A pump is a type of hydraulic machine that moves fluid by suction and discharge using kinetic or potential energy. The pump is necessary for use in fire-fighting equipment, for draining liquids in residential areas, for supplying fuel and many other purposes. There are different types and types of pumps depending on the area of application, design, and principle of operation. When using pumps for various purposes, you need to know what types there are and how they differ.

Separation of pumps by application

The scope of application of pumps is very wide. Today they are used in almost all areas: construction, industry, mining, and in the development of fire extinguishing systems. Various types of pumps are also used on a small scale, and their applications range from domestic use for irrigation, to installation in water supply and heat transfer systems. Depending on the scope of application, types and types of pumps are distinguished. Below are descriptions, their characteristics and varieties.

Pump types

By purpose:

- submersible pumps;

- surface pumps.

By energy supply method:

- electric pumps;

- liquid fuel pumps.

Depending on the type of water:

- for clean water;

- for water of medium degree of contamination;

- for highly contaminated water.

Types of household pumps and their scope

By area of application, pumps are divided into household and industrial. Household pumps come in surface and submersible types. For domestic use, the first type is most often used. Surface pumps are used for autonomous water supply to private houses, watering the surrounding area, pumping water from basements and ponds, increasing pressure during autonomous water supply to a private house.

There are four types of household pumps:

- garden;

- pumping stations;

- drainage;

- deep.

Description and characteristics of pumps

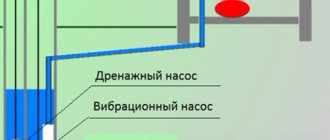

There are 2 types of pumps: surface and submersible. Surface pumps are installed at ground level; a hose is lowered into a well or hole. If the pump is equipped with an automatic on-off system when water is supplied, then it is called a station. Submersible pumps include: drainage pumps, sewage pumps, circulation pumps, pumps installed in wells and boreholes.

Types of pumps by design

All pumps differ in design. They can be vertical and horizontal. All pumps differ in their assembly; depending on the model, they may use vanes, blades, or screws.

Pumping equipment parameters

When choosing water pumps, you need to determine the purpose - for what needs the equipment will be used - and what power is needed. Let's look at the main characteristics of electric water pumps.

Performance, water pressure

Based on the performance and pressure at which the water is supplied, the efficiency of the pump can be determined. The productivity of the device is the entire water mass pumped using the equipment. Water pressure is the height to which a volume of water is or can be supplied. Indicators directly depend on pressure.

To calculate what characteristics a pump should have, you need to determine the size of the area where it will be operated, household needs, groundwater quality, and others.

- If you choose equipment for construction or excavation work, you need a pump with a capacity of 1 - 2 m³/hour.

- For the household needs of a family of 3 - 5 people, 1-2 m³/hour is enough.

Characteristics of the water supply

This is an important parameter that determines the efficiency of the entire water supply system of a private home. Particularly relevant for 2 and 3-story buildings. When choosing a water supply system, several parameters are taken into account: its length, material of production, diameter, valves, tees, and rotary parts.

Idle control

This function allows you to automatically shut down if there is no water. This way the equipment will last longer and will not break down prematurely.

Classification by operating principle - by type of working chamber

There are different types of pumps based on their operating principle and design. They are divided into positive displacement and dynamic pumps.

- Positive displacement pumps are those in which liquid is moved by changing the volume of a chamber containing liquid under the influence of potential energy.

- Dynamic pumps are mechanisms in which fluid moves along with a chamber under the influence of kinetic energy.

Dynamic pumps, in turn, are divided into vane and jet pumps.

Separately, there are types of volumetric pumps based on the principle of operation, depending on the design:

- Rotary pumps are a solid body, with a certain number of blades/blades driven by the rotor.

- Gear pumps are the simplest type of mechanism, consisting of interlocking gears that move under a forced change in the cavity between the gears.

- Impeller - blades are enclosed in an eccentric body, which squeeze out liquid when rotating.

- Cam pumps are pumps, the housing of which contains 2 rotors, which, when rotating, pump liquids of varying degrees of viscosity.

- Peristaltic - the body includes an elastic sleeve in which the liquid is located. When additional rollers rotate, the liquid moves along the sleeve.

- Screw pumps are pumps consisting of a rotor and a stator. When the rotor rotates, the liquid begins to move along the axis of the pump.

