When replacing equipment, and when transforming the position of plumbing in the bathroom, the question of connection with the sewer system arises. A corrugated pipe for a toilet allows you to solve this problem as quickly and simply as possible, which is why the work on the product is significantly simplified. But it is extremely important to choose exactly the option that is suitable for your conditions and will help for as long as possible, this is what this article will be devoted to.

What it is?

A corrugated toilet flush is a transitional element for connecting the toilet to the sewerage system; it is a wide pipe with corrugated walls, made of thermoplastic.

The faucet pipe has at one end a pipe with a funnel-shaped expansion with seals inside - this side of the pipe is put on the toilet. On the other side of the pipe there is a pipe with an attached rubber sealing coupling to facilitate connection to the sewer riser.

Thanks to the corrugation, such an adapter can easily be stretched to the desired length and makes it easier to install.

Polypropylene bends for sewerage

Sewage outlets made of gray polypropylene are used only indoors; for outer diameters of sewer pipes of 110 mm, products with rotation angles of 15, 30, 45, 67, 87 degrees are used. Products made of polypropylene plastic have the following main characteristics:

- Polypropylene is afraid of ultraviolet radiation, so it is used only indoors.

- Neutrality towards acid, alkaline and alcohol solutions and inorganic compounds.

- The melting point of the material is about 170 C., during operation, the permissible temperature of the working fluid should not exceed 95 C.

- The brittleness temperature of the material ranges from -20 to -25 C.

As can be seen from the given characteristics, polypropylene is destroyed at insufficiently low temperatures, therefore the pipe and polypropylene sewer outlet are not used in external pipelines.

Rice. 7 Sewer outlet - types and sizes

When does it make sense to install corrugation?

It is not always necessary to use corrugation. Often the connection diagram does not change, and you can get by with ordinary plastic sewerage components. But there are situations when it is necessary to connect the toilet to the sewer using corrugated pipes:

- if, after repairs, the level of the toilet floor has changed and the sewer pipe does not coincide in level with the toilet outlet;

- if the release of the modern model does not coincide with the release of the dismantled one, and the drainage sewer systems in the house have not been changed (the old sewer system was installed based on a toilet with an oblique outlet, and modern models have a direct outlet);

- the diameter of the outlet of the sanitary fixture and the sewer pipe does not match;

- for temporary connection - if repairs are still underway and the pot needs to be used.

Advantages:

- low price;

- simple installation;

- Possibility of use in difficult cases when it is impossible to make an outlet using pipes or bends.

Disadvantages of corrugation:

- The main disadvantage of corrugation is its low strength. It can be damaged by a piece of glass or a piece of ceramic tile that accidentally falls into the drain, or a fallen object;

- plastic is not very resistant to heat, and poured boiling water can deform the plastic;

- if the corrugation is bent too much, a blockage may occur in it;

- a long corrugation may sag under the weight of its contents, and over time a blockage may occur; in this case, it is necessary to install supports;

- corrugation is not very aesthetic;

- Constant use of sewer cleaning products can lead to thinning of the walls of the adapter and the formation of leaks;

- black plaque on the walls can be visible through the stretched plastic;

- This adapter cannot be placed inside a wall.

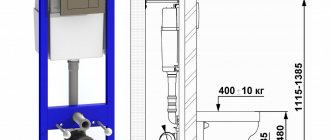

Wall-hung toilet

Installations today do not fall into the category of common toilet models, so connecting them is often difficult. Wall-hung plumbing fixtures are installed using a support structure in the form of a metal frame to secure the flush cistern and bowl. Installation and finishing make it possible to make only the toilet bowl and cistern button visible, and the piping system of frame and block structures is covered with finishing materials.

Model advantages:

- operational comfort;

- almost silent operation;

- absence of unpresentable appearance of risers;

- the ability to select a device to match the overall style.

Main disadvantages of the configuration:

- difficulty in choosing the optimal connection scheme;

- high cost of plumbing fixtures;

- complexity of audit and maintenance.

