Loading…

Loading…

Raise water from a well or well using a pump. The Aquarius pump is characterized by users as a reliable and easy-to-use device. Manufactured under the Aquarius brand, the pumps have a European Quality certificate and are inexpensive. The equipment is completed with domestic parts, with the exception of the thermal relay. The block is supplied from Germany from the Thermik company.

Scope of application

The main purpose of this device is to provide water supply to houses and summer cottages with water rising from a depth of up to 100 meters at a speed of 0.32 - 1.6 liters per second. Submersible well pumps Aquarius are designed for domestic use, including:

- Delivery of water from wells of various types (drilled into sand and limestone) with a diameter of 110 mm.

- Providing water to residential buildings and country houses without a centralized water supply.

- Irrigation of a personal plot from wells, reservoirs and other open reservoirs.

Important: The Aquarius pump is not suitable for pumping out contaminated liquids, as well as alkalis, acids and solutions, and is not intended for pumping out water mixed with sand and other substances.

Device and mechanism of action

The Aquarius well pump is a practical, productive and at the same time quite simple to install and maintain unit, characterized by reliability and durability in operation.

Its design includes the following elements:

— pumping part of a multistage type;

- single-phase electric motor.

Under the device body there is a drive shaft with blades, impellers and drive-type rings. All parts are fixed using a cap with internal threads.

When the pump starts, the impellers begin to move, creating a centrifugal force that pumps water to fill the inside of the unit.

The motor part of the pump includes a stator, a rotor and two ball bearings that move in an oily environment. The engine operation is controlled by the Thermik system, which protects it from overheating when operating under critical load conditions.

The unit is supplied with a submersible cord for fastening

The material of the unit body is stainless steel, the impeller is noryl. There is a capacitor box on the power cord.

Benefits and Features

According to users who have tested the Aquarius submersible pump, the technical characteristics of which can be called quite worthy and serious, in their country houses and garden plots, its main advantages include:

Deep pump Aquarius

- Significant working life of all units and elements of the unit and excellent quality of its assembly.

- Good maintainability. Any of its parts that fail can be easily replaced, restoring its functionality in the shortest possible time and without unnecessary financial costs.

- Low power consumption.

- Unpretentiousness and low demands on operating conditions.

- Compact and light weight. Thanks to these qualities, the pump is easy and convenient to operate without much effort.

- Reliability of the electrical part of the device. This allows the deep pump for the Aquarius well to operate without failures or shutdowns even with small voltage drops.

- Affordable price.

- The presence of a long cable, as well as a cord for hanging the device in wells and boreholes.

In addition, one can note the increased performance of “Aquarius”, which distinguishes it favorably from other popular brands, such as “Rucheek” or “Malysh”. Unlike the latter, it can be operated without interruptions in operation, while the operating time of the “Kid” should not exceed two hours.

The permissible temperature of the working environment is no more than +35 ⁰С. Work in winter is allowed.

Submersible pump Aquarius - technical specifications

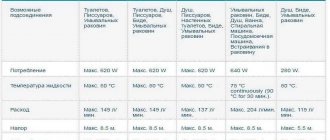

Let's look at the technical characteristics of Aquarius deep-well pumps for wells. The following data will help you get an objective impression of the capabilities of Aquarius pumps:

- Materials used: the pump body and other metal parts in contact with water are made of stainless steel and brass. The impellers and membranes are made of technopolymer, which is approved for contact with food.

- Maximum pressure: various models of Aquarius pumps can develop a pressure from 27 to 150 meters of water column (mwst). It should be taken into account that the maximum head of vibration pumps does not exceed 60 m.

- Maximum performance: the lowest-power model (vibration unit) is capable of pumping 0.4 cubic meters. m of liquid per hour (6 – 7 l/min). Centrifugal pumps have the highest productivity - up to 12 cubic meters. m/h (200 l/min).

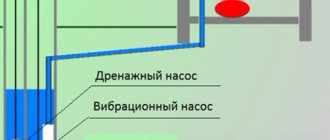

- Caliber: household centrifugal pumps have a housing with a diameter of 105 mm. This means that they can be lowered into a well with a diameter of 120 mm and above. Vibrating models are more compact, their diameter is only 86 mm. Accordingly, the minimum borehole diameter for such devices is already 100 mm.

- Maximum immersion depth: for centrifugal pumps is 20 m, for vibration pumps – 5 m. Resource: as indicated by the manufacturer, the working life of Aquarius pumps is 20 thousand hours. When used under normal conditions (autonomous water supply to a cottage with 5 residents), the service life of the unit will be about 15 years.

- Power consumption: varies from 0.4 to 1.9 kW for different models.

- Built-in automation: there is overheating protection manufactured by the German company Thermik and a soft start function.