There is also a division of dynamic pumps according to the operating principle:

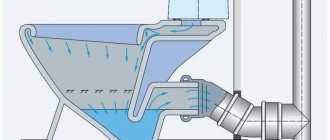

- Centrifugal - includes an impeller with liquid inside; when the wheel rotates, the particles acquire kinetic energy, and centrifugal force begins to act, under the influence of which the liquid passes into the motor housing.

- Vortex pumps are similar in principle to centrifugal pumps, but are smaller in size and have lower efficiency.

- Jet - based on the transition of potential energy into kinetic energy.

The vortex pump type is the most commonly used due to its ease of installation. For domestic needs, such a unit is installed in country houses to ensure water supply. Water circulation is ensured by liquid supplied to the blades located in the pump housing. The key element here is the wheel, to which water is supplied through the inlet. This type of pump is also used for wells, as it creates high pressure. They have the ability of self-priming and can process not only liquid, but a gas-water mixture.

Centrifugal pumps are often used for domestic and industrial purposes:

- for organizing water supply systems at industrial enterprises;

- for organizing water supply systems for residential areas;

- for irrigation systems.

These pumps are easy to use, as the operating principle is quite simple. The main load is taken by the wheel with blades, to which the liquid is supplied, but if there is no liquid inside, the pump will fail. Most often such pumps are surface pumps. Due to this, their productivity decreases. Centrifugal-type submersible pumps require high-quality casing tightness.

Selection tips, criteria

In outline

When purchasing a water pump, it is necessary to take into account its scope, service life, whether the product has a warranty, cost, quality, and manufacturer.

First, you need to decide what category of pump is required - household or industrial. Then, a device is selected that meets all the requirements and is most suitable for work in a particular area.

It is not advisable to purchase a device from dubious sellers, as there is a risk of running into scammers. Also, it is important to pay attention to user reviews of a particular pump: if the product gets mostly negative reviews, you should think about purchasing another one.

Criterias of choice

Price. This is the first thing that most people pay attention to when purchasing a particular product. First of all, you need to analyze the market: find the average price of the required pump and, starting from it, look for offers from sellers. You cannot choose a device based on too low a cost: such a pump will most likely not last long, or will not be of the same quality as the price.

Quality. In order to understand how convenient a particular product is to use, it is best to study reviews of real users about it - there are special sites for this, reviews are also left in online stores, etc.

Device power. This criterion determines how much water is pumped out in a certain unit of time (minute). The higher the power, the more energy the device consumes, but the faster the work process occurs. For household needs, a power of 1 kW is sufficient.

Service life, warranty - all this is clarified immediately before purchasing a specific pump from the seller. If the purchased device turns out to be defective or inoperative, it is returned back to the distributor and either the amount paid for it is refunded, or the product must be exchanged for a new one that works.

When it comes to drainage pumps, the permissible size of solid particles in the water is also taken into account. If this criterion does not meet the actual operating conditions, the pump will break down.

Scope of work. If the device is needed to carry out work in a country house, suburban area, etc., first of all you should pay attention to household pumps: they have a suitable price and perform the appropriate functions.

Outlet pipe diameter. Subsequently, it is also necessary to additionally purchase a hose of suitable size.

The maximum depth to which the pump can be immersed in water (if we are talking about submersible, drainage and other pumps). This parameter depends on the purpose for which the device is purchased.

Classification by purpose

Depending on their intended purpose, various types of pumps are used for industrial purposes (in the food, chemical, paper industries). For domestic purposes, pumps are used in construction, pumping water from wells and wells, for drilling wells, and for heat supply. Drilling a well requires the use of a pumping station or submersible pump. The pump supplies water from the well under low pressure.

In cars and industrial machines, pumps are auxiliary devices.

When extracting minerals, various types of pumps are used to drill a well, develop the area adjacent to the well, pump out liquids, and process liquids. In industry, pumps are installed at enterprises for hydraulic removal of production waste.

Pumps used in the food industry often have devices to crush materials (other than stone and metals) to prevent pipeline clogging.

Separately, there are pumps for fire extinguishing. The design of such pumps provides for the supply of water under high pressure.

Drainage pumps are submersible; they are characterized by the presence of a grinding and filtration system.

Pressure pumps are used in systems that require increased pressure during operation (heat supply, water supply).

There are types of water pumps according to their purpose:

- Water lifting.

- Circulating.

- Drainage

Depending on the scope of use, there is a classification of water pumps according to their operating principle.

- Water lift pumps are used to extract liquid from wells or wells.

- Circulating types of pumps are used to move fluid in heating, air conditioning and water supply systems.

