General information about microarc oxidation of aluminum (MAO).

Today, one of the most popular structural materials is aluminum. It is distinguished at the same time by its lightness, strength, electrical and thermal conductivity, and corrosion resistance. Under the influence of atmospheric oxygen or other oxidizing agents, aluminum is easily passivated - a natural oxide film (Al2O3) 0.002-0.005 microns thick appears on its surface. The passive film significantly inhibits the corrosion processes on aluminum under atmospheric conditions, despite the fact that it itself is a very active metal.

Al2O3 is stable in neutral and slightly acidic solutions, has pronounced dielectric properties and is one of the hardest compounds in nature. The disadvantage of natural aluminum protection is the small thickness of the passive film. For this reason, it does not provide it with adequate resistance to either corrosion in aggressive environments or abrasion.

To improve these parameters, the thickness of the oxide film must be artificially increased. This process is called oxidation.

Oxidation of metals is, in principle, carried out by thermal, chemical, anodic and microarc methods.

For aluminum, the last three oxidation methods are used:

• Chemical oxidation is significantly inferior to anodic and microarc in terms of performance characteristics, but is the simplest and cheapest.

• Good results can be obtained with anodic oxidation (the most common method).

• The best coatings are obtained using MAO, but this is also the most expensive, complex and energy-intensive process.

MAO is a relatively new method for modifying the surface of aluminum. It was developed at the Institute of Inorganic Chemistry SB RAS in 1969 under the leadership of G.A. Markova. MAO allows the application of ultra-strong oxide coatings with unique protective, electrical insulating, and decorative properties. In appearance, the coating obtained by the microarc method is very similar to ceramics. The process is applicable not only to aluminum, but also to other valve group metals, such as Ti, Zr, Mg, Ta, Be.

MAO is performed in an electrolyte solution under current, just like anodizing, but differs from it by using a much higher voltage and high-density electric current. When such a current passes through the metal-electrolyte interface, chaotic microplasma discharges with high temperatures appear on the surface of the part, which outwardly looks like a luminous halo. These microdischarges have a plasma-chemical and thermal effect on the coating and electrolyte. At the discharge site, a film is formed from oxidized forms of the base metal and electrolyte components. It is possible to obtain coatings with different thicknesses, porosities and properties by selecting the desired oxidation mode and electrolyte composition.

Microarc oxidation

The microarc oxidation laboratory performs the following types of work:— develops technologies for strengthening parts for various purposes, — carries out hardening of pilot batches, — develops and manufactures equipment and devices for creating MAO sections at the Customer’s enterprises.

Microarc oxidation makes it possible to obtain multifunctional ceramic-like coatings with a unique set of properties, including wear-resistant, corrosion-resistant, heat-resistant, electrical insulating and decorative coatings, characterized by high performance. The essence of the method is the formation on the surface of the part under the influence of microarc discharges of a high-strength wear-resistant coating (MAO coating), consisting mainly of a-Al₂O₃ (corundum) and other aluminum oxides.

The main difference of the microarc oxidation process is the use of the energy of electrical discharges migrating along the surface being treated, immersed in an electrolyte, resulting in the formation of ceramic-like coatings with elemental and phase composition, structure and properties adjustable over a wide range. Other technological differences include the fact that the process is carried out at operating voltages up to 1000 V, and more often not direct, but alternating and pulsed currents are used, and electrolytes are not acidic, but mainly slightly alkaline.

The main advantages of the MAO process are: no need for special preliminary preparation of the treated surface, non-aggressive and environmentally friendly electrolytes, the ability to obtain thick (up to 300-400 microns) coatings without the use of complex and environmentally hazardous refrigeration equipment, achieving uniquely high hardness (up to 2000-2500 kg/ mm²) and wear resistance of MAO coatings.

The structure and composition of the oxide layers, in addition to the nature of the metal being processed, are determined by the external conditions of their formation and, above all, by the composition of the electrolyte, the components of which can be included in the coating structurally, by time, and by the processing mode parameters specified by the source of the technological current, which determine the thermal, temporal and other characteristics of microdischarges .

