Making a gas burner for a boiler with your own hands

The main element of a gas boiler is the burner. It is around it that all other elements are displayed. Many aspects of the use of the equipment depend on the design of the node. First of all, it is safety and efficiency. Therefore, many people want to make a gas burner for the boiler with their own hands, which will meet all the requirements of the owners. At first glance, this may seem like a complicated process, but in reality it is not.

Types of burners

Many people believe that a burner is simply a nozzle through which gas is supplied. But it is not so. It also mixes air into the fuel. It is important to consider that the product must have a special design that makes the mixture stable.

The device can be of several types, depending on the method of adding oxygen to the gas:

- atmospheric burner;

- ventilator;

- diffusion-kinetic.

Atmospheric

The operating principle of this component is simple: gas passes through an ejector, where its pressure is reduced. In this case, air gets inside due to different atmospheric parameters.

These devices have many advantages:

- simple design;

- compactness;

- quiet operation;

- reasonable cost;

- the possibility of converting a solid fuel boiler for this equipment - the burner is simply installed in the ash pan chamber.

Fan

In this type of device, air is supplied in the required quantity through a fan. Due to this supply of oxygen, they have many advantages:

- There are no restrictions on power - any amount of gas is provided with the required amount of air, which is needed for complete combustion without residues.

- The chamber in which the reaction takes place may be closed. Oxygen enters inside through a special air duct. This allows you to completely prevent combustion products from entering the house due to reverse draft. There is no need to install a separate air duct. For this, special coaxial chimneys are used, which in fact are a pipe located inside another. The smoke is discharged through the internal element, and oxygen enters the boiler, passing between the internal and external walls.

- Human participation during use is minimized, since the equipment has a “smart” configuration function.

This type of burner also has a number of disadvantages:

- Compared to atmospheric ones, they are noticeably louder.

- They have a high price.

- They only work in conjunction with electricity - they must have their own uninterruptible power supply. Otherwise, they may fail due to voltage drop.

Diffusion-kinetic

Basically, such equipment is found in large industrial heaters. The operating principle is based on both atmospheric and fan heating.

DIY gas burner

Since designing a fan type requires special equipment, let’s consider creating a gas burner for a solid fuel boiler with your own hands. It is best to choose a valve from an oxygen cylinder, standard VK-74. To do this you need:

- The outlet pipe is additionally equipped with a fitting, which can be connected to the reactor using a hose.

- A cap with a small hole for connection to the nozzle is installed on the inlet side of the pipe connected to the cylinder. The latter can be taken from a blowtorch or stove.

- A steel pipe with a length of 100 mm and a wall thickness of 2 mm is welded to the cap.

- It is imperative to ensure that there is a gap of 15 mm between the cap and the nozzle, through which oxygen will flow. That is why you must first attach three small pieces of wire to the first one (they can then be bent to the desired location), and only then the pipe.

- The burner itself is ready. After this, you need to make a base on which it will be located for installation in the combustion chamber.

In addition to creating the burner itself, it is also important to follow the process of lighting it:

- The gas supply valve on the cylinder or line opens.

- A match is brought to the nozzle.

- The main valve opens.

Important! The power of the device can be adjusted using a valve. The hottest flame is green-blue.

The whole setup consists of placing the torch in the center. To do this, the wire holders are slightly bent.

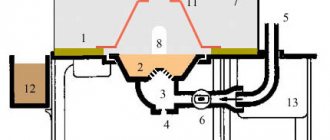

The manufacturing process of an atmospheric gas burner

An atmospheric burner is easier to build, since it is structurally much simpler than its fan counterpart. The most typical example known to most Russians is the burner block in old-style geysers. There are no energy-dependent elements in its design that force gas and air to mix in the required proportions.

Air is drawn into the chamber with the atmospheric burner module spontaneously as needed. Blue fuel processing products are discharged naturally through a standard chimney due to the presence of draft. All the work consists of constructing a manifold with gas nozzles through which gas will flow at the required speed.

To make a burner with your own hands to equip a gas heating boiler, you will need:

All of the above elements are assembled mainly by welding. Therefore, skills and minimal knowledge in welding will be very useful for an enterprising “do-it-yourselfer”. However, where it is possible to use threads, it should remain a priority.

The gas supply channel must be impeccable and sealed, because safety depends on its condition. A distance of 10 cm must be maintained between the gas inlet into the device and the nozzle, which is necessary for mixing fuel with air.

