- Storage type installations

It should be borne in mind that there is no universal device used as a local sewage treatment system for a home or cottage. Knowledge of the design features of various types of septic tanks and the cleaning technologies used will allow you to choose an effective construction option, reduce material costs for its construction and subsequent operation.

Benefits of using a septic tank

It must be said that building a high-quality and efficiently operating septic tank on a site is a difficult task. Why do homeowners choose this option? The thing is that a septic tank that does not require frequent pumping has many advantages and conveniences:

- The cesspool on the site is a source of unpleasant odor. A properly constructed septic tank uses a different operating principle and will not emit odors;

- The cesspool has a limited volume; with a large flow of water, it will fill up very quickly, so you will have to often call sewer trucks to pump it out. The septic tank uses the principle of sedimentation and biotreatment, so the installation does not require frequent pumping. You will have to call the vacuum cleaners for pumping once a year.

- A septic tank is environmentally safer because it uses the principle of natural water purification.

Operating principle of a concrete two-chamber system

The simplest treatment station in design consists of a settling tank with activated sludge, in which aerobic bacteria process wastewater into water and sludge for 3 or more days. At the next stage, the water is poured into a filtration well, from which it moves into the ground through a bottom sand filter.

To increase productivity, several settling tanks are connected in series. This option improves the quality of wastewater treatment and increases the service life between repairs.

Simple in design, multi-chamber stations guarantee only a satisfactory level of cleaning. In particular, a septic tank with a three-day cycle does not provide the required indicator of biochemical oxygen demand (BOD), allowing the discharge of treated wastewater outside the site. Even in treated wastewater, the volume of mineral and organic components reaches 90-100 mg/l.

Stations with a ten-day cycle have better performance. In such devices, the quality of purification varies between 25-28 mg/l of treated wastewater. Therefore, the only advantage of sectional three-day plants is ease of maintenance, since all sludge is accumulated in the first settling tank.

Drawing up a diagram

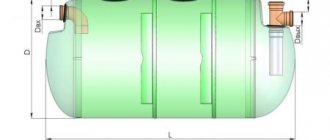

- The basic operating principle of a septic tank is multi-stage settling, so the installation has several chambers. In a private house, most often, a two-chamber septic tank is built.

- A two-chamber septic tank works like this: in the first chamber, settling takes place and anaerobic fermentation of the sludge begins. In the second chamber, the process of sedimentation of smaller suspended particles takes place, and the biological treatment of wastewater continues. After which the water is discharged to filtration fields, where the principle of aerobic biotreatment is used.

Advice! It is recommended to install single-chamber septic tank models when the water flow rate is small (less than a cubic meter per day), for example, in a country house where it is not planned to install a bathtub.

- One of the main conditions for the safe operation of a septic tank is the principle of sealing the chambers. It is very important that contaminated water from sedimentation tanks cannot penetrate the soil.

Advice! In addition, if the septic tank is constructed at a high groundwater level, the tightness of the chambers will protect them from flooding from the outside.

Commissioning of the station

Strains of aerobic bacteria that process wastewater can be purchased at a specialty store. Another option is to load activated sludge from the operating device in an amount of up to 20% of the total volume of the chamber. Depending on the composition of the sewage and the ambient temperature, the septic tank reaches maximum productivity in a period of 4 weeks to 3-4 months.

To speed up the commissioning of the station, the use of special preparations will mostly be ineffective, so they are more often used to eliminate the consequences of spills of large volumes of sewage.

Materials for the construction of chambers

You need to start building a two-chamber septic tank with your own hands by choosing the material for the chambers. In addition, you need to draw up a diagram of the overflow septic tank, and also think about the organization of post-treatment.

These can be filtration fields or an infiltrator. Both of these devices use the same operating principle. Once on the filtration fields, the liquid is filtered mechanically and purified biologically (the principle of aerobic biopurification is used).

