One of the most common elements found in the earth is titanium. According to the results of studies, it ranks 4th in terms of prevalence, behind the leading positions of aluminum, iron and magnesium. Despite such widespread use, titanium began to be used in industry only in the 20th century. Titanium alloys have largely influenced the development of rocketry and aviation, due to the combination of low density with high specific strength, as well as corrosion resistance. Let's take a closer look at all the features of this material.

General characteristics of titanium and its alloys

It is the basic mechanical properties of titanium alloys that determine their wide distribution. If you do not pay attention to the chemical composition, then all titanium alloys can be characterized as follows:

- High corrosion resistance. The disadvantage of most metals is that when exposed to high humidity, corrosion forms on the surface, which not only worsens the appearance of the material, but also reduces its basic performance qualities. Titanium is less susceptible to moisture than iron.

- Cold resistance. Too low a temperature causes the mechanical properties of titanium alloys to be significantly reduced. You can often encounter a situation where operation at subzero temperatures causes a significant increase in fragility. Titanium is quite often used in the manufacture of spacecraft.

- Titanium and titanium alloys have relatively low densities, which significantly reduces weight. Light metals are widely used in a wide variety of industries, for example, in aircraft manufacturing, skyscraper construction, and so on.

- High specific strength and low density are characteristics that are rarely combined. However, it is precisely due to this combination that titanium alloys are most widely used today.

- Manufacturability during pressure processing determines that the alloy is often used as a workpiece for pressing or other types of processing.

- The lack of response to the influence of a magnetic field will also be called the reason why the alloys in question are widely used. You can often encounter a situation where the production of structures is carried out, the operation of which generates a magnetic field. The use of titanium eliminates the possibility of bonding.

These main advantages of titanium alloys have determined their fairly wide distribution. However, as previously noted, much depends on the specific chemical composition. An example is that hardness changes depending on which substances are used for alloying.

It is important that the melting point can reach 1700 degrees Celsius. Due to this, the resistance of the composition to heat significantly increases, but the processing process also becomes more complicated.

Physical properties of products.

The elasticity of titanium is low, and when increased to 350 degrees it is reduced to a minimum. This is the only drawback of the material, but special attention should be paid to it when constructing a rigid structure and more sections should be used in the product.

Titanium has a high electrical resistivity, which depends on metal impurities and ranges from 42.10 to 80.90 Ohms. These products are paramagnetic, but compared to other metals, when heated, the magnetic susceptibility increases significantly.

Types of titanium alloys

Titanium alloys are classified according to a fairly large number of characteristics. All alloys can be divided into several main groups:

- High-strength and structural - durable titanium alloys, which also have fairly high ductility. Due to this, they can be used in the manufacture of parts subject to variable loads.

- Low-density heat-resistant alloys are used as a cheaper alternative to heat-resistant nickel alloys within a certain temperature range. The strength of such a titanium alloy can vary over a fairly wide range, depending on the specific chemical composition.

- Titanium alloys based on a chemical compound present a heat-resistant structure with low density. Due to a significant reduction in density, the weight is also reduced, and the heat resistance allows the material to be used in the manufacture of aircraft. In addition, this brand is also associated with high plasticity.

Types of titanium alloys

| Brand | Ti | Al | V | Mo | Zr | Si | Fe | O | N | C | Ost |

| VT1-00 | basic | 0,08 | 0,15 | 0,1 | 0,04 | 0,05 | 0,1 | ||||

| VT1-0 | basic | 0,1 | 0,3 | 0,2 | 0 | 0,1 | 0,3 | ||||

| VT1-2 | basic | 0,15 | 1,5 | 0,3 | 0,15 | 0,1 | 0,3 | ||||

| VTZ-1 | basic | 5,5-7,0 | 2,0-3,0 | 0,5 | 0,15-0,40 | 0,2-0,7 | 0,15 | 0,05 | 0,1 | 0,3 | |

| OT4 | basic | 3,5-5.0 | 0,3 | 0,12 | 0,3 | 0,15 | 0,05 | 0,1 | 0,3 | ||

| OT4-0 | basic | 0,4-1,4 | 0,3 | 0,12 | 0,3 | 0,15 | 0,05 | 0,1 | 0,3 | ||

| OT4-1 | basic | 1,5-2,5 | 0,3 | 0,12 | 0,3 | 0,15 | 0,05 | 0,1 | 0,3 | ||

| VT5 | basic | 4,5-6,2 | 1,2 | 0,8 | 0,3 | 0,12 | 0,3 | 0,2 | 0,05 | 0,1 | 0,3 |