The versatility of MAO coatings facilitates their use in a wide variety of industries (aerospace, instrument making, electronics, chemical, oil and gas, automotive, instrumental, textile, medical, mechanical engineering, production of building structures, household goods, etc.), in various components (shut-off valves, parts of pumps and compressors, press equipment, parts of internal combustion engines, etc.) to increase wear resistance, corrosion-protective properties, dielectric, heat-shielding and decorative characteristics.

The list of parts that can be subjected to MAO processing is quite wide and includes all kinds of parts made of aluminum and titanium alloys.

Samples of parts processed by micro-arc oxidation

The Center's specialists have developed a technology for strengthening turboexpander impellers made of AK-6 aluminum alloy. It is shown that, along with good adhesion of the coating to the base, which ensures that it does not chip at sharp corners of the working surfaces under conditions of sharp temperature changes (working temperatures - temperatures of liquid gases), the coating reliably protects the surface from cavitation, erosion and other types of wear.

Based on the research performed, a technological regulation was developed, which is given in the document “Temporary technological regulation for applying a ceramic coating using the micro-arc oxidation method to a pilot batch of turboexpander impellers.”

In aircraft and automobile engine building, applying coatings to the cylinder-piston group makes it possible to protect it from high-temperature gas erosion and reduce the temperature of the base metal by approximately 1.5 times. This also applies to turbine blades and propulsion nozzles.

In instrument making, electrical and electronics industries, MAO coatings are used as anti-diffusion layers of heating systems used in the production of chips; dielectric layers of heat sinks of integrated circuits; frosted - giving diffuse scattering and black - absorbing (up to 96-98% in the wave range 370-600 nm) layers - working as radiator absorbers.

The use of MAO for forming tantalum anodes of electrolytic capacitors makes it possible to increase their volumetric specific capacitance by 2-5 times while reducing the process time by two orders of magnitude.

In the petrochemical and gas industries, corrosion-wear-resistant MAO coatings on aluminum and two-layer coatings (sprayed aluminum - MAO) on steel have proven themselves to be effective - for pump plungers, mechanical seals (instead of siliconized graphite and hard alloy), gate valves, many times increasing their service life services in hydrogen sulfide-containing environments.

There are developments on oxidized aluminum drill pipes and information on the use of MAO coatings as catalysts for oxide catalysis.

In the urban water industry, MAO coatings are used to protect parts of water and submersible pumps (housing, impeller, cover, rotor, stator, etc.) and shut-off valves of water taps - to protect against wear and corrosion.

In the medical industry, possible applications include the production of non-rejectable bioceramics based on titanium and zirconium for implants in dentistry, artificial joints and vertebrae, for bone reconstruction, etc., and also as thin filters for blood plasma.

In mechanical engineering, examples of the use of MDO include fast-rotating parts of submersible water and vacuum oil-free pumps and compressors, as well as high-performance grinder-disintegrators made from aluminum and titanium alloys with subsequent oxidation instead of alloy steel, for work in severe tribological conditions, casting molds and high quality rods, lightweight mandrels - mandrels for molding fiberglass products with improved product alignment. In addition to a multiple increase in wear resistance and mean time between failures, the use of aluminum alloys with MAO coatings significantly facilitates the operation of moving parts.

For the tool industry, gauges (instead of carbide) and laps made of duralumin with a wear-resistant MAO coating, as well as oxidized disks made of aluminum alloys for loading carbide tools instead of diamond ones, are promising.

In the textile industry, spindles made of aluminum alloys with wear-resistant MAO coatings are successfully used for twisting natural thread, bushings and plates of tension devices, pairs and hooks of control and cleaning devices of winding and reeding machines, as well as laying rollers, which require increased wear resistance, heat resistance and a certain degree of roughness in the production of lavsan fiber.

In the production of building structures, colored light-resistant MAO coatings can be used as protective and decorative coatings for both external and internal architectural design of buildings and structures.