Each kit is complemented by a detailed connection diagram to the sewer pipe, and installation problems may be caused by the location of the toilet outlet, which is completely incompatible with the inlet in the tee. Under such conditions, a suspended model is connected to the sewer network using a flexible pipe. Corrugation allows you to connect elements located in different planes, but also lengthens the outlet section, which is not always necessary when installing an installation.

Alternatives to corrugations for releases

In fact, the only alternative to corrugation for connecting the toilet to the sewer pipe is the use of plastic pipes and toilet elbows (corners). Nowadays a huge variety of components for plastic sewers are produced, and you can always choose the right parts. Pipes and bends have sockets. The joints are sealed using rubber cuffs and sealant.

Connecting with plastic pipes is more aesthetically pleasing and durable, but more cumbersome. A serious disadvantage is that to replace the pipes you will have to dismantle the toilet.

Vertical release

Such models are rarely installed and mainly in bathrooms in private homes. The main reason is that to repair the sewerage, you will have to open up the floors. It is connected using straight pipes with a diameter of 110 mm and the same angles (one at 90° or two at 135°).

Toilet pipes are cut if necessary.

Horizontal release

The most common model of modern sanitaryware. Connect using corner bends with a diameter of 110 mm.

Oblique release

Connect using corner bends with a diameter of 110 mm.

Standards regulating the diameters of sewer pipes

Any structurally required diameter of sewer pipes is regulated by SNiP 2.04.01085. There are methods for calculating all the main parameters of such pipes. The calculations there are not simple; they involve taking into account a variety of factors, for example, the slope of horizontal sections, the angle at which the outlets from the apartments are connected to the riser, and many others.

The tables, which are presented in this SNiP for clarity, contain data that allows one to calculate the maximum permeability of a pipe with a clearly fixed diameter, in other words, to solve the inverse problem.

But most often we need a solution that is clear, simple and gives accurate values for all the main characteristics.

And the solution is this:

- A pipe with a diameter of one hundred millimeters will be quite enough to organize a sewer system in any house or apartment, when the number of plumbing fixtures is within reason.

- A fifty-millimeter sewer pipe is suitable for washbasins, bidets, bathtubs and urinals: this diameter is sufficient for flushing plumbing fixtures.

Advice!

It must be remembered that the internal diameter of cast iron sewer pipes decreases over time due to the fact that they become silted.

Diameters and slopes of pipes according to SNIP for certain sections and plumbing fixtures of the sewer system

- In multi-storey buildings, if there are five floors, the risers are made with a diameter of one hundred millimeters, if there are more floors - 150 mm.

- The areas of the drainage system that are common to several risers, as well as the exit to the well, are made with a diameter of 200 millimeters.

Plastic sewer pipes do not change their internal diameters, unlike cast iron ones. Due to the fact that their surface is smooth, fat deposits do not form on it. If the correct slope of the pipe is organized and there are no unevenness or roughness inside it, then there will be no deposits of sand and silt either.

It is this phenomenon that makes it possible to install different diameters of pipes made of cast iron or plastic: the diameter of a plastic pipe can be chosen smaller than a cast iron one, for example, a cast iron “fifty” can be replaced with a forty-millimeter plastic pipe.

How to choose?

According to technical characteristics and design, several types of toilet corrugation can be distinguished:

- in terms of rigidity - hard and soft. The soft one is made of thinner plastic, more elastic, suitable for a toilet with any outlet - vertical, horizontal, oblique. It is easier to install, as it is more elastic and bends easier. Rigid corrugation has thicker walls and is more wear-resistant;

- according to reliability - reinforced or unreinforced. Reinforced corrugation has greater rigidity, greater strength, wear resistance, and, as a result, greater durability. Reinforced, reinforced with thin wire cast into the walls. Reinforced products are usually imported and cost slightly more than non-reinforced ones, but this is the case when “the miser pays twice”;

- long or short. The length is chosen according to the distance from the plumbing to the sewer, but it should be borne in mind that the corrugation should not be greatly stretched - this negatively affects the service life and appearance. A stretched product is more likely to cause sagging and leaks.