- Drainage pumps are used to pump out liquid from basements and sewers.

How to choose

Before you start choosing a drainage pump model, you need to determine the parameters of the underground tank for which you plan to use such a device:

- the depth of the well (it can be determined using a cord with a weight attached to its end);

- parameters of the cross-section of the well shaft - the diameter or size of the sides of the shaft if it has a square shape.

Knowing these parameters, you can calculate the maximum volume of water that needs to be pumped out. To make such calculations more accurate, it is necessary to take into account at what level in the well shaft the water surface is located.

Design features of pumps for clean and dirty water

The quality characteristics of the water in the well are another important parameter that should be taken into account when choosing a drainage pump. In this case, this parameter refers to both the number of insoluble inclusions in the water composition and their linear dimensions. The instructions for each model of drainage pump must contain information about the size of solid particles in the pumped water with which such a device can work. Naturally, in order for the pump you have chosen to work correctly and not fail after short-term use, the size of the inclusions contained in the pumped water should not exceed the standard values for a specific model.

The choice of drainage pump is also influenced by the mode in which such equipment will be used - year-round, seasonal or periodic.

Higher demands are placed on the selection and use of drainage pumps that are operated year-round. Installation of such pumps is carried out in a heated room to avoid freezing of the liquid in the pipeline system during the cold season.

To more accurately select a drainage pump, it is necessary to determine and take into account the following parameters:

- minimum and maximum water level in the well;

- average water level in the well being served;

- the intensity with which water flows into the well (source debit).

Area of application of the unit

If you plan to use the unit only for watering garden beds from a nearby reservoir or to drain a flooded cellar, you can get by with a device with a capacity of 120 l/min.

The size of solid elements that the unit can “digest” is indicated in the instructions for the specific model. On sale you can find models designed only for slightly polluted water, the structure of which may contain only a small amount of sand. There is also a wide range of units that can successfully handle even small stones.

When planning to use the unit for pumping dirty water, including fibrous structures and various-sized debris, it is worth considering the option of purchasing a fecal pump.

In addition, units of this type are created from materials with increased strength and are not afraid of exposure to aggressive environments. Therefore, they have a longer service life than conventional garden pumps for dirty water.

Main characteristics and rules for their calculation

In addition to the parameters of the well, before choosing a drainage pump, it is necessary to determine the characteristics of the device itself. This includes the performance of the pump and the pressure force of the liquid that such equipment pumps.

The performance of the pump, which characterizes the volume of liquid pumped by it per unit of time, is determined based on the total volume of water in the well and the length of time during which all the liquid contained in the underground reservoir must be pumped out.

To determine the amount of liquid pressure, the depth of water intake and the distance over which the pumped water must be transported along the horizontal section of the system are summed up.

Calculation of pressure for a drainage pump

Design features

The suction hole of a submersible drainage pump is located at the bottom of the device, which ensures the most complete pumping of water from the well shaft. For the manufacture of the hydraulic machine body, cast iron, polymer material or steel alloy can be used. More preferable are devices with a steel body, which is not too heavy and is highly durable. Cast iron cases, although reliable, have a significant weight, and plastic ones are not strong enough.

The size of inclusions in the pumped water that a pump can handle without compromising its technical condition is mainly influenced by the size of its working chamber.

Auto shut off float

Although automation increases the cost of equipment, it helps prevent engine overheating.

The float is a device in the form of a plastic floating box. An electrical cable and a steel ball are placed inside it. It reacts to changes in water level and closes/opens the switch contacts.

The main advantage of the device is that it simultaneously performs two functions: it acts as a water level sensor and serves as an actuator for controlling the pump.

By spending a little more money on a device equipped with an automation system, you don’t have to worry that after pumping out the water it will run dry. The only thing is that once every few months it is recommended to wash the float switch with a stream of water under pressure to remove dirt. Preventative cleaning will prevent the float from sticking to the outlet pipe.

Classification by type of pumped medium

Depending on what type of fluid will pass through the pump, design and other features will vary.

Pumps are used to pump:

- clean liquid and slightly contaminated liquid;

- moderately contaminated liquids with light suspended impurities;

- not highly gassed liquids;

- mixtures of gas and liquid;

- aggressive liquids;

- liquid metals.

To work with different types of liquid, positive displacement pumps are used. This type of pump works on the principle of changing the volume of the chamber, which leads to the conversion of engine energy into the energy of the substance. Such pumps can handle any media, but high levels of vibration must be taken into account.