In addition, MAO coatings, having the appropriate porosity, are ideally suited for the subsequent application of varnish, paint, Teflon, insulating material, etc., i.e. as a soil.

The above can be effectively used in the manufacture of instrument panels.

Decorative MAO coatings on aluminum knitting needles and bicycle pump housings prevent them from staining.

Numerous laboratory, bench and full-scale industrial tests of the above-mentioned coated products under appropriate operating conditions have shown their universal versatility and high protective ability, which allows us to recommend them for wide use in various industries.

Micro-arc oxidation equipment

The Center's specialists have experience in the development and creation of power supplies and components for micro-arc oxidation installations.

At the request of some enterprises, several power supplies were manufactured, and a comprehensive development of the area for the formation of MAO coatings with a total capacity of up to 150 kVA was carried out. The site was put into operation in 2012.

The microarc oxidation (MAO) installation has a block design and consists of the following main parts:

— electrolytic bath with systems for fastening parts, cooling, boration and ventilation; — power source (amplifier unit), including: power unit, switching unit, control and alarm unit; — bathtub safety guard with locking system.

Main technical characteristics of UMDO

| 380±40 3 50±1 | ||

| 2 | Total power consumption, no more, KVA | 50 |

| 3 | Capacity of the capacitor bank of the power source, μF | 2000 |

| 4 | Maximum voltage amplitude developed at the source, V | 760 |

| 5 | Rated operating current, A | 60 |

| 6 | Short circuit current, A | 100 |

| 7 | Number of current control stages | 5 |

| 8 | Electrolytic bath volume, l | 450; 60 |

| 9 | Electrolyte temperature, K (°C) | 293 – 333 (20 – 60) |

| 10 | Overall dimensions, mm: - electrolytic bath - power supply - protective fence | 910x1200x850 500x2000x1700 1000x1800x2400 |

| 11 | Total weight, kg, no more | 950 |

Composition of electrolytes for MDO.

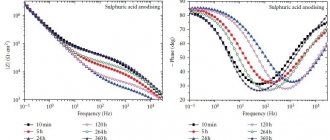

The composition of the electrolyte during MAO, along with the substrate material, treatment mode and time, is a determining factor in the process.

Electrolytes used for MDO are:

• do not have components that form insoluble oxides: solutions of sulfuric, phosphoric acid, alkali. The coatings formed in such electrolytes penetrate deeper into the metal due to its oxidation. • which contain cations or anions that form insoluble oxides and hydrolysis products: aluminate and silicate-alkaline solutions, as well as solutions containing soluble phosphates, bicarbonates and molybdates). After thermolysis, these electrolyte components in the discharge zone become part of the coating and provide an additional increase in the size of the part after the formation of the oxide layer.

The applied MDO modes differ in:

• type of current (direct current, alternating current, alternating current superimposed on direct current); • polarity of the applied voltage; • changes in electrical parameters (galvanostatic, galvanodynamic, potentiostatic, potentiodynamic, constant or falling power modes); • the nature of the discharge (spark, microarc, arc, arc electrophoresis); • degree of control (manual, semi-automatic, automatic).

The voltage on the bath is 600-1000 V, the current density is up to 30 A/dm2, the specific power consumption reaches 11000-30000 W/dm2. For comparison, when anodizing, the output voltage is in the range of 12-180 V (higher values are used extremely rarely), current density is 0.5-2 A/dm2, specific power consumption is only 6-360 W/dm2. Chemical oxidation is carried out without any current at all.

No special surface preparation is required before applying the coating.

In practice, the microarc oxidation process is carried out mainly in weakly alkaline electrolytes when pulsed or alternating current is supplied.

Equipment and technology for microarc oxidation of valve metals and alloys

Compound:

MAO coatings are ceramics of complex composition. The coating during microarc oxidation is formed due to the oxidation of the metal surface, while oxide and hydroxide forms of this metal are formed. On the other hand, the coating grows due to the inclusion of electrolyte elements in its composition. Electrolyte elements are included in the coating in the form of salts, oxides and hydroxides of complex composition. If necessary, MAO technology allows you to introduce any desired chemical element into the coating. The more time it takes to process a part, the more elements from the electrolyte accumulate in the surface layer. The lower layer of the coating adjacent to the base metal consists mainly of its oxide compounds.

