Submersible pump repair

Repairing a submersible pump is an integral part of the proper operation of the unit, which allows you to increase its service life. For any private plot, the presence of such equipment makes it easier to deliver water to the living area and water the garden. Despite the fairly high manufacturing reliability, sometimes repairs of borehole submersible pumps are required. This article suggests how to make it correctly with your own hands.

How deep water pumps work

To use reserves from underground sources, wells or boreholes, it is best to use deep-well pumps. Their operating principle is as follows:

- The unit is lowered into the liquid to a level below the surface level.

- The pressure created in the device forces water to be pushed upward, for which a hose or pipe is installed for a deep-well pump.

- Simple devices of this type can get water from a depth of up to 40 meters, more technologically advanced and expensive ones - up to 80 meters.

- There are two main categories of pumps:

Devices and main components of a submersible pump

Currently in Russia you can find hydraulic equipment from manufacturers in Italy, the USA, Germany, France, Denmark: ZDS, PEDROLLO, CALPEDA, WILO, Busch, GRUNDFOS, Tapflo and others; Russian companies Gilex, Ampika, Pinsky OMZ, GMS Livgidromash.

Submersible pumps are designed to pump water from wells, wells or basements of buildings and, if necessary, supply it to a collapsible water supply network. At the same time, their working area is immersed in liquid, which is why they are called that.

There are several types of these devices:

- Centrifugal, in which the main element is an impeller (impeller) or a screw. Examples of them are “Vodomet”, “Aquarius”, “Whirlwind”, “Octopus”.

- Vibrating ones, which are headed by a piston. An example of them is the “Kid” pump.

- Vortex pumps are similar to centrifugal pumps, but are distinguished by a higher circular velocity of the fluid. An example is the “Vikhr” vortex pump.

Note: centrifugal units are divided into rod-type, when the hydraulic part and the electric motor are located in different places and are connected to each other by a rod, and rodless, when the electric motor is combined with hydraulics.

The main components of centrifugal apparatuses include:

- impeller or screw/auger;

- electric motor;

- barbell;

- stuffing boxes;

- couplings;

- bearings.

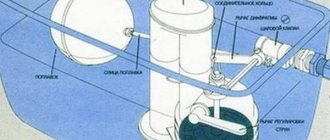

The main components of vibration devices include:

- working part body;

- drive unit;

- electric coil;

- piston;

- diaphragm;

- valve

- shock absorber;

- emphasis;

- coupling

Basic malfunctions of submersible pumps

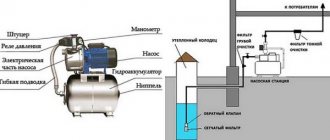

If malfunctions are noticed in the operation of a submersible pump, it does not always need to be removed from the well for inspection. This recommendation only applies to pumping stations that have a pressure switch installed. It is because of this that the device may not turn on, not turn off, or create poor water pressure. Therefore, the functionality of the pressure sensor is first checked, and only after that, if necessary, the pump is removed from the well.

Important! In the case of submersible pumps operating without hydraulic accumulators, they should always be removed from the shaft at the slightest sign of failure.

It will be easier to diagnose water pump malfunctions if you first become familiar with the most common breakdowns of this unit.

Pump doesn't work

The reasons that the pump does not work may be the following.

- Electrical protection has tripped. In this case, you should disconnect the device from the network and turn on the machine again. If it knocks out again, then the problem should not be looked for in the pumping equipment. But when the machine is turned on normally, do not turn on the pump again; you must first find the reason why the protection was triggered.

- Fuses have blown. If after replacement they burn out again, then you need to look for the cause in the power cable of the unit or in the place where it is connected to the electrical network.

- The underwater cable has been damaged. You should remove the device and check the cord.

- The pump's dry start protection has tripped. Before starting the device, make sure that it is immersed in liquid to the required depth.

Also, the reason that the device does not turn on may lie in the incorrect operation of the pressure switch installed in the pumping station. It is necessary to adjust the starting pressure of the pump motor.

The pump works, but does not pump

There may also be several reasons why the device does not pump water.

- The shut-off valve is closed. You should turn off the device and slowly open the tap. In the future, you should not start the pumping equipment with the valve closed, otherwise it will fail.

- The water level in the well has dropped below the pump. It is necessary to calculate the dynamic water level and immerse the device to the required depth.

- Check valve stuck. In this case, it is necessary to disassemble the valve and clean it, if necessary, replace it with a new one.