Dynamic pumps can also handle any type of liquid, but they are not self-priming. Depending on the design features of the pumps, there are various ways to process the fluid being moved. For example, dynamic vortex pumps are not designed to handle contaminated fluids that include abrasives. For such units, liquid with impurities is destructive, leading to thinning of the pump walls.

TOP electric water pumps 2021

| Model | Productivity, m³/h | Max. head, m | Power, W | Purpose | type of instalation | price, rub. |

| Grundfos UPS 32−80 180 | 11 | 8 | 220 | For clean water | Horizontal and vertical | View prices |

| GILEKS 330/12 | 19,8 | 12 | 1200 | Even pumps dirty water | Vertical | View prices |

| Grundfos SB 3−45 A | 3 | 45 | 1050 | For clean water | Vertical | View prices |

| KARCHER BP 1 Barrel Set | 3,8 | 11 | 400 | For clean water | Vertical | View prices |

| Aquarius BCPE 0.5−50U | 3,6 | 75 | 1140 | For clean water | Vertical | View prices |

Grundfos UPS 32−80 180

According to online stores as of July 2021, this is the most popular surface circulation pump. Buyers appreciate the device for its reliability and build quality. Additional features include an overheat protection function. To operate the device, a mains voltage of 220−230 V is required.

Rated power 135 W. Weight 4.8 kg, dimensions (WxHxD): 14.7x17.3x18 cm. The pump operates with liquid whose temperature ranges from -25°C to 110°C. The rotor is “wet”, the thread diameter of the outlet hole is 2″, the noise level is 43 dB. The pump comes with 2 nuts and instructions. The service life of the equipment is at least 10 years, of which 2 years are guaranteed.

GILEKS 330/12

This submersible pump is popular due to its excellent build quality and low noise level. Additional functions include dry-running protection. There is a float automatic control of the water level. The immersion depth of the pump is 8 m. The weight of the device is 7.5 kg, the required mains voltage is 220/230 V. The pump pumps dirty water, the filtered particle size is 37 mm. The length of the network cable is 10 m. The declared service life is 10 years, of which 1 year is guaranteed.

Grundfos SB 3−45 A

This is a submersible well pump with low noise and good water pressure. Maximum immersion depth of 12 m with overheating and dry-running protection functions. Equipment weight 10.4 kg, dimensions (WxHxL): 15×56 cm, 1″ - thread diameter of the outlet hole (G), power cord 15 m. Filtered parts - 1 mm, required mains voltage 220/230 V.

The pump is capable of pumping clean water at temperatures up to 40 degrees. At the same time, the ambient temperature can be up to 50 degrees. The water level is controlled automatically by float. Noise level 50 dB. The declared service life is 10 years, of which 2 years are under warranty.

KARCHER BP 1 Barrel Set

KARCHER BP 1 Barrel Set is a submersible drainage pump with low noise levels and excellent build quality. Immersion depth 7 m, required mains voltage 220/230 V, filtered particles 1 mm in size.

The pump is equipped with a dry-running protection function, the permissible fluid temperature is up to 35 °C. Power cord 10 m long, thread diameter of the outlet hole ¾″. Device weight 4.6 kg, dimensions (WxHxD): 17x52x13.5 cm. Automatic float control of water level, noise level 44 dB.

For convenient operation of the water pump, it comes with: a watering gun, 2 connectors, 1 of them with the “Aqua Stop” function, a 15-meter hose with a diameter of ½″.

Types of industrial pumps

There are different types of pumps used in industry. The main types of pumps used in various enterprises:

- multi-stage;

- gear oil pumps;

- chemical submersible pumps;

Industrial pumps are used in various fields

- in light industry;

- in the chemical industry;

- in construction;

- in mechanical engineering;

- in mining.

The type and type of pump is selected depending on the needs of the enterprise, the properties and quality of the pumped liquid.

The most popular are deep-well pumps, as they are widely used for domestic and industrial purposes. They are easy to install when installing water supply and heating systems; they are used for drawing water from wells and in heating systems.

Main types of pumps by type of energy input:

- pumps powered by mechanical energy;

- water jet pumps;

- pumps powered by compressed steam or gas.

Pumps powered by mechanical energy include piston pumps, propeller pumps, screw pumps, centrifugal pumps and rotary pumps. Despite the same principle of operation, these pumps are very different in design. Water jet pumps - elevators, ejectors, operate by supplying liquid to the wheel blades.

Comparative review of the best manufacturers

It is rightfully considered the market leader. The Danish company is the oldest manufacturer of pumping equipment. The developments introduced by the leading company's technologists were subsequently adopted by other manufacturers.