Let's start with choosing the material. When constructing septic tanks that do not require frequent pumping, it is advisable to use the following materials with your own hands:

- Reinforced concrete. There are two options here: purchasing ready-made well rings or building a monolithic septic tank. Having chosen the option with rings, you will need to take time to seal the chambers at the joints of individual elements. In addition, such a septic tank is difficult to build with your own hands; the use of lifting equipment will be required.

- Brick. If a home craftsman has experience in bricklaying, then he can build brick chambers quite quickly.

Advice! When choosing brick as a material for constructing a septic tank, it is necessary to take a certain type of material, namely clinker. This type of brick is made from baked clay, so it is not destroyed by water. But it is not advisable to use ordinary porous or silicate bricks.

- Plastic. If the master has ready-made plastic containers of the required volume at his disposal, then the construction of a septic tank will be extremely simple and convenient. Most often, Eurocubes are used to construct chambers.

Advice! For example, when building a septic tank with your own hands, using a metal tank or barrel as a chamber is not the best choice. Even with careful anti-corrosion treatment, such a structure is unlikely to last more than 5-6 years.

Do-it-yourself septic tank installation for a private home: basic materials

If every person who has a private house told what material his septic tank was made of, statistics would indicate the active use of the following varieties:

- Septic tanks made from wheels. This is the most budget option. Here they use waste rubber from heavy-duty vehicles. The main disadvantages of such a system is the complete lack of tightness. Therefore, such a septic tank often resembles an ordinary, poorly prepared drainage pit. In addition, the light weight of the wheels suggests displacement of the rubberized ring when the drainage hole is completely filled.

- Brick septic tanks. Good quality red ordinary brick will withstand a long period of use in wet conditions. That is why, on the basis of red ordinary brick, round, oval, rectangular and any other septic tanks of the required volume are assembled. Bricks are also used to construct drainage holes, leaving the gaps between the bricks leaky.

It is important to know. The brick option is the most expensive and also takes a lot of time than installing concrete rings. But such a septic tank can be completely equipped with your own hands.

- Concrete rings. This option is the most common today. Modern market conditions make it possible to purchase rings of different diameters, starting from 1 m. Thus, you can obtain the required volume of the septic tank. The ability to buy well rings of different diameters allows you to equip full-fledged septic tanks consisting of several tanks. Installation of such systems includes the ability to make a second tank of smaller volume.

- Monolith. When equipping such a septic tank, formwork is assembled, which is an expensive and rather complex process. Then, the formwork space is filled with concrete of a grade not lower than M 100. The result is a sealed, completely reliable option that will last more than 50 years. It is recommended to lay the overflows at the required level at the time of pouring the formwork, since later it will be problematic to make a hole of the required diameter.

- Eurocube The use of such containers is quite rare. The main reason is the high cost and impracticality, since there are well rings and other options for installing a septic tank. At the same time, during use it is recommended to further strengthen the side surfaces, since there is a possibility of the plastic body being compressed by groundwater or soil when freezing.

Planning

Having decided on the materials that will be used for construction, you can begin designing. It will be necessary to calculate the volume of the chambers, as well as choose the right location for the construction of the treatment plant.

Calculations

In order to correctly calculate the volume of the chambers, it is important to know how the septic tank is designed and what operating principle it uses. The main cleaning method used in septic tanks is sedimentation, so it is important that the water remains in the chambers for a long time. Otherwise, the impurities contained in the drains simply will not have time to sink to the bottom.

In order for the wastewater to remain in the septic tank for a long time, the chambers must accommodate the volume of wastewater that is generated in the house over three days. When performing calculations, it is usually assumed that one person uses about 200 liters of water per day. To find out the daily consumption, you need to multiply this figure by the number of people living in the house.

As a rule, when installing a sewer system for a private house, a two-chamber septic tank is built. In this case, the first chamber, which acts as a receiver and primary settling tank, should account for 75% of the total volume.