Graph of changes in the content of aluminum and phosphorus on the surface of a MAO coating depending on the time of treatment in a phosphate electrolyte.

Thickness:

The thickness of coatings is determined by several main factors. These are the nature of the electrolyte, the metal alloy material, the processing mode and the process time. MAO makes it possible to obtain coatings with thicknesses ranging from fractions to hundreds of micrometers. The required coating thickness depends on the purpose and operating conditions. To apply a sublayer for painting, 5-10 microns are sufficient; to impart electrical insulating properties or high wear resistance, 50-100 microns are required. Decorative properties and anti-corrosion properties in atmospheric conditions are provided by 20-40 microns of coating.

Porosity:

The porosity of coatings varies in the range of 5-50%, sizes from 0.01 to 10 microns. The structure of pores with a coating thickness of more than 5-10 microns is complex, branched with many branches and closed spaces. Pore-free coatings cannot be obtained due to the nature of the process. If necessary, porosity can be reduced by impregnation with various materials or by applying a layer of polymer (dye). The most commonly used are impregnation with fluoroplastic and application of polymer powder paints. In some cases, porosity is a positive factor. When the coating works for wear under lubrication conditions, the latter enters the pores of the coating and ensures gradual entry into the friction zone. In medicine, bioactive MAO coatings can contain drugs in their pores.

Wear resistance:

Coatings are used as wear-resistant coatings in various components and assemblies of machines and mechanisms. Due to this, in many cases it is possible to use products made of aluminum - a metal that is quite soft and difficult for traditional methods of surface treatment (for example, electroplating). Comparative tests were carried out on samples with MAO coating on aluminum and a steel sample with a wear-resistant layer of chromium applied. The specific load during testing was 0.64 N/mm2. MAO coatings showed less wear, especially at elevated temperatures.

Heat resistance:

MAO coatings have increased resistance to thermal and thermocyclic loads. Coatings can operate without restrictions at temperatures from -40 to +60°C. When the part is gradually heated, the heat resistance of the MAO coating is limited by the melting temperature of the metal of the part itself, since these values for metal are obviously lower than for ceramics. Tests have shown that coatings can withstand up to 280 thermal cycles of 310-15WeC and up to 25 thermal cycles of 500-15WeC. In such tests, a coated sample is heated to a predetermined temperature in an oven and then dropped into cold water.

Roughness:

During processing, the surface roughness increases over time. It is possible to obtain coatings with roughness up to class 8. Roughness depends on the alloy material, the state of its surface and the processing mode.

Corrosion resistance:

The MAO method makes it possible to obtain coatings that are resistant in atmospheric conditions and in various corrosive environments - chemically aggressive solutions, vapors, sea water, etc. Since MAO coating is a ceramic of complex composition, the corrosion resistance of the coating material is quite high. Protection against corrosion of the base metal can be ensured by the thickness of the coating and regulation of the number and structure of pores. Additional protection is provided by impregnation of the pores with an inert material (most often fluoroplastic). Tests (GOST V 20.57.304-76, GOST RV 20.57.304-88) showed that the resulting coatings can be used as corrosion-resistant for 15 years.

Dielectric properties:

The voltage at which breakdown of the coating occurs, as well as corrosion resistance, depends on the thickness of the coating, the type and size of the pores. Also, this value can be significantly increased by using a material that fills the pores. The average breakdown voltage of the coating is 600 V. The breakdown voltage of the coating with pore filling is up to 2500 V.

Adhesion:

MAO coatings have excellent adhesion to the base metal, which is ensured by the presence of a transition layer at the metal-coating interface. The transition layer is formed both inside and outside the metal, and also has a profile with many bends.

