Polymer sewer hatches

The polymer sewer hatch is capable of coping with the tasks assigned to it at a high level. The design is considered practical at low cost, and at the same time looks attractive.

Polymer lids are popular among consumers along with their cast iron counterparts. In some cases, plastic products have advantages in application.

It is convenient to use it to equip sewer wells in a summer cottage.

Advantages and disadvantages of polymer hatches

In addition to the already mentioned advantage of being able to withstand loads, products made from polymers have a number of other positive qualities.

The list of advantages includes characteristics:

- Price;

- Long service life, reaching up to half a century;

- Light weight, ensuring ease of transportation to the installation site, and no need to involve special equipment or use additional tools for installation;

- The environmental friendliness of the finished product is ensured by the use of polymer and sand in the production process;

- High elasticity value, which significantly reduces fragility;

- Lack of metals in the composition, which makes the product unattractive to scrap metal collectors;

- Resistance to corrosion;

- The use of high-quality heat-resistant pigments, as well as special components, allows protection against fading in the sun and the negative effects of ultraviolet rays;

- The ability to purchase the product in any color, which significantly expands the number of places for use;

- Resistance to temperature changes.

The main disadvantage of polymer products lies in the fact that such products are not suitable for installation on highways. Heavy vehicles constantly move along such roads, and polymer elements will not be able to withstand a load exceeding the previously specified 20 tons.

External decor of hatches

Externally, the hatches look very beautiful. You can choose a product to suit every taste. Hatches are produced in different colors; you can match the hatch to your landscape design, or disguise the part. The hatches have different designs and marking fonts. According to GOST, the decor of the cover may differ at the request of the manufacturer, so you can find a large selection of different hatches on the market.

Thanks to the polymer material, all hatches can withstand high temperatures, they do not fade under the sun, the products do not dry out or delaminate. These properties affect the preservation of the appearance of products for many years.

Attention! The product will last at the dacha for about twenty years; if necessary, you can simply change the lid yourself, because the lid is light in weight.

Shape of polymer hatches

According to the produced form, polymers are:

- In the shape of a square;

- In the shape of a circle.

types

Since, according to the design features of the underground well, the shaft has a round shape, the lid for it will be the same. This type allows you to prevent various debris from entering the sewer system, causing an emergency situation. In addition, the circle-shaped lid will not fall into the shaft.

But the square analogue easily falls inward if there is significant physical impact on it.

Features of plastic hatches

Hatches are made to solve the same global problems, but there are many of their subtypes, which affects their design features, strength, cost and a number of other characteristics.

As a result, polymer products are beginning to be divided into varieties, which are influenced by: functional purpose and dimensions.

Functional application and dimensions

So, according to the profile GOST, there are the following types of polymer products:

- Lightweight, small-sized hatch, abbreviated as LM ;

- Light hatch or just L.

Most often, the first category of products is dealt with by the owners of private houses, plots on which communications are laid, and they are encountered by visitors to parks. The reason is that lightweight, compact small hatches are designed for pedestrian and green areas.

Domestic guidelines divide all hatches into many categories according to their ability to withstand loads. But varieties made from polymer materials meet the requirements of only the two lightest of them

They meet the requirements of load class A15, which means that they can withstand the weight of even a truck. But nevertheless, if these are one-time attacks, and not systemic ones, and over a long period of time.

According to GOST, any such hatch must:

- withstand at least 1500 kg load or 15 kN;

- have a diameter of 450 mm.

The seating depth in the shell should not be less than 20 mm; this is necessary in order to exclude the possibility of the hatch spontaneously leaving its seat under some unusual circumstances, for example, from a gust of strong wind.

The lightweight hatch is designed to perform the same tasks as its lightweight, compact counterpart. But it has a larger diameter - from 550 mm.

From various sources you can glean information that polymer hatches can withstand much greater loads than indicated above.

This may be true, but the profile GOST in the section devoted to the materials of hatch covers and bodies contains requirements stating that plastic can only be used for the manufacture of the above listed products.