- Weight: the most compact and low-power pump weighs 4 kg, the most productive – 25 kg.

Self-priming pumps are either centrifugal or vortex. We will consider the operating principle of a vortex pump, as well as the comparative characteristics of vortex and centrifugal pumps in the next topic.

We will discuss the features of choosing a well pump for a country house in this article.

Detailed information about the Malysh pump is presented here: https://aquacomm.ru/vodosnabzenie/zagorodnyie-doma-v/avtonomnoe-vodosnabzhenie/istochniki/nasos-malyish-technich-harakteristiki.html. Technical characteristics, device, maintenance and possible malfunctions.

The lineup

In the model range of pumps produced by Kharkovskaya, there are several varieties of these devices of varying power, including:

— Deep well pumps BTsPE series.

These include (differ in performance):

- Pumps Aquarius BCPE 0.32.

- Pumps Aquarius BCPE 0.5.

- Pumps Aquarius BTsPE 1,2.

- Pumps Aquarius BCPE 1.6.

Types and technical characteristics of Aquarius pumps of the BCPE 0.5 series.

The price for these pumps for Aquarius wells will be from 7,100 to 16,200 rubles, depending on the model.

— Surface type pumps BC series.

— Drainage pumps BCPD.

Selecting a model based on specific characteristics

Let's consider all the stages of choosing a brand pump. These recommendations are general in nature; you can find more detailed information in the technical data sheet and installation instructions.

By clarifying the technical data of the well and comparing the characteristics of different pumps, you can choose the model that is best suited for your site

Before purchasing, it is important to consider all the characteristics necessary to make the right choice.

Namely:

- well diameter;

- well flow rate;

- water levels in the well (static and dynamic);

- estimated water consumption;

- distance from source to home;

- pressure in the hydraulic accumulator (damper tank).

The diameter of the well is very easy to determine - it is indicated in the technical passport, which is issued by the company that drills and installs equipment. Most likely, the diameter is standard, that is, it has dimensions of 100 mm, 133 mm, 152 mm. Aquarius pumps are best installed in wells with a cross-section of more than 100 mm.

The flow rate is also indicated in the passport, thanks to this parameter it is easy to select a pump based on performance. It is important that the pump parameters do not exceed the figures specified in the documents.

Let's assume that the flow rate of the source is 3 m³/h. This is a fairly low figure, which means that there is no need to purchase models from the BTsPE 1.2 series (or higher performance), BTsPE 0.5 is sufficient.

When operating more powerful equipment, the volume of water in the source will not have time to recover, drying will occur and the device will automatically turn off.

The water level must be known in order to correctly determine the installation depth of the pump. Usually the distance to the water surface and from the surface to the bottom is indicated in the passport, but you need to remember a couple of nuances.

The first concerns the installation features of a submersible pump - it is lowered 4-5 m below the surface. The second concerns the variability of the water level.

During the warm period, the level usually decreases, and the difference with the initial value can be up to 4-5 m. It turns out that for installation you need to know the minimum level.

Even at the planning stage of the water supply system, it is necessary to draw up a diagram of the house indicating all possible water collection points - the data will be useful both for installing the wiring and for selecting a pump

To calculate the total water consumption, several factors must be taken into account:

- number of permanent residents;

- number of points of use inside the house (bathroom, kitchen, shower);

- the presence of distribution points outside the house (watering the garden, a tap in the summer kitchen, a tap in the bathhouse), etc.

On average, if you do not take into account additional facilities, the daily consumption per person is 200 liters.

The distance between the water source and the house is necessary to calculate the additional load on the pump. Standard calculation: 10 m of horizontally laid pipes equals 1 m of vertically laid pipes (both – 0.1 atmosphere).

The pressure of the damper tank affects the shutdown threshold. Let’s assume that if you have a volumetric tank of 300 liters installed, then to turn it off you need a pressure of 3.5 atmospheres (converted to vertical meters - 35).

Image gallery

Photo from

Installing a pump in a well

Pump automation

Well caisson with deep pump

Shallow well head

Installation and operation rules

Before lowering the device into a well intended for water supply, it is prepared. For this:

- Its pressure pipeline is connected. In this case, it is necessary to take into account the depth at which the pump will be located and the future nature of its operation. For example, when working in conjunction with a hydraulic accumulator, for a stationary installation, you need to use a plastic pipe or a regular watering hose if the pump will be used only for irrigation purposes.

- Install a check valve. Do this in one of the following ways:

- Install it on the pipeline, retreating approximately 1 m from the outlet pipe.

- By mounting it directly into the pipe.

Useful information: When purchasing a check valve, pay attention to models with a brass seat, which are characterized by better quality and reliability.

- Secure the nylon or steel cable by passing it through the special holes on the pump body.

