What is “PV” and what does this indicator affect?

PV

- this is

the duration of switching on of the welding machine

, i.e. the time of its continuous operation.

This indicator is one of the main characteristics of a welding inverter

. The duty cycle is always indicated in % based on a 10-minute welding cycle. Indicated on the nameplate on the rear panel of the device. For all welding inverters (SAI), the PV at maximum current is 70% (for example, for SAI 220, the PV is 70% at a current of 220A), i.e. the device works for 7 minutes, after which, in theory, it requires 3 minutes of rest.

The average person may misunderstand this indicator. They say: “What can I cook in 7 minutes? And then he constantly needs to rest for 3 minutes?” NO ! PV

shows the duration of continuous cooking. It is impossible to cook continuously for seven minutes! Firstly, because the electrode will burn out much faster and while the person is changing the electrode, the device cools down. Secondly, after 3–5 minutes of the welding process, there is usually a need to prepare parts for further work and check the welding seam - this time is enough for the AIS to cool down. That is why, when working in domestic conditions, almost 100% PV is usually achieved - work is carried out continuously and with high quality throughout the day!

If, nevertheless, the buyer wants to purchase a welding machine with a high duty cycle

, than 70% (usually professional welders or older people who heard “somewhere, something” from a neighbor), he should simply be recommended to purchase a device of a higher rating than he chose. Because 70% is at the maximum welding current; when the value on the regulator decreases, this figure immediately increases. That is, for example, for SAI 160 PF3 at 160A is 70%, and for SAI 250 at the same 160A it will already be 100%, i.e. continuous operation (see Fig. 2).

Always pay attention to the PV

! It can help you a lot in positioning the AIS. So, for example, what we can see when considering the Telwin SAI 165. The duty cycle at the maximum current (150A) is not indicated at all, there is data only for 140A and the duty cycle at this current is only 7% (42 seconds.). This is just that time out of a 10-minute lfiacria that the welder at this current is in operating mode. Not a bad argument in our favor, right? Yes, here one person out of a thousand can argue about the temperature conditions for which PV is considered (you can read about this in any source on the Internet). But still, an attempt at justification will sound sluggish!

Also, for example, for devices (Weld hWD-200) and “DON” (DON-230), the actual PV indicator is almost 3 times lower than the declared one: 13% and 12%, respectively, with a declared 35% at maximum current.

Important: Remember that the PV indicator is calculated for an ambient temperature of +25°C, therefore, if a person works with the machine in the summer in the heat at a higher temperature, the body of the device will additionally heat up (accordingly, the PV indicator will drop slightly) and the likelihood of the welder turning off due to thermal protection increases. If suddenly the temperature approaches the limit value, the overheating indicator on the front panel of the AIS will light up and the device will turn off and turn on only after cooling.

Source

Duration of inclusion (DT) as a means of manipulating the buyer

As we can see, the duration of switching on at maximum current for an inverter is, on the one hand, a rather important indicator. Imagine a situation in which you choose two similar models of welding machine. A number of characteristics, including the maximum current, are almost similar, but the duty cycle differs. It is reasonable to assume that the cooling system of the model with a higher PV is more advanced and efficient. This has a positive effect on the efficiency of the welding task, reliability and overall service life of the equipment.

BUT! It is not always worth focusing on this indicator in such cases. And there are a number of reasons for this that definitely deserve to be taken into account. These reasons include:

- Manipulation of measurements by manufacturers. Especially little-known equipment manufacturers often make mistakes with this indicator. In the passport for a household inverter with a duty cycle of 80-90%, it may be written in small font “measurements were made at 100 A). That is, not at the maximum output current, but at a different amperage value, loading the device noticeably less intensively.

- Rare work of a welder at maximum current. This circumstance can significantly increase the continuous operation time of the inverter without the need for a break to cool it.

- A significant PV indicator is not needed for all types of welding. As a rule, a standard electrode lasts no more than a minute or so of continuous burning. Thus, the welder will probably have to stop to replace it, check the quality of the weld, or clean its surface. Meanwhile, the inverter will cool down. Therefore, the duration of switching on at a maximum current of even 50% is quite enough to perform most household welding tasks.

As you can see for yourself, the duty cycle indicator is not a priority for choosing household welding machines. When selecting professional welding equipment for a particular production, completely different criteria come to the fore.