For difficult cases, there are models with a curved bell with a bend angle of 45° and 90°.

For compact placement of other plumbing fixtures in small bathrooms, there are models with an outlet to which you can connect a bathtub or sink drain.

Sizes and prices

Products found on the market have standardized sizes.

- Length of products: short corrugation in a compressed state has a length of 212 mm, in an extended state - 320 mm; long - 285 and 500 mm, respectively. If a short model will have to be stretched greatly, then it is better to choose a longer model.

- Diameters: the socket that fits onto the sanitary fixture has a diameter of 134 mm; the hole in the seal in the socket has an internal diameter of 75 mm; the cuff for connection to the sewer has an outer diameter of 110 mm.

How to remove the old one and install a new corrugation?

Sometimes it becomes necessary to remove the old corrugation and replace it with a new one.

This process will be easier if:

- If the old corrugation is stretched to its maximum. Then it is easy to remove it from the pipe, and then from the sewer pipe. The remaining liquid is easily removed from the pipe and drained into the sewer.

- If the toilet is in a corner, then the arc rule is used. Then the corrugation can be easily removed from both pipes. First, it is removed from the toilet pipe. It happens that the corrugation is not stretched because the toilet is located very close to the drain. To make it easier to remove it, you will need to dismantle the toilet itself.

Then you can install a new corrugation. Installation is carried out in reverse order.

Installation

- First, the pipe is thoroughly cleaned of excess seals and connections that were previously in it. Approximately the same is done with a sewer drain pipe. It happens that old joints are sealed using concrete, then it is necessary to knock them down with a hammer and chisel.

- The joints are wiped dry so that no greasy stains or dust remain there. It is necessary not to allow traces of sealant or other means from previous installation to remain on the surface of the pipe.

- First, the corrugation is inserted into the toilet, it is moved towards the drain and the other end is inserted into it.

- It is advisable that the corrugated pipe is not under strong tension. This will extend the period of its use.

- Finally, the toilet is attached to the floor.

Practical recommendations:

- The plumbing fixture can be located at an impressive distance from the wall. Then some try to stretch the pipe. This does not need to be done until the moment when it is securely fixed in the socket of the sewer pipe and the pipe. It is more advisable to do this before connecting to communications, otherwise the resulting length may exceed the required length for a long period. And the walls will become thinner and the risk of them bursting will increase.

- Do not allow sagging to form on the surface of the tube . In such a place, waste may accumulate. Because of this, the pipe may become clogged, and waste disposal will be difficult. This causes leaks and the need for repairs. In order to eliminate sagging, you need to correctly set the height of the toilet and sewer outlet opening. They should be at the same height and at a low distance from the floor. Otherwise, you will need to make the stand yourself from the materials you have on hand. It supports the corrugation in the middle.

- Nowadays, most people strive for an aesthetic appearance of the bathroom; they hide the corrugation with boxes or a screen. To avoid empty spaces, various accessories are sometimes placed and stored. But do not forget that the corrugation, although reinforced, is not cast iron and overload is contraindicated for it. Deflections may occur and there is a risk that the pipe will burst.

- If a crack is detected on the corrugation, it must be replaced without delay with another one. Often, owners tried to solve the problem with their own hands using improvised means. But this does not make it possible to correct the situation. The glued areas will subsequently diverge and leak. And this problem can only be eliminated by replacing the corrugation.

- To ensure a reliable connection between the pipe and the corrugation, a special sealant for plumbing products is used. Although a high-quality product should already have membranes that seal the joints, these actions are still necessary.

- When installation is completed , you need to check the tightness of the entire structure. You need to rinse the water from the barrel into the bowl and make sure that the liquid does not flow from any pipes or from their connections.