- The inlet filter is clogged. To clean the filter, the hydraulic machine is removed and the filter mesh is cleaned and washed.

Low device performance

Advice! If the performance of pumping equipment drops, you should first check the voltage in the network. It is precisely because of its reduced value that the engine of the unit cannot gain the necessary power.

Reduced performance also causes:

- partial clogging of valves and faucets installed in the water supply system;

- partially clogged lift pipe of the device;

- pipeline depressurization;

- incorrect adjustment of the pressure switch (applies to pumping stations).

Frequently turning on and off the device

This problem occurs if a submersible pump is paired with a hydraulic accumulator. In this case, frequent starts and stops of the unit may be caused by the following factors:

- the pressure in the hydraulic tank has dropped below the minimum (by default it should be 1.5 bar);

- the rubber bulb or diaphragm in the tank has ruptured;

- The pressure switch is not working correctly.

You can hear the hum of the machine, but the water does not pump

If the pump hums and water is not pumped out of the well, there may be several reasons:

- “gluing” of the device’s impeller with its body occurred due to long-term storage of the device without water;

- the engine start capacitor is faulty;

- the voltage in the network dropped;

- The pump impeller is jammed due to dirt accumulated in the device body.

Water is supplied with pulsation

If you notice that water from the tap does not flow in a constant stream, then this is a sign that the water level in the well has decreased below the dynamic level. It is necessary to lower the pump deeper if the distance to the bottom of the shaft allows this.

The unit does not turn off

If the automation does not work, the pump will work without stopping, even if excessive pressure is created in the hydraulic tank (as can be seen from the pressure gauge readings). The culprit is a pressure switch that has failed or is incorrectly adjusted.

Subtleties of repairing units of different brands

Since there are models of pumping equipment from different manufacturers on sale, differing in strength and design features, the repair and operation of such devices must be carried out taking into account the model. Since you could choose not a “Water Cannon” or a “Whirlwind” as a well unit, but a model of another brand, we decided to list the weaknesses of the most common pumping products, as well as the features of their repair:

- Most Grundfos models have special motor insulation and built-in valves. Therefore, sometimes it is necessary to change the thermal insulation seals of the motor. This work can only be done by a professional.

- Gilex brand pumps often experience fluid leakage from the electric motor. To repair, it is necessary to replace the fluid with a similar product. This can only be done at a special service center.

- The most popular is the domestic pump “Malysh”. Although the price for service repairs is quite reasonable, it is not difficult to repair this device yourself. A common problem is that the unit makes a lot of noise after switching on, but does not pump water. This usually occurs due to a rupture in the central axis on which the membrane and anchor are installed. Typically, disassembling the unit allows you to quickly identify the problem. The axle needs to be replaced. You can learn more about repairing the “Malysh” pump from the video below:

- The Aquarius well pump quite often overheats during operation. This is especially true for units installed in shallow wells. However, since the repair of such equipment can amount to about half of its cost, if an inexpensive pump breaks down, it is easier to buy a new device.

- The Vodomet and Whirlwind pumps are fairly reliable equipment that, if used correctly, can last for a long time without breakdowns. If used incorrectly, the units can become clogged with silt and sand. For repairs, you will need to change the pump part.

- Rucheyok pumping equipment is also famous for its ability to overheat. And this despite the design in compliance with European standards. According to the manufacturer's instructions, the device can work without stopping for 7 hours, but in practice this will cause overheating. Therefore, it is recommended to give the pump a break after 2-3 hours of operation.

How to diagnose a breakdown

To get rid of a breakdown, you need to find its cause. Diagnostics consists of the following sequential stages:

- Remove the distribution panel yourself.

- Disconnect the impeller from the engine.

- Check how it rotates when there is no load. If in future you want the engine to run smoothly and quietly, attach a smoothing capacitor to the part.

- With the impeller set aside, determine whether the motor is in working order or whether it is burnt out.

- If the shaft does not turn, most likely a part has broken, causing the engine to jam. Then small and, conversely, large parts of soil enter the unit along with water.

- It is likely that the stator winding burned out due to the accumulation of dirt and untimely disposal of it.

Please note that if the shaft rotates correctly, the lower component of the motor is assembled.

Replacement and repair of faulty parts

Now that you know how to disassemble a hydraulic machine, you can try to repair a submersible pump yourself.

Impeller

Basically, blocking of the impellers occurs due to their clogging with sand or due to the formation of a coating of dirt on them. In addition, the impellers can be soldered together when a high temperature occurs in the block when the pump is idling (dry running). To repair this section of the unit, it is necessary to remove the impeller(s) and remove accumulated dirt. If the impellers are damaged, they will need to be replaced with new ones.