The home craftsman just has to figure out how to secure a homemade gas burner in the combustion chamber of a used water heater or in the firebox of a former wood-burning boiler. Please note that you need to leave room for air flow. Air must be regularly supplied to the chamber, for which round or longitudinal holes must be cut in the door.

Do not forget that the above option can hardly be called a safe gas supply device. The design does not have automatic equipment that interrupts the operation of the boiler in case of blowing out or unstable flame. Owners will not have the opportunity to adjust the pressure and gas flow, so there can be no talk of either convenience or savings.

Features of use

Gas burners are unpretentious in maintenance. The main feature is annual cleaning. In this case, the procedure should only be carried out by highly qualified specialists, since this requires disassembling the boiler. Most often, burner cleaning is carried out by a service center.

Dirt can be easily removed using compressed air. It is important to set the appropriate pressure. The fact is that some modern parts may not withstand a flow of 10 atm.

To make the cleaning process faster and less frequently required, a special filter is installed on the gas supply. This is done by the master after submitting an application to the appropriate structure.

Well, despite the fact that a gas burner in a heating boiler seems like a very complex engineering unit, you can still make it yourself without any problems. To do this, you need to prepare all the necessary materials and have the skills to work with metal. In addition, you must have several units of special tools.

Types of gas burners

Before classifying gas burners for boilers, you should determine what is happening inside, and this is:

- passage of flammable material through the burner (in our case gas),

- adding air to this fuel.

The design of the device must maintain combustion stability of the gas-air composition.

There are several types of burners based on the method of supplying air to the gas flow:

- atmospheric;

- with fans;

- diffuse-kinetic.

Also, a homemade gas burner differs in the number of stages:

- One step. First of all, this is the operation of the device with stable power: the temperature of the air in the premises or the thermal fluid is maintained at a certain level. This is the merit of igniting or turning off the burner at the required time. In this case, temperature jumps are observed within a certain spectrum. It is worth noting the rather modest service life of such a burner.

- Two steps. The device operates in two modes. When the load on the heating network is low, half mode operates, ensuring stable operation of the boiler and less wear and tear on the equipment. The nominal mode is activated at heavy loads. The power of the device can be controlled gradually from zero to the nominal value. Therefore, gas equipment can operate continuously and in optimal conditions for many years.

As for the characteristic features of a good burner, these are: the efficiency of the device, nitrogen oxide and carbon monoxide enter the air;

- decent service life of the device;

- simplicity of design;

- ease of installation;

- noise within sanitary standards;

- quick changeover from one type of fuel to another. This criterion applies to combined versions.

Atmospheric gas burners

They suck in air like a jet pump. That is, the gas follows through the ejector, where due to high dynamics its pressure decreases. Air is introduced into the gas flow due to pressure surges.

- simple design;

- compact dimensions;

- energy independence;

- low noise;

- attractive prices.

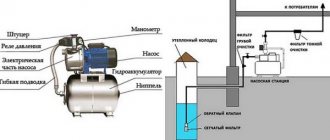

Installing a gas burner in a solid fuel boiler

After sound reflection and a real assessment of their capabilities, most home craftsmen still give preference to the modernization of solid fuel boilers that previously processed firewood or coal. A factory-made gas burner is simply placed in their firebox.

To equip your country property, you can purchase a solid fuel unit, which can be converted into a gas one. For example, a Teplodar stove in which a gas burner is mounted

Let's consider the stages of installing a Teplodar AGG burner device:

- Dismantling the firebox door, the ashpan damper (or the ashpan itself, if it is made in the form of a drawer with a solid door), the bumper and the grate. In short, you need to remove all structural parts located within the firebox and ash pan.

- Fixing the burner device. A burner block is mounted in the firebox channel freed from the above elements. If the Teplodar stove is designed for changing fuel, then the burner module is fixed in the channel through standard ears with screws and nuts threaded into them.

- Connecting automation to the remote control. The devices included in the design of the burner block that ensure automatic operation of the boiler are connected to the control panel.

- Thermostat sensor mount. It is installed on the supply pipe, wrapped in insulation to protect against external mechanical and temperature influences, and on top with ties.

- Putting it into operation. It is carried out after checking the draft and burst ventilation of the room with a modernized boiler. Using a simple handle, you select the most suitable mode.

We remind you that in accordance with the requirements outlined in the “Safety Rules for Gas Distribution and Gas Consumption Systems”, all work on installing equipment, replacing burners, servicing equipment and connecting to the network supplying blue fuel must be carried out by gas workers.