Buyers of welding equipment can draw the appropriate conclusions on their own. And if you are looking for appropriate high-tech products for your needs, we recommend looking for them in our online store.

What is PV Welding Machine

Any welding machine has one important characteristic - on-time

, more often you can find the abbreviation “PV”. This characteristic is measured as a percentage and is nothing more than the ratio of operating time under load to cooling time. All this is measured at a specific ambient temperature.

According to European standards, PT should be indicated at 40°C and a 5-minute interval. According to the standards of the CIS countries at 20°C and 10 minutes. In Belarus, in 95% of cases you will find the Duration of On indicator, calculated precisely at 20°C and 10 minutes.

PV (PN) - what is it?

In this article we will consider the components of the element characteristics of a welding inverter - PV(PN)

On-time (ON) or load duration (LO) as a percentage is the ratio of the operating time under load or cooling over a certain period of time, at a certain ambient temperature. (the ratio of the time of work under load and rest from overheating). The accepted value of the total time according to the European standard is 5 minutes at 40 degrees Celsius, in other countries and Russia 10 minutes at 20 degrees Celsius. The optimal PV value is about 50%, i.e. 6 minutes of work and 4 minutes of break. Increasing the operating time under load will trigger the thermal protection of the control unit.

In other words, if you turn on the device at maximum load and detect the time after which it turns off due to overheating, this will be its duty cycle. And since PV is measured in %, this is the ratio of the “work” and “rest” time of the welding machine.

We give an example if we take a welding cycle of 10 minutes (and not 5 minutes - European standard), the ambient temperature is 20 degrees (and not 40 degrees - European standard) and the machine turns off after 5 minutes, which means the duty cycle is 50% (we work for 5 minutes, rest for 5 minutes), if it turns off after 3 minutes, then the duty cycle is 30% (work for 3 minutes, rest for 7 minutes), if the device turns off after 6 minutes, then the duty cycle is 60% (work for 6 minutes, rest for 4 minutes). What does this mean for us in a practical sense? PV 50-60% (welding cycle 10 minutes and ambient temperature 20 degrees) is more than enough for any MMA welding work at currents up to 200A.

That is, if the welding machine has a duty cycle of 60%, then at maximum current it will work for 6 minutes, and will cool down for 4 minutes. But PV is measured by switching on the device to a constant load (for example, using a ballast rheostat), which never happens in life! MMA welding (RDS Manual Arc Welding) involves welding with an electrode, and no electrode will burn for more than 40-50 seconds, and in addition, the welding seam must be cleared of slag, cleaned, etc. This means that the device will not work continuously for all six minutes, and will have time to cool down. It follows from this that 60% PV is solid 100% for MMA (RDS Manual Arc Welding)

Let's consider another option - PV 10-15%, which means that you work for 1-1.5 minutes and rest for about 9 minutes, and this is the opposite situation. That is, you burn one electrode, the device will turn off due to overheating, wait 9 minutes, then the cycle will repeat. And if it’s hot outside, then the PV becomes even less. Having bought a device with such a PV, instead of welding two garage hinges in twenty minutes, you will spend several hours of your precious time on this. Careless manufacturers either underestimate the PV values or write them in such a way that it is almost impossible for someone uninitiated in welding to understand. For example, they indicate PV not at maximum power, but at 20-30% of it, for example, on a 160 A device they indicate PV -60% -100 A, which means practically PV 35% -160 A. On the one hand, they indicated the real PV, on the other hand, they deliberately mislead if the buyer does not have enough information. There is another trick: unscrupulous manufacturers indicate, for example, PV -60% -160 A, and then write in small print that the PV measurement time is 3 or 5 minutes, which means that the real PV at 10 minutes, at a maximum power of 160 A, means practically the same same PV 35% -160 A.

To choose a welding inverter, you can always contact our managers by phone or email. This way you will receive qualified advice on any issue related to welding.

Information reprinted from the site https://www.tdfeb.ru/

Principle of operation

Inverter welding machine: what does it mean? A welding inverter is a converter of alternating current 220 volts to direct current 70-120 volts . An outdated welding rectifier does the same thing. The quality of the weld made using a transformer-rectifier strongly depends on the stability of the characteristics in the electrical network. The operation of the device itself can greatly influence the stability of the network parameters; when the arc is ignited, voltage surges begin. What is inverter welding? The welding inverter also outputs 70-90 volts, but the conversion is carried out as follows.

