History of origin

The first micrometers appeared in the sixteenth century, but then they were not used - there simply were no mechanisms that would require such great accuracy. Everything changed in the nineteenth century, when more advanced and precise lathes and other mechanisms appeared. Thanks to the development of mechanical engineering, micrometers again became in demand, and several types of this instrument appeared.

Expert opinion

Torsunov Pavel Maksimovich

Often, a caliper is used instead of a micrometer. These are different tools, but for some jobs they are to some extent interchangeable. For example, when you need to group small objects by size. A caliper does not provide the same accurate measurements, but it can be used as a clamp.

What are micrometers?

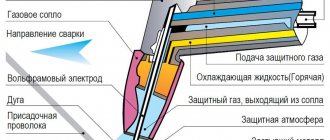

Almost all micrometers are the same type of device with a similar structure.

To determine the size of objects, a screw pair is used, by moving which you can accurately determine the size of a part or object. Any modern micrometer is equipped with a screw-nut pair, which allows you to measure objects with high accuracy. Also on each of the micrometers there is a scale that allows you to determine the size being measured.

Due to the difference in the types of work that is performed with a micrometer, its shape may vary slightly. For example, there are micrometers for measuring the thickness of sheets, for measuring products with complex configurations (geared), for measuring pipes and their walls, for measuring the size of thin products, and others. The peculiarity of these micrometers is in the structure of the bracket, lever and control screw.

These shapes vary depending on what kind of work the micrometer is intended for. This is obvious, since you can only get close to the inner plane of the pipe to measure the walls with a special micrometer. Accordingly, in other cases.

Most micrometers are handheld, but there are also stationary (desktop) models. They are more accurate and allow you to measure very small parts using a pointer or clock mechanism. However, using them in everyday life is not very convenient.

The division of micrometers by accuracy deserves special mention. Cheaper and simpler micrometers have slightly lower accuracy, usually up to 50 microns. Such micrometers are used when performing work where extremely high precision is not needed - in the manufacture of simple parts. More expensive ones can have an accuracy of up to 2 microns, and they are used when working with electronics, bearings and other work where maximum accuracy is needed.

Some modern micrometers are made not mechanical, but digital. Such micrometers are more expensive, but they are easier to use and allow you to make measurements even more accurately - up to 1 micron.

Types and purposes of micrometric instruments

Measuring distance requires the correct type of tool and a working micrometer screw. To measure the thickness of an object, the appearance is used. These common tools are also known as micrometer calipers. From the outside, the tool measures wires, spheres and blocks. Internal micrometers take the opposite measurement, the distance inside an object, such as the diameter of a hole. Tube micrometers measure the thickness of the tube, while depth micrometers measure the depth of the slot or pitch.

Favorable prices for micrometers

Each type is equipped with specialized equipment for specific tasks. Because the object being measured is grasped, the anvil and spindle tip are parts that are customized for unique applications. Some micrometers have multiple anvils for more accurate measurements. The anvil can be shaped into a disk, a v-shape, or form part of a screw thread. Some micrometers come with interchangeable anvils to allow for different types of measurements. Let's consider the most famous and common micrometric instruments, their types and purposes.

Outer

A common and constantly used type is the external appearance.

Its action is used to measure the outer diameter of an object.

Used to measure the outer diameter of an object

Interior

The internal view is used to measure the internal diameter of a hole or tube.

Two kinds of internal micrometer:

- Caliper

- Tubular

Used to measure the inside diameter of a hole or tube

Vernier caliper option

Internal varieties have measuring jaws similar to those found on a caliper. The jaws are inserted into the space to be measured and adjusted by turning a thimble or ratchet.

Internal varieties have measuring jaws similar to those found on a caliper

Tubular and rod

Tubular and rod micrometers are placed into the space being measured and expanded until the measuring surface touches the edge of the space being measured.

Fits into measured space

The rod tool comes with a set of measuring rods that attach to the micrometer, thereby expanding the measuring capabilities of the device.

Some rod micrometers have a handle that connects to the instrument and helps the user measure in hard-to-reach areas.

Rod micrometers are placed in the space being measured

The rod tool comes with a set of measuring rods

Deep

Depth ones are used to measure the depth of holes, grooves and steps.