Engine

It is not recommended to independently repair the pump motor, since diagnosing this unit and subsequent repairs requires special knowledge and the necessary equipment.

In some pump models, removing the motor will require pressing it out using special equipment. Replacement of the oil seal and bearing is also carried out at the service center.

Capacitor

If the engine hums and does not start, you should check the capacitor. It is located in the pump block in which the motor is installed.

Advice! Before disassembling the engine block, try turning the engine shaft with the pump block disconnected. If the shaft rotates, then the reason may be that the impellers are jammed.

But when the shaft with impellers rotates without problems, then in order to eliminate the hum in the water pump, you should disconnect the capacitor and replace it with a new one. Of course, it is better to check this part with a multimeter, since similar symptoms can be caused by a short circuit in the motor windings.

Oil

The water pump motor is located in a special glass filled with oil, and by its condition it is possible to determine some breakdowns in the electric motor block.

- The oil has a characteristic, unpleasant odor. This means that the engine is still in working condition, but was working under heavy overloads.

- Cloudy oil - water has entered the engine housing due to a crack in the housing or failure of the oil seal (cuff).

- Black oil with an unpleasant odor. In this case, we can say with great confidence that the varnish was burning on the engine coils.

Important! Normally, the oil should be transparent. Its quantity is determined by the model of the unit. On average, the volume of oil poured into the chamber is 0.5 liters.

If, when opening the engine, the above changes in the quality of the oil were noticed, then you first need to repair this unit, and only then fill in new lubricant.

How to disassemble correctly

First, turn off the power, then dismantle, disconnect the pressure pipeline and disassemble it:

- remove the coarse filter;

- disconnect the motor part from the hydraulic part.

Disassembling the hydraulic unit:

- the hydraulic part is clamped with a vice onto the pressure pipe;

- the housing is unscrewed;

- All parts are removed from the shaft;

- if necessary, replace worn or broken ones;

- the parts are washed and then assembled onto the shaft.

Important: in order not to confuse the parts, they must be placed in the order of disassembly or put on any axis/rod without changing position.

Motor disassembly:

- it is installed with the lid facing up;

- unscrew the lid and remove the sealing gasket;

- oil is drained;

- using a press, the lower motor cover is pushed down, the locking ring is released, and then removed;

- with light blows of a mallet on the end of the shaft, the bottom cover with the rotor is knocked out;

- the engine rotor with bearings is removed;

- if replacement is necessary, remove the bearings from the shaft and the oil seal from the top cover of the motor;

- windings are checked; if necessary, the stator is sent for repair. Assembly is carried out in the reverse order.

How to disassemble the pump for repair?

To repair any pumping equipment with your own hands, you need to learn how to disassemble it. We will look at how to do this using the example of the Vodomet pump. Disassembly is carried out in the following sequence:

- At the inlet pipe, it is necessary to unscrew the cylinder with the perforated bottom. This is a coarse filter that protects the product from sand and siltation.

- Next, with your own hands, all washers, disks and “cups” are removed from the shaft on the pump unit motor. To make it easier for you to put the removed products back in the desired order, lay them out next to each other in the order in which you remove them.

It is important to know: the impeller consists of 16 components, removable parts, not counting the same number of anti-friction washers. Therefore, it is very important to follow the sequence of removal and reinstallation of all elements.

- After this, it is necessary to remove the motor retaining ring from the Vodomet well pump. This part covers the engine compartment lid. To do this you need to use a mallet. Using this tool, we move the engine down, then pull the cord and return it back. After such manipulations, the o-ring will move. After this, the retaining ring is moved towards the housing with a screwdriver. As a result, the stopper will become skewed and will be easy to remove.

- Next, disconnect the wiring and open the engine compartment lid. After this, using a mallet and a screwdriver, you can remove the motor from the housing.

As a result of this disassembly, you can easily wash and clean the impeller and all its component elements. The engine can be taken for diagnostics and repair to a specialized workshop. After cleaning and repair, assembly occurs in the reverse order.

Do-it-yourself repair of downhole equipment parts

To repair downhole devices, they are first de-energized, then removed upward and disconnected from the pressure pipe.

Piston replacement:

- the tightening bolts are unscrewed;

- body is removed:

- the nuts are unscrewed from the rod;

- the valve is removed from the stem;

- a new one is installed;

- tighten the nuts securing the valve to the stem;

- the housing is put in place;

- both parts are bolted together.