The equipment of this manufacturer is famous for its ability to easily cope with water of any degree of contamination without harm, as well as its high reliability

The range of manufactured products is represented by pumps of all varieties and types. And they all have one thing in common - the highest quality, confirmed by an effective manufacturer’s guarantee.

Another imported brand that has earned a positive reputation among buyers from different parts of the world is the Pedpollo brand.

“Pedrollo pumps work everywhere” is the main slogan of the world famous brand. And if you study the characteristics of the equipment he produces, it is worth highlighting the versatility of its application. The pumps are capable of operating in contaminated water, aggressive environments and at high temperatures.

Among domestically produced pumping equipment, the most well-proven products are those manufactured under the following brands:

- "Dzhileks" - pumping equipment of a domestic manufacturer is focused on the conditions of the Russian outback with its abundance of "difficult" soils and wetlands, as well as possible fluctuations in power supply networks.

- “Whirlwind” - pumps from this manufacturer are famous for their high power and low noise. The certified equipment produced by the company undergoes numerous tests for performance and endurance.

- “Foreman” - powerful and easy-to-maintain pumps of this brand are manufactured using advanced technologies. This allows the company to keep the quality level at a high level.

Among the brands of pumps for dirty water, the brands “DAB”, “Karcher” and “Belamos” have also proven themselves well. The equipment produced under these brands is famous for its optimal price-quality ratio.

When purchasing a suitable model, you have to set priorities: pay more and choose an unquestionable European brand, or purchase an inexpensive domestic product, but risk receiving low-quality warranty support.

Pumps for fire extinguishing systems

The main requirement for fire extinguishing system pumps is the supply of water under high pressure. Centrifugal pumps are the most commonly used because they allow water to be pumped quickly using centrifugal force. Important points when choosing a fire extinguishing pump are:

- pressure;

- wheel speed;

- efficiency;

- suction lift;

- volume of water moved.

Depending on the number of wheels with blades, pumps are single-stage or multi-stage. Multistage units allow you to create higher pressure, which in turn affects the pressure and height of the supplied liquid. When installing fire extinguishing systems in buildings, it is worth considering that the equipment must be checked periodically, since stagnation can cause difficulties during startup. Fire trucks are equipped with centrifugal pumps and auxiliary units. Auxiliary pumps fill the centrifugal pump housing with liquid and turn off automatically.

How to choose a water pump for your dacha

We think about choosing a pump as soon as we get our hands on a treasured vegetable garden or plot of land for a summer cottage. There is a need to supply water for watering, irrigation, construction or domestic needs. Therefore, the simplest, easiest to install, unpretentious to operate and moderately priced hand pump will serve you faithfully (RN-01 NZh). An undeniable advantage is the ability to operate in the absence of electricity in your area.

As your business grows, or with design requirements for higher water consumption, you cannot do without electric pumps. This is much more convenient, and most importantly more productive (more powerful) than when using mechanical pumps. An equally important characteristic is pressure. It shows to what height water can be supplied. When choosing a unit, it is also necessary to take into account the expected water consumption, based on the number of people, water supply points, and the hydraulic resistance of the system. Correct calculation will help to avoid extremes in the form of low or, conversely, excessively high pressure in the system.

If you do not resort to outside help to clean the sedimentation tanks, then a fecal pump will serve you well. If you don’t get hung up on the name, then it can be safely used for pumping water (for example, from natural or artificial reservoirs)

Oil and fuel pumps

Industrial types of pumps include oil and fuel devices installed on automobile and machine engines and internal combustion engines.

Oil pumps reduce friction between interacting engine parts. They are adjustable and unregulated. Car engines are equipped with rotary or gear pumps for pumping oil.

Fuel pumps are installed in cars without fail. They ensure the delivery of fuel from the tank to the combustion chamber. Depending on the design, fuel pumps are either mechanical or electric.

Submersible pumps

Submersible pumps are used when working at a depth of more than eight meters. All types of submersible pumps have a cooling system and are also made of durable material that helps avoid deformation under pressure. Submersible pumps are either centrifugal or vibration pumps. In the second type of pumps, liquid is sucked in using a vibration or electromagnetic mechanism.

When choosing a pump, it is important to consider a large number of factors:

- purpose of use;

- place of use;

- the need to install auxiliary units;

- pump dimensions;

- pump operation method.

Next

Pumps and pumping equipmentTypes and classification of pumping units