The list of materials from which hatches can be made includes cast iron, the same metal, but with concrete inserts, and polymers. The father-in-law says nothing about sand bonded with plastic in GOST.

As a result, the use of any plastic hatches will not be entirely legal and may entail sanctions, especially if some kind of incident occurs because of them.

All plastic products are divided into 2 main types, which are lightweight, small-sized and simply lightweight hatches. Therefore, any polymer hatches can be used exclusively in park areas, the private sector and other places where there is no active traffic

The above is also true for polymer-sand products. As for composite covers, they, according to sellers and manufacturers, can withstand an impressive 25 tons of load.

And this statement is true. True, their cost is higher than their plastic counterparts.

Regardless of the variety, each lid should have a relief of 10-70% of the entire surface. In addition, all of them must fit freely into the housings. In this case, the gap between both parts of the structure should not exceed 3 mm.

And the hatches must fit tightly to the supporting parts of their hulls. So the tolerance should not exceed 2 mm.

Nuances of marking polymer hatches

Each polymer product can belong not only to the category of hatches, but also to other products. For example, to be a storm drain, a repair insert.

And to avoid any misuse that is fraught with negative consequences, each such product must be marked by the manufacturer.

Polymer hatches are intended for different purposes and, to avoid confusion, GOST requires them to be marked. Thus, a product manufactured for industrial or domestic sewerage must be designated with the letter “K”

That is, according to the current GOST, the word is indicated on cases and covers:

- "Luke";

- "rain water inlet";

- "insert".

The manufacturer's mark must confirm such information. It is also important that you cannot mix parts for different purposes.

In addition, each hatch must have a date of manufacture. Since the polymer has a shelf life (usually 20 years), after which it begins to noticeably lose its qualities, and the accompanying documents are unlikely to be preserved during this time, the GOST requirements for this moment are quite stringent.

Therefore, without a stamp with the month and year of manufacture, the hatch will be non-standard.

Shape and dimensions of covers

In addition, the division of plastic products can be carried out according to a number of other characteristics.

Which include:

- form;

- dimensions;

- availability of additional equipment;

- decorative qualities.

So on sale you can find plastic equipment of different shapes - round, square, rectangular.

Although the industry is ready to supply anything, it should be remembered that according to the rules set out in GOST, only round hatches are considered standard.

The reason is that they are the safest. So, this form will not allow the product to fall down, and not in one position; it can better withstand some types of load.

At points of sale you can find polymer products of various shapes and sizes. But GOST recognizes only the round variety of hatches due to the greatest safety. And so that specialists can carry out all the required installation operations, the diameter of the cover must be at least 45 cm, and even better if 55 cm, as is the case with a light hatch

All other subspecies are not prohibited, but it is advisable to use them exclusively in places where they cannot lead to injury or other troubles.

The dimensions of round plastic hatches for sewer and other wells are listed in GOST (they are listed above). In all other cases, manufacturers act at their own discretion, since the dimensions of square and other products are not regulated.

But the practice has developed when the length of the sides ranges from 30 cm to a meter, with the pitch usually being 50 mm.

Availability of additional equipment

Polymer products can be standard or equipped with various devices to solve certain problems.

So additional equipment may include:

- constipations that prevent hatches from being blown away by the wind and being displaced by car wheels;

- locks that exclude vandalism and illegal actions, for example, theft.

In addition, hatches are often equipped with openings for dismantling, preventing the accumulation of gases and other equipment.

Modern polymer hatches are often equipped with additional equipment, such as locks, designed to protect property from theft or an unfortunate combination of circumstances in the form of a strong gust of wind that can tear the lid out of its seat

Decorative qualities of products

Manufacturers, taking into account the tastes of different categories of consumers, supply the market with products that have high aesthetic qualities.

Polymer hatches come in a variety of colors, allowing you to choose the right product for almost any occasion. And all this for a very reasonable cost, especially in comparison with their cast iron counterparts

Which provide:

- Color selection . Today, a plastic cover of any sewer or other type of manhole can shine with almost all the colors of the rainbow. This allows you to present such a product in a favorable light or disguise it.