Valve replacement:

- the tightening bolts are unscrewed;

- the housing of the hydraulic part is removed;

- the valve mount is unscrewed;

- the old one is removed;

- the new valve is screwed onto the body;

- the housing is installed in place;

- both parts are fastened with coupling bolts;

- The operation of the installation is checked in a container with water.

Coil replacement:

- unscrew the coupling bolts;

- remove the hydraulic housing;

- remove the piston assembly with the diaphragm, clutch, shock absorber and armature;

- heat the compound filling of the electromagnet with a burner or on a hot plate until it softens;

- remove the electromagnet from the motor housing;

- clean his nest;

- remove the coil from the core;

- disconnect the power cable;

- replace the coil;

- solder the power cable and insulate the soldering points with PVC pipes;

- install the coil on the core;

- place the coil with the core exactly in place in the engine compartment;

- fill the electromagnet with epoxy resin according to the instructions;

- after 15-30 minutes, add resin to the upper level of the core;

- Allow the resin to harden overnight;

- install the anchor assembly on the engine compartment;

- put the pump housing in place;

- install coupling bolts;

- Check the operation of the unit in a container with water.

Replacing the discharge pipe:

- to repair deep-well pumps, they need to be de-energized, raised to the surface, then disconnected the pressure pipe;

- unscrew the check valve;

- unscrew the discharge pipe;

- screw in the new discharge pipe, having previously wound the FUM tape or FUM thread onto the thread;

- screw on the check valve, winding the threads with FUM tape or FUM thread;

- connect the pressure pipe;

- lower the apparatus into the well;

- connect power supply.

Engine thermal insulation:

- to replace the thermal insulation of the engine, you need to disconnect the hydraulic and motor parts;

- remove the retaining ring;

- remove the seal and install a new one in its place;

- assemble the unit;

- connect the pressure pipeline;

- lower the unit into the well;

- connect power.

Fluid has leaked from the engine:

- disconnect the motor part;

- install the engine vertically, with the cover up, unscrew the motor cover;

- pour in environmentally friendly non-toxic oil (some experts recommend pouring Vaseline oil);

- check the integrity of the gasket; if necessary, replace;

- screw the top cover;

- connect the motor part to the hydraulic part;

- lower the device into the well;

- connect power.

Broken rod. To repair the rod yourself, you need to turn off the power to the device, lift it to the surface, disconnect the pressure pipe, then proceed to repair the submersible pump itself:

- unscrew the coupling bolts;

- remove the hydraulic part cover;

- remove the rod assembly;

- remove the piston, stop, coupling from it;

- unscrew the nuts securing the rod to the shock absorber and remove it;

- remove the armature with the rod shank from the engine compartment;

- remove the rod shank from the armature;

- insert a new rod into the armature;

- put the shock absorber on it, tighten the fastening nuts;

- put the coupling, stop, piston on the rod and tighten the fastening nut;

- lock the nut or cap the end of the rod;

- install the hydraulic part cover;

- tighten the coupling bolts;

- connect the pressure pipe;

- lower the installation into the well;

- connect power.

Blockages. Centrifugal, vortex and screw type devices can become clogged.

- To clean the installation from silt, salt deposits and adhering sand, you need to turn off the power, take it to the surface of the earth, disconnect the pressure pipe, disconnect the hydraulic part and the motor.

- Then disassemble all the pump parts from the shaft.

- Rinse all components, the coarse filter, replace worn parts if necessary, then reassemble everything in the reverse order.

- Connect the pressure pipe, lower the unit onto the workplace, and connect the power.

How to make device repair easier

There are several ways that can help make deep well pump repair easier:

- Disassembling the upper part of the electric motor must begin after installing it vertically. This will prevent oil from leaking out, which is unacceptable, since oil in most modern systems is the working fluid.

- Remove the cover where the wires supplying voltage to the electric motor fit. The starting capacitor is also clearly visible here.

- Checking the resistance of the starting and operating windings should be done using an ohmmeter, the terminals of which are connected to the winding.

- By rotating the handle, it is necessary to create a voltage of several hundred volts. If the device reading has a certain value, but not infinite, it means that all windings are working. The device reading on the working winding of infinity indicates a break in the working phase of the motor.

- A small resistance value indicates that there is a short circuit between the motor turns.

Advice: If the above breakdowns occur, it is almost impossible to fix everything yourself. In this case, it is better to send the device for repair to a specialized workshop.

