Classification of hand jigsaws for wood

Today, hand-held jigsaws for woodworking are often used at home, in schools for labor lessons, and in manufacturing companies.

It has several advantages over a hacksaw:

- When cut, the surface remains smoother, which is important in some cases.

- It is possible to quickly change the canvas if necessary.

- The teeth are small, so the safety of using this tool is much higher.

Externally, the tool consists of a handle made of wood or other material, a metal frame that holds the blade, as well as the cutting blade itself. When choosing, you need to pay attention to the size of the frame. It can be rectangular or pointed. It is necessary to understand how the tool will be used in order to choose the right one.

Expert opinion

Levin Dmitry Konstantinovich

Thus, the difference between manual jigsaws lies only in the size of the frame. However, you should not buy cheap Chinese models. They have a small margin of safety, so there is a high risk of damage to the frame during operation. It is better to purchase proven brands like Stayer Master, Fit, and so on.

Classification

Electric tabletop jigsaws can be classified according to different criteria.

Purpose of a jigsaw

According to the purpose of use, there are household (household), professional and industrial stationary jigsaws. Home and professional machines differ in their functionality. Household jigsaws are designed to perform simple household work and perform a minimum of functions. Their power does not exceed 500 watts, and the duration of continuous operation is about 30 minutes. To cut thick material, you will need a professional machine. The power of its engine is in the range of 750-1500 watts, which allows you to saw wood blanks with a greater thickness (up to 13 cm), as well as process any type of material. In addition, professional jigsaws are designed for a longer service life, and their operating time without interruption is about 3 hours. Industrial stationary jigsaws are powerful mechanisms that can operate for about 20 hours, withstanding enormous loads.

By food type

Based on the type of power supply, there are jigsaws that are connected to a stationary power supply (mains) and those that run on a battery (rechargeable). Corded jigsaws have significantly higher productivity. Tabletop machines are only networked. Battery-powered jigsaws can be used where there is no fixed power supply.

By the nature of the design

With a reciprocating or pendulum mechanism. Jigsaws with a pendulum stroke have higher productivity and a longer service life of the device. This mechanism ensures that the saw blade is deflected from the workpiece during cutting. As a result, sawing is carried out by moving the blade in two directions: vertical and horizontal.

With lower support. These jigsaws are the most widely used. The desktop consists of two parts: upper and lower. The cutting and cleaning mechanism is at the top, and at the bottom are the control module, electric motor, transmission device and switch. This device can be used to work with material of any size.

Double-slide jigsaw. It has an additional rail at the top of the worktable, which makes work easier when processing small-sized parts.

Jigsaws on suspension. Jigsaws of this type are not equipped with a solid frame, so they have great mobility. During processing, the saw blade moves, but the material being processed is motionless. The working mechanism is fixed to the ceiling, which allows you to work with materials of various sizes.

Jigsaw with degree scale. This stationary jigsaw is used to perform precise work using drawings.

There are also specialized jigsaws - devices adapted to work with a certain type of material, for example, for sawing foamed or fiber-based materials with a thickness of about 30 cm. There are also special types of jigsaws designed to perform specific operations. To cut small workpieces, electric mini jigsaws with small dimensions are used.

A band jigsaw is a multifunctional device with a powerful motor. It is used to obtain smooth and neat cuts in wood parts of different sizes. They are very easy to use and have high speed. To perform artistic cutting, both electric and manual jigsaws are used - this way you can achieve a more accurate reproduction of the design.

Classification of files

There are several types of saw blades that are designed for hand jigsaws.

| File name | Short description |

| Standard or Standard tooth | The teeth are the same size and equally directed from each other. Used to perform most tasks. |

| Reverse or Reverse Skip-tooth | Some of the teeth of this blade are directed upwards. This allows you to cut the wood while moving it backwards. Thus, there are almost no chips on the reverse side, making it easier to process the wood. |

| With a missing tooth or Skip tooth Blades | Such files are necessary to reduce the risk of the hand jigsaw jamming and to avoid excessive heating of the blade itself. Also, sawdust is better removed, resulting in a smoother surface. |

| With double teeth or Double tooth Blades | In this case, you can get an almost perfectly smooth cut. The file hardly heats up and removes sawdust well. |

The canvases also vary in length. There is a gradation by numbers from 2.0 to 12. The higher the number, the rougher the processing. That is, large files need to be purchased to work with thick bars. If you need to make complex patterns, then you should buy small files.

Depending on the type of work planned, you need to purchase one or another type of saw blade. They are quite strong, but can break if over-tensioned, so it is always worth having a reserve so that you can complete the job using a spare blade.

How to choose a jigsaw?

It’s good when there are senior comrades nearby who already have experience working with this tool - they will suggest a model that is suitable for the price, and recommend a set of replacement tools, or even directly help with choosing a model. The temptation to stick to drive versions, for example, cordless jigsaws, is great, but you should know that beginners should not use jigsaws. There are a number of reasons for this:

- Lack of practical skills often leads to rapid breakage of saw blades, because they do not take any bending loads well.

- Driven jigsaws are often purchased by craftsmen engaged in the mass production of shaped crafts from wood and plywood.

- It is impossible to cut a complex profile with a jigsaw.

- The primary skills of cutting wood with a hand jigsaw have already been recorded at the level of manual labor lessons at school, so mastering the tool will go much faster.