As a result, the adhesion of the coating to the metal turns out to be greater than the strength of the coating itself, and when loaded, the coating does not come off along the metal-coating interface. The adhesion values calculated based on the results of Scrach testing reach 350 MPa.

Structure and composition of the oxide coating during MAO.

Anodic microarc discharges pass between the surface of the oxide film and the electrolyte, heating the film to high temperatures of 1000-2000 °C. At such temperatures, thermal destruction of water occurs with the formation of atomic and ionized oxygen. High-temperature phases are formed in the coating (corundum α-Al2O3), decomposition of the electrolyte components and their interaction with the base metal oxides occurs. MAO coating, therefore, is not purely oxide, but has a complex composition and structure.

The resulting oxide layer is approximately 70% formed deep into the base metal and only 30% of the coating extends beyond the original dimensions of the part.

The metal-oxide-discharge-electrolyte system realized during MAO has ionic conductivity, and the current flows through the discharge channels. Therefore, the formation of pores in the coating is a prerequisite for its formation.

MAO coating has a layered structure, an example of which is shown in Figure 1:

• The outer layer (technological) is loose. When using an alkaline electrolyte with the addition of liquid glass, this layer consists of mullite Al2O3*2SiO2 • The inner layer is dense and has high microhardness. Consists of aluminum oxide Al2O3. • The transition layer is thin, from 0.01 - 0.1 microns, located between the substrate material and the oxide layer.

The top loose layer is often removed by sandblasting and the part with a dense oxide coating is put into service.

Figure 1 - Layer-by-layer structure of the coating obtained by the MAO method: 1 - outer (technological) layer, 2 - dense (working) layer: 3 - transition layer: 4 - base material.

The composition of the coating depends on the processing time. An example is shown in Figure 2.

Figure 2 - Change in the content of aluminum and phosphorus on the surface of the MAO coating depending on the time of treatment in the phosphate electrolyte.

Main Applications

- SHIPBUILDING - decorative finishing and protection against wear and corrosion of elements of boats, yachts, jet skis, boats, etc.

- AUTO-MOTO TUNING - decorative finishing and protection against wear and corrosion of parts made of aluminum, magnesium and titanium alloys.

- MECHANICAL ENGINEERING – friction pairs, plain bearings, gears, pistons, cylinders, mechanical seals for internal combustion engines, machine tools and machines for various purposes in shipbuilding, the aviation industry, parts for agricultural machinery

- MEDICINE – protection of surgical endoprostheses

The main advantages of micro-arc coatings are

- the ability to create ultra-durable coatings second only to diamonds in strength

- possibility of applying coatings on external and internal surfaces of parts of any configuration

- possibility of obtaining different coating colors without additional painting

- no need for pre-treatment of surfaces

- high resistance to corrosion fatigue (high endurance limit).

Technical characteristics of MAO coatings on alloys

| Characteristic | Aluminum alloys | Magnesium alloys |

| Coating thickness | 10-300 microns | 10-300 microns |

| Microhardness | 800-1950 HV | 650-950 |

| Friction coefficient | 0,01-0,02 | 0,01-0,02 |

| Breakdown voltage | up to 4500 V | 600 V |

The properties of the coatings are achieved through the formation of ceramic oxide films on the surface of products, in particular Al2O3 (corundum), which make it possible to significantly increase the wear resistance and corrosion resistance of parts, giving them a beautiful decorative appearance.

| Color chart of MDO coatings | |

| Alloy | Coating color |

| Coating color determined by the alloy itself | |

| D16 | black Brown _ |

| B95 | pink |

| AMg5 | beige |

| Aluminum alloy with titanium | blue |

| ML5 | beige , gray |

| AK12 | grey |

| Coating colors available on any alloy | |

| 1. brown | |

| 2. black | |

| 3. brown | |

| 4. blue | |

| 5. white | |

Our organization offers services for applying MAO coatings to any of the Customer’s products, both at its production base, and services for the sale of equipment and technology for organizing a site for applying such coatings on a turnkey basis.

The maximum dimensions of processed products are 2000x500x500 mm.