However, the last rule is not feasible in all cases. For example, the design of a septic tank made of concrete rings or Eurocubes provides that all chambers will be of equal volume.

Selecting a construction site

It is important that the treatment plant and filtration fields are removed as far as possible from the well or well. According to the standards, the minimum distance should be 20-50 meters.

Of course, you should not locate a septic tank, and especially a filtration field, directly next to the house. This is due not only to the fact that sewerage systems do not smell like roses, but also to the need to protect the foundation of the house from flooding with water entering the filtration fields. Building codes recommend building a septic tank at a distance of at least 6 meters from the house.

In addition, when choosing a construction site, it will be necessary to take into account the need for periodic pumping of sludge, that is, it is necessary to ensure the passage of a sewage truck. You can organize the pumping process yourself; for this you will need a fecal pump. But in this case, difficulties will arise with the disposal of the substance obtained as a result of pumping.

How to choose the right place to place the cleaning system?

According to current norms and standards, the distance from the treatment plant to the neighboring house is 5 meters, to the border of adjacent land or a landscaped road surface is 4 meters. The distance to ornamental and fruit trees is 2 and 4 meters, respectively. The minimum distance to the water intake device is 20 meters. This indicator can be reduced only after agreement with the hydrogeological service.

Construction

Let's look at how to build a septic tank that does not require frequent pumping with your own hands.

Excavation

This stage is perhaps the most labor-intensive, unless, of course, the homeowner has the opportunity to use earth-moving equipment. You will need to prepare:

- Pit for a wastewater treatment plant. Its size and shape will be determined by the selected construction material;

- Trenches for laying pipes, and when constructing trenches it is necessary to maintain a slope of 2 cm, this is necessary so that water can move through the pipes by gravity.

At the bottom of the pit and pipes, it is necessary to make a shock-absorbing cushion of sand and crushed stone 20 cm high. In addition, the bottom of the pit for installing settling chambers will have to be concreted. This will prevent wastewater from seeping into the ground.

Construction of chambers

The list of works at this stage depends on the selected material. The easiest way is to build chambers from well rings and Eurocubes. The first ones are installed one above the other using a manipulator crane or other lifting equipment. When using Eurocubes, containers previously prepared for connection are simply installed in the pit.

If the chambers are assembled from brick or well rings, then the principle of tightness must be observed. That is, it is necessary to carry out waterproofing measures. This work can be done with your own hands.

As a rule, bitumen-based penetrating mastic is used for this purpose. The top of the septic tank chambers is covered with a ceiling; in this case, it will be necessary to leave a hole for the cleaning hatch and install a ventilation pipe.

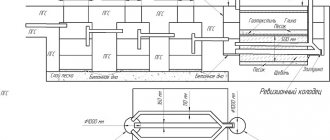

Construction of the filtration field

At the last stage, the filtration field is constructed. If you are doing the construction of a filtration field yourself, you need to dig several trenches (with a slope) and fill them with a mixture of sand and crushed stone (the thickness of the filter layer is at least 1 meter). Perforated pipes are laid in the trenches. They will supply clarified water removed from the septic tank.

So, you can build a septic tank that does not require frequent pumping and a filtration field yourself, although completing this work is not an easy task. However, the result of the work performed will allow you to improve the house with minimal costs.

Household station resource

With timely maintenance, the service life of the bottom filter varies between 15-18 years, the filtration well - no more than 8-10. The service life between repairs can be significantly extended by connecting additional cameras in series.

Sludge sediment is removed by raising its level to the edge of the supply pipe by 200-240 mm. It is not advisable to postpone maintenance indefinitely, since the critical level is only 100 mm.

Complete sludge purification is carried out after a large amount of washing and detergents containing chlorine or other active chemical compounds enter the system. In the standard version, to quickly restore the functionality of the system, activated sludge should be left in the septic tank in an amount of 20-30 percent relative to the volume of the chamber.