- If all instruments indicate that the elements are in good condition, you will need to check the starting capacitor. It is possible that it is faulty or there is a break in the element. Such a defect can be accurately detected by the device, although outwardly everything looks fine. You can replace the capacitor yourself.

Stages of disassembling and repairing the pump yourself

So, the problematic pump needs to be removed from the well, disconnected from the power supply and disassembled.

Immediately after purchase, it is recommended to replace the screws with heads for a flat-head screwdriver with those that can be unscrewed with a Phillips head. In this case, it will be easier to unscrew fasteners that have become soured or seized with rust.

Parts with mechanical damage should be replaced.

The condition of the winding is checked by measuring its resistance. The multimeter should show a value between 4 and 5 ohms. If there is an interturn short circuit, the resistance will be much lower - from 0.5 to 1 Ohm. If the display shows “infinity”, then the wire is burnt out.

Disassembling the Vodomet pump

If you have some experience, you can rewind the electromagnet winding of a vibration pump yourself. This is done like this:

- The part of the housing with the electromagnet is heated on a hot plate to 150 - 190 degrees, which is necessary to soften the compound. After this, it will be enough to hit the case several times on a wooden block so that the magnet falls out. The melted compound must be removed from the housing immediately.

- Holding the magnet in your hands (you will need an assistant), carefully knock the magnetic circuit out of the winding. You need to hit not the magnetic circuit itself, but the wooden block laid on it. You need to hold the magnet in your hands in order to avoid destruction of the winding frames.

- The old winding is removed, and instead of it, a new one is wound using a winding machine - from copper enameled winding wire with a diameter of 0.65 mm (PETV brand). You will get two coils of 8 layers. The winding should be secured with cotton tape.

- Frames with coils are placed on a magnetic circuit.

- All that remains is to prepare a new compound from epoxy resin, hardener and plasticizer, pour it into the electromagnet installed in the housing and wait a day until it hardens completely.

Epoxy fumes are highly toxic. You need to work in the air and preferably in a respirator or gas mask.

Revision of the motor part

Deep well pumps are equipped with a single-phase, mostly brushless induction motor. The connection diagram contains a starting capacitor. The stator of the electric motor has a monolithic attachment to the housing; it is often filled with epoxy compound.

In pumps of a monolithic design, the motor must be squeezed out of the glass by pressing on the connection outlet of the outgoing pipeline with the impellers removed. In rod pumps, the motor part is disconnected when the two halves are separated, in screw pumps - after removing the working screw. In all cases, the insides of the engine (capacitor, connecting terminals) can only be accessed after removing the sealed plug. It is fixed with 2-3 screws on the side surface of the sleeve and a powerful locking ring. In some types of pump, the plug may require the use of a special puller.

Well pump motor stator

All well pump motors are filled with oil, which performs lubricating, cooling and dielectric functions. The oil used is special food grade, but it is commercially available. Signs of low quality may be a cloudy color of the oil when mixed with water, darkening or the presence of mechanical impurities, as well as insufficient levels. If the oil is normal, it should be drained into a clean, dry container, leaving the motor housing for 15–20 minutes until the residue completely drains from the walls. Insufficient oil filling of the engine indicates wear of the oil seals.

In addition to spoiled oil, engine malfunctions can be caused by worn bearings, which can be determined by play and free-wheeling noise. If the pump has been operated for a long time under extreme conditions, the shaft may be bent (twisted) and the winding insulation may overheat. Burnt stators are practically beyond repair, but they are quite easy to replace.

Burning of the stator winding due to water entering the motor

Inspection of the pump mechanism

In addition to contamination, the main cause of breakdown of the pumping mechanism is long-term dry operation. Due to the lack of liquid, the centrifugal impeller blocks get very hot and sinter, so the only repair option is to replace them. The situation is similar with the auger and landing bushings. Also, with jammed impellers, the shaft can rotate in the mounting holes, and in powerful pumps, it can become deformed and even destroyed.

In screw pumps, screws and landing bushings are consumables; they are replaced every 3–5 years, depending on the intensity of use. The main reasons are the natural aging of elements and exposure to small abrasive particles.

Screw and bushing for screw pump

Let us draw your attention to the fact that the parts of the well pumps have a high precision of fit, thanks to which the cleaned mechanism is easily assembled and disassembled. If during assembly the parts do not fit into place freely, then the order of installation of the elements is incorrect. Different pump models have specific design differences, but basic recommendations for self-repair and disassembly for inspection purposes are always described in the user manual, which often includes an assembly diagram.