How to make a replacement:

- The old corrugation is removed, then the toilet pipe and pipes are thoroughly cleaned. It happens that old joints are sealed with concrete, then you have to use a hammer and chisel.

- The joints should be wiped with a dry cloth so that no sealant from the previous installation remains.

- A new corrugation is attached to the outlet of the toilet.

- Installation of the toilet, then the other end of the tube is inserted into the sewer hole.

- Installation of a drain tank.

Installation procedure

The need to connect the corrugation arises in two cases:

- when installing new plumbing;

- when replacing a leaking connector.

Before choosing a fitting, you need to measure the distance from the outlet to the sewer, and think about which model will be convenient to install.

How to remove the old connector?

If there is a need to repair the outlet, you must first remove the old connector. First, the corrugation is compressed and removed from the outlet of the sanitary fixture, then pulled out of the sewer socket. If your pot was connected using plastic pipes, then you should cut a piece out of the pipe and remove the remains of the connector. If the toilet was connected using a cast iron pipe, then it is almost impossible to keep the earthenware product intact - you will have to break it.

Then the remaining silicone, cement, and limescale deposits are removed from the sanitary fixture and sewer pipe - they affect the tightness of the future connection.

How to shorten the corrugation?

The idea is risky, but not hopeless. Using a thin knife with a narrow blade, you need to carefully disconnect the corrugation from the pipe from the sewer side, shorten the pipe itself, and carefully glue the sealant back into the pipe. Allow to dry for at least three hours. Insert the pipe back into the sewer riser. Drain the tank and check the joint for leaks. If it leaks, coat it with sealant.

These actions will help you survive until Saturday, but you shouldn’t leave such a homemade project forever - the neighbors will have to give their money for repairs forever.

How to install corrugation?

Before starting work, you should inspect the drain pipe to see if there are any cracks and whether it is suitable in size, length and shape (some have a curved pipe and an outlet for other plumbing fixtures).

First, the corrugation is installed on the toilet, then it is installed in place. You need to apply a little sealant to the outlet from the outside and pull the edge of the corrugation with a socket and a special rubber cuff for the toilet over it. You need to tighten the socket with great effort - then the seal will stretch and securely grip the outlet. The bell should sit without distortion and cover the edge of the outlet by 5-6 cm.

You need to let the sealant set and install the plumbing in place. The time for partial hardening of the plumbing sealant is approximately 3 hours, the time for the film to appear is 15 minutes, and the time for complete drying is 24 hours.

Before connecting the socket of a sewer pipe with a rubber seal, it is necessary to lubricate the socket with sealant (inside) and insert the other edge of the pipe (with the sealing collar). Let it sit for 2-3 hours, pour three liters of water into the toilet, then check for leaks. If all is well, pour out ten liters and inspect the corrugation again.

You can wrap the corrugation with toilet paper - the slightest leak will be clearly visible.

If a leak is found, this place should be coated with sealant and allowed to set, wipe the joints dry and pour water again and check for leaks.

That's it - the corrugation is installed, the toilet is connected!

Common mistakes

- the pipe is too stretched. Reduces mechanical strength, increases the likelihood of leakage. It sags and looks unsightly. It is better to place a support under the sagging area;

- pipe is too compressed. When replacing the corrugation in the future, it cannot be dismantled; the toilet will have to be dismantled;

- Pipe bend angle is too sharp. Lead to blockages and premature destruction.

Sealing the outlet

Sealing joints is an absolutely necessary procedure. It should not be neglected.

Installing and replacing toilet corrugations in a toilet is quite a task even for an inexperienced home plumber. We hope that this article will help our reader learn how to properly install corrugation on a toilet.

Share useful information on social networks with friends. Subscribe to our newsletter - and you will always be aware of all the useful tips for renovating your home.