- Corrugation pattern, font type . GOST allows manufacturers to choose the design of the manhole cover themselves, which, together with the color, gives a positive effect and variety.

Modern polymers are not affected by temperature changes, do not fade, and do not delaminate. This significantly improves the decorative qualities of the lids and maintains their appearance in their original condition for several decades.

Thus, a practical cover made of polymer material will serve its purpose for decades, covering a manhole or a plastic sewer well, or another well in a country house in which utilities are located, and after 20 years you can buy a new one and, due to its low weight, can be easily replaced her with her own hands.

Specifications

When choosing a polymer lid, you should definitely pay attention to each technical characteristic of such a product. The main features are considered to be:

- Weight (this parameter is especially important);

- Type;

- Rated load.

It is important to have an idea of the permissible load class of the product, because the maximum value of the load that the product can withstand without damage depends on this parameter. Also, this value influences the choice of installation location. For example, a cover belonging to type “L” is a lightweight product that can withstand a maximum load of one and a half tons. Accordingly, such covers are not allowed for installation on the roadway. To close the drainage system shafts in courtyard driveways or parking lots, medium and heavy structures are used. Such products can easily withstand loads ranging from 15 to 25 tons.

You may also like: Sewer well - types and design

Classification

Sewer hatches have a corrugated surface that prevents slipping and provides good traction with shoe soles and car tires. The weight of structures mounted on the roadway must be at least 60 kilograms to prevent spontaneous opening when vehicles collide with them.

By purpose

According to their purpose, sewer manholes are divided into the following groups:

- Inspection rooms are designed to monitor the condition of engineering systems and pipelines. They are installed at turns, branches, and in places where pipeline diameters or slopes change.

- Storage tanks are used for access to storage tanks when pumping out sewage.

- Stormwater. Installed on rainwater wells.

- Inspection hatches are suitable for servicing internal water supply and sewerage systems. They are mainly produced in rectangular shape. They can be installed in bathrooms or bathrooms in a wall or box, made of plasterboard or siding.

All hatches are designed to protect wells for various purposes. Ensure the safe presence of people, animals and vehicles in areas where utility lines pass.

By shape

The most popular shape of hatches is round. This design looks compact and is easy to use. Has no sharp corners. If necessary, the heavy round lid can be rolled for ease of transportation.

Square or rectangular hatches are less common. They are usually installed on storm sewer wells. Available in one side sizes from 300 to 800 mm.

The production of square hatches is not economically profitable, since more raw materials are spent on them than on round hatches of similar sizes.

The rectangular cover is not convenient for transportation, installation or maintenance. It may fall into a well if you accidentally move it diagonally.

2. According to their design, hatches are:

- standard parameters;

- with locking mechanisms that prevent entry into the well and theft of products;

- with recesses in the lid for the possibility of weighting using concrete or polymer fillers;

- with devices built into the lid for lifting them using lifting equipment.

By application

Utility hatches according to intended use are divided into two main groups:

- Hatches installed on expressways, airfields, transport terminals and production sites, parking areas for tracked vehicles and heavy vehicles. Heavy T-type cast iron products weighing 80-150 kilograms are suitable for these purposes.

- Well covers installed on sidewalks, in squares and parks, city yards and private households are marked with the letter “L”. Lightweight hatches are made of polymer, rubber and composite materials and weigh from 15 to 60 kilograms.

Heavy cast iron hatches are much more expensive than their light counterparts.

Classification by type of construction

As noted above, sewer manholes are classified according to the permissible load. The list of product types is as follows (data on how much the sewer hatch weighs is also indicated here).

| Construction type | Installation location | Permissible load | Product weight |

| Garden (type L) | Pedestrian sidewalks; Green areas. | 1500 kg. | 25 kg. |

| Light (type L) | Car parking; green areas; pedestrian sidewalks. | 3000 kg. | 45 kg. |

| Medium (type C) | City parks; Vehicle parking. | 7500 kg. | 52 kg. |

| Heavy (type T) | Roads with moderate vehicle traffic | 15000 kg. | 57 kg. |

| Heavy trunk (type TM) | Roads with heavy traffic | 25000 kg. | 60 kg. |

It is worth noting that the weight of a cast iron sewer manhole will be significantly greater than the weight of the polymer product.