The technical documentation attached to the Teplodar stove contains a detailed description of the process of installing a gas burner for converting a solid fuel unit into a gas one

In accordance with federal regulations and standards, it is necessary to conclude an agreement with representatives of gas services for the supply of gas and related services. It is clear that not all remote settlements will be able to be served by employees of gas organizations. However, it is advisable to adhere to the requirements in order to avoid catastrophic consequences.

When it decreases and suddenly goes out, the current coming from the electrical element is weakened, as a result of which the gas supply channel is blocked. Overheating of water in the boiler is detected by a temperature sensor, which transmits a signal to open the contact pair blocking the burner

Should you take risks or value and protect your health with the well-being of your loved ones? It's up to you to decide. It is wiser to refuse threatening measures, but knowing about the process of their implementation is very useful in order to monitor how efficiently and honestly the gas workers work.

The process of creating a burner yourself

A homemade version of the burner for gas boilers operating on solid fuel can be made based on a valve from a gas cylinder, more precisely an oxygen one. A homemade fitting must be inserted into its outlet pipe. It can then be attached to the gearbox. The connecting element becomes a rubber-fabric hose when manufactured independently.

The inlet pipe enters the cylinder itself during the manufacturing process. You need to put a cap on it. A hole is made in the cap for connecting a jet, which is taken from a gas stove or a blowtorch.

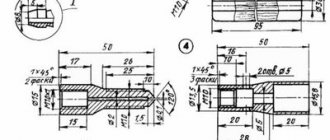

Using welding, a nozzle is attached to a homemade cap. The nozzle is a steel pipe element. Its length is 10 cm. Wall density is 2 mm.

The cap and the nozzle separate some space - 1.5 cm. Air is drawn in through it. For this reason, three thick wire elements are first attached to the cap in the same way. And a pipe-nozzle is mounted to them.

The methods for igniting this homemade product are as follows: opening a tap on the main gas network, or on a cylinder (it is needed when using a liquefied gas format).

The nozzle holds a fire source: a match, a lighter or a lit paper wick. Production is not difficult, at first glance.

How to do it yourself?

Let's consider an example of manufacturing a gas burner for a boiler unit operating on solid fuel. It is better to use a valve from an oxygen cylinder made according to the standard, VK-74.

To create a burner you must complete the following steps.

- The outlet pipe should be equipped with a fitting, which will be connected to the reactor using a hose.

- We mount a cap on the inlet pipe part connected to the cylinder, where there is a small hole for connecting to the nozzle. It can be found on the stove or in a blowtorch.

- Now a steel pipe with a length of one hundred millimeters and a wall thickness of two millimeters is welded to the cap.

- There should be a distance of one and a half centimeters between the nozzle and the cap, through which access to oxygen will be provided. For this reason, you first need to attach 3 small pieces of wire to the cap, and then the pipe itself.

The burner is ready. All that remains is to make a base on which the device will be placed for installation in the combustion chamber.

In addition to making the burner itself, you should follow certain recommendations when lighting it:

- first we open the gas supply;

- bring the match to the nozzle;

- open the main valve.

It should be said that the power of a homemade burner is easy to regulate using a valve.

Opening the valve

The power of such a device can be controlled by closing or opening the valve. The highest temperature is concentrated in the green-blue part of the fire. To adjust the nozzle, you need to place a torch in the middle of it. To do this, the wire holders are slightly bent.

To create a working version of the burner, a tip is welded to its nozzle. Its angle of curvature is 45 ⸰.

The basis for manufacturing may be a steel valve (also from a cylinder). A plug with a hole for the nozzle is threaded onto its exiting section. It is taken from a blowtorch. The diameter of its nozzle is 0.8 mm. The required diameter of the burner nozzle is 3 cm. The length of the nozzle can be varied with nozzles. This is how the torch parameters are controlled. The valve becomes the regulator here.

Service details

Maintenance of gas burners of any homemade version involves only cleaning it. This process must be annual. Doing it yourself is not recommended. After all, you will have to disassemble and reassemble the boiler. As a rule, people turn to service centers for service. Accumulated contaminants are eliminated by air blowing. The air here is compressed.

The pressure to the burners must be adjusted carefully. For example, for some current versions of burners, parameters of 8-10 atm can be detrimental.

The need for cleaning the burner can be reduced significantly if a filter is installed on the gas supply pipe. This work is performed by a gas service employee, who should be contacted with a special request.