(

1 ratings, average: 5.00 out of 5)

Advantages and disadvantages

Corrugated toilet flush is in demand among consumers due to a number of positive qualities :

- easy installation: no special tools are needed, as well as extensive experience in performing such work;

- light weight of the product: installation is done by hand;

- low price;

- when displaced or in an area of complex configuration, a flexible pipe makes it possible to connect the sewer riser and the toilet outlet;

- corrugation helps to join elements of the sewerage system that do not match in diameter;

- resistance to corrosion;

- no need to dismantle the toilet;

- significant permeability due to the device: when stretched, the stiffening rings that make up the walls of the flexible pipe acquire a certain volume, which slightly increases the diameter of the product in the area between the cuffs.

Corrugation for the toilet: advantages and disadvantages.

This product also has disadvantages:

- low strength: when a sharp object, a splinter, gets into the pipe, the risk of damage to the walls increases, which may result in a leak that cannot be eliminated;

- Do not use a pipe that is too small or large, as it will sag under the weight of the contents;

- installation errors (installation at an inappropriate angle, significant bending) can lead to clogging;

- rapid clogging is also determined by the ability of the pipe to retain contaminants on the walls;

- insufficiently long service life;

- In terms of attractiveness, such a product is inferior to smooth-walled analogues;

- installation restrictions: it is impossible to cover the toilet outlet with plasterboard, as well as install it inside the floor.

The prohibition on installation in the thickness of the wall is due to the high probability of leakage. It is difficult to detect damage in time; as a result, sewage will enter the premises.

Some useful installation tips

To increase the service life of plastic fittings, following a number of rules:

- The sleeve must correspond to the dimensions of the toilet and waste pipe. For a non-standard type of device location, use an adapter with an offset of up to 200 mm.

- You cannot rotate a reinforced part at an angle of 90⁰.

- If the accordion is strongly pinched, the drain will not be effective, and the fittings may burst. To bend the element, it is necessary to connect 2 corrugated pipes.

- Such fittings are not intended for heavy loads, and the connector cannot be installed in the walls. It is also prohibited to use it as a channel for hot water.

Pull out the corrugation before connecting it to the sewer system. Otherwise, the sleeve will sag and a cavity will appear in which deposits will begin to accumulate. Clamps or supports will prevent rupture of the pipe shell. They can also be used when installing the adapter at a distance from the floor.

You should take care of the safety of the corrugation when installing a protective panel for masking communications in the toilet yourself, since a heavy object can damage it.

When should you install a corrugated connector?

Before purchasing, study the technical specifications.

It is permissible to install such a pipe when other options cannot be used:

- corrugation is used as a temporary measure, during the construction phase or in case of leakage of an existing pipe, and it takes more time to select, purchase and deliver a new one;

- changing the existing layout of plumbing fixtures in the bathroom: the toilet is shifted relative to the sewer riser, the floor level becomes higher;

- discrepancy between the diameters of the toilet flush and the pipe connection of the sewerage system;

- The plumbing fixture was replaced, and when purchasing a new one, the type of outlet was not taken into account: straight or oblique.

The reason may be due to repairs. In this case, the cladding is often mounted on top of the old coating. The bathroom also contains household appliances, such as a washing machine. Often problems during the installation of communications arise when you need to install a new plumbing fixture in a bathroom where the pipes have not been changed for a long time.

Types and sizes of corrugated pipes

Available options:

- rigid pipe;

- non-rigid

Corrugation options for toilet bowl.

The first type is much stronger. The significant thickness of the walls makes this corrugation wear-resistant. In this case, the connection to the sewer riser outlet is made when the deviation from the horizontal is small. Such a pipe serves for a long time, but due to its rigidity, its scope of application is narrowed.

Non-rigid products, on the contrary, are elastic. They easily take the desired shape and allow you to make a bend of any size. Such properties help to install corrugation on any toilet (with direct, oblique outlet). However, the pipe wall is thin, which reduces strength and wear resistance.