Typical breakdowns of pumps of different brands

Equipment from popular domestic and foreign brands has its own characteristic failures. Devices from the Danish manufacturer Grundfos, despite their reliability and durability, require regular replacement of the mechanical seals. If this is not done in a timely manner, water will penetrate inside and damage the winding.

It is not advisable to service the unit at home. The specific design requires that repairs be carried out by an experienced specialist, ideally an employee of a company service center.

A pronounced hum and pressure that has dropped to a minimum indicate that the impeller in the pump has worn out or has moved along the axis. The device must be disassembled, cleaned of sand, damaged elements replaced and new seals installed.

Gilex units often leak fluid from the electric motor. It can be replaced, but only with a similar composition.

Some craftsmen believe that it is not necessary to buy an expensive substance. You can get by with glycerin or transformer oil. However, this is not the best advice. The equipment does not tolerate filling with alternative means very well and can completely fail after such an operation.

It is better not to repair the device yourself, but to entrust this task to qualified specialists. They are guaranteed to fill the engine with the original composition and do so in strict accordance with the manufacturer’s wishes. After servicing it will work just as well as on the first day of purchase.

Worn seals are indicated by a low oil level in the pump motor. It is better to replace them as quickly as possible. This will protect the motor from overheating

In the “Malysh” devices of the Russian enterprise Livgidromash, coils often fail. Dry work provokes this problem. A strong noise heard when turned on without pumping out water indicates a break in the central axis to which the membranes with the anchor are attached. This breakdown is easy to detect after disassembling the unit.

Replacing an axle even at home is not difficult. But finding a part on sale is really a problem.

Aquarius pumps tend to overheat. This drawback is especially active when the equipment operates in shallow wells. Repairs are expensive and sometimes amount to about 50% of the original cost. In such cases, many users prefer to buy a new device, albeit from a different manufacturer.

The same problem is typical for the “Rucheek” models. Despite the modern design and compliance with current European standards, they do not tolerate continuous operation.

The manufacturer says that the devices can continuously pump water for no longer than 7 hours. However, almost always such a load leads to overheating. To avoid problems, it is better to take breaks and let the equipment rest every 2-3 hours. In this way, the service life of the pump can be extended.

Do not start water pumping devices with the shut-off valve closed. In the future, this will lead to breakdown of pumping equipment. Before turning on, the valve must be opened

Vodomet pumping equipment is considered to be quite reliable and operationally stable. Most breakdowns here occur due to improper use. Also, when equipment comes into contact with contaminated water, it quickly becomes clogged with silt and sand. In this case, the pump part of the unit requires replacement.

When a problem cannot be solved at home, you should seek help from the professional technicians of a certified service center. They will quickly determine what happened to the equipment and restore its functionality. Or they will recommend purchasing and installing a new pump if the old one cannot be repaired or it is not economically viable.

Nuances of breakdowns depending on the brand of pump

There are many reasons for equipment failure: weather conditions, quality of equipment, compliance with safety regulations, handling of the device. In addition, products of the same brand have typical faults, which is important to consider when repairing and diagnosing equipment.

"Aquarius"

Aquarius pumps are distinguished by a long service life (up to 6 years), undemanding operating conditions (voltage fluctuations or excessively polluted water), and low noise level.

Despite its high quality, the equipment is prone to overheating, especially when working in shallow wells. This is a fairly common problem that can cause a lot of damage, and the cost of repair can be equal to half the cost of the device.

Grundfos

Grundfos models have a valve system and are equipped with motors with built-in thermal insulation - these parts fail. To replace or repair them, it is necessary to disassemble the housing.

"Baby"

The products of electric pumps from this company have a common feature - extraneous noise during operation when the device does not pump out liquid. This is a popular problem associated with the rupture of the axle that holds the armature and membrane.

"Gilex"

One of the typical failures of water pumps is engine leakage. Oil is topped up at a service center due to the complexity of repair work.

"Stream"

These pumps and pumps have a long service life and can work for more than 7 hours at a time. This is possible thanks to the use of branded parts and high-quality assembly. However, it is recommended to turn off the device every 2-3 hours to prevent overheating.

Marquis (Marcus)

The main problem with these pumps is impeller souring. This does not cause much damage to the device, but the device will only turn on after a slight blow to it or to the connected pipe. This can be solved by disassembling the unit and cleaning the impeller, which you can do yourself.