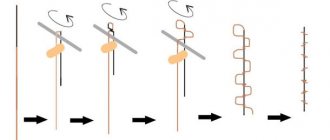

- alternating current 220 volts 50 hertz is rectified and supplied to the input of the high-frequency generator;

- the generator creates a high-frequency (20-50 kilohertz) signal;

- it is fed to a transformer, which reduces the voltage to 70-90 volts;

- the current is rectified by the second rectifier and direct current is supplied to the electrode and the workpiece;

- the electric arc is ignited, the edges of the workpiece are melted, the electrode also melts, forming a cloud of protective gases and replenishing the weld pool;

- after cooling of the seam material, a permanent connection of high strength and durability is formed.

Now it becomes clear what inverter means: it is a converter with double inversion (from the Latin inversio, turning over, rearranging) voltage from alternating to direct and back.

Converting current at high frequencies made it possible to reduce the weight and dimensions of the transformer many times . Controlling the process at each stage using electronic circuits made it possible to ensure high stability of the output voltage, its independence from fluctuations in the supply network (within certain limits) and eliminated the negative impact of the inverter itself on jumps in the parameters of this network. In addition, welding inverters provide high stability of the arc, facilitate its ignition and prevent the electrode from sticking.

Welding rectifier device. The low-frequency transformer accounts for the bulky dimensions and heavy weight of the device.

These are the main differences between an inverter and welding rectifiers. Semi-automatic welding machines are also built on the basis of an inverter current source , supplying welding wire to the working area instead of a rod electrode.

If the parameters of the electrical network are significantly lower than 180-190 volts, then a conventional inverter can no longer compensate for such a voltage drop. Often in remote areas it drops to 150 volts.

Why is this indicator important and at the same time not important?

All these arguments are extremely revealing. But there is one extremely unpleasant nuance. Many manufacturers lately, fighting for the client, resort to very ugly tricks. So, for example, many unscrupulous developers prescribe a duty cycle of 90% or even 100%, but they forget to note that this is not at maximum currents, but at 100 A, for example. It’s sad, but true, today you can only trust proven brands, such as Svarog, EWM or ITS.

That is why we have prepared 4 reasons for you, which indicate that you should not rely only on the PV value when buying a welding machine:

- You don't always brew at maximum current. But the indicator was calculated specifically for him. This means that if the welding process is carried out at lower currents, then the duration of switching on can be safely increased, because the device will not overheat so quickly.

- Are you sure you need a high PV? Look, a standard electrode burns for no more than a minute. In any case, you will have to periodically interrupt, during which time the welder will “rest” and cool down, even a low duty cycle of 30–50% will be unnoticeable.

- You will be interrupting your work anyway. After all, it is impossible to cook all day and not monitor the quality of the seam and not clean it. But even half a minute is enough for the equipment to cool down slightly.

- There is too much false information out there. Look at the instructions. Does it clearly indicate how and under what conditions the duration of inclusion was assessed? No? Then you can focus on this indicator with a very low degree of probability.

This is how it turns out that the PV of a welding machine is both important and not at the same time. All this primarily concerns household use. If you are planning to purchase equipment for use in production, then you should choose according to completely different criteria. In any case, we recommend that all our customers take a closer look at the Russian brand “Svarog”. Each of its devices undergoes pre-sale testing; a whole staff of engineers works in production to monitor the output quality of the supplied products. In any case, you won’t find a better ratio of price and functionality, so go to the catalog and choose!

How does the device work?

Welding transformers are already fading into the background. With the advent of inverters, welding metal structures has become much easier. Their design is simple and lightweight. The equipment itself can be easily placed in a small bag or car for transportation, for example, to the country. At the same time, learning the welding process using an inverter is much easier than using a transformer. This device does not require such effort and special training.

Before starting work, it is recommended to understand the basic principles of operation of this equipment. The operating principle consists of several stages of converting electric current using an inverter type. The basic process is as follows:

- Electrical alternating current from the main network is converted into direct current while passing through the spiral, which allows the arc to be stabilized.

- Direct current is again converted to alternating current. At the same time, its frequency increases several times.

- After this, the voltage level of the electric current is reduced to the most optimal value. As a result, it is possible to achieve the maximum current value.

- After this, the voltage level in the network is rectified.