They come with a variety of interchangeable rods of different lengths so that they can be used to measure a range of depths.

Used to measure the depth of holes, grooves and steps

Instructions for use

Before using the micrometer for the first time, you must set it up, namely, set the zero mark. Subsequently, this will need to be done regularly in order to ensure the accuracy of the measurements. To do this, use a micrometer to unscrew the drum so that it rotates freely. You need to twist it and look at it at right angles.

When observing not at a right angle, accuracy cannot be achieved. The task is to ensure that the zero mark on the drum coincides with the standard mark on the micrometer body. When the zero position is reached, the drum can be locked. To do this, hold the cylinder and tighten the nut back. You cannot grasp other parts with a micrometer, otherwise there is a risk of losing all settings.

Each time before using the micrometer, its surface must be thoroughly wiped from dirt and dust, especially for the screw. Even slight contamination affects the accuracy of the results. This applies to both digital and mechanical micrometers.

To measure something with a micrometer, you need to extend the screw to the required length. Next you need to place the part between the different ends of the screw. After this, we begin to tighten the nut and thereby move the screw towards the part. When the screw clamps the part, it will click when further attempts are made to turn the nut. We stop twisting, take out the part and look at the micrometer readings. The digital one gives readings automatically, while the mechanical one needs to look at the scale. The upper left part of the scale is millimeters, the lower left is tenths of a millimeter, the right is hundredths of a millimeter.

The micrometer has a clamp that allows you to fix the instrument and scale in one position. This may be useful when grouping items by size and checking the accuracy of similar parts when rejecting.

The procedure for taking measurements with a micrometer

The working surfaces of the micrometer are set apart by an amount slightly larger than the size of the part being measured, otherwise it can be scratched during operation.

The fact is that the end surfaces of the heel and micrometer screw have high hardness for abrasion resistance. The heel is lightly pressed against the part and the micrometer screw is rotated using a ratchet until it comes into contact with the surface being measured. The ratchet is used to regulate the tension force - usually 3-5 clicks are made. The position of the micrometer screw is fixed using a locking device in order not to disrupt the readings when reading values from the scale.

When working with a micrometer, it should be held by the bracket so that the stem scale is visible and readings can be taken on the spot.

When measuring the diameter of a shaft, the measuring surfaces must be placed at diametrically opposite points. In this case, the heel is pressed against the shaft, and the micrometer screw, which is slowly rotated with a ratchet, is sequentially aligned in two directions: axial and radial. After work, you need to check the accuracy of the tool using a standard.

How to choose

The main thing when choosing a micrometer is to decide on your tasks. For home use and household purposes, an ordinary mechanical micrometer with an accuracy of up to 50 microns is suitable. Such a tool is inexpensive and copes with any household task. A handheld micrometer is best suited for home use, as it is compact and better suited for standard household tasks.

If a micrometer is needed for professional purposes - performing complex construction and finishing, turning, milling and foundry work, then you should think about buying more expensive micrometers. A manual or tabletop mechanical one, including a pointer one, is suitable. It is important to buy a high-precision micrometer, since the quality of the work performed depends on it. It often happens that drills of the same diameter (by eye) have different degrees of wear, which is why the quality of the fasteners suffers during installation work. By regularly using a micrometer, such problems can be avoided.

The most accurate and expensive digital and pointer-mechanical micrometers are needed in laboratories, jewelry, electronics and when creating precise models. In these areas of activity, a micrometer with the usual degree of error cannot be used. Accordingly, you need to buy the most accurate micrometers.

Rating of the best models

We have compiled a ranking of the best micrometers for you. When compiling the list, we were guided by customer reviews, workmanship and functionality of micrometers. Everyone who chooses a micrometer has their own tasks. Accordingly, we consider tools of different classes and accuracy. In addition, we selected micrometers in such a way that their price corresponds to their quality.

FIT 19909

The best budget micrometer. A hand-held mechanical tool with a standard-shaped bracket. It has measurement accuracy sufficient for everyday purposes. Suitable for home workshop. The micrometer has a clamp that allows you to fix the instrument and its scale in one position. This model is characterized by high reliability and versatility, as well as a low price. Among budget micrometers, FIT is the most popular. The only drawback is that the measurement accuracy is not the greatest, even if we take into account other mechanical micrometers from more expensive price categories.