Is it worth designing a gas boiler yourself?

Let’s begin our analysis of options for making a gas boiler with our own hands with the fact that the fuel they process is classified as toxic and explosive substances. Gas is highly flammable. The slightest miscalculations in the design and implementation of homemade products can result in serious destruction, damage to health, and loss of property.

Therefore, we do not recommend developing a model of a gas boiler for people who do not have a technical education with a specialization in the design of gas equipment. Yes, often even experienced gas workers will not take on such a project.

The optimal solution is quite reasonably considered to be:

- Converting a solid fuel model into a gas boiler by installing a gas burner in the firebox;

- Improvement of an old but functional unit with a focus on use in a heating circuit. Supplementing the factory model with devices for heating and stimulating the movement of coolant;

- Manufacturing of a pyrolysis boiler - equipment that generates gaseous fuel as a result of processing solid fuel at the initial stage. At the secondary stage, the gas released during the combustion of wood is burned in an additional firebox.

If you still have a desire to thoroughly study the issue and invent a version of a homemade gas boiler for autonomous heating in a private house, get ready for a literal “walk through agony.” You will have to obtain permits and confirmation of the safety of the invention from a number of government supervisory authorities.

An independent craftsman will need:

- Check the boiler for compliance with safety requirements , and then obtain a confirming or refuting document.

- Obtain permits from GosTechNadzor, Fire Inspectorate of the Ministry of Emergency Situations and GorGaz.

- Apply for a patent and a certificate allowing one-time or continuous production.

This list, although not numerous, is quite impressive and can discourage any folk from inventing documents. However, it will not be able to quell the desire to modernize an existing unit by installing factory-assembled burner modules. The improvement easily combines operational safety with increased efficiency.

The most important working part in gas equipment is the burner. Installing it will turn any boiler into the type of coolant and hot water heater we require for sanitary purposes.

Depending on the method of supplying the combustion air required for combustion to the combustion chamber, burners are divided into two main groups:

- Atmospheric. They are installed in open combustion chambers of atmospheric boilers. In them, air is drawn freely from the room in which the boiler is located.

- Fan (also known as blower). Such models are equipped with closed combustion chambers into which air is forced in a forced manner and captured from the street. To remove flue gases, they require a coaxial chimney and a fan.

Blowing designs are too complex for home creativity. They are easier and more profitable to buy. After all, purchasing all the adjustment and safety devices for operating a fan burner can be more expensive than purchasing a module ready for installation.

It is also advisable to purchase an atmospheric burner, but you can make the simplest version with your own hands. Below we will consider how and from what it can be assembled.

Fan

In such devices, air is pumped by a fan in the amount required. Thanks to the forced supply of oxygen, the following can be achieved:

- The power is not limited in any way - with the help of a fan, any amount of gas fuel can be provided with a sufficient volume of air for complete combustion.

- The combustion chamber can be made closed, that is, isolated from the boiler room. Air enters such a chamber from the outside - through a special air duct. Accordingly, the danger of flue gases entering the house due to reverse draft is eliminated, and the requirements for supply ventilation of the boiler room are reduced. In a boiler with an atmospheric burner, a closed chamber would be impossible, since the force of natural draft would not be able to overcome the aerodynamic resistance of the air duct and deliver a sufficient amount of air to the burner. It should be emphasized that for the operation of a boiler with a closed chamber it is not necessary to install a separate air duct: the so-called. coaxial chimneys, which are a pipe in a pipe. Flue gases are discharged through the inner pipe, and fresh air is supplied through a cylindrical channel between the walls of the pipes - internal and external.

- Devices with forced air supply “know how” to perform self-tuning, due to which user participation is reduced to a minimum.

Pressurized gas burner

Fan burners are more expensive than atmospheric burners and are noisier in operation. In addition, they cannot work without electricity, so they have to be equipped with uninterruptible power supplies.

There is another type of burners - diffusion-kinetic. Such devices are usually seen in high-power industrial-grade heaters. They combine the principles of atmospheric and forced-air burners.

If you need to heat a utility room or cottage, it is not necessary to buy a heating device. You can make a simple heater with your own hands, saving a decent amount.

Read about the characteristics and types of combination boilers here.

And here https://microklimat.pro/otopitelnoe-oborudovanie/kotly/gazovyj-konord-otzyvy.html you can read reviews from people about the use of Conord gas boilers.