| VT5-1 | basic | 4.3-6,0 | 1 | 0,3 | 0,12 | 0,3 | 0,15 | 0,05 | 0,1 | 0,3 | |

| VT6 | basic | 5,3-6,8 | 3,5-5,3 | 0,3 | 0,1 | 0,6 | 0,2 | 0,05 | 0,1 | 0,3 | |

| VT6S | basic | 5,3-6,5 | 3,5-4,5 | 0,3 | 0,15 | 0,25 | 0,15 | 0,04 | 0,1 | 0,3 | |

| VT8 | basic | 5,8-7,0 | 2,8-3,8 | 0,5 | 0,20-0,40 | 0,3 | 0,15 | 0,05 | 0,1 | 0,3 | |

| VT9 | basic | 5,8-7,0 | 2,8-3,8 | 1,0-2,0 | 0,20-0,35 | 0,25 | 0,15 | 0,05 | 0,1 | 0,3 | |

| VT14 | basic | 3,5-6,3 | 0,9-1,9 | 2,5-3,8 | 0 | 0,2 | 0,3 | 0,2 | 0,1 | 0,1 | 0,3 |

| VT15 | basic | 2,3-3,6 | 6,8-8 | 0,15 | 0,3 | 0,12 | 0,05 | 0,1 | 0,3 | ||

| VT16 | basic | 1,8-3,8 | 4-5 | 4,5-5,5 | 0,3 | 0,15 | 0,25 | 0,15 | 0,05 | 0,1 | 0,3 |

| VT18 | basic | 7,2-8,2 | 0,2-1 | 10-12 | 0,05-0,18 | 0,15 | 0,14 | 0,05 | 0,1 | 0,3 | |

| VT20 | basic | 5,5-7,0 | 0,8-2,5 | 0,5-2,0 | 1,5-2,5 | 0,15 | 0,25 | 0,15 | 0,05 | 0,1 | 0,3 |

| VT22 | basic | 4,4-5,7 | 4,0-5,5 | 4,0-5,5 | 0,3 | 0,15 | 0,5-1,5 | 0,18 | 0,05 | 0,1 | 0,3 |

| VT23 | basic | 4-6,3 | 4-5 | 1,5-2,5 | 0,3 | 0,15 | 0,4-0,1 | 0,15 | 0,05 | 0,1 | 0,3 |

| PT3V | basic | 3,5-5,0 | 1,2-2,5 | 0,3 | 0,12 | 0,25 | 0,15 | 0,04 | 0,1 | 0,3 | |

| PT-1M | basic | 0,2-0,7 | 0,3 | 0,1 | 0,2 | 0,12 | 0,04 | 0,07 | 0,3 | ||

| PT-7M | basic | 1,8-2,5 | 2,0-3,0 | 0,12 | 0,25 | 0,15 | 0,04 | 0,1 | 0,3 |

The marking of titanium alloys is carried out according to certain rules, which make it possible to determine the concentration of all elements. Let's take a closer look at some of the most common types of titanium alloys.

When considering the most common grades of titanium alloys, you should pay attention to VT1-00 and VT1-0. They belong to the class of technical titans. The composition of this titanium alloy includes a fairly large number of various impurities, which determine a decrease in strength. However, due to a decrease in strength, ductility increases significantly. High technological plasticity determines that technical titanium can be obtained even in the production of foil.

Very often the alloy composition in question is cold-worked. Due to this, strength increases, but ductility is significantly reduced. Many experts believe that the processing method in question cannot be called the best, since it does not have a comprehensive beneficial effect on the basic properties of the material.

The VT5 alloy is quite common and is characterized by the use of exclusively aluminum as an alloying element. It is important to note that aluminum is considered the most common alloying element in titanium alloys. This is due to the following points:

- The use of aluminum can significantly increase elastic moduli.

- Aluminum also allows you to increase the value of heat resistance.

- This metal is one of the most common of its kind, due to which the cost of the resulting material is significantly reduced.

- The indicator of hydrogen embrittlement decreases.

- The density of aluminum is lower than that of titanium, due to which the introduction of the alloying substance in question can significantly increase the specific strength.

When hot, VT5 is well forged, rolled and stamped. That is why it is often used for forging, rolling or stamping. Such a structure can withstand exposure to no more than 400 degrees Celsius.

Titanium alloy VT22 can have a very different structure, which depends on the chemical composition. The operational features of the material include the following points:

- High technological plasticity during hot pressure processing.

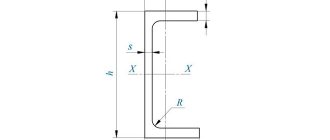

- Used for the manufacture of rods, pipes, plates, stampings, profiles.