Non-rigid products do not last long. During operation, there is a risk of damaging the corrugation, since it is exposed to any relatively sharp object. An elastic pipe is used only when it is impossible to install a smooth-walled analog or rigid corrugation. Such products quickly begin to sag, which is why they are soon damaged because they cannot withstand the load exerted by the contents.

There are other types of corrugated products:

- reinforced;

- unreinforced.

The first option better withstands loads, is durable and wear-resistant. Thanks to these properties, corrugation lasts longer. It is distinguished by the presence of reinforcement in the walls. To strengthen the pipe, use wire of a minimum cross-section. It is poured into the thickness of the material at the production stage.

Non-reinforced products are inferior in strength. They cannot withstand significant loads, so they do not last long. This option is used as a temporary measure. Reinforced corrugation is also used on an ongoing basis. Only a flexible pipe is used for connection in a difficult area.

Varieties of corrugation sizes for toilet bowls.

There are products that differ in length. It is recommended to purchase a pipe with a margin of no more than 5 cm. Otherwise, the corrugation will sag, which will lead to blockage.

For the same reason, do not install too long products. If the corrugation is short, it will have to be stretched to the limit due to the stiffening rings. Because of this, the functionality of the product is reduced, since the load is placed not only on the stiffening rings, but also on the soft areas.

The diameter of the corrugation is 50-200 mm. In apartments, a 110 mm product is installed for connection to the sewerage system. The length is limited: 0.23-0.5 m. Communications that are less than or greater than the values of the specified range are not advisable to use.

Practical recommendations

- Do not stretch the corrugation before installing it on the toilet. This can only be done immediately before starting installation work. If you stretch the corrugation too much, it will be difficult to return it to its original state.

- Do not use a corrugated pipe as an additional shelf for various household items. If you place a heavy object on it, it may burst.

- When buying corrugation, pay attention to the thickness of the walls: the thicker it is, the longer the product will last. In addition, try to buy products from European manufacturers. They are more expensive, but their quality is significantly higher than that of their domestic and Chinese counterparts.

- If you are the happy owner of your own home, then you should seriously think about the need to use plastic corrugated pipes. The fact is that mice, rats and other small rodents consider plastic a very tasty product. If these uninvited guests are noticed in your home, then you better opt for metal pipes.

Related article: How to decorate heating pipes

A corrugated pipe for a toilet bowl can be a real salvation in difficult situations related to mismatches in the parameters of the connected equipment. Like any other modern technical solution, it has its advantages and disadvantages. Use light and elastic corrugation or use more bulky, durable and long-lasting connection methods – it’s up to you. But whatever your decision, we hope that our article helped you make the right choice.

pros

The use of corrugation for a toilet bowl has both advantages and disadvantages. Let's look at both sides of this phenomenon.

So, the advantages of using corrugated pipes:

- Installing corrugation will not be difficult even for those who are just starting to take their first steps in the field of plumbing work.

- In difficult connection cases, you cannot do without corrugation, as it is the most flexible of all the options offered.

- Corrugation can be considered as a temporary connection option that can be quickly dismantled.

- If the type of toilet outlet does not match the sewer pipe, then a corrugated pipe easily solves this problem.

Installation and fastening of the toilet

Before you begin connecting the toilet to the drainage system, it must be securely installed and secured. There are 2 main types of installation: attaching the toilet directly to the floor screed or through an intermediate taffeta. In the first case, fastening is carried out using dowels through the corresponding tides at the base of the structure. The plumbing fixture is placed in the selected location, and 4 fasteners are marked. Then, using a hammer drill, holes are made in the concrete floor screed into which the dowels are driven. The toilet itself is secured with large screws through a plastic sleeve that prevents damage to the porcelain.

Better leveling and eliminating the risk of damage is achieved by using taffeta - a wooden plate made from hard, durable wood. First, such taffeta is secured to the floor using anchors. It is carefully leveled horizontally using a building level. The toilet is then attached to the wooden plastic with screws.