Types of material for manufacturing hatches, their purpose

Hatches may have different shapes, colors, weights, but they are all designed,

to solve the following problems:

1.ensure the safe movement of vehicles and pedestrians on the roads.

2. protect communication networks and wells from blockages and mechanical damage.

3.Prevent theft of communication parts.

Several types of polyethylene are used to make hatches. This is high-density polyethylene of a secondary type, or low-density polyethylene with modified additives inside. For casting products, the method of pressing elements that are heated to three hundred degrees above zero is suitable.

Attention! Modern covers made of polymer material are considered lightweight, comfortable, and durable.

Dimensions

According to the given classifications by shape and type of construction, polymer sewer manhole sizes are:

- Lightweight and able to withstand a maximum load of up to one ton, the body size is 720x60 and the dimensions of the lid itself are 600x25.

- Lightweight products that can withstand a load of up to two tons have a body size of 750x90. The lid size in this case is 690x55.

- Hatches (light), withstanding a load of up to two tons and produced in the shape of a square, are 640x640 in the body. The lid itself measures 600x600.

- Lightweight products that can withstand loads of up to five tons: body - 750x90, cover - 690x55.

- Medium, withstanding a load of up to 15 tons: body - 750x100, cover - 690x50.

- The class of heavy products with a maximum permissible load of 25 tons has body dimensions of 800x110, and covers of 700x70.

The cast iron sewer hatch dimensions will be identical to the above values.

It is important to understand that light covers can be mounted at a depth of up to 45 millimeters, medium ones up to 60 millimeters, and for heavy ones this value is up to 85 millimeters.

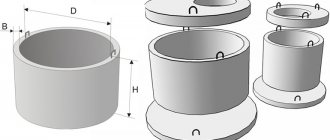

According to current standards, the diameter of the sewer manhole depends on the shape of the product. Thus, the diameter of a round sewer manhole is 1.88 meters. Of course, the diameter of the manhole cover will be an order of magnitude smaller.

Installation features

The technology for installing a sewer hatch consists of the following steps:

- Installation of the support ring on the base - using mortar or anchors - depending on the material of the hatch.

- Holding for a specified period of time to harden the concrete mass.

- Installation of the hatch directly.

- Construction of a blind area to remove atmospheric moisture.

- Lubricating contacting surfaces with lithol - to protect against freezing.

- Checking for proper operation - opening and closing, as well as testing the locking mechanism, if any.

Important! The type of material and size of the manhole have a direct impact on the installation procedure and quality. The larger and heavier the product, the more difficult and precise it needs to be installed. Incorrect installation will cause the heavy cover to warp. Because of this, it will be more exposed to destructive factors - weight loads during a collision, weather conditions, etc., which will significantly shorten its service life. In addition, it will no longer be able to ensure the tightness of the underground tank.

Installation Features

Installation of a polymer sewer cover is identical to the list of works that are performed when installing a cast iron product. The main difference lies in how much the manhole cover weighs. Naturally, metal is much heavier than plastic. This means that you won’t have to hire help to install the polymer structure.

When the required hatch option has been selected, you can begin to work:

- First of all, the ring is installed on the cover of the sewer shaft. This part is very often called the shell. Here it is important to check in advance that a support ring is installed between the shaft cover and the hatch. This element allows you to reduce the load directly on the slab by three times. Instead of a factory part, you can use a masonry installation. However, the brick crumbles over time and the lid may fail. Here it is important to remember how much a sewer hatch weighs in order to choose the right method for arranging the support.

- To achieve the ideal installation of the ring, which serves to distribute the load, it is worth resorting to the help of a building level. It is strictly forbidden to mount the structure at an angle, because such actions will lead to subsidence and deformation.

- Next, the ring is filled with concrete mortar around the entire perimeter of the outer side.