- All the most common methods can be used for welding.

- An important point is that after completion of the welding process, it is recommended to carry out annealing, which significantly increases the mechanical properties of the resulting weld.

The performance qualities of VT22 titanium alloy can be significantly improved by using complex annealing technology. It involves heating to a high temperature and holding for several hours, after which gradual cooling in an oven is carried out, also holding for a long period. After high-quality annealing, the alloy is suitable for the manufacture of highly loaded parts and structures that can heat up to temperatures of more than 350 degrees Celsius. Examples include elements of the fuselage, wings, parts of the control system or fastenings.

Titanium alloy VT6 is now widely used abroad. The purpose of such a titanium alloy is to manufacture cylinders that can operate under high pressure. In addition, according to the results of studies, in 50% of cases in the aerospace industry, a titanium alloy is used, which in its performance qualities and composition corresponds to VT6. The GOST standard today is practically not used abroad to designate titanium and many other alloys, which should be taken into account. The designation uses its own unique marking.

VT6 has exceptional performance properties due to the fact that vanadium is also added to the composition. This alloying element is characterized by the fact that it increases not only strength, but also ductility.

This alloy deforms well when hot, which can also be called a positive quality. When using it, pipes, various profiles, plates, sheets, stampings and many other workpieces are obtained. All modern methods can be used for welding, which also significantly expands the scope of application of the titanium alloy in question. To improve performance, heat treatment is also carried out, for example, annealing or hardening. For a long time, annealing was carried out at temperatures no higher than 800 degrees Celsius, but the results of the studies indicate that it makes sense to increase the indicator to 950 degrees Celsius. Double annealing is often performed to improve corrosion resistance.

The VT8 alloy has also become widespread. Compared to the previous one, it has higher strength and heat-resistant qualities. They were able to achieve unique performance qualities by adding large amounts of aluminum and silicon to the composition. It is worth considering that the maximum temperature at which this titanium alloy can be operated is about 480 degrees Celsius. A variation of this composition can be called VT8-1. We will name the following points as its main operational qualities:

- High thermal stability.

- Low probability of cracks forming in the structure due to the provision of strong bonds.

- Manufacturability when carrying out various processing procedures, for example, cold stamping.

- High ductility combined with increased strength.

To significantly improve performance, double isothermal annealing is often carried out. In most cases, this titanium alloy is used in the production of forgings, ponds, various plates, stampings and other workpieces. However, it is worth considering that the characteristics of the composition do not allow welding work.

Heat-resistant Ti alloys

Heat-resistant titanium alloys – VT3 1, VT8-1, VT-9, VT8M-1, VT-18, VT-25 (1000.0-1500.0 MPa).

VT8-1, VT8M-1 - these grades of titanium alloys are characterized by heat resistance, crack resistance and stability at T 400-550C. They have low sensitivity to local stresses and are used for aircraft engines with a long service life.

The domestic alloy VT-25 with a strength index of up to 1150.0 MPa, significantly exceeds foreign analogues, has the highest properties at temperatures up to 550.0C.

VT-18 has the most durable properties at temperatures up to 600.0C - the best among domestic alloys used in industry.

Application of titanium alloys

Considering the areas of application of titanium alloys, we note that most of the varieties are used in the aviation and rocket industries, as well as in the manufacture of marine vessels. Other metals are not suitable for the manufacture of aircraft engine parts due to the fact that when heated to relatively low temperatures they begin to melt, resulting in deformation of the structure. Also, an increase in the weight of elements causes a loss of efficiency.

We will use the material in production:

- Pipelines used to supply various substances.

- Shut-off valves.

- Valves and other similar products that are used in aggressive chemical environments.

- In the aircraft industry, the alloy is used to produce skins, various fasteners, landing gear parts, power sets and other units. As the results of ongoing research show, the introduction of such material reduces weight by approximately 10-25%.

- Another area of application is rocketry. Short-term operation of the engine, movement at high speed and entry into dense layers becomes the reason why the structure experiences serious loads that not all materials can withstand.

- In the chemical industry, titanium alloy is used because it does not react to various substances.

- Titanium is good in shipbuilding because it does not react to the effects of salt water.

In general, we can say that the scope of application of titanium alloys is very extensive. In this case, alloying is carried out, due to which the basic performance qualities of the material are significantly increased.