So, a manual jigsaw is a tool that is conducive to leisurely, thoughtful and quiet work somewhere in the country, or on the balcony - a good alternative to mechanized options.

The first step is to choose the right manual jigsaw. The selection criteria are usually:

- Frame shape: depending on its configuration, it will become clear what the longest cutting length is. There are jigsaws on sale whose frame length reaches 300 mm, which significantly expands the technological capabilities of the tool, but at the same time leads to an increase in its weight and dimensions. For home craftsmen who do not have experience in figure sawing, it is worth purchasing manual jigsaws with a frame length of no more than 150 mm.

- Frame material: when pressing on the bow, the frame should spring back, which is a good sign of quality - such a frame will not break when noticeable lateral loads are applied to a manual jigsaw for wood.

- Frame height: for reasons of strength, this parameter should not be more than three times the length, otherwise the rigidity of the jigsaw will decrease and the quality of the cutting line will be unsatisfactory.

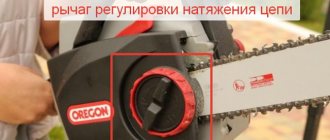

- Method of tensioning the saw blade: usually wing nuts of different lengths are used for this, which, in turn, depends on the diameter of the thread. As the diameter increases, the length of the nut antennae increases, which increases the convenience of tightening. The presence of holes on the antennae increases the accuracy of fixation. Nuts should not be cast, but stamped.

Assembly instructions

Not everyone knows how to properly assemble this tool, as electronic models are increasingly being used. They are highly effective, but cannot be used for some jobs. And the high cost also does not allow them to be purchased for teaching in schools.

Jigsaw assembly steps:

- First you need to purchase the necessary files. It is important that their length matches your model. Some people create their own hand jigsaws. Then you need to ensure that the distance between the ends of the frame is standard.

- Then you need to unscrew the clamps. These can be drums or regular nuts.

- Insert the file into the special groove and tighten the clamps.

Expert opinion

Levin Dmitry Konstantinovich

It is necessary to ensure that the file stands firmly in the tool. Do not pull it too hard, otherwise it can easily break. If a file breaks, you need to unscrew the clamp and remove it, then insert a new one.

Breakage of saw blades occurs for various reasons. This is usually too much tension. This can also happen due to overheating of the material or accidental external influence on it. The cost of the paintings is low, so everyone can afford to have several spare products.

Expert advice on choosing

What wood jigsaw do you use?

ManualElectro

When choosing a tool, you need to be guided by some rules, namely:

- Product weight . Since you have to hold it for quite a long time with one hand, you need to buy lightweight jigsaws. Otherwise, it will be difficult to work effectively.

- The anatomical handle is more expensive, but will allow you to work longer. It reduces the risk of hand spasms, making it more pleasant to work with.

- Frame strength is the main indicator. Models made of aluminum or iron are short-lived and fragile. They are easy to bend or break. It is much better to buy jigsaws where the frame is made of steel or titanium.

- Drum clamps are much more convenient, so it’s worth buying such models. This will speed up the process of changing blades.

The best manufacturers

Today, the main manufacturers of manual jigsaws include several companies.

Bison

This is a well-known Russian company that specializes in the production of various tools and consumables for them. Hand and power tools are popular among professionals due to their high reliability and excellent ergonomics. Many products are sold outside of Russia, which is a reason to trust this manufacturer. The cost is low, and there are no problems finding components. The Zubr company has many partners who sell jigsaws themselves and elements for them.

Stayer Master

This company offers a large number of hand tools. Its distinctive features are yellow and black colors. The cost is slightly higher than that of the Bison, but the quality is about the same level.

Fit

A fairly large manufacturer of tools, which today has more than 140 service centers and 160 territorial divisions in Russia. Thus, finding the necessary components for a jigsaw will not be a problem. The cost of the tools is average, the quality is moderate.

Matrix

It is considered a well-known large manufacturer that is present in several countries. The cost of the products is slightly higher than average, which allows the use of the highest quality materials in production. The jigsaws fully meet all requirements, and a large number of partner stores does not cause problems with finding components.

The price of an instrument is influenced by several factors: store, season, volume of goods purchased, manufacturer, model, and so on. All this must be taken into account when purchasing. Usually consultants are ready to help with the choice if there are doubts.

What rules will protect against injury?

The mechanism seems harmless and simple only at first glance.

When performing any work, you must follow basic safety rules to avoid injury. There is work to be done

Safety rules when working with a jigsaw

with a sharp, metal part that hurts painfully, and on occasion will reach the bone. Before work, you need to inspect the jigsaw, check that the handle is firmly and firmly secured. If the fastening is broken during creative actions, the handle will fall off, but the hand will continue to move until it comes into contact with the metal pin. Which won't bring anything good.

A workbench or metalworking table must also be equipped with all special devices for safe work. Sometimes even a fall from a simple, unstable chair can cause injury and bone fractures.

The master always tries to take a closer look at his creation. This should not be done during work processes. If you lower your head too low, shavings will get into your eyes.

When a person gets used to a jigsaw and overcomes all the difficult moments, working with it becomes a real passion, and crafts become a source of pride. But a hobby can be combined with a source of income. Manual labor has always been valued much more than mechanical stamping.

- Related Posts

- Rating of manual riveters

- How to choose a spray gun

- DIY metal clamp

« Previous entry