lowered into the well. It's difficult to do this manually. The seamless option is reliable if the well does not fall from a great height on its side. However, even concrete rings in such a situation are not durable.

Mounting process

Basically, the installation of a well made of plastic rings is based on the rules for installing a well made of reinforced concrete. But, nevertheless, there are 2 installation methods, based on the geological data of the site.

- On dense soil, a hole for a well is dug in diameter larger than the rings at the maximum possible depth. To install the structure, the rings are screwed together using sealant and put in place. The bottom is covered with a substrate of sand and stones, and a similar mixture is poured between the rings and the pit, but with the addition of a small fraction of crushed stone.

- When the soil is loose or there is a lot of water in it, a different method is used. The soil needs to be dug to the depth of the first ring. After it is installed and leveled, it settles by removing soil from the bottom. Only then work is carried out with subsequent elements. The process is longer than the first option and lasts until the required depth is obtained. It is important to correctly position the filter at the bottom and carry out sealing work around the perimeter of the well in order to prevent the elements from bulging out in the event of freezing. This method often uses concrete anchors at the very bottom of the trunk. Due to the properties of the material, the structure can withstand even freezing water.

Installation of a well for sewerage with rings can be completed in 20 minutes. Key points of work:

- - a hole is dug with a depth equal to the height of all the rings plus 30 cm, so that in the future the well does not become higher than ground level;

- — the first ring is lowered, leveled, the bottom is filled with sand and compacted;

- — the second ring is lowered, again focusing on the level indicators;

- — the remaining rings can be mounted without using a level;

- — when the installation is completed, gravel is poured onto the sand layer for greater stability and filtration.