Advantages:

- inexpensive;

- lightweight and compact;

- reliable;

- there is a clamp.

Flaws:

- measurement accuracy (within 100 µm).

| Type | Mechanical smooth |

| Measurement accuracy | 0.1 mm |

| Peculiarities | Fixing clamp |

| Price | 1000 rubles |

BISON "EXPERT"

Another inexpensive micrometer, but this time it's digital. This micrometer already has sufficient accuracy to be used for precision work, including jewelry. Unlike hand-held mechanical micrometers, this micrometer is easier to use - during normal maintenance, the measurement simply requires placing the object correctly between the ends of the screw, and the correct value will be displayed on the screen. However, there is also a traditional mechanical scale that allows you to use a micrometer just like a regular one. It is better to choose a digital micrometer for those who often use this tool - it saves work time.

Advantages:

- convenient operation;

- high accuracy;

- speed of work;

- there is a clamp;

- mechanical and digital scale.

Flaws:

- depends on the power source;

- costs more than regular micrometers.

| Type | Sleek digital |

| Measurement accuracy | 0.001 mm |

| Peculiarities | Fixing clamp, digital screen, mechanical scale |

| Price | 3500 rubles |

MCC 25 GRIFF

An advanced digital micrometer designed for high precision measurements. The main feature of this micrometer is that it is equipped with a special port that allows you to connect it to a computer. This makes it easy to record and study measurement results and perform computational work. This micrometer is suitable for professional tasks and allows you to do work in a constant flow. This micrometer operates in digital mode only, there is no mechanical scale to determine measurements.

Advantages:

- high accuracy;

- ability to connect to a PC;

- Durable carbide screw.

Flaws:

- depends on the power source;

- no mechanical scale;

- high price.

| Type | Sleek digital |

| Measurement accuracy | 0.001 mm |

| Peculiarities | Fixing clamp, connection to computer |

| Price | 5000 rubles |

ASIMETO 152-01-0

A lever mechanical micrometer that is suitable for making precise measurements down to 0.001 mm. Thanks to the movable heel (one of the ends of the screw), the micrometer can clamp the part with great force, which increases the accuracy of the device. This micrometer is suitable for use in production for inspection of parts or when performing other complex work.

Advantages:

- high measurement accuracy;

- lever mechanism;

Flaws:

- weight - 80 grams;

- price;

- small measuring range.

| Type | Lever mechanical |

| Measurement accuracy | 0.001 mm |

| Peculiarities | Locking clamp, lever heel without ratchet |

| Price | 20,000 rubles |

Sheet micrometer ML-25

ML-25 is designed for measuring the thickness of metal sheets or other materials: paper, plastic, glass, etc. The U-shape makes it easy and convenient to measure sheets of the listed materials. A fixed heel and a screw pair are used as a meter. This micrometer has a mechanical radial scale that operates with an accuracy of 0.01 mm.

Advantages:

- convenient to work with sheets;

- lightweight and compact;

- high measurement accuracy.

Flaws:

- limited range of tasks;

- price.

| Type | Mechanical sheet |

| Measurement accuracy | 0.01 mm |

| Peculiarities | Radial scale |

| Price | 7500 rubles |

What is a micrometer

A micrometer is a precision measuring instrument used in machine shops around the world. The test showed that mechanical, as well as instruments with digital display, easily carry out high-precision measurements.

The word "micrometer" refers to two terminologies:

- the first is the smaller metric unit, which is 1/1000 of a millimeter

- the second is a measuring device called a micrometer, which measures dimensions with very high accuracy, because during the measurement process, the line of the object being measured is parallel to the axis of the device.

The instrument is used to measure smaller dimensions such as length, width and depth of precision machine parts and objects with an accuracy of 0.01 mm in the case of a metric scale and up to 1/1000 of an inch in the case of an inch scale engraved on a micrometer head.

A huge number of micrometers are used in industry, for conditions such as linear lengths, angular distances and hole depths.

Widely used in machine shops

Hole width

Diameter of precision parts

Used in industry

Thread depth of precision parts

Thickness of precision parts