Advantages/disadvantages

- Advantages:

- low density (4500 kg/m 3 ) helps reduce the weight of manufactured products;

- high mechanical strength. It is worth noting that at elevated temperatures (250-500 °C) titanium alloys are superior in strength to high-strength aluminum and magnesium alloys;

- unusually high corrosion resistance due to the ability of Ti to form thin (5-15 μm) continuous films of TiO2 oxide on the surface, firmly associated with the mass of the metal;

- the specific strength (the ratio of strength and density) of the best titanium alloys reaches 30-35 or more, which is almost twice the specific strength of alloy steels.

- Flaws:

- high production cost, Ti is much more expensive than iron, aluminum, copper, magnesium;

- active interaction at high temperatures, especially in the liquid state, with all gases that make up the atmosphere, as a result of which Ti and its alloys can only be melted in a vacuum or in an environment of inert gases;

- difficulties in involving titanium waste into production;

- poor antifriction properties due to Ti adhesion to many materials; titanium paired with titanium cannot work on friction at all;

- high susceptibility of Ti and many of its alloys to hydrogen embrittlement and salt corrosion;

- poor machinability, similar to the machinability of austenitic stainless steels;

- high chemical activity, tendency to grain growth at high temperatures and phase transformations during the welding cycle cause difficulties in welding titanium.

Heat treatment of titanium alloys

To improve performance, titanium alloys are subjected to heat treatment. This process becomes significantly more complicated due to the fact that the restructuring of the crystal lattice of the surface layer takes place at temperatures above 500 degrees Celsius. For VT5 and VT6-S alloys, annealing is often carried out. The holding time may vary significantly, depending on the thickness of the workpiece and other linear dimensions.

Parts made from VT14 must withstand temperatures of up to 400 degrees Celsius at the time of use. That is why heat treatment involves hardening followed by aging. In this case, hardening requires heating the environment to a temperature of about 900 degrees Celsius, while aging involves exposure to an environment with a temperature of 500 degrees Celsius for more than 12 hours.

Induction heating methods allow a wide variety of heat treatment processes to be carried out. Examples include annealing, aging, normalization, and so on. Specific heat treatment modes are selected depending on what performance characteristics need to be achieved.

Indicators of the specific gravity of other metals

Specific gravity is an indicator that is an integral characteristic of other metals.

The specific gravity of silver is affected by the fineness of the alloy. When other metals (copper, nickel) are added to it, the specific gravity and density are lost. Thus, the density of copper is 8.93 g/cm3, nickel – 8.91 g/cm3. All values are calculated using formulas.

Silver is the same noble metal as gold. Its specific gravity is 10.5 g/cm3. It melts at a temperature of 960 degrees. The main physical characteristics of silver are:

- corrosion resistance;

- low resistance;

- increased light reflectivity.

Despite its natural softness, silver has a high density and specific gravity.

Titanium is a non-ferrous metal of a white-silver hue. It has high strength, although it is light in weight. So, it is 12 times stronger than aluminum and 4 times stronger than copper and iron. In terms of the degree of presence in the earth's crust, titanium is given fourth place among the rest.

The low specific gravity of titanium - 4.505 g/cm3 is more consistent with alkali metals. An oxide film forms on its surface, which prevents the formation of corrosion.

Zinc is also a non-ferrous metal with a white-bluish tint. It has medium hardness and an initial melting point of 419 degrees. Under the influence of a temperature of 913 degrees, this metal acquires a vaporous state. Zinc has a specific gravity of 7.13 g/cm3.

Normal temperature makes zinc brittle, but increasing it to 100 degrees makes the metal flexible and ductile. When interacting with air, an oxide film forms on the surface of zinc.

The color of lead is dirty gray, but this does not affect the natural shine of the metal. However, the glow stops quite quickly due to the formation of an oxide film on the surface of the lead. The lead alloy has a high specific gravity - 11.337 g/cm3. In this indicator, it exceeds zinc, aluminum, iron and some other metals. Despite its high density, lead is a very soft metal.

The table shows the specific gravity and melting points of other metals.

| Name of metal | Melting point, °C | Specific gravity, g/cc |

| Zinc | 419.5 | 7.13 |

| Aluminum | 659 | 2.69808 |

| Lead | 327.4 | 11.337 |

| Tin | 231.9 | 7.29 |

| Copper | 1083 | 8.96 |

| Titanium | 1668 | 4.505 |

| Nickel | 1455 | 8.91 |

| Magnesium | 650 | 1.74 |

| Vanadium | 1900 | 6.11 |

| Tungsten | 3422 | 19.3 |

| Chromium | 1765 | 7.19 |

| Molybdenum | 2622 | 10.22 |

| Silver | 1000 | 10.5 |

| Tantalum | 3269 | 16.65 |

| Iron | 1535 | 7.85 |

| Gold | 1095 | 19.32 |

| Platinum | 1760 | 21.45 |