- Carefully lower the pump into the well and secure it at the desired depth using a cable. This must be done as carefully as possible, making sure that its cable and pressure hose are not too tight. After this, the pump can be started.

Important: Lowering and lifting the device by the cable is strictly prohibited!

Connection diagram for the Aquarius pump

Despite the fact that pumps for Aquarius wells do not require special care and maintenance, it must be removed from the well and inspected once every two years , paying attention to the following points:

- Rotation of the motor axis. It should be soft and loose.

- Condition of pump seals and bearings. If necessary, they are replaced with new ones.

- Oil level.

- Motor winding condition. There should be no damage or signs of overheating.

Read about barrel, surface and submersible pumps for watering your garden in a separate article. In it you will also find information about popular models.

Many people use the Malysh pump. If you are faced with a breakdown, you may find our article about repairing it useful.

And how the operation of the pressure switch that regulates the operation of the pump works is described in this material https://okanalizacii.ru/vodosnabzhenie/nasosy-i-stancii/rele-davleniya-vody-dlya-nasosa.html

Repair and cleaning

One of the reasons why the pump stops rotating can be damage or clogging of its impellers. A small blockage can be removed on your own. This is done as follows:

- The protective mesh is removed. On new generation models, to do this, you need to open the clip that secures the mesh, hooking it with a screwdriver and pressing it in the middle. In older models, the mesh is held on by two unscrewing screws.

- On wide pumps, it is necessary to additionally remove the cable channel, which looks like a small metal groove.

- We separate the engine from its pumping part. To do this, unscrew the four bolts that secure it and remove the plastic couplings connecting the engine and the pump part.

- We lay out the disassembled structure on a flat surface.

- Using a 12mm socket or socket wrench, rotate the pump shaft, holding its upper part with your hand. When it moves, we rinse the pump part with a stream of water, trying to remove any debris that has clogged the device. If this attempt is successful and the shaft moves again without difficulty, we flush the pump and reassemble it, proceeding in the reverse order.

If the impellers are damaged, it is necessary to disassemble the pumping part of the unit. However, due to the complexity of this operation, it must be performed in specialized services, where worn parts will be replaced professionally and quickly.

In case of self-repair of the device, the following operations are performed:

- The pump housing is compressed with force from the top and bottom sides, with emphasis on the brass element located in its lower part.

- Using narrow-nose pliers, carefully remove the retaining ring installed in a special recess, which should expand after compressing the pump housing.

- The impellers and thrust cover with bearing are removed one by one.

- After the jam is removed, the pump is reassembled. (Sequence of actions: in reverse order).

When starting this work, you need to understand that it will be very difficult to carry out these manipulations yourself due to the need to use special equipment (press).

Thus, we can conclude that Aquarius deep pumps for wells, the technical characteristics and cost of which have made them very popular among consumers, are truly effective and convenient for meeting household needs. Subject to the rules of operation and regular and timely maintenance, they will serve for a long time without requiring the cost of repairs and reinstallation.

How to repair an Aquarius pump with your own hands is shown in the video.

Types of Aquarius pumps

The developer and manufacturer of Aquarius pumps is (Kharkov, Ukraine).

The device has a cylindrical body divided into two parts: the first contains an electric drive, the second contains a working chamber with a discharge mechanism.

The latter comes in three types:

- Centrifugal: Aquarius centrifugal pumps are multistage, that is, their discharge mechanism consists of not one, but several impellers (impellers). The pumped liquid sequentially passes through all stages, acquiring additional energy at each of them. As a result, it is possible to achieve a high pressure, which is equal to the sum of the pressures of each stage. An electric motor is used to drive a centrifugal pump.

- Vortex: Aquarius pumps of this type, with a significantly smaller size and power, allow you to pump water with the same pressure as centrifugal multistage ones. But due to their low efficiency (on average, only 34%), such units are not used in everyday life; their purpose is to solve specific problems in industry.

- Vibrating: pumps of this group differ from centrifugal pumps in their simpler design and smaller size. The engine and pump compartments are separated by an elastic membrane, which, in essence, is a discharge mechanism. The drive is an electromagnet, which, through an alternating magnetic field, causes the rod connected to the membrane to oscillate. Due to the movement of the latter, the volume of the working chamber either increases (liquid is sucked in) or decreases (liquid enters the discharge pipeline). At the beginning of the cycle, the valve of the suction pipe opens and the discharge pipe closes; When pumping, the position of the valves changes to the opposite.

The disadvantages of vibration pumps are low pressure, as well as a strong impact on the bottom and walls of the well, as a result of which the dirt and sand present on them form a cloudy suspension.

All Aquarius well pumps, regardless of type, are suspended with the engine compartment down.