- For the last stage of work, it is necessary to wait until the concrete mixture has completely hardened.

- The installation is carried out directly into the ring. In this case, it is quite important to treat the working surface with grease or lithol. These substances are capable of ensuring 100% opening of the well even at negative temperatures outside the window.

Design, features and purpose

A sewer hatch is a monolithic or stamped product, usually round in shape, installed on a special ring-shaped neck in the upper part of a septic tank, pit or well. Depending on the device, it can be removable or folding - with hinges and a lock. In addition, the hatch structure may have two covers - one on top of the other. The inner one is equipped with a locking mechanism, the upper one performs the task of protection.

In general, such a hatch performs the following number of functions:

- Prevents accidents caused by people or animals falling into holes in the ground.

- Protects the container from various objects entering from the outside and subsequent clogging.

- Eliminates the spread of sewer odors in the surrounding area.

- Participates as an element of decoration of the exterior of the yard.

- Provides quick and reliable access when inspecting, cleaning and maintaining an underground tank.

- Creates reliable conditions for the passage of pedestrians and the passage of ground transport.

Strength of plastic hatch Source ytimg.com

Note! Before purchasing and installing a cover for a septic tank, you need to find out how much a sewer hatch weighs and what characteristics it affects. The further nature of the product’s operation will largely depend on this parameter. First of all, the heavier the product, the thicker and stronger it is, and the less likely it is that it will break when hit by a car and a stranger can easily open it or even steal it. For example, an ordinary cast iron hatch weighs about 100 kg.

Materials for the manufacture of sewer covers, product sizes

The design of all hatches is similar - a support ring (shell), which is directly mounted on the neck of the inspection shaft, and a cover that performs protective functions.

The purpose of the material, the degree of strength and tightness, and the cost of the hatch depend on the type of material:

- Cast iron. The most durable and durable, but also the most expensive material. Products made from it are installed in areas with increased load (roads, access roads), the service life is up to 100 years.

- Polymer. The optimal option in terms of performance characteristics and cost for installation in pedestrian areas, green areas, and private households.

- Concrete. They are rarely used, as a rule, in the case of non-standard sizes of the neck of the sewer well. The main disadvantages are low tightness and large mass.

Most hatches are made with a round cross-section; rectangular (square) products are also produced for the corresponding shafts. It is rare to find triangular, oval and other exotic shapes. Round models are easier to install, practically do not sag relative to the initial installation level, and they are completely prevented from falling to the bottom of the shaft.

Sewage hatches are available in a wide range of sizes, which makes it easy to choose the right product:

- cast iron round – from 380 to 810 mm;

- polymer round – from 315 to 1000 mm;

- square – the length of one edge is from 300 mm to 800 mm in increments of 50 mm.

Technical characteristics of hatches

Advantages and disadvantages

Advantages:

- low price, much cheaper than cast iron;

- weight, have a weight in the range of 10−50 kg, which reduces transportation costs;

- do not corrode, do not break;

- stability, fireproof, do not fade in the sun, can withstand temperature changes from -50 to +50 °C, they can be used in the workshops of chemical enterprises;

- long service life, they can be used for 50 years or more;

- interchangeable, plastic covers are used in cases made of metal or cast iron;

- environmentally friendly and have an aesthetic appearance.

Disadvantage: low loads. Plastic hatches are not used for heavy loads.

Installation

Installation of different types of polymer products also has its own characteristics. Thus, a lightweight polymer-sand hatch is mounted to a depth of 25-45 mm, and a medium-heavy structure – to a depth of 60 mm. Heavy hatches are deepened the most - they are mounted 85 mm below ground level.

The installation process of a polymer structure begins with the installation of a ring (on a concrete floor). It is poured with cement mortar and left until completely dry. Next, the master installs the hatch cover itself.

A blind area is built around the well (with a slight slope). It is needed to prevent moisture from penetrating into the collector. The width of the blind area usually varies from 1 to 1.5 meters. You can significantly simplify the process of installing a hatch by purchasing a product